Abstract

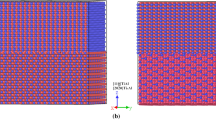

To understand the atomistic mechanisms of tension failure of Ni-based superalloy, in this study, the classical molecular dynamics (MD) simulations were used to study the uniaxial tension processes of both the Ni/Ni3Al interface systems and the pure Ni and Ni3Al systems. To examine the effects of interatomic potentials, we adopted embedded atom method (EAM) and reactive force field (ReaxFF) in the MD simulations. The results of EAM simulations showed that the amorphous structures and voids formed near the interface, facilitating further crack propagation within Ni matrix. The EAM potentials also predicted that dislocations were generated and annihilated alternatively, leading to the oscillation of yielding stress during the tension process. The ReaxFF simulations predicted more amorphous formation and larger tensile strength. The atomistic understanding of the defect initiation and propagation during tension process may help to develop the strengthening strategy for controlling the defect evolution under loading.

Similar content being viewed by others

References

R.C. Reed, The Superalloys: Fundamentals and Applications (Cambridge University Press, Cambridge, 2008)

W. Betteridge, S.W.K. Shaw, Mater. Sci. Technol. 3, 682 (1987)

C.T. Sims, N.S. Stoloff, W.C. Hagel. Superalloys II (Wiley, New York, 1987)

K.A. Green, T.M. Pollock, H. Harada, in Proceedings of the Tenth International Symposium on the Superalloys (TMS, Warrendale, 2004), pp. 381–390

Madeleine. Durand-Charre, Microstruct. Superalloys (2017). https://doi.org/10.1201/9780203736388

H. Harada, H. Murakami, Springer Series in Materials Science (Springer, Berlin, 1999), p. 39

J.X. Zhang, T. Murakumo, Y. Koizumi, T. Kobayashi, H. Harada, S. Masaki, J. R. Metall. Mater. Trans. A 33, 3741 (2002)

J. Yu, Q. Zhang, R. Liu, Z. Yue, M. Tang, X. Li, RSC Adv. 4, 32749 (2014)

R.C. Reed, D.C. Cox, C.M.F. Rae, Mater. Sci. Technol. A 23, 893 (2007)

Y.G. Zhang, Y.F. Han, G.L. Chen, J.T. Guo, X.J. Wan, D. Feng, Structural Intermetallics (National Defense Industry Press, Beijing, 2001), p. 120

J.D. Nystrom, T.M. Pollock, W.H. Murphy, A. Garg, Metall. Mater. Trans. A 28, 2443 (1997)

P.J. Warren, A. Cerezo, G.D.W. Smith, Mater. Sci. Eng. A 250, 88 (1998)

K.E. Yoon, D. Isheim, R.D. Noebe, D.N. Seidman, Interface Sci. 9, 249 (2001)

J. Rüsing, N. Wanderka, U. Czubayko, V. Naundorf, D. Mukherji, J. Rösler, Scr. Mater. 46, 235 (2002)

A. Mottura, R.T. Wu, M.W. Finnis, R.C. Reed, Acta Mater. 56, 2669 (2008)

A. Mottura, N. Warnken, M.K. Miller, M.W. Finnis, R.C. Reed, Acta Mater. 58, 931 (2010)

J.X. Zhang, T. Murakumo, Y. Koizumi, T. Kobayashi, H. Harada, Acta Mater. 51, 5073 (2003)

J.X. Zhang, H. Harada, Y. Koizumi, J. Mater. Res. 21, 647 (2006)

J.X. Zhang, H. Harada, Y. Ro, Y. Koizumi, T. Kobayashi, Acta Mater. 56, 2975 (2008)

B. Reppich, Acta Metall. 30, 87 (1982)

B. Reppich, P. Schepp, G. Wehner, Acta Metall. 30, 95 (1982)

E. Nembach, K. Suzuki, M. Ichihara, S. Takeuchi, Philos. Mag. A 51, 607 (1985)

E. Nembach, Particle Strengthening of Metals and Alloys (Wiley, New York, 1996), pp. 22–27

J.K. Kim, H.J. Park, D.N. Shim, Acta Metall. Sin. (Engl. Lett.) 29, 1 (2016)

W.P. Wu, Y.F. Guo, Y.S. Wang, Philos. Mag. 91, 357 (2011)

Y.L. Li, W.P. Wu, Z.G. Ruan, Acta Metall. Sin. (Engl. Lett.) 29, 689 (2016)

N.L. Li, W.P. Wu, K. Nie., Phys. Lett. A 382, 1361 (2018)

K. Yashiro, M. Naito, Y. Tomita, Int. J. Mech. Sci. 44, 1845 (2002)

A. Prakash, J. Guénolé, J. Wang, Acta Mater. 92, 33 (2015)

P. Zhao, C. Shen, S.R. Niezgoda, Int. J. Plast. 109, 153 (2018)

S.Y. Ma, J.X. Zhang, Mol. Simul. 42, 102 (2016)

S.A. Sajjadi, S. Nategh, M. Isac, S.M. Zebarjad, J. Mater. Process. Technol. 155, 1900 (2004)

P. Zhang, Y. Yuan, S.C. Shen, B. Li, R.H. Zhu, G.X. Yang, X.L. Song, J. Alloys Compd. 694, 502 (2017)

G.P. Purja Pun, Y. Mishin, Philos. Mag. 89, 3245 (2009)

K.S. Yun, H. Kwak, C. Zou, J. Phys. Chem. A 116, 12163 (2012)

W.X. Song, S.J. Zhao, Chin. J. Energ. Mater. 20, 571 (2012)

C. Zou, Y.K. Shin, A.C.T. Van Duin, H. Fang, Z.K. Liu, Acta Mater. 83, 102 (2015)

H. Kwak, Y.K. Shin, A.C.T. Van Duin, A.V. Vasenkov, J. Phys. Condens. Matter 24, 485006 (2012)

S. Plimpton, Comput. Phys. 117, 1–19 (1995)

A. Stukowski, Model. Simul. Mater. Sci. Eng. 18, 015012 (2009)

E.H. Megchiche, S. Pérusin, J.C. Barthelat, C. Mijoule, Phys. Rev. B 74, 064111 (2006)

P.S. Maiya, J.M. Blakely, J. Appl. Phys. 38, 698 (1967)

U.R. Kattner, T.B. Massalski, Binary alloy phase diagrams (ASM International, Materials Park, 1990), p. 147

H.J. Peng, Y.Q. Xie, Y.Z. Nie, Mater. Rep. 21, 131 (2007)

T.R. Lee, C.P. Chang, P.W. Kao, Mater. Sci. Eng. A 408, 131 (2005)

L. Ma, S. Xiao, H. Deng, W. Hu, Phys. Status Solidi B 253, 726 (2016)

H.T. Li, Y.C. Liang, W.L. Zhong, X.Z. Qin, J.T. Guo, L.Z. Zhou, W.L. Ren, Acta Metall. Sin. (Engl. Lett.) 30, 280 (2017)

Acknowledgements

This work was financially supported by the National Key Research and Development Program of China (Grant Nos. 2017YFB0701502 and 2017YFB0702901) and the National Nature Science Foundation of China (Grant No. 91641128).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, H., Du, W. & Liu, Y. Molecular Dynamics Study of Tension Process of Ni-Based Superalloy. Acta Metall. Sin. (Engl. Lett.) 33, 741–750 (2020). https://doi.org/10.1007/s40195-020-01004-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-020-01004-4