Abstract

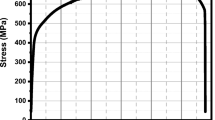

In this study, double-sided submerged-arc-welded CSEF steel joints were considered for microstructural and mechanical (hardness, ductility and strength) characterisations for four different cases of preheating and PWHT processes. The XRD and EDS analyses were also performed to investigate the phase transformation and chemical composition. Preheating was observed to be an improving factor for ductility and hardness of the welds. Similarly, PWHT enhanced the uniformity in the hardness distribution owing to reduced austenitic grain size in the HAZ as well as equiaxed fine-grained ferrite matrix in the FZ. It was observed that preheating and combined preheating and PWHT increased the ductility of the weld by 16.9% and 56.3%, respectively, from the as-welded case. Furthermore, it was also observed that preheating individually and preheating combined with PWHT reduced the maximum hardness values by 8.2% and 60.2%, respectively.

Similar content being viewed by others

References

El-azim M E A, Nasreldin A M, Zies G, and Klenk A, Mater Sci Technol21 (2005) 779, https://doi.org/10.1179/174328405x43216.

Pandey C, Mohan M, Kumar P, and Saini N, J Alloys Compd743 (2018) 332, https://doi.org/10.1016/j.jallcom.2018.01.120.

Pandey C, Giri A, and Mahapatra M M, Mater Sci Eng A664 (2016) 58, https://doi.org/10.1016/j.msea.2016.03.132.

Francis J A, Mazur W, and Bhadeshia H K D H, Review Type IV Cracking in Ferritic Power Plant Steels Type IV Cracking in Ferritic Power Plant Steels, vol. 0836 (2013), https://doi.org/10.1179/174328406x148778.

Cohn M J and Henry J F, Fabrication, Construction, and Operation Problems for Grade 91 Fossil Power Components By (2016), https://doi.org/10.1115/1.1904054.

Coleman K and Newell W, Weld J-NY, 86 (2007) 29.

Pandey C and Mahapatra M M, J Mater Eng Perform25 (2016) 2195, https://doi.org/10.1007/s11665-016-2064-x.

Mahapatra C P M M, Trans Indian Inst Met69 (2016) 1657, https://doi.org/10.1007/s12666-015-0826-z.

Pandey C, Giri A, and Mahapatra M M, Mater Sci Eng A657 (2016) 173, https://doi.org/10.1016/j.msea.2016.01.066.

Weman K, in Welding Process Handbook, 2nd edn., Sicencedirect (2012), p. 105.

Santella M L, Swindeman R W, Reed R W, and Tanzosh J M, Martensite Formation in 9 Cr-1 Mo Steel Weld Metal and Its Effect on Creep Behavior.

Zhang S, Melfi T, and Narayanan B K, Sci Technol Weld Join, 21 (2016) 147.

Roy J, Rai R N, and Saha S C, Evaluation of Microstructure and Mechanical Properties of P91 Steel Weldment Due to Addition of Boron Trioxide into Flux During Submerged Arc Welding (2017), https://doi.org/10.1007/s40194-017-0515-0.

Rao R V and Kalyankar V D, Int J Adv Manuf Technol69 (2013) 93, https://doi.org/10.1007/s00170-013-5007-9.

Suman S, Biswas P, Kumar S, Pratap V, Kumar A, and Kuriachen B, Mater Today Proc (2019). https://doi.org/10.1016/j.matpr.2019.12.049.

Suman S and Biswas P, J Manuf Process51 (2020) 19, https://doi.org/10.1016/j.jmapro.2020.01.012.

Suman S and Biswas P, Mater Today Proc (2020). https://doi.org/10.1016/j.matpr.2019.12.299.

Suman S and Biswas P, Advances in Mechanical Engineering. Lecture Notes in Mechanical Engineering, Springer, Singapore (2020).

Suman S, Pankaj P, Tiwari A, Biswas P, Kuriachen B and Sinha A, Advances in Additive Manufacturing and Joining. Lecture Notes on Multidisciplinary Industrial Engineering, Springer, Singapore (2020).

Singh A K, Dey V, and Rai R N, J Manuf Process, 25 (2017) 1, https://doi.org/10.1016/j.jmapro.2016.09.006.

Sireesha M, Sundaresan S, and Albert S, J Mater Eng Perform10 (2001) 320, https://doi.org/10.1361/105994901770345033.

Dhandha K H and Badheka V J, J Manuf Process17 (2015) 48, https://doi.org/10.1016/j.jmapro.2014.10.004.

Pandey C, Mahapatra M M, Kumar P, and Kumar S, J Mater Process Tech266 (2018) 140, https://doi.org/10.1016/j.jmatprotec.2018.10.024.

Pandey C and Mahapatra M M, J Mater Eng Perform25 (2016) 2761, https://doi.org/10.1007/s11665-016-2127-z.

Pandey C, Giri A, Mahapatra M M, and Kumar P, Met Mater Int23 (2017) 12, https://doi.org/10.1007/s12540-017-6394-5.

Gopal J, Pandey C, Mohan M, and Mulik R S, J Manuf Process48 (2019) 249, https://doi.org/10.1016/j.jmapro.2019.10.002.

Chaurasia P K, Pandey C, Giri A, Saini N, and Mahapatra M M, Arch Metall Mater63 (2018) 1019, https://doi.org/10.24425/122437.

Pandey C, Saini N, Mahapatra M M, and Kumar P, Eng Fail Anal71 (2016) 131, https://doi.org/10.1016/j.engfailanal.2016.06.012.

Hurtado-noreña C, Danón C A, Luppo M I, and Bruzzoni P, Proc Mater Sci8 (2015) 1089, https://doi.org/10.1016/j.mspro.2015.04.172.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Suman, S., Biswas, P. & Tiwari, A. Microstructure Evolution and Mechanical Behaviour of SAW Weldments of CSEF Steel on Preheating and PWHT. Trans Indian Inst Met 73, 1185–1197 (2020). https://doi.org/10.1007/s12666-020-01961-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-01961-5