Abstract

Cast Al alloys are widely employed for engine components, structural parts, gear box, chassis, etc. and subjected to mechanical cyclic load during operation. The accurate fatigue life prediction of these alloys is essential for normal operation as fatigue cracks initiated during operation induce the lubrication oil leak and serious safety hazard. Microstructural heterogeneity, including shrinkage/gaspores and secondary phase particles, is the most detrimental factor that affects fatigue life of cast Al alloys. The approximate fatigue life cycles could be estimated based on the size distribution and locations of shrinkage pores/defects. The relationship between crack population and stress was reported by statistical distributions and the cumulative probability for cast Al alloys fail at a certain stress could be predicted by combination of Paris law and pore size distribution. Pore depth was found to dominate the stress field around the pore on the surface and the maximum stress increases sharply when the pore intercepted with the surface at its top. The microstructure of cast Al alloys usually is composed of primary Al dendrites, eutectic silicon, Fe-rich particles and other intermetallic particles are dependent upon alloy composition and heat treatment. The coalescence of microcracks initiated from the fractured secondary phases was clearly found and can accelerate the initiation and propagation of the fatigue cracks. A link between defect features and the fatigue strength needs to be established through a good understanding of the fatigue damage mechanisms associated with the microstructural features under specific loading conditions. This paper reviews the influences of shrinkage/gaspores and secondary phase particles, formed during casting process, on the fatigue life of Al-Si-Mg cast Al alloys.

摘要

铸造铝合金材料被广泛应用于发动机部件、结构材料、齿轮箱、底盘等部件, 在使用过程中承 受交变应力。准确预测铸铝材料的使用寿命对于部件的安全运转极为重要, 因疲劳裂纹而导致的漏油 等事故可能产生极为危险的后果。铸铝材料的使用寿命可以通过其铸造缩/气孔的尺寸分布或者尺寸最 大的缩/气孔的直径结合裂纹扩展速率公式进行预测。缩孔的深度及相对位置对于应力集中具有重要影 响。通常情况下, 铸造铝合金的组织主要包括铝基体、共晶硅、富铁相及其他一些第二相颗粒。因这 些第二相颗粒开裂而产生的微裂纹会导致铸铝材料疲劳寿命的降低。因此, 如何通过显微组织合理预 测铸铝材料的疲劳寿命对于铸铝材料的使用极为重要。本文回顾了以往研究中铸造缩/气孔和第二相颗 粒等组织缺陷对Al-Si-Mg 铸造铝合金疲劳寿命的影响。

Similar content being viewed by others

References

CHU S, MAJUMDAR A. Opportunities and challenges for a sustainable energy future [J]. Nature, 2012, 488(7411): 294–303.

ZINKLE S J, WAS G S. Materials challenges in nuclear energy [J]. Acta Mater, 2013, 61(3): 735–758.

BERANGER M, FIARD J M, AMMAR K, CAILLETAUD G. A new fatigue model including thermal ageing for low copper aluminum-silicon alloys [J]. Procedia Engineering, 2018, 213: 720–729.

PRASAD S V, ASTHANA R. Aluminum metal-matrix composites for automotive applications: Tribological considerations [J]. Tribology Letters, 2004, 17(3): 445–453.

IMMARIGEON J, ZHAO L, WALLACE W J. Lightweight materials for aircraft applications [J]. Materials Characterization, 1995, 35(1): 41–67.

RIOJA R J. Fabrication methods to manufacture isotropic Al-Li alloys and products for space and aerospace applications [J]. Materials Science & Engineering A, 1998, 257(1): 100–107.

SONSINO C M. Structural durability of cast aluminium gearbox housings of underground railway vehicles under variable amplitude loading [J]. International Journal of Fatigue, 2005, 27(8): 944–953.

DIXON B, MOLENT L, BARTER S. A study of fatigue variability in aluminium alloy 7050-T7451 [J]. International Journal of Fatigue, 2016, 92: 130–146.

ÖZDES H, TIRAKIOGLU M. On the relationship between structural quality index and fatigue life distributions in aluminum aerospace castings [J]. Metals, 2016, 6(4): 81–91.

OSMOND P, LE V D, VIET-DUC, MOREL F, BELLETT D, SAINTIER N. Effect of porosity on the fatigue strength of cast aluminium alloys: From the specimen to the structure [J]. Procedia Engineering, 2018, 213: 630–643.

HOURIA M I, NADOT Y, FATHALLAH R, ROY M, MAIJER D M. Influence of casting defect and SDAS on the multiaxial fatigue behaviour of A356-T6 alloy including mean stress effect [J]. International Journal of Fatigue, 2015, 80: 90–102.

LE V D, MOREL F, BELLETT D, SAINTIER N, OSMOND P. Multiaxial high cycle fatigue damage mechanisms associated with the different microstructural heterogeneities of cast aluminium alloys [J]. Materials Science & Engineering A, 2016, 649(1): 426–440.

KOUTIRI I, BELLETT D, MOREL F, PESSARD E. A probabilistic model for the high cycle fatigue behaviour of cast aluminium alloys subject to complex loads [J]. International Journal of Fatigue, 2013, 47: 137–147.

ROTELLA A, NADOT Y, AUGUSTIN R, PIELLARD M, L’HERITIER S. Defect size map for cast A357-T6 component under multiaxial fatigue loading using the defect stress gradient (DSG) criterion [J]. Engineering Fracture Mechanics, 2016, 174: 227–242.

WU Sheng-chuan, XIAO Ti-qiao, WITHERS P J. The imaging of failure in structural materials by synchrotron radiation X-ray microtomography [J]. Engineering Fracture Mechanics, 2017, 182: 127–156.

ASTM, E155-15. Standard reference radiographs for inspection of aluminum and magnesium castings[M]. West Conshohocken, PA: ASTM International, 2015.

LAMPMAN S R. ASM handbook: Volume 19, fatigue and fracture [M]. Park, Ohio: Materials, ASM International, 1996.

MUGHRABI H. Dislocations and properties of real materials [M]. London: The Institute of Metals, 1985: 244.

BASQUIN O. The exponential law of endurance tests [C]// Proc Am Soc Test Mater. 1910: 625–630.

SHIGLEY J E, MISCHKE C R. Mechanical engineering design [M]. Singapore: McGraw-Hill, 1989.

JUVINALL R C, MARSHEK K M. Fundamentals of machine component design [M]. New Jersey, US: Wiley, 1991.

DOWLING N E. Mechanical behavior of materials: engineering methods for deformation, fracture, and fatigue [M]. New Jersey: Prentice Hall, 2012.

COFFIN L F. A study of the effects of cyclic thermal stresses on a ductile metal [J]. Transactions of the American Society of Mechanical Engineers, 1954, 76: 931–950.

MANSON S S. Fatigue: A complex subject-Some simple approximations [J]. Experimental Mechanics, 1965, 5: 193–226.

MITCHELL M. Fundamentals of modern fatigue analysis for design [C]// Fratigue and Fracture. Ohio: ASM internationd, 1996: 227–249.

RAMBERG W, OSGOOD W R. Description of stress-strain curves by three parameters [R]. Washington, DC: NACA, 1943.

BAUMEL A, SEEGER T, BOLLER C. Materials data for cyclic loading: Supplement 1 [R]. Dutch: Elsevier Science Ltd, 1990.

NIESLONY A, DSOKI C E, KAUFMANN H, KRUG P. New method for evaluation of the Manson-Coffin-Basquin and Ramberg-Osgood equations with respect to compatibility [J]. Materialwissenschaft und Werkstofftechnik, 2008, 30(10, 11): 1967–1977.

RICHARD C, RICE M. SAE fatigue design handbook [M]. Warrendale (PA): SAE Publication, 1988.

SKELTON R, MAIER H, CHRIST H J. The bauschinger effect, masing model and the Ramberg-Osgood relation for cyclic deformation in metals [J]. Materials Science and Engineering A, 1997, 238(2): 377–390.

PARIS P C. A rational analytic theory of fatigue [J]. The Trend in Engineering, 1961, 13: 9.

NEWMAN J C. Review of modelling small-crack behavior and fatigue-life predictions for aluminum alloys [J]. Fatigue & Fracture of Engineering Materials & Structures, 1994, 17(4): 429–439.

NEWMAN J C, EDWARDS P. Short-crack growth behaviour in an aluminum alloy-An AGARD cooperative test programme[M]. France: Advisory Group for Aerospace Research and Development Neuilly-Sur-Seine, 1988.

EDWARDS P, NEWMAN J C. Short-crack growth behaviour in various aircraft materials [R]. Washington, DC: NACA, 1990.

PEARSON S. Initiation of fatigue cracks in commercial aluminium alloys and the subsequent propagation of very short cracks [J]. Engineering Fracture Mechanics, 1975, 7(2): 235–247.

HADDAD M H E, DOWLING N E, TOPPER T H, SMITH K N. Jintegral applications for short fatigue cracks at notches [J]. International Journal of Fracture, 1980, 16(1): 15–30.

HIRONOBU N, KEN-ICHI T. Significance of initiation, propagation and closure of microcracks in high cycle fatigue of ductile metals [J]. Engineering Fracture Mechanics, 1981, 15(3, 4): 445–456.

NEWMAN J C. A nonlinear fracture mechanics approach to the growth of small cracks [R]. Virgina: NASA Langley Research Center, 1983.

TING J C, LAWRENCE F V. Modeling the long-life fatigue behavior of a cast aluminum alloy [J]. Fatigue & Fracture of Engineering Materials & Structures, 1993, 16(6): 631–647.

PARK S K, LAWRENCE F V. A long-life regime probability-based fatigue design method for weldments [R]. Illinois: University of Illinois at Urbana-Champaign, 1988.

MANSON S S. Behavior of materials under conditions of thermal stress, national advisory committee for aeronautics [R]. NACA TN-2933, 1954.

DANG-VAN K. Macro-micro approach in high-cycle multiaxial fatigue [C]// Advances in Multiaxial Fatigue. ASTM International, 1993: 120–130.

SINES G. Behavior of metals under complex static and alternating stresses [J]. Metal Fatigue, 1959, 1: 145–169.

CHARKALUK E, CONSTANTINESCU A, MAITOURNAM H, VAN K D. Revisiting the Dang Van criterion [J]. Procedia Engineering, 2009, 1(1): 143–146.

BROWN M, MILLER K. Two decades of progress in the assessment of multiaxial low-cycle fatigue life [C]// Low-cycle Fatigue and Life Prediction. ASTM International, 1982.

WANG C H, BROWN M W. A path-independent parameter for fatigue under proportional and non-proportional loading [J]. Fatigue & Fracture of Engineering Materials & Structures, 1993, 16(12): 1285–1297.

LIU K. A method based on virtual strain-energy parameters for multiaxial fatigue life prediction [C]// Advances in Multiaxial Fatigue. ASTM International, 1993: 67–84.

GLINKA G, WANG G. A. Plumtree, mean stress effects in multiaxial fatigue [J]. Fatigue & Fracture of Engineering Materials & Structures, 1995, 18: 755–764.

KAMAL M, RAHMAN M M. Advances in fatigue life modeling: A review [J]. Renewable & Sustainable Energy Reviews, 2018, 82(1): 940–949.

LAMPAN S. Casting design and performance [M]. Materials Park, Ohio: ASM International, 2009: 165.

RAO P N. Manufacturing technology [M]. New York: Tata McGraw- Hill Education, 2013.

PRILLHOFER B, BOTTCHER H, ANTREKOWITSCH H. Development and practical performance characteristics of a new impeller for metal treatment in casting/holding furnaces [C]// Light Metals, TMS Annual Meeting, 2009: 749–754.

AMMAR H R, SAMUEL A M, SAMUEL F H. Effect of casting imperfections on the fatigue life of 319-F and A356-T6 Al-Si casting alloys [J]. Materials Science and Engineering A, 2008, 473(1): 65–75.

WANG Q G, APELIAN D, LADOS D A. Fatigue behavior of A356-T6 aluminum cast alloys. Part I. Effect of casting defects [J]. Journal of Light Metals, 2001, 1(1): 73–84.

ZHANG Yuan-bing, XU Jian-hui, ZHAI Tong-guang. Distributions of pore size and fatigue weak link strength in an A713 sand cast aluminum alloy [J]. Materials Science and Engineering A, 2010, 527(16, 17): 3639–3644.

PARIS P, ERDOGAN F J. A critical analysis of crack propagation laws[J]. Journal of Basic Engineering, 1963, 85(4): 528–539.

WANG Q G, CREPEAU P N, DAVIDSON C J, GRIFFITHS J R. Oxide films, pores and the fatigue lives of cast aluminum alloys [J]. Metallurgical and Materials Transactions B, 2006, 37(6): 887–895.

TIRYAKIOGLU M. Statistical distributions for the size of fatigue-initiating defects in Al-7%Si-0.3%Mg alloy castings: A comparative study [J]. Materials Science and Engineering A, 2008, 497(1): 119–125.

BARTER S, MOLENT L, GOLDSMITH N, JONES R. An experimental evaluation of fatigue crack growth [J]. Engineering Failure Analysis, 2005, 12(1): 99–128.

MURAKAMI Y, ENDO M. Effects of defects, inclusions and inhomogeneities on fatigue strength [J]. International Journal of Fatigue, 1994, 16(3): 163–182.

MURAKAMI Y. Metal fatigue: Effects of small defects and nonmetallic inclusions [M]. Dutch: Elsevier, 2002.

GNEDENKO B. Sur la distribution limite du terme maximum d’une serie aleatoire [J]. Annals of Mathematics, 1943, 44(3): 423–453.

JENKINSON A F. The frequency distribution of the annual maximum (or minimum) values of meteorological elements [J]. Quarterly Journal of the Royal Meteorological Society, 1955, 81(348): 158–171.

TIRYAKIOGLU M. On the size distribution of fracture-initiating defects in Al- and Mg-alloy castings [J]. Materials Science and Engineering A, 2008, 467(1, 2): 174–177.

SHI G, ATKINSON H V, SELLARS C M, ANDERSON C W. Application of the generalized pareto distribution to the estimation of the size of the maximum inclusion in clean steels [J]. Acta Materialia, 1999, 47(5): 1455–1468.

ATKINSON H V, SHI G. Characterization of inclusions in clean steels: A review including the statistics of extremes methods [J]. Progress in Materials Science, 2003, 48(5): 457–520.

MAYER H, PAPAKYRIACOU M, ZETTL B, STANZLTSCHEGG S. Influence of porosity on the fatigue limit of die cast magnesium and aluminium alloys [J]. International Journal of Fatigue, 2003, 25(3): 245–256.

NAYHUMWA C, GREEN N R, CAMPBELL J. Influence of casting technique and hot isostatic pressing on the fatigue of an Al-7Si-Mg alloy [J]. Metallurgical and Materials Transactions A, 2001, 32(2): 349–358.

WANG Q, JONES P, OSBORNE M. The effects of applied pressure during solidification on the microstructure and mechanical properties of lost foam A356 castings [J]. Advances in Aluminum Casting Technology II, 2002, 10: 75–84.

PRZYSTUPA M A, BUCCI R J, MAGNUSEN P E, HINKLE A J. Microstructure based fatigue life predictions for thick plate 7050-T7451 airframe alloys [J]. International Journal of Fatigue, 1997, 19(93): 285–288.

YI J Z, GAO Y X, LEE P D, FLOWER H M, LINDLEY T C. Scatter in fatigue life due to effects of porosity in cast A356-T6 aluminum-silicon alloys [J]. Metallurgical and Materials Transactions A, 2003, 34(9): 1879–1890.

STEPHENS M A. Tests based on EDF statistics[M]// Goodness-of-Fit Techniques. New York: Marcel Dekker, 1986.

ASTM, E2283-08(2014). Standard practice for extreme value analysis of nonmetallic inclusions in steel and other microstructural features [S]. West Conshohocken, PA: ASTM International, 2014.

MAKKONEN L, RABB R, TIKANMAKI M. Size effect in fatigue based on the extreme value distribution of defects [J]. Materials Science and Engineering A, 2014, 594: 68–71.

MAKKONEN L. Problems in the extreme value analysis [J]. Structural Safety, 2008, 30(5): 405–419.

MAKKONEN M. Predicting the total fatigue life in metals [J]. International Journal of Fatigue, 2009, 31(7): 1163–1175.

WALLIN K. Statistical aspects of fatigue life and endurance limit [J]. Fatigue & Fracture of Engineering Materials & Structures, 2010, 33(6): 333–344.

XU Zhi-qiang, ZHANG Xin-liang, WANG Wei, ZHAI Tong-guang. Effect of pore position in depth on stress concentration around pore on sample surface [J]. Journal of Yansan University, 2012, 36(4): 293–297. (in Chinese)

ZHAI T. Strength distribution of fatigue crack initiation sites in an Al-Li alloy [J]. Metallurgical and Materials Transactions A, 2006, 37(10): 3139–3147.

XU Zhi-qiang, WEN Wei, ZHAI Tong-guang. Effects of pore position in depth on stress/strain concentration and fatigue crack initiation [J]. Metallurgical and Materials Transactions A, 2012, 43: 2763–2770.

ZHAI T, WILKINSON A J, MARTIN J W. A crystallographic mechanism for fatigue crack propagation through grain boundaries [J]. Acta Materialia, 2000, 48(20): 4917–4927.

WANG L, DANIEWICZ S R, HORSTEMEYER M F, SINTAY S, ROLLETT A D. Three-dimensional finite element analysis using crystal plasticity for a parameter study of microstructurally small fatigue crack growth in a AA7075 aluminum alloy [J]. International Journal of Fatigue, 2009, 31(4): 651–658.

SERRANO-MUNOZ I, BUFFIERE J Y, MOKSO R, VERDU C, NADOT Y. Location, location & size: Defects close to surfaces dominate fatigue crack initiation [J]. Scientific Reports, 2017, 7: 45239.

BOZEK J E, HOCHHALTER J D, VEILLEUX M G, LIU M, HEBER G, SINTAY S D, ROLLETT A D, LITTLEWOOD D J, MANIATTY A M, WEILAND H, CHRIST R J, PAYNE J, WELSH G, HARLOW D G, WAWRZYNEK P A, INGRAFFEA A R. A geometric approach to modeling microstructurally small fatigue crack formation: I. Probabilistic simulation of constituent particle cracking in AA 7075-T651 [J]. Modelling and Simulation in Materials Science and Engineering, 2008, 16(6): 065007.

PANG H T, REED P A S. Fatigue crack initiation and short crack growth in nickel-base turbine disc alloys-The effects of microstructure and operating parameters [J]. International Journal of Fatigue, 2003, 25: 1089–1099.

FAN J, MCDOWELL D L, HORSTEMEYER M F, GALL K. Cyclic plasticity at pores and inclusions in cast Al-Si alloys [J]. Engineering Fracture Mechanics, 2003, 70: 1281–1302.

GAO Y X, YI J Z, LEE P D, LINDLEY T. The effect of porosity on the fatigue life of cast aluminium-silicon alloys [J]. Fatigue & Fracture of Engineering Materials & Structures, 2004, 27: 559–570.

LI P, LEE P D, MAIJER D M, LINDLEY T C. Quantification of the interaction within defect populations on fatigue behavior in an aluminum alloy [J]. Acta Materialia, 2009, 57: 3539–3548.

HENAFF G, MARCHAL K, PETIT J. On fatigue crack propagation enhancement by a gaseous atmosphere: Experimental and theoretical aspects [J]. Acta Metallurgicaurgica et Materialia, 1995, 43: 2931–2942.

GASQUERES C, SARRAZIN-BAUDOUX C, PETIT J, DUMONT D. Fatigue crack propagation in an aluminium alloy at 223 K [J]. Scripta Materialia, 2005, 53: 1333–1337.

PETIT J, SARRAZIN-SARRAZIN C. Some critical aspects of low rate fatigue crack propagation in metallic materials, An overview on the influence of the atmosphere environment on ultra-high-cycle fatigue and ultra-slow fatigue crack propagation [J]. International Journal of Fatigue, 2006, 28: 1471–1478.

PETIT J, SARRAZIN-SBAUDOUX C. Some critical aspects of low rate fatigue crack propagation in metallic materials [J]. International Journal of Fatigue, 2010, 32(6): 962–970.

RICHARD S C, GASQUERES SARRAZIN-SBAUDOUX C, PETIT J. Coupled influence of microstructure and atmosphere environment on fatigue crack path in new generation Al alloys [J]. Engineering Fracture Mechanics, 2010, 77(11): 1941–1952.

CHAPMAN T P, KAREH K M, KNOP M, CONNOLLEY T, LEE P D, AZEEM M A, RUGG D, LINDLEY D, DYE D. Characterisation of short fatigue cracks in titanium alloy IMI 834 using X-ray microtomography [J]. Acta Materialia, 2015, 99: 49–62.

SERRANO-MUNOZ I, BUFFIERE J Y, VERDU C, GAILLARD Y, MU P, NADOT Y. Influence of surface and internal casting defects on the fatigue behaviour of A357-T6 cast aluminium alloy [J]. International Journal of Fatigue, 2016, 82: 361–370.

BILLAUDEAU T, NADOT Y. Support for an environmental effect on fatigue mechanisms in the long life regime [J]. International Journal of Fatigue, 2004, 26: 839–847.

MALLICK P K. 2-advanced materials for automotive applications: An overview [M]. Cambridge, UK: Woodhead Pubishing, 2012.

KAUFMAN J G. Understanding wrought and cast aluminum alloy designations [R]. NASA, 2013.

WANG Q G, CACERES C H. On the strain hardening behaviour of Al-Si-Mg casting alloys [J]. Materials Science and Engineering A, 1997, 234-236: 106–109.

CACERES C H, DAVIDSON C J, GRIFFITHS J R. The deformation and fracture behaviour of an Al-Si-Mg casting alloy [J]. Materials Science and Engineering A, 1995, 197: 171–179.

CACERES C H, GRIFFITHS J R, REINER P. The influence of microstructure on the Bauschinger effect in an Al-Si-Mg casting alloy [J]. Acta Materialia, 1996, 44: 15–23.

JIAO Yi-nan, ZHANG Yi-fan, MA Shi-qing, SANG De-li, ZHANG Yang, ZHAO Jin-jin, LIU Yong-qiang, YANG Shao-pu. Role of secondary phase particles in fatigue behavior of high-speed railway gearbox material [J]. International Journal of Fatigue, 2020, 131: 105336.

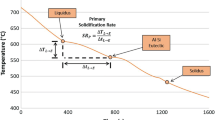

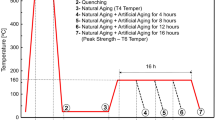

WANG Q G, DAVIDSON C J. Solidification and precipitation behaviour of Al-Si-Mg casting alloys [J]. Journal of Materials Science, 2001, 36: 739–750.

WANG Q G, APELIAN D, LADOS D A. Fatigue behavior of A356/357 aluminum cast alloys. Part II-Effect of microstructural constituents [J]. Journal of Light Metals, 2001, 1: 85–97.

ODANOVIC Z, DURDEVIC M, PAVLOVIC J K, ARSIC M, KATAVIC B. Some applications of the image analysis in the metal material science [J]. Acta Physica Polonica A, 2012, 121: 111–113.

DEZECOT S, BUFFIERE J Y, KOSTER A, MAUREL V, SZMYTKA F, CHARKALUK E, DAHDAH N, El BARTALI A, LIMODIN N, WITZ N. In situ 3D characterization of high temperature fatigue damage mechanisms in a cast aluminum alloy using synchrotron X-ray tomography [J]. Scripta Materialia, 2016, 113: 254–258.

WANG Q G, CARLOS H, CACERES C H. Mg effects on the eutectic structure and tensile properties of Al-Si-Mg alloys [J]. Materials Science Forum, 1997, 242: 159–164.

CACERES C H, GRIFFITHS J R. Damage by the cracking of silicon particles in an Al-7Si-0.4Mg casting alloy [J]. Acta Materialia, 1996, 44(1): 25–33.

BROWN L M. Back-stresses, image stresses, and workhardening [J]. Acta Materialia, 1973, 21: 879–885.

BOILEAU J M, ALLISON J E. The effect of solidification time and heat treatment on the fatigue properties of a cast 319 aluminum alloy [J]. Metallurgical and Materials Transactions A, 2003, 34(9): 1807–1820.

WANG Q, CACERES C, GRIFFITHS J. Cracking of Fe-rich intermetallics and eutectic Si particles in an Al-7Si-0.7 Mg casting alloy [J]. Transactions of the American Foundrymen’s Society, 1998, 106: 131–136.

WANG Q G, CACERES C H. The fracture mode in Al-Si-Mg casting alloys [J]. Materials Science and Engineering A, 1998, 214(1, 2): 72–82.

NADOT Y, IBEN HOURIA M I, FATHALAH R, MAIJER D. Through process modelling applied to the fatigue resistance of cast aluminum [J]. Procedia Engineering, 2018, 213: 296–302.

CACERES C H, DAVIDSON C J, GRIFFITHS J R, WANG Q G. The effect of Mg on the microstructure and mechanical behavior of Al-Si-Mg casting alloys [J]. Metallurgical and Materials Transactions A, 1999, 30(10): 2611–2618.

WANG Q G, CACERES C H, GRIFFITHS J R. Damage by eutectic particle cracking in aluminum casting alloys A356/357 [J]. Metallurgical and Materials Transactions A, 2003, 34(12): 2901–2912.

CHAN K S, JONES P, WANG Q. Fatigue crack growth and fracture paths in sand cast B319 and A356 aluminum alloys [J]. Materials Science and Engineering A, 2003, 341: 18–34.

DYE D, STONE H J, REED R C. Intergranular and interphase microstresses [J]. Current opinion in Solid State and Materials Science, 2001, 5(1): 31–37.

CHO K, GURLAND J. The law of mixtures applied to the plastic deformation of two-phase alloys of coarse microstructures [J]. Metallurgical Transactions A, 1988, 19(8): 2027–2040.

BYUN T S, KIM I S. Stress and strain partition in elastic and plastic deformation of two phase alloys [J]. Journal of Materials Science, 1991, 26: 3917–3925.

ARGON A, IM J, SAFOGLU R. Cavity formation from inclusions in ductile fracture [J]. Metallurgical and Materials Transactions A, 1975, 6(4): 825–837.

GELL M, WORTHINGTON P J. The plastic deformation and fracture of Iron-3% Silicon in the temperature range 295 K- 473 K [J]. Acta Materialia, 1996, 14: 1265–1271.

BARNBY J T. The initiation of ductile failure by fractured carbides in an austenitic stainless steel [J]. Acta Metallurgica, 1967, 15: 903–909.

LASSANCE D, FABREGUE D, DELANNAY F, PARDOEN T. Micromechanics of room and high temperature fracture in 6xxx Al alloys [J]. Progress in Materials Science, 2007, 52(1): 62–129.

JIAO Y, ZHENG W, KISH J R. Stress corrosion cracking susceptibility of thermally-aged Type 310S stainless steels in supercritical water [J]. Corrosion Science, 2018, 135: 1–11.

LEE J, EARMME Y, AARONSON H, RUSSELL K. Plastic relaxation of the transformation strain energy of a misfitting spherical precipitate: Ideal plastic behavior [J]. Metallurgical and Materials Transactions A, 1980, 11(11): 1837–1847.

BROCHU M, VERREMAN Y, AJERSCH F, BUCHER L. Fatigue behavior of semi-solid cast aluminum: A critical review [J]. Solid State Phenomena, 2008, 141: 725–730.

CHAN K S. Roles of microstructure in fatigue crack initiation [J]. International Journal of Fatigue, 2010, 32(9): 1428–1447.

WU S C, HU Y, DUAN H, YU C, JIAO H. On the fatigue performance of laser hybrid welded high Zn 7000 alloys for next generation railway components [J]. International Journal of Fatigue, 2016, 91: 1–10.

WU S C, YU C, YU P S, BUFFIERE J, HELFEN L, FU Y. Corner fatigue cracking behavior of hybrid laser AA7020 welds by synchrotron X-ray computed microtomography [J]. Materials Science and Engineering A, 2016, 651: 604–614.

LIU Y L, KANG S B, KIM H W. The complex microstructures in an as-cast Al-Mg-Si alloy [J]. Mater Lett, 1999, 41(6): 267–272.

MOUSTAFA M A, SAMUEL F H, DOTY H W. Effect of solution heat treatment and additives on the microstructure of Al-Si (A413.1) automotive alloys [J]. Journal of Materials Science, 2003, 38(22): 4507–4522.

LADOS D A, APELIAN D. Fatigue crack growth characteristics in cast Al-Si-Mg alloys: Part I. Effect of processing conditions and microstructure [J]. Materials Science and Engineering A, 2004, 385: 200–211.

DASGUPTA R, BROWN C, MAREK S. Analysis of overmodified 356 aluminum alloy [J]. AFS Trans, 1988, 96: 297–310.

ARGO D, GRUZLESKI J. Porosity in modified aluminum alloy castings [J]. AFS Transactions, 1988, 96: 65–74.

LEE P D, SRIDHAR S. Direct observation of the effect of strontium on porosity formation during the solidification of aluminium-silicon alloys [J]. International Journal of Cast Metals Research, 2000, 13(4): 185–198.

MOUSTAFA M A, SAMUEL F H, DOTY H W, VALTIERRA S. Effect of Mg and Cu additions on the microstructural characteristics and tensile properties of Sr-modified Al-Si eutectic alloys [J]. International Journal of Cast Metals Research, 2002, 14(4): 235–253.

ZANDBERGEN H, ANDERSEN S, JANSEN J. Structure determination of Mg5Si6 particles in Al by dynamic electron diffraction studies [J]. Science, 1997, 227: 1221–1225.

JOENOES A, GRUZLESKI J. Magnesium effects on the microstructure of unmodified and modified Al-Si alloys [J]. Cast Metals, 1991, 4: 62–71.

SIMENSEN C J, ROLFSEN T L. Production of π-AlMgSiFe crystals [J]. Zeitschrift für Metallkunde, 1997, 88: 142–146.

TAN Y H, LEE S L, LIN Y L. Effects of Be and Fe additions on the microstructure and mechanical properties of A357.0 alloys [J]. Metallurgical and Materials Transactions A, 1995, 26: 1195–1205.

SAMUEL F, SAMUEL A, DOTY H. Factors controlling the type and morphology of Cu-Containing phases in 319 Al alloy (96-30) [J]. Transactions of the American Foundrymen’s Society, 1996, 104: 893–902.

MIAO W, LAUGHLIN D. Effects of Cu content and preaging on precipitation characteristics in aluminum alloy 6022 [J]. Metallurgical and Materials Transactions A, 2000, 31: 361–371.

SHIH T S, SHIH F S. Effects of silicon, magnesium and strontium content on the qualities of Al-Si-Mg alloys [J]. Journal of Cast Metals Research, 1998, 10: 273–282.

SINGH R, GANGULY R, DHINDAW B. Application of statistical design of experiments for quantitatively studying the strengthening characteristics of cast Al-Si-Cu-Mg alloys [J]. British Foundryman, 1984, 77: 436–440.

TASH M, SAMUEL F, MUCCIARDI F, DOTY H, VALTIERRA S. Experimental correlation between metallurgical parameters and hardness in heat-treated 319 alloys: A quantitative study using factorial analysis [J]. Transactions of the American Foundry Society, 2006, 114: 71–84.

BUDIANSKY B, HUTCHINSON J, SLUTSKY S. Mechanics of solids [M]. Oxford, UK: Pergamon Press, 1982.

PARDOEN T, HUTCHINSON J. An extended model for void growth and coalescence [J]. Journal of the Mechanics and Physics of Solids, 2000, 48: 2467–2512.

GOGOGANU M, LEBLOND J B, DEVAUX J. Approximate models for ductile metals containing non-spherical voids—Case of axisymmetric prolate ellipsoidal cavities [J]. Journal of the Mechanics and Physics of Solids, 1993, 41: 1723–1754.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Foundation item: Projects(11790282, U1534204, 11572267, 51804202, 51705344) supported by the National Natural Science Foundation of China; Project(E2019210292) supported by the Natural Science Foundation of Hebei Province, China; Project(A2019210204) supported by the National Natural Science Foundation for Distinguished Young Scholars, China; Project(KQTD20170810160424889) supported by the Shenzhen Peacock Team Program, China; Project(2019DB013) supported by the Key Research Project of Southern Xinjiang, China; Project(C201821) supported by the High Level Talent Support Project in Hebei, China; Project supported by the Youth Top-notch Talents Supporting Plan of Hebei Province, China; Project(MCMS-E-0519G04) supported by the State Key Laboratory of Mechanics and Control of Mechanical Structures, Nanjing University of Aeronautics and Astronautics, China; Project(201919) supported by the Open Fund of State Key Laboratory of Metastable Materials Science and Technology, Yanshan University, China

Rights and permissions

About this article

Cite this article

Jiao, Yn., Zhang, Yf., Ma, Sq. et al. Effects of microstructural heterogeneity on fatigue properties of cast aluminum alloys. J. Cent. South Univ. 27, 674–697 (2020). https://doi.org/10.1007/s11771-020-4323-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-020-4323-0