Abstract

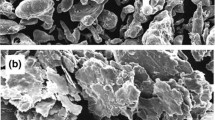

The evolution of semisolid microstructure during partial remelting of (CNTs + Sip)/AZ91D powder compacts prepared by cold pressing was studied. The results indicate that rapid grain coarsening is driven by the dissolution of eutectic β phase material during the initial heating period of 0–10 min, so the AZ91D powders with fine equiaxed grains surrounded by intergranular eutectic phases evolve into compact particles. As the heating time proceeds, α-Mg particles were gradually separated by liquid due to the phase transformations of α-Mg + β → L and α-Mg → L. The primary particles coarsened rather slowly and the as-received Mg powder evolved into nearly spheroidal particles surrounded by liquid phase after partial remelting. The in situ synthesized Mg2Sip were distributed homogeneously around the CNTs with maintained structural integrity during partial remelting. Moreover, this microstructural evolution was accompanied by densification through pore filling. An ideal semisolid ingot suitable for thixoforming can therefore be obtained by partially remelting a (CNTs + Sip)/Mg powder compact.

Graphic abstract

Similar content being viewed by others

References

Du XD, Wang F, Gao Y, Liu Z, Mao PL. Effect of heat treatment process on mechanical and corrosion properties of Mg–7Al–1Ca–0.5Sn alloy. Chin J Rare Met. 2019;43(12):1283.

Liu BS, Li HX, Ren YP, Jiang M, Qin GW. Phase equilibria of low-Y side in Mg–Zn–Y system at 400 °C. Rare Met. 2020;39(3):262.

Li Q, Rottmair CA, Singer RF. CNT reinforced light metal composites produced by melt stirring and by high pressure die casting. Compos Sci Technol. 2010;70(16):2242.

Wang L, Qin XY. The effect of mechanical milling on the formation of nanocrystalline Mg2Si through solid-state reaction. Scr Mater. 2003;49(3):243.

Mousavian RT, Khosroshahi RA, Yazdani S, Brabazon D. Manufacturing of cast A356 matrix composite reinforced with nano- to micrometer-sized SiC particles. Rare Met. 2017;36(1):46.

Iijima S. Helical microtubules of graphitic carbon. Nature. 1991;354(6348):56.

Popov VN. Carbon nanotubes: properties and application. Mater Sci Eng R Rep. 2004;43(3):61.

Zhou L, Xu ZW, Cai XL, Feng M. Effect of rare earth La–Ce on microstructure and properties of CNTs/Cu composites. Chin J Rare Met. 2019;43(12):1297.

Zhang L, Wang QD, Liao WJ, Guo W, Li WZ, Jiang HY, Ding WJ. Microstructure and mechanical properties of the carbon nanotubes reinforced AZ91D magnesium matrix composites processed by cyclic extrusion and compression. Mater Sci Eng A. 2017;689:427.

Guo BS, Zhang XM, Cen X, Wang XH, Song M, Ni S, Yi JH, Shen T, Du Y. Ameliorated mechanical and thermal properties of SiC reinforced Al matrix composites through hybridizing carbon nanotubes. Mater Charact. 2018;136:272.

Kim WJ, Yu YJ. The effect of the addition of multiwalled carbon nanotubes on the uniform distribution of TiC nanoparticles in aluminum nanocomposites. Scr Mater. 2014;72–73:25.

So KP, Jeong JC, Park JG, Park HK, Choi YH, Noh DH, Keum DH, Jeong HY, Biswas C, Hong CH, Lee YH. SiC formation on carbon nanotube surface for improving wettability with aluminum. Compos Sci Technol. 2013;74:6.

Zhang X, Li SF, Pan D, Pan B, Kondoh K. Microstructure and synergistic-strengthening efficiency of CNTs–SiCp dual-nano reinforcements in aluminum matrix composites. Compos A. 2018;105:87.

Li PB, Chen TJ, Qin H. Effects of mold temperature on the microstructure and tensile properties of SiCp/2024 Al-based composites fabricated via powder thixoforming. Mater Des. 2016;112:34.

Fan LL, Zhou MY, Zhang YW, Tang Q, Quan GF, Liu B. The semi-solid microstructural evolution and coarsening kinetics magnesium AZ80–0.2Y–0.15Ca alloy. Mater Charact. 2019;154:116.

Chen TJ, Jiang XD, Ma Y, Li YD, Hao Y. Microstructural evolution and phase transformations during partial remelting of AZ91D magnesium alloy refined by SiC. J Alloys Compd. 2010;497(1):147.

Fan Z. Semisolid metal processing. Int Mater Rev. 2002;47(2):49.

Li PB, Chen TJ, Zhang SQ, Guan RG. Research on semisolid microstructural evolution of 2024 aluminum alloy prepared by powder thixoforming. Metals. 2015;5(2):547.

Chen Q, Meng Y, Yi YS, Wan YY, Sugiyama S, Yanagimoto J. Microstructure and mechanical properties of cup-shaped parts of 15% SiCp reinforced AZ91 magnesium matrix composite processed by thixoforging. J Alloys Compd. 2019;774:93.

Shi Q, Tse YY, Higginson RL. Effects of processing parameters on relative density, microhardness and microstructure of recycled Ti–6Al–4V from machining chips produced by equal channel angular pressing. Mater Sci Eng A. 2016;651:248.

Rokni MR, Widener CA, Crawford GA, West MK. An investigation into microstructure and mechanical properties of cold sprayed 7075 Al deposition. Mater Sci Eng A. 2015;625:19.

Chen B, Lei J, Li SF, Imai H, Takahashi M, Kondoh K. In situ synthesized Al4C3 nanorods with excellent strengthening effect in aluminum matrix composites. Adv Eng Mater. 2014;16(8):972.

Chen B, Li SF, Imai H, Jia L, Umeda J, Takahashi M, Kondoh K. An approach for homogeneous carbon nanotube dispersion in Al matrix composites. Mater Des. 2015;72:1.

Bakshi SR, Agarwal A. An analysis of the factors affecting strengthening in carbon nanotube reinforced aluminum composites. Carbon. 2011;49(2):533.

Chen TJ, Jiang XD, Ma Y, Li YD, Hao Y. Effect of initial as-cast microstructure of AZ91D magnesium alloy on its semisolid microstructure. J Alloys Compd. 2010;505(2):476.

Snyder VA, Alkemper J, Voorhees PW. The development of spatial correlations during Ostwald ripening: a test of theory. Acta Mater. 2000;48(10):2689.

Chen TJ, Hao Y, Sun J. Microstructural evolution of predeformed SiCp/ZA27 composites during partial remelting. Metall Mater Trans A. 2004;35(7):2073.

Schaffer GB, Hall BJ, Bonner SJ, Huo SH, Sercombe TB. The effect of the atmosphere and the role of pore filling on the sintering of aluminium. Acta Mater. 2006;54(1):131.

Kareh KM, Lee PD, Atwood RC, Connolley T, Gourlay CM. Pore behaviour during semi-solid alloy compression: Insights into defect creation under pressure. Scr Mater. 2014;89:73.

Svoboda J, Riedel H, Gaebel R. A model for liquid phase sintering. Acta Mater. 1996;44(8):3215.

Acknowledgements

This study was financially supported by the Ningxia Natural Science Foundation of China (No. 2018AAC03031), the Basic Scientific Fund of Ningxia university (No. NGY2018009), and the Natural Science Foundation of Ningxia University (No. ZR1702).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, PB., Tan, WT., Gao, MM. et al. Semisolid microstructural evolution of (CNTs + Sip)/AZ91D powder compacts prepared from powders by cold pressing and remelting. Rare Met. 39, 733–742 (2020). https://doi.org/10.1007/s12598-020-01396-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01396-3