Abstract

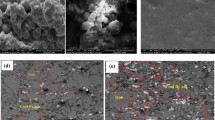

This study focus on the effects of silicon inclusion carbonaceous particulate on the hardness and microstructural properties of carburized low carbon steel, at constant temperature of 900 °C with different holding time from 2 to 5 h. The cow bone and coal dust composite particles were varied with 20% CaCO3 used as the energizer. Hardness and microstructural testing of the various specimens were then carried out using Vickers hardness machine and metallurgical scanning electron microscope. From the result, it was noticed that there was an increase in microhardness performance on both cow bone and coal dust reinforced matrix compared to the as-received samples. For coal dust carburized carbon steel, the hardness value improved from 286 HVN control samples 434.55 HVN in 5 h. It was seen that the introduction of cow bone composite particulate also provides a reasonable mechanical hardness improvement to 418.2 HVN although a little short fall against the coal dust metal matrix. From the microstructure and macrostructure studies highly pearlitic matrix steel was observed with grain refinement of CB and CD found at the interface providing an effective nucleation site along the boundaries.

Similar content being viewed by others

References

Aramide FO, Ibitoye SA, Oladele IO, Borode JO (2009) Effects of carburization and temperature on the mechanical properties of carburized mild steel, using activated carbon as carburizer. Mater Res 12(4):483–487

Prime MB, Prantil VC, Bottger AJ, Delhez R, Mittemeijer EJ (2006) Residual stress measurement and prediction in hardened steel ring. Material science forum, residual stress ECRS5. Thomson scientific, Stamford, pp 223–228

Mahmoud AE, Mahfouz MG, Gad- Elrab HG (2014) Influence of zirconium on the grain refinement of Al 6063 alloy Int. Journal of Engineering Research and Applications 4(7 (Version 6):188–194

Pio LY (2011) Effect of T6 heat treatment on the mechanical properties of gravity die cast A356 Aluminium alloy. J Appl Sci 11(11):2048–2052

Poornesh M, Harish N, Kiran A (2016) Mechanical and Tribological properties of centrifugally cast Al-Si-SiC. Composites American Journal of Materials Science 6(4A):31–35

Umunakwe R, Okoye OC, Madueke CI, Komolafe DO (2017) Effects of carburization with palm kernel Shell/coconut Shell mixture on the tensile properties and case hardness of low. Carbon Steel FUOYE Journal of Engineering and Technology 2(1)

Darmo S, Soenoko R, Siswanto E, Dwi T Widodo study on mechanical properties of pack carburizing ss400 steel with energizer pomacea canalikulata lamarck shell powder. International Journal of Mechanical Engineering and Technology (IJMET) 2018, 9(5):14–23

Afolalu SA, O Oluwaseyi funmi SO, Ongbali AA, Abioye IP (2018) Okokpujie , O. Olamilekan. The study of the impact of Nano carbon additives on Astm A53 mild steel during machining IOP Conf. Series: Materials Science and Engineering 413:1–8

Major Š, Jakl V, Hubálovský Š (2011) Effect of carburizing on fatigue life of highstrength steel specimen under push-pull loading. Advances in Engineering Mechanics and Materials:143–146

J. Purbolaksono, J.I. Inayat-Hussain, N. Wahab Effects of carburization on expected fatigue life of alloys steel shafts Mater Des 2011, Volume 32, Issue 6, Pp3544–3547

Fayomia OSI, Josepha OO, Akandeb IG, Ohiria CK, Enechia KO (2019) N.E. Udoyea effect of CCBP doping on the multifunctional Al-0.5Mg-15CCBP Superalloy using liquid metallurgy process for advanced application. J Alloys Compd 783:246–255. https://doi.org/10.1016/J.Jallcom.2018.12.312

M AIA, Madugu F, Asuke OSI, Fayomi FA (2013) Ayeni effect of thermal ageing treatment on the mechanical properties of antimony-modified A356.0-type Al-Si-mg alloy. Journal Material And Environmental Science 4(1):87–92

Fayomi OSI, Gbenebor OP, Abdulwahab M, Bolu CA, Popoola API (2013) Structural modification, strengthening mechanism and electrochemical assessment of the enhanced conditioned Aa6063-type Al-mg-Si alloy. J New Mater Electrochem Syst 16:059–064

Inegbenebor AO, Bolu CA, Babalola PO, Inegbenebor AI, Fayomi OSI (2016) Aluminum silicon carbide particulate metal matrix composite development via stir casting processing. Silicon 10:343–347. https://doi.org/10.1007/S12633-016-9451-7

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Joshua, T.O., Fayomi, O.S.I., Seriki, E.O. et al. Effect of Silicon Inclusion Carbonaceous Composite Particulate on the Thermal-Ageing Characteristics and Mechanical Performance of Low Carbon Steel. Silicon 12, 1231–1236 (2020). https://doi.org/10.1007/s12633-019-00221-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-019-00221-6