Abstract

Timely detection of fatigue cracks is necessary to avoid catastrophic failure of rotating machines which can lead to economical losses and accidental risk. This paper presents an exhaustive literature survey on theoretical and experimental vibration analysis of the rotating shaft in the presence of crack. Various non-destructive methods adopted by several researchers for crack detection in rotating machinery have been discussed. The vibration-based crack detection methods such as vibration-based diagnostics methods and vibration-based signal processing techniques have been broadly categorized along with their advantages and disadvantages. In general, various methodologies such as breathing mechanism, finite-element method, Hilbert–Huang transform, artificial intelligence techniques, wavelet transform and wavelet finite-element transform have been applied to investigate the presence of crack in the rotating shaft. The parameters such as natural frequencies, \(1{\times }\), \(2{\times }\) and \(3{\times }\) harmonic components of dynamic response, critical speeds and whirl orbits have been significantly influenced due to the presence of crack in the rotating shaft. Several studies have been carried out to study variations in these parameters. Still, there is a need of more reliable and accurate modelling approach to detect variations in these parameters. In this paper, an attempt has been made to deliver all the modelling approaches implemented by the various researchers to detect crack within the rotating shaft. The modelling approaches are categorized based on the methodologies adopted by the various researchers to detect crack. Moreover, the critical observations made from the proposed modelling approaches are summarized and presented.

Similar content being viewed by others

References

Abdi, H., Nayeb-Hashemi, H., Hamouda, A.M., Vaziri, A.: Torsional dynamic response of a shaft with longitudinal and circumferential cracks. J. Vib. Acoust. 136(6), 061011 (2014). https://doi.org/10.1115/1.4028609

Nabian, M., Vaziri, A., Olia, M., Nayeb-Hashemi, H.: The effects of longitudinal and circumferential cracks on the torsional dynamic response of shafts. In: ASME 2013 International Mechanical Engineering Congress and Exposition 2014 April 2. ASME Paper No. IMECE2013-65593. https://doi.org/10.1115/IMECE2013-65593 (2014)

Darpe, A.K.: Coupled vibrations of a rotor with slant crack. J. Sound Vib. 305(1–2), 172–193 (2007). https://doi.org/10.1016/j.jsv.2007.03.079

Sekhar, A.S., Prasad, P.B.: Dynamic analysis of a rotor system considering a slant crack in the shaft. J. Sound Vib. 208(3), 457–474 (1997). https://doi.org/10.1006/jsvi.1997.1222

Prabhakar, S., Sekhar, A.S., Mohanty, A.R.: Transient lateral analysis of a slant-cracked rotor passing through its flexural critical speed. Mech. Mach. Theory 37(9), 1007–1020 (2002). https://doi.org/10.1016/s0094-114x(02)00020-4

Ramezanpour, R., Ghayour, M., Ziaei-Rad, S.: A novel method for slant crack detection in rotors based on turning in two directions. Arch. Appl. Mech. 83, 783–798 (2013). https://doi.org/10.1007/s00419-012-0717-2

Darpe, A.K.: Dynamics of a Jeffcott rotor with slant crack. J. Sound Vib. 303(1–2), 1–28 (2007). https://doi.org/10.1016/j.jsv.2006.07.052

Ichimonji, M., Watanabe, S.: The dynamics of a rotor system with a shaft having a slant crack: a qualitative analysis using a simple rotor model. JSME Int. J. 31(4), 712–718 (1988). https://doi.org/10.1299/jsmec1988.31.712

Sabnavis, G., Kirk, R.G., Kasarda, M., Quinn, D.: Cracked shaft detection and diagnostics: a literature review. Shock Vib. Dig. 36(4), 287–297 (2004). https://doi.org/10.1177/0583102404045439

Dirr, B.O., Popp, K., Rothkegel, W.H.: Detection and simulation of small transverse cracks in rotating shafts. Arch. Appl. Mech. 64, 206–222 (1994). https://doi.org/10.1007/BF00806818

Pennacchi, P., Bachschmid, N., Vania, A.: A model-based identification method of transverse cracks in rotating shafts suitable for industrial machines. Mech. Syst. Signal Process. 20(8), 2112–2147 (2006). https://doi.org/10.1016/j.ymssp.2005.04.005

Gasch, R.: Dynamic behaviour of the Laval rotor with a transverse crack. Mech. Syst. Signal Process. 22(4), 790–804 (2008). https://doi.org/10.1016/j.ymssp.2007.11.023

Bachschmid, N., Pennacchi, P., Tanzi, E.: Some remarks on breathing mechanism, on non-linear effects and on slant and helicoidal cracks. Mech. Syst. Signal Process. 22(4), 879–904 (2008). https://doi.org/10.1016/j.ymssp.2007.11.007

Jun, O.S., Eun, H.J., Earmme, Y.Y., Lee, C.W.: Modelling and vibration analysis of a simple rotor with a breathing crack. J. Sound Vib. 155(2), 273–290 (1992). https://doi.org/10.1016/0022-460x(92)90511-u

Al-Shudeifat, M.A., Butcher, E.A.: On the modeling of open and breathing cracks of a cracked rotor system. In: International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, ASME Paper No. DETC2010-28289, pp. 919–928 (2011). https://doi.org/10.1115/DETC2010-28289

Gasch, R.: A survey of the dynamic behaviour of a simple rotating shaft with a transverse crack. J. Sound Vib. 160(2), 313–332 (1993). https://doi.org/10.1006/jsvi.1993.1026

Dimarogonas, A.D.: Vibration of cracked structures: a state of the art review. Eng. Fract. Mech. 55(5), 831–857 (1996). https://doi.org/10.1016/0013-7944(94)00175-8

Wauer, J.: On the dynamics of cracked rotors: a literature survey. Appl. Mech. Rev. 43(1), 13–17 (1990). https://doi.org/10.1115/1.3119157

Kumar, C., Rastogi, V.: A brief review on dynamics of a cracked rotor. Int. J. Rotat. Mach. 2009(2), 1–6 (2009). https://doi.org/10.1155/2009/758108

Fan, W., Qiao, P.: Vibration-based damage identification methods: a review and comparative study. Struct. Health Monit. 10(1), 83–111 (2011). https://doi.org/10.1177/1475921710365419

Doebling, S.W., Farrar, C.R., Prime, M.B.: A summary review of vibration-based damage identification methods. Shock Vib. Dig. 30(2), 91–105 (1998). https://doi.org/10.1177/058310249803000201

Carden, E.P., Fanning, P.: Vibration based condition monitoring: a review. Struct. Health Monit. 3(4), 355–377 (2004). https://doi.org/10.1177/1475921704047500

Sekhar, A.S.: Identification of unbalance and crack acting simultaneously in a rotor system: modal expansion versus reduced basis dynamic expansion. J. Vib. Control 11(9), 1125–1145 (2005). https://doi.org/10.1177/1077546305042531

Guo, C.Z., Yan, J.H., Bergman, L.A.: Experimental dynamic analysis of a breathing cracked rotor. Chin. J. Mech. Eng. 30(5), 1177–83 (2017). https://doi.org/10.1007/s10033-017-0180-7

Yang, H., Mathew, J., Ma, L. (2003) Vibration feature extraction techniques for fault diagnosis of rotating machinery: a literature survey. In: Asia-Pacific Vibration Conference, November 12–14, pp. 801–807. Gold Coast, Australia (2003)

Guo, C., Al-Shudeifat, M.A., Yan, J., Bergman, L.A., McFarland, D.M., Butcher, E.A.: Application of empirical mode decomposition to a Jeffcott rotor with a breathing crack. J. Sound Vib. 332(16), 3881–3892 (2013). https://doi.org/10.1016/j.jsv.2013.02.031

Pilkey, W.D.: Analysis and Design of Elastic Beams, vol. 2002, pp. 24–29. Wiley, New York (2002)

Patel, T.H., Darpe, A.K.: Influence of crack breathing model on nonlinear dynamics of a cracked rotor. J. Sound Vib. 311(3–5), 953–972 (2008). https://doi.org/10.1016/j.jsv.2007.09.033

Mobarak, H.M., Wu, H., Spagnol, J.P., Xiao, K.: New crack breathing mechanism under the influence of unbalance force. Arch. Appl. Mech. 88(3), 341–372 (2018). https://doi.org/10.1007/s00419-017-1312-3

Xie, J., Cheng, W., Zi, Y.: Modified breathing mechanism model and phase waterfall plot diagnostic method for cracked rotors. J. Mech. Sci. Technol. 32(6), 2527–2539 (2018). https://doi.org/10.1007/s12206-018-0510-4

Georgantzinos, S.K., Anifantis, N.K.: An insight into the breathing mechanism of a crack in a rotating shaft. J. Sound Vib. 318(1–2), 279–295 (2008). https://doi.org/10.1016/j.jsv.2008.04.010

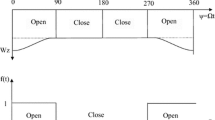

Al-Shudeifat, M.A., Butcher, E.A.: New breathing functions for the transverse breathing crack of the cracked rotor system: approach for critical and subcritical harmonic analysis. J. Sound Vib. 330(3), 526–544 (2011). https://doi.org/10.1016/j.jsv.2010.08.022

Guo, C., Al-Shudeifat, M.A., Yan, J., Bergman, L.A., McFarland, D.M., Butcher, E.A.: Stability analysis for transverse breathing cracks in rotor systems. Eur. J. Mech. A/Solids 42, 27–34 (2013). https://doi.org/10.1016/j.euromechsol.2013.04.001

De Oliveira, L.R., De Melo, G.P.: Crack detection and dynamic analysis of a cracked rotor with soft bearings using different methods of solution. In: International Conference on Rotor Dynamics, pp. 3–17. Springer, Cham (2018). https://doi.org/10.1007/978-3-319-99268-6_1

Hossain, M., Wu, H.: Crack breathing behavior of unbalanced rotor system: a quasi-static numerical analysis. J. Vibroeng. 20(3), 1459–1469 (2018). https://doi.org/10.21595/jve.2018.19692

Zhang, B., Li, Y.: Six degrees of freedom coupled dynamic response of rotor with a transverse breathing crack. Nonlinear Dyn. 78(3), 1843–1861 (2014). https://doi.org/10.1007/s11071-014-1563-2

Mayes, I.W., Davies, W.G.: Analysis of the response of a multi-rotor-bearing system containing a transverse crack in a rotor. J. Vib. Acoust. Stress Reliab. Des. 106(1), 139–145 (1984). https://doi.org/10.1115/1.3269142

Wauer, J.: Modelling and formulation of equations of motion for cracked rotating shafts. Int. J. Solids Struct. 26(8), 901–914 (1990). https://doi.org/10.1016/0020-7683(90)90076-8

Dimarogonas, A.D., Papadopoulos, C.A.: Vibration of cracked shafts in bending. J. Sound Vib. 91(4), 583–593 (1983). https://doi.org/10.1016/0022-460x(83)90834-9

Papadopoulos, C.A., Dimarogonas, A.D.: Coupled longitudinal and bending vibrations of a rotating shaft with an open crack. J. Sound Vib. 117(1), 81–93 (1987). https://doi.org/10.1016/0022-460x(87)90437-8

Al-Shudeifat, M.A.: On the finite element modeling of the asymmetric cracked rotor. J. Sound Vib. 332(11), 2795–2807 (2013). https://doi.org/10.1016/j.jsv.2012.12.026

AL-Shudeifat, M.A.: Stability analysis and backward whirl investigation of cracked rotors with time-varying stiffness. J. Sound Vib. 348, 365–380 (2015). https://doi.org/10.1016/j.jsv.2015.03.007

Wu, X., Sawicki, J.T., Friswell, M.I., Baaklini, G.Y.: Finite element analysis of coupled lateral and torsional vibrations of a rotor with multiple cracks. In: ASME Turbo Expo 2005: Power for Land, Sea, and Air, ASME Paper No. GT2005-68839, pp. 841–850 (2005). https://doi.org/10.1115/GT2005-68839

Darpe, A.K., Gupta, K., Chawla, A.: Coupled bending, longitudinal and torsional vibrations of a cracked rotor. J. Sound Vib. 269(1–2), 33–60 (2004). https://doi.org/10.1016/s0022-460x(03)00003-8

Darpe, A.K.: A novel way to detect transverse surface crack in a rotating shaft. J. Sound Vib. 305(1–2), 151–171 (2007). https://doi.org/10.1016/j.jsv.2007.03.070

Haji, Z.N., Oyadiji, S.O.: The use of roving discs and orthogonal natural frequencies for crack identification and location in rotors. J. Sound Vib. 333(23), 6237–6257 (2014). https://doi.org/10.1016/j.jsv.2014.05.046

Haji, Z.N., Oyadiji, S.O.: Detection of cracks in stationary rotors via the modal frequency changes induced by a roving disc. In: Proceedings of the ASME 12th Biennial Conference on Engineering Systems Design and Analysis, ESDA2014, June 25–27, 2014, Copenhagen, Denmark. ASME Paper No. ESDA2014-20611 (2014). https://doi.org/10.1115/ESDA2014-20611

Sinou, J.J., Lees, A.W.: The influence of cracks in rotating shafts. J. Sound Vib. 285(4–5), 1015–1037 (2007). https://doi.org/10.1016/j.jsv.2004.09.008

Sinou, J.J., Lees, A.W.: A non-linear study of a cracked rotor. Eur. J. Mech. A/Solids 26(1), 152–170 (2007). https://doi.org/10.1016/j.euromechsol.2006.04.002

Sinou, J.J.: Detection of cracks in rotor based on the \(2\times \) and \(3\times \) super-harmonic frequency components and the crack–unbalance interactions. Commun. Nonlinear Sci. Numer. Simul. 13(9), 2024–2040 (2008). https://doi.org/10.1016/j.cnsns.2007.04.008

Upadhyay, D.K., Satankar, R.K.: Dynamic analysis of a cracked rotor bearing disc system-finite element investigation. Glob. J. Eng. Sci. Res. 4(8), 86–95 (2017). https://doi.org/10.5281/zenodo.847606

Khorrami, H., Rakheja, S., Sedaghati, R.: Vibration behavior of a two-crack shaft in a rotor disc-bearing system. Mech. Mach. Theory 113, 67–84 (2017). https://doi.org/10.1016/j.mechmachtheory.2017.03.006

Ghozlane, M.: Dynamic response of cracked shaft in rotor bearing-disk system. In: Design and Modeling of Mechanical Systems—II, pp. 615–624. Springer, Cham (2015). https://doi.org/10.1007/978-3-319-17527-0_61

Huang, N.E., Shen, Z., Long, S.R., Wu, M.C., Shih, H.H., Zheng, Q., Yen, N.C., Tung, C.C., Liu, H.H.: The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. Proc. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 454(1971), 903–995 (1998). https://doi.org/10.1098/rspa.1998.0193

Peng, Z.K., Peter, W.T., Chu, F.L.: A comparison study of improved Hilbert–Huang transform and wavelet transform: application to fault diagnosis for rolling bearing. Mech. Syst. Signal Process. 19(5), 974–988 (2005). https://doi.org/10.1016/j.ymssp.2004.01.006

Guo, D., Peng, Z.K.: Vibration analysis of a cracked rotor using Hilbert–Huang transform. Mech. Syst. Signal Process. 21(8), 3030–3041 (2007). https://doi.org/10.1016/j.ymssp.2007.05.004

Jiao, W., Yang, S., Chang, Y., Yan, G., Hu, J.: Detecting a cracked rotor with HHT-based time-frequency representation. In: IEEE International Conference on Automation and Logistics, pp. 790–793 (2008). https://doi.org/10.1109/ICAL.2008.4636257

Li, B., Zhang, C., He, Z.: HHT-based crack identification method for start-up rotor. Front. Mech. Eng. 7(3), 300–304 (2012). https://doi.org/10.1007/s11465-012-0328-1

Babu, T.R., Srikanth, S., Sekhar, A.S.: Hilbert–Huang transform for detection and monitoring of crack in a transient rotor. Mech. Syst. Signal Process. 22(4), 905–914 (2008). https://doi.org/10.1016/j.ymssp.2007.10.010

Feldman, M.: Time-varying vibration decomposition and analysis based on the Hilbert transform. J. Sound Vib. 295(3–5), 518–530 (2006). https://doi.org/10.1016/j.jsv.2005.12.058

Lin, L., Chu, F.: HHT-based AE characteristics of natural fatigue cracks in rotating shafts. Mech. Syst. Signal Process. 26, 181–189 (2012). https://doi.org/10.1016/j.ymssp.2011.07.017

Chandra, N.H., Sekhar, A.S.: Fault detection in rotor bearing systems using time frequency techniques. Mech. Syst. Signal Process. 72, 105–133 (2016). https://doi.org/10.1016/j.ymssp.2015.11.013

Liu, J., Liu, W., Wang, X.: Research of crack detection and delay crack propagation on a nonlinear rotor. Strojniski Vestnik/J. Mech. Eng. 64(10), 601–610 (2018). https://doi.org/10.5545/sv-jme.2018.5242

Peng, Z.K., Chu, F.L.: Application of the wavelet transform in machine condition monitoring and fault diagnostics: a review with bibliography. Mech. Syst. Signal Process. 18(2), 199–221 (2004). https://doi.org/10.1016/s0888-3270(03)00075-x

Zhong, S., Oyadiji, S.O.: Crack detection in simply supported beams without baseline modal parameters by stationary wavelet transform. Mech. Syst. Signal Process. 21(4), 1853–1884 (2007). https://doi.org/10.1016/j.ymssp.2006.07.007

Zhong, S., Oyadiji, S.O.: Detection of cracks in simply-supported beams by continuous wavelet transform of reconstructed modal data. Comput. Struct. 89(1–2), 127–148 (2011). https://doi.org/10.1016/j.compstruc.2010.08.008

Jiang, Y.Y., Li, B., Zhang, Z.S., Chen, X.F.: Identification of crack location in beam structures using wavelet transform and fractal dimension. Shock Vib. 2015, 1–10 (2015). https://doi.org/10.1155/2015/832763

Mogal, S.P., Lalwani, D.I.: A brief review on fault diagnosis of rotating machineries. Appl. Mech. Mater. 541, 635–640 (2014). https://doi.org/10.4028/www.scientific.net/amm.541-542.635

Gómez, M.J., Castejón, C., García-Prada, J.C.: Review of recent advances in the application of the wavelet transform to diagnose cracked rotors. Algorithms 9(1), 19 (2016). https://doi.org/10.3390/a9010019

Gómez, M.J., Castejón, C., García-Prada, J.C.: Crack detection in rotating shafts based on 3X energy: analytical and experimental analyses. Mech. Mach. Theory 96, 94–106 (2016). https://doi.org/10.1016/j.mechmachtheory.2015.09.009

Huo, Z., Zhang, Y., Zhou, Z., Huang, J.: Crack detection in rotating shafts using wavelet analysis, Shannon entropy and multi-class SVM. In: International Conference on Industrial Networks and Intelligent Systems, pp. 332–346. Springer, Cham (2017). https://doi.org/10.1007/978-3-319-74176-5_29

Soeffker, D., Wei, C., Wolff, S., Saadawia, M.S.: Detection of rotor cracks: comparison of an old model-based approach with a new signal-based approach. Nonlinear Dyn. 83(3), 1153–1170 (2016). https://doi.org/10.1007/s11071-015-2394-5

Ma, J., Xue, J., Yang, S., He, Z.: A study of the construction and application of a Daubechies wavelet-based beam element. Finite Elem. Anal. Des. 39(10), 965–975 (2003). https://doi.org/10.1016/s0168-874x(02)00141-5

Chen, X., Yang, S., Ma, J., He, Z.: The construction of wavelet finite element and its application. Finite Elem. Anal. Des. 40(5–6), 541–554 (2004). https://doi.org/10.1016/s0168-874x(03)00077-5

Xiang, J.W., Chen, X.F., Li, B., He, Y.M., He, Z.J.: Identification of a crack in a beam based on the finite element method of a B-spline wavelet on the interval. J. Sound Vib. 296(4–5), 1046–1052 (2006). https://doi.org/10.1016/j.jsv.2006.02.019

Xiang, J., Chen, X., Mo, Q., He, Z.: Identification of crack in a rotor system based on wavelet finite element method. Finite Elem. Anal. Des. 43(14), 1068–1081 (2007). https://doi.org/10.1016/j.finel.2007.07.001

Li, B., Dong, H.: Quantitative identification of multiple cracks in a rotor utilizing wavelet finite element method. Comput. Model. Eng. Sci. (CMES) 84(3), 205–228 (2012). https://doi.org/10.3970/cmes.2012.084.205

Gomez-Mancilla, J., Sinou, J.J., Nosov, V.R., Thouverez, F., Zambrano, A.: The influence of crack–imbalance orientation and orbital evolution for an extended cracked Jeffcott rotor. C. R. Mec. 332(12), 955–962 (2004). https://doi.org/10.1016/j.crme.2004.09.007

Karaagac, C., Öztürk, H., Sabuncu, M.: Free vibration and lateral buckling of a cantilever slender beam with an edge crack: experimental and numerical studies. J. Sound Vib. 326(1–2), 235–250 (2009). https://doi.org/10.1016/j.jsv.2009.04.022

Stoisser, C.M., Audebert, S.A.: Comprehensive theoretical, numerical and experimental approach for crack detection in power plant rotating machinery. Mech. Syst. Signal Process. 22(4), 818–844 (2008). https://doi.org/10.1016/j.ymssp.2007.11.013

Machorro-López, J.M., Adams, D.E., Gómez-Mancilla, J.C., Gul, K.A.: Identification of damaged shafts using active sensing—simulation and experimentation. J. Sound Vib. 327(3–5), 368–390 (2009). https://doi.org/10.1016/j.jsv.2009.06.025

Bennoud, S., Zergoug, M., Allali, A.: Numerical simulation for cracks detection using the finite elements method. Int. J. Multiphys. 8(1), 1–10 (2016). https://doi.org/10.1260/1750-9548.8.1.1

Jain, A.K., Rastogi, V., Agrawal, A.K.: Experimental investigation of vibration analysis of multi-crack rotor shaft. Proc. Eng. 144, 1451–1458 (2016). https://doi.org/10.1016/j.proeng.2016.05.177

Saravanan, K., Sekhar, A.S.: Crack detection in a rotor by operational deflection shape and kurtosis using laser vibrometer measurements. J. Vib. Control 19(8), 1227–1239 (2013). https://doi.org/10.1177/1077546312444770

Fu, C., Ren, X., Yang, Y., Lu, K., Wang, Y.: Nonlinear response analysis of a rotor system with a transverse breathing crack under interval uncertainties. Int. J. Nonlinear Mech. 105, 77–87 (2018). https://doi.org/10.1016/j.ijnonlinmec.2018.07.001

Kumar, C., Rastogi, V., Singh, N.B.: Dynamic modeling and simulation of transverse cracks in rotating shafts through dissipative coupling. Simulation 88(10), 1260–1276 (2012). https://doi.org/10.1177/0037549712450344

Müller, P.C., Bajkowski, J., Söffker, D.: Chaotic motions and fault detection in a cracked rotor. Nonlinear Dyn. 5(2), 233–254 (1994). https://doi.org/10.1007/BF00045678

Ishida, Y., Inoue, T.: Detection of a rotor crack using a harmonic excitation and nonlinear vibration analysis. J. Vib. Acoust. 128(6), 741–749 (2006). https://doi.org/10.1115/1.2346693

Qin, W., Chen, G., Ren, X.: Grazing bifurcation in the response of cracked Jeffcott rotor. Nonlinear Dyn. 35(2), 147–157 (2004). https://doi.org/10.1023/b:nody.0000020959.82954.45

Wang, X., Liu, J., Ge, W.: A practical method to detect a transverse cracked rotor using transient response. Strojniški vestnik/J. Mech. Eng. 63(6), 394–404 (2017). https://doi.org/10.5545/sv-jme.2017.4332

Wang, X., Liu, J., Ge, W.: Detection of a transverse crack in a nonlinear rotor using non-stationary response. J. Vibroeng. 19(7), 4953–4964 (2017). https://doi.org/10.21595/jve.2017.18186

Wang, S., Zi, Y., Qian, S., Zi, B., Bi, C.: Effects of unbalance on the nonlinear dynamics of rotors with transverse cracks. Nonlinear Dyn. 91(4), 2755–2772 (2018). https://doi.org/10.1007/s11071-017-4044-6

Zhou, T., Sun, Z., Xu, J., Han, W.: Experimental analysis of cracked rotor. J. Dyn. Syst. Meas. Control 127(3), 313–320 (2005). https://doi.org/10.1115/1.1978908

Zhu, C., Robb, D.A., Ewins, D.J.: The dynamics of a cracked rotor with an active magnetic bearing. J. Sound Vib. 265(3), 469–487 (2003). https://doi.org/10.1016/s0022-460x(03)00174-3

Cao, J., Xue, S., Lin, J., Chen, Y.: Nonlinear dynamic analysis of a cracked rotor-bearing system with fractional order damping. J. Comput. Nonlinear Dyn. 8(3), 031008-1–14 (2013). https://doi.org/10.1115/1.4023010

Thatoi, D.N., Nanda, J., Das, H.C., Parhi, D.R.: Analysis of the dynamic response of a cracked beam structure. Appl. Mech. Mater. 187, 58–62 (2012). https://doi.org/10.4028/www.scientific.net/amm.187.58

Hou, L., Chen, Y.: Super-harmonic responses analysis for a cracked rotor system considering inertial excitation. Sci. China Technol. Sci. 58(11), 1924–1934 (2015). https://doi.org/10.1007/s11431-015-5850-z

Chen, X.: Nonlinear responses analysis caused by slant crack in a rotor-bearing system. J. Vibroeng. 18(7), 4369–4387 (2016). https://doi.org/10.21595/jve.2016.16921

Bovsunovskii, A.P.: On determination of the natural frequency of transverse and longitudinal vibrations of a cracked beam. Part 1. Analytical approach. Strength Mater. 31(2), 130–137 (1999). https://doi.org/10.1007/BF02511102

El Arem, S., Zid, M.B.: On a systematic approach for cracked rotating shaft study: breathing mechanism, dynamics and instability. Nonlinear Dyn. 88(3), 2123–2138 (2017). https://doi.org/10.1007/s11071-017-3367-7

El Arem, S.: Nonlinear analysis, instability and routes to chaos of a cracked rotating shaft. Nonlinear Dyn. 96(1), 667–683 (2019). https://doi.org/10.1007/s11071-019-04813-0

He, Y., Guo, D., Chu, F.: Using genetic algorithms and finite element methods to detect shaft crack for rotor-bearing system. Math. Comput. Simul. 57(1–2), 95–108 (2001). https://doi.org/10.1016/s0378-4754(01)00295-6

Vakil-Baghmisheh, M.T., Peimani, M., Sadeghi, M.H., Ettefagh, M.M.: Crack detection in beam-like structures using genetic algorithms. Appl. Soft Comput. 8(2), 1150–1160 (2008). https://doi.org/10.1016/j.asoc.2007.10.003

Xiang, J., Zhong, Y., Chen, X., He, Z.: Crack detection in a shaft by combination of wavelet-based elements and genetic algorithm. Int. J. Solids Struct. 45(17), 4782–4795 (2008). https://doi.org/10.1016/j.ijsolstr.2008.04.014

Saridakis, K.M., Chasalevris, A.C., Papadopoulos, C.A., Dentsoras, A.J.: Applying neural networks, genetic algorithms and fuzzy logic for the identification of cracks in shafts by using coupled response measurements. Comput. Struct. 86(11–12), 1318–1338 (2008). https://doi.org/10.1016/j.compstruc.2007.08.004

Thatoi, D.N., Das, H.C., Parhi, D.R.: Review of techniques for fault diagnosis in damaged structure and engineering system. Adv. Mech. Eng. 4, 327569 (2012). https://doi.org/10.1155/2012/327569

Baviskar, P.R., Tungikar, V.B.: Experimental investigations on crack detection using modal analysis and prediction of properties for multiple cracks by neural network. J. Inst. Eng. (India) Ser. C 94(4), 299–306 (2013). https://doi.org/10.1007/s40032-013-0088-7

Babu, T.R., Sekhar, A.S.: Shaft crack identification using artificial neural networks and wavelet transform data of a transient rotor. In: 13th National Conference on Mechanisms and Machines (NaCoMM07), pp. 327–332. IISc, Bangalore (2007)

Mohammed, A.A., Neilson, R.D., Deans, W.F., MacConnell, P.: Crack detection in a rotating shaft using artificial neural networks and PSD characterisation. Meccanica 49(2), 255–266 (2014). https://doi.org/10.1007/s11012-013-9790-z

Gómez, M.J., Castejón, C., García-Prada, J.C.: Automatic condition monitoring system for crack detection in rotating machinery. Reliab. Eng. Syst. Saf. 152, 239–247 (2013). https://doi.org/10.1016/j.ress.2016.03.013

Nanda, J., Parhi, D.R.: Theoretical analysis of the shaft. Adv. Fuzzy Syst. 2013, 8 (2013). https://doi.org/10.1155/2013/392470

Castejón, C., García-Prada, J.C., Gómez, M.J., Meneses, J.: Automatic detection of cracked rotors combining multiresolution analysis and artificial neural networks. J. Vib. Control 21(15), 3047–3060 (2015). https://doi.org/10.1177/1077546313518816

Bachschmid, N., Pennacchi, P., Tanzi, E., Vania, A.: Identification of transverse crack position and depth in rotor systems. Meccanica 35(6), 563–582 (2000). https://doi.org/10.1023/A:1010562205385

Sekhar, A.S.: Crack identification in a rotor system: a model-based approach. J. Sound Vib. 270(4–5), 887–902 (2004). https://doi.org/10.1016/s0022-460x(03)00637-0

Green, I., Casey, C.: Crack detection in a rotor dynamic system by vibration monitoring—part I: analysis. J. Eng. Gas Turb. Power 127(2), 425–436 (2005). https://doi.org/10.1115/1.1789514

Varney, P., Green, I.: Crack detection in a rotor dynamic system by vibration monitoring—part II: extended analysis and experimental results. J. Eng. Gas Turb. Power 134(11), 112501 (2012). https://doi.org/10.1115/1.4007275

Sekhar, A.S., Mohanty, A.R., Prabhakar, S.: Vibrations of cracked rotor system: transverse crack versus slant crack. J. Sound Vib. 279, 1203–1217 (2005). https://doi.org/10.1016/j.jsv.2004.01.011

Sinha, J.K.: Higher order spectra for crack and misalignment identification in the shaft of a rotating machine. Struct. Health Monit. 6(4), 325–334 (2007). https://doi.org/10.1177/1475921707082309

Naik, S.S.: Crack detection in pipes using static deflection measurements. J. Inst. Eng. (India) Ser. C 93(3), 209–215 (2012). https://doi.org/10.1007/s40032-012-0027-z

Jun, O.S., Gadala, M.S.: Dynamic behavior analysis of cracked rotor. J. Sound Vib. 309(1–2), 210–245 (2008). https://doi.org/10.1016/j.jsv.2007.06.065

Jun, O.S.: Dynamic behavior analysis of cracked rotor based on harmonic motion. Mech. Syst. Signal Process. 30, 186–203 (2012). https://doi.org/10.1016/j.ymssp.2012.01.014

Xiang, L., Zhang, Y., Hu, A.: Crack characteristic analysis of multi-fault rotor system based on whirl orbits. Nonlinear Dyn. 95(4), 2675–2690 (2019). https://doi.org/10.1007/s11071-018-4715-y

Zhang, C., Li, B., Yang, Z., Xiao, W., He, Z.: Crack location identification of rotating rotor systems using operating deflection shape data. Sci. China Technol. Sci. 56(7), 1723–1732 (2013). https://doi.org/10.1007/s11431-013-5243-0

Cavalini Jr., A.A., Sanches, L., Bachschmid, N., Steffen Jr., V.: Crack identification for rotating machines based on a nonlinear approach. Mech. Syst. Signal Process. 79, 72–85 (2016). https://doi.org/10.1016/j.ymssp.2016.02.041

Castejón, C., Gómez, M.J., Garcia-Prada, J.C., Ordonez, A., Rubio, H.: Automatic selection of the WPT decomposition level for condition monitoring of rotor elements based on the sensitivity analysis of the wavelet energy. Int. J. Acoust. Vib. 20(2), 95–100 (2015). 20\_2\_number\_341161434963609

Spagnol, J.P., Wu, H., Yang, C.: Vibration analysis of a cracked rotor with an unbalance influenced breathing mechanism. Int. J. Mech. Eng. Robot. Res. 7(1), 22–29 (2018). https://doi.org/10.18178/ijmerr.7.1.22-29

Spagnol, J.P., Wu, H., Xiao, K.: Dynamic response of a cracked rotor with an unbalance influenced breathing mechanism. J. Mech. Sci. Technol. 32(1), 57–68 (2018). https://doi.org/10.1007/s12206-017-1207-9

Ebrahimi, A., Heydari, M., Behzad, M.: Forced vibration analysis of rotors with an open edge crack based on a continuous vibration theory. Arch. Appl. Mech. 87, 1871 (2017). https://doi.org/10.1007/s00419-017-1295-0

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kushwaha, N., Patel, V.N. Modelling and analysis of a cracked rotor: a review of the literature and its implications. Arch Appl Mech 90, 1215–1245 (2020). https://doi.org/10.1007/s00419-020-01667-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-020-01667-6