Abstract

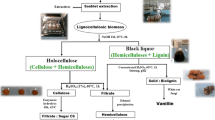

The aim of this work was to demonstrate the production of polyol from microbial oil using wood-based hemicellulose stream through a greener enzymatic process. Yeast biomass concentration of 16.54 ± 0.65 g/L and lipid concentration of 6.97 ± 0.58 g/L were obtained by batch fermentation of hemicellulose prehydrolysate of poplar wood using an oleaginous yeast Cryptococcus curvatus. The produced microbial oil was successfully converted to epoxidized oil catalyzed by lipase with 84.55 ± 1.80% conversion. The epoxidation followed by ring opening reaction to produce polyol with hydroxyl value of 299.53 ± 1.24 mg KOH/g. This showed the possible use of the hemicellulose stream of lignocellulosic biomass to microbial oil and its subsequent conversion to polyol, a precursor to polyurethane and a number of value-added products. This bio-based polyol could be used to substitute the conventional polyols.

Similar content being viewed by others

Abbreviations

- A i :

-

Atomic weight of iodine

- A 0 :

-

Atomic weight of oxygen

- AIER:

-

Acid ion exchange resin

- CALB:

-

Candida antarctica lipase

- HMF:

-

Hydroxy methyl furfural

- IV:

-

Iodine value

- MO:

-

Microbial oil

- OO exp :

-

Experimental oxirane value

- OO th :

-

Theorical oxirane value

- PHL:

-

Prehydrolysate liquor

- TGA:

-

Triacylglycerides

References

Miao, S., P. Wang, Z. Su, and S. Zhang (2014) Vegetable-oil-based polymers as future polymeric biomaterials. Acta Biomater. 10: 1692–1704.

Liang, M. H. and J. G. Jiang (2013) Advancing oleaginous microorganisms to produce lipid via metabolic engineering technology. Prog. Lipid Res. 52: 395–408.

Adrio, J. L. (2017) Oleaginous yeasts: promising platforms for the production of oleochemicals and biofuels. Biotechnol. Bioeng. 114: 1915–1920.

McNutt, J. and Q. S. He (2016) Development of biolubricants from vegetable oils via chemical modification. J. Ind. Eng Chem. 36: 1–12.

Ratledge, C. (2004) Fatty acid biosynthesis in microorganisms being used for single cell oil production. Biochimie. 86: 807–815.

Koutinas, A. A., A. Chatzifragkou, N. Kopsahelis, S. Papanikolaou, and I. K. Kookos (2014) Design and techno-economic evaluation of microbial oil production as a renewable resource for biodiesel and oleochemical production. Fuel. 116: 566–577.

Boviatsi, E., A. Papadaki, M. N. Efthymiou, G. J. E. Nychas, S. Papanikolaou, J. A. da Silva, D. M. Freire, and A. Koutinas (2020) Valorisation of sugarcane molasses for the production of microbial lipids via fermentation of two Rhodosporidium strains for enzymatic synthesis of polyol esters. J. Chem. Technol. Biotechnol. 95: 402–407.

Lehoux, R. R. and C. B. Bradt (2014) Solid/fluid separation device and method for treating biomass including solid/fluid separation. US Patent 8,746,138.

Meesters, P. A. E. P., G. N. M. Huijberts, and G. Eggink (1996) High-cell-density cultivation of the lipid accumulating yeast Cryptococcus curvatus using glycerol as a carbon source. Appl. Microbiol. Biotechnol. 45: 575–579.

Uprety, B. K., S. S. Dalli, and S. K. Rakshit (2017) Bioconversion of crude glycerol to microbial lipid using a robust oleaginous yeast Rhodosporidium toruloides ATCC 10788 capable of growing in the presence of impurities. Energy Convers. Manag. 135: 117–128.

Manirakiza, P., A. Covaci, and P. Schepens (2001) Comparative study on total lipid determination using Soxhlet, Roese-Gottlieb, Bligh & Dyer, and modified Bligh & Dyer extraction methods. J. Food Compos. Anal. 14: 93–100.

Vlček, T. and Z. S. Petrović (2006) Optimization of the chemoenzymatic epoxidation of soybean oil. J. Amer. Oil Chem. Soc. 83: 247–252.

Paquot, C. (2013) Standard Methods for the Analysis of Oils, Fats and Derivatives. 6th ed., pp. 66 and 89. Elsevier, Amsterdam, Nederlands.

Miao, S., S. Zhang, Z. Su, and P. Wang (2013) Synthesis of bio-based polyurethanes from epoxidized soybean oil and isopropanolamine. J. Appl. Polym. Sci. 127: 1929–1936.

Sluiter, A., B. Hames, R. Ruiz, C. Scarlata, J. Sluiter, and D. Templeton (2006) Determination of sugars, byproducts, and degradation products in liquid fraction process samples. National Renewable Energy Laboratory, Golden, CO, USA.

Sluiter, A., B. Hames, D. Hyman, C. Payne, R. Ruiz, C. Scarlata, J. Sluiter, D. Templeton, and J. Wolfe (2008) Determination of total solids in biomass and total dissolved solids in liquid process samples. National Renewable Energy Laboratory, Golden, CO, USA.

Bracharz, F., T. Beukhout, N. Mehlmer, and T. Brück (2017) Opportunities and challenges in the development of Cutaneo-trichosporon oleaginosus ATCC 20509 as a new cell factory for custom tailored microbial oils. Microb Cell. Fact. 16: 178.

Yu, X., Y. Zheng, K. M. Dorgan, and S. Chen (2011) Oil production by oleaginous yeasts using the hydrolysate from pretreatment of wheat straw with dilute sulfuric acid. Bioresour. Technol. 102: 6134–6140.

Papanikolaou, S. and G. Aggelis (2011) Lipids of oleaginous yeasts. Part I: Biochemistry of single cell oil production. Eur. J. Lipid Sci. Technol. 113: 1031–1051.

Samavi, M., B. K. Uprety, and S. Rakshit (2019) Bioconversion of poplar wood hemicellulose prehydrolysate to microbial oil using Cryptococcus curvatus. Appl. Biochem. Biotechnol. 189: 626–637.

Soccol, C. R., C. J. Dalmas Neto, V. T. Soccol, E. B. Sydney, E. S. F. da Costa, A. B. P. Medeiros, and L. P. S. Vandenberghe (2017) Pilot scale biodiesel production from microbial oil of Rhodosporidium toruloides DEBB 5533 using sugarcane juice: performance in diesel engine and preliminary economic study. Bioresour. Technol. 223: 259–268.

Carus, M. and L. Dammer (2018) The circular bioeconomy— concepts, opportunities, and limitations. Ind. Biotechnol. 14: 83–91.

Uprety, B. K., J. V. Reddy, S. S. Dalli, and S. K. Rakshit (2017) Utilization of microbial oil obtained from crude glycerol for the production of polyol and its subsequent conversion to polyurethane foams. Bioresour. Technol. 235: 309–315.

Papadaki, A., K. V. Fernandes, A. Chatzifragkou, E. C. G. Aguieiras, J. A. C. da Silva, R. Fernandez-Lafuente, S. Papanikolaou, A. Koutinas, and D. M. G. Freire (2018) Bioprocess development for biolubricant production using microbial oil derived via fermentation from confectionery industry wastes. Bioresour. Technol. 267: 311–318.

Zhang, C., T. F. Garrison, S. A. Madbouly, and M. R. Kessler (2017) Recent advances in vegetable oil-based polymers and their composites. Prog. Polym. Sci. 71: 91–143.

Sharmin, E., S. M. Ashraf, and S. Ahmad (2007) Synthesis, characterization, antibacterial and corrosion protective properties of epoxies, epoxy-polyols and epoxy-polyurethane coatings from linseed and Pongamia glabra seed oils. Int. J. Biol. Macromol. 40: 407–422.

Saurabh, T., M. Patnaik, S. L. Bhagt, and V. C. Renge (2011) Epoxidation of vegetable oils: a review. Int. J. Adv. Eng. Technol. 2: 491–501.

Tan, S. G. and W. S. Chow (2010) Biobased epoxidized vegetable oils and its greener epoxy blends: a review. Polym Plast. Technol. Eng. 49: 1581–1590.

Lin, H., J. Y. Liu, H. B. Wang, A. A. Q. Ahmed, and Z. L. Wu (2011) Biocatalysis as an alternative for the production of chiral epoxides: a comparative review. J. Mol. Catal. B Enzym. 72: 77–89.

Lu, H., S. Sun, Y. Bi, G. Yang, R. Ma, and H. Yang (2010) Enzymatic epoxidation of soybean oil methyl esters in the presence of free fatty acids. Eur. J. Lipid Sci. Technol. 112: 1101–1105.

Miao, S., S. Zhang, Z. Su, and P. Wang (2008) Chemoenzymatic synthesis of oleic acid-based polyesters for use as highly stable biomaterials. J. Polym. Sci. A. Polym Chem. 46: 4243–4248.

Sun, S., X. Ke, L. Cui, G. Yang, Y. Bi, F. Song, and X. Xu (2011) Enzymatic epoxidation of Sapindus mukorossi seed oil by perstearic acid optimized using response surface methodology. Ind. Crops. Prod. 33: 676–682.

Ghaly, A. E., D. Dave, M. S. Brooks, and S. Budge (2010) Production of biodiesel by enzymatic transesterification: review. Am. J. Biochem. Biotechnol. 6: 54–76.

Hasan, F., A. A. Shah, and A. Hameed (2006) Industrial applications of microbial lipases. Enzyme Microb. Technol. 39: 235–251.

Milchert, E., K. Malarczyk, and M. Kłos (2015) Technological aspects of chemoenzymatic epoxidation of fatty acids, fatty acid esters and vegetable oils: a review. Molecules. 20: 21481–21493.

Chen, B., J. Hu, E. M. Miller, W. Xie, M. Cai, and R. A. Gross (2008) Candida antarctica lipase B chemically immobilized on epoxy-activated micro-and nanobeads: catalysts for polyester synthesis. Biomacromolecules. 9: 463–471.

Törnvall, U., C. Orellana-Coca, R. Hatti-Kaul, and D. Adlercreutz (2007) Stability of immobilized Candida antarctica lipase B during chemo-enzymatic epoxidation of fatty acids. Enzyme Microb. Technol. 40: 447–451.

Sulciene, M., A. Karalius, and I. Matijosyte (2014) Chemoenzymatic route for the production of biopolyol from rapeseed oil. Curr Org Chem. 18: 3037–3043.

Bajwa, A. S., S. Sathaye, V. M. Kulkarni, and A. V. Patwardhan (2016) Chemoenzymatic epoxidation of Karanja oil: an alternative to chemical epoxidation? Asia. Pac. J. Chem. Eng. 11: 314–322.

Ortiz, C., M. L. Ferreira, O. Barbosa, J. C. S. dos Santos, R. C. Rodrigues, Á. Berenguer-Murcia, L. E. Briand, and R. Fernandez-Lafuente (2019) Novozym 435: the “perfect” lipase immobilized biocatalyst? Catal. Sci. Technol. 9: 2380–2420.

Li, Y., X. Luo, and S. Hu (2015) Bio-based Polyols and Polyurethanes. 1st ed., pp. 1–13. Springer International Publishing, Cham, Switzerland.

Veronese, V. B., R. K. Menger, M. M. C. Forte, and C. L. Petzhold (2011) Rigid polyurethane foam based on modified vegetable oil. J. Appl. Polym. Sci. 120: 530–537.

Wood, G. (1990) The ICI Polyurethanes Book. 2nd ed., pp. 41–42. John Wiley and Sons, NJ, USA.

Kiatsimkul, P. P., G. J. Suppes, F. H. Hsieh, Z. Lozada, and Y. C. Tu (2008) Preparation of high hydroxyl equivalent weight polyols from vegetable oils. Ind. Crops. Prod. 27: 257–264.

Hazmi, A. S. A., M. M. Aung, L. C. Abdullah, M. Z. Salleh, and M. H. Mahmood (2013) Producing Jatropha oil-based polyol via epoxidation and ring opening. Ind. Crops. Prod. 50: 563–567.

Zlatanić, A., C. Lava, W. Zhang, and Z. S. Petrović (2004) Effect of structure on properties of polyols and polyurethanes based on different vegetable oils. J. Polym. Sci B. Polym Phys. 42: 809–819.

Wang, C. S., L. T. Yang, B. L. Ni, and G. Shi (2009) Polyurethane networks from different soy-based polyols by the ring opening of epoxidized soybean oil with methanol, glycol, and 1, 2-propanediol. J. Appl. Polym. Sci. 114: 125–131.

Monteavaro, L. L., E. O. da Silva, A. P. O. Costa, D. Samios, A. E. Gerbase, and C. L. Petzhold (2005) Polyurethane networks from formiated soy polyols: synthesis and mechanical characterization. J. Amer. Oil Chem. Soc. 82: 365–371.

Guo, Y., J. H. Hardesty, V. M. Mannari, and J. L. Massingill Jr (2007) Hydrolysis of epoxidized soybean oil in the presence of phosphoric acid. J. Amer. Oil Chem. Soc. 84: 929–935.

Guo, A., Y. Cho, and Z. S. Petrović (2000) Structure and properties of halogenated and nonhalogenated soy-based polyols. J. Polym. Sci A. Polym Chem. 38: 3900–3910.

Zhang, J., J. J. Tang, and J. X. Zhang (2015) Polyols prepared from ring-opening epoxidized soybean oil by a castor oil-based fatty diol. Int. J. Polym. Sci. 2015: 529235.

Abril-Milán, D., O. Valdés, Y. Mirabal-Gallardo, A. F de la Torre, C. Bustamante, and J. Contreras (2018) Preparation of renewable bio-polyols from two species of Colliguaja for rigid polyurethane foams. Materials. 11: 2244.

Acar, M., S. Çoban, and B. Hazer (2013) Novel water soluble soya oil polymer from oxidized soya oil polymer and diethanol amine. J. Macromol. Sci. A. 50: 287–296.

Acknowledgments

We would like to thank Greenfield Global Inc., Chatham, Canada, for the supply of the hemicellulose substrate.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Neither ethical approval nor informed consent was required for this study

Additional information

Publisher's Note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Samavi, M., Rakshit, S. Utilization of Microbial Oil from Poplar Wood Hemicellulose Prehydrolysate for the Production of Polyol Using Chemo-enzymatic Epoxidation. Biotechnol Bioproc E 25, 327–335 (2020). https://doi.org/10.1007/s12257-019-0416-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12257-019-0416-8