Abstract

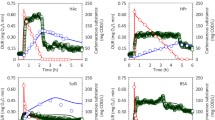

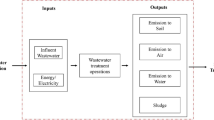

Economic estimation of an environmental-friendly biomethanation process based on economic values of consumed and produced gases would be a unique attitude. In this paper, time and space dependent concentration profiles of components involved in a batch process, designed for biomethanation, were predicted through a mass transfer modelling. The reaction terms used in the modeling required bio-kinetic parameters of μmax, m, kL, YC/L, YX/L, and YP/L which were globally optimized via a predefined algorithm using some experimental data as 0.0987 day1, 0.1374 day1, 1.5422 mole m−3, 1.3636, 0.0183, 0.0908. Upon model verification, process income was calculated for a long-term scenario under a variety of factors and maximized through response surface methodology. The maximum income achieved was $-0.4/m3 bioreactor. A term carbon subsidy was considered in the income equation in order to find a break-even income for subsidy value of $363/ton CO2. Sensitivity analysis revealed that the amount of carbon subsidy directly influenced the selection of low or high levels of some process parameters to make the process profitable. In addition, it was found that pressure and liquid volume were the most important factors to achieve maximum income when $30 and $300/ton CO2 carbon subsidy were allocated to the process, respectively.

Similar content being viewed by others

Abbreviations

- \({\rm{C}}_{L_{ini}}\) :

-

initial concentration in liquid phase mole·m−3]

- \({\rm{C}}_{g_{ini}}\) :

-

initial concentration in gas phase [mole·m−3]

- D̅ij :

-

multicomponent Fick diffusivity [m2·s−1]

- C L :

-

time and space dependent concentration in the liquid phase [mole·m−3]

- CLave :

-

space-averaged concentration in liquid phase [mole· m−3]

- CLs :

-

liquid concentration on gas-liquid interface [mole·m−3]

- CX :

-

time and space dependent concentration of biomass [mole·

- m−3] Cg :

-

time and space dependent concentration in gas phase [mole· m−3]

- C g.ave :

-

space-averaged concentration in gas phase [mole·m−3]

- C gs :

-

gas concentration on gas-liquid interface [mole·m−3]

- DL,i :

-

diffusivity coefficient of gases in liquid phase [m2·s−1]

- Deff,i :

-

effective diffusion coefficient of component i in gas mixture [m2 ·s−1]

- DTi :

-

thermal diffusion coefficient

- D ij :

-

diffusion coefficient of pair gases [m2 ·s−1]

- NL :

-

liquid diffusive flux [mole·m2·s−1]

- N g :

-

gas diffusive flux [mole·m−2·s−1]

- Y i/L :

-

theoretical maximal (C)-molar yields on the basis of hydro gen

- Y mod :

-

response value obtained via modelling

- Y prd :

-

response value predicted by RSM

- kL :

-

saturation constant [mole· m−3]

- qmaxL :

-

maximum H2 consumption [mole·m−3]

- rH2 :

-

H2 consumption rate [mole·m-3 ·s−1]

- rC :

-

CO2 consumption rate [mole·m ·s

- rP :

-

CH4 production rate [mole· ·s

- rX :

-

biomass growth rate [mole·m−3 ·s−1]

- yj :

-

mole fraction in gas phase

- ω j :

-

mass fraction

- ▽VP:

-

pressure gradient

- ▽T:

-

temperature gradient

- Hr:

-

dimensionless Henrys constant

- m:

-

microorganism maintenance coefficient [day−1 ]

- u:

-

velocity [m·s−1]

- p :

-

mixture density [Kg·m−3]

- μ max :

-

maximum growth rate of biomass [day−1]

References

C. Ampelli, S. Perathoner and G. Centi, Philos. Trans. R. Soc. A, 373, 20140177 (2015).

C. Steinlechner and H. Junge, Angew. Chem. Int. Ed., 57, 44 (2018).

J. G Olivier and J Peters, Trends n global CO2and total green house gas emissions, Report (2018).

B. Dudley, BP statistical review of world energy, Report (2018).

Q. Chai, Z. Xiao, K.-h. Lai and G. Zhou, Int. J. Prod. Econ., 203, 311 (2018).

H. Naims, Environ. Sci. Pollut. Res., 23, 22226 (2016).

M. Bailera, P. Lisbona, L. M. Romeo and S. Espatolero, Renew. Sust. Energy Rev, 69, 292 (2017).

G. Iaquaniello, S. Setini, A. Salladini and M. De Falco, Int. J. Hydrogen Energy, 43, 17069 (2018).

J. Squalli, Energy, 127, 479 (2017).

H. Blanco, W Nijs, J. Ruf and A. Faaij, Appl. Energy, 232, 323 (2018).

J. H. Kim, W S. Chang and D. Pak, Korean J. Chem. Eng, 32, 2067 (2015).

E. Inkeri, T. Tynjälä, A. Laari and T. Hyppänen, Appl. Energy, 209, 95 (2018).

K. Ghaib and F.-Z. Ben-Fares, Renew. Sust. Energy Rev, 81, 433 (2018).

R. Tarkowski, Renew. Sust. Energy Rev, 105, 86 (2019).

S. Savvas, J. Donnelly, T. Patterson, Z. S. Chong and S. R. Esteves, Appl. Energy, 202, 238 (2017).

J. Biswas, R. Chowdhury and P. Bhattacharya, in Industry interactive innovations in science, engineering and technology, S. Bhattacharyya, S. Sen, M. Dutta, P. Biswas and H. Chattopadhyay Eds., Springer, Singapore (2018).

I. Diaz, C. Perez, N. Alfaro and F. Fdz-Polanco, Bioresour. Technol, 185, 246 (2015).

W Merkle, K. Baer, J. Lindner, S. Zielonka, F. Ortloff, F. Graf, T. Kolb, T. Jungbluth and A Lemmer, Bioresour. Technol, 232, 72 (2017).

D. Strubing, B. Huber, M. Lebuhn, J. E. Drewes and K. Koch, Biore-sour. Technol., 245, 1176 (2017).

Y. Huang, F. Mahmoodpoor-Dehkordy, Y. Li, S. Emadi, A. Bagtzo-glou and B. Li, Chem. Eng. J., 334, 1383 (2018).

A. Bensmann, R. Hanke-Rauschenbach, R. Heyer, F. Kohrs, D. Ben-ndorf, U. Reichl and K. Sundmacher, Appl. Energy, 134, 413 (2014).

G. Leonzio, Chem. Eng. J., 290, 490 (2016).

J. Y. Leu, Y. H. Lin and F. L. Chang, Chem. Eng. Res. Des., 89, 1879 (2011).

S. Osfouri and R. Azin, Gas Process., 4, 14 (2016).

W. Hayduk and H. Laudie, AIChE J., 20, 611 (1974).

D. Fairbanks and C. Wilke, Ind. Eng. Chem., 42, 471 (1950).

T. R. Marrero and E. A. Mason, J. Phys. Chem. Ref. Data, 1, 3 (1972).

S. Weissman and G. Dubro, J. Chem. Phys., 54, 1881 (1971).

T. Chu, P. S. Chappelear and R. Kobayashi, J. Chem. Eng. Data, 19, 299 (1974).

R. Fernández-Prini, J. L. Alvarez and A. H. Harvey, J. Phy s. Chem. Ref. Data, 32, 903 (2003).

G. Luo and I. Angelidaki, Bi otechn ol. Bioeng. , 109, 2729 (2012).

J. Zabranska and D. Pokorna, Biotechnol. Adv., 36, 707 (2018).

J. Owens and J. Legan, FEMS Microbiol. Rev., 3, 419 (1987).

S. P. Cadogan, G. C. Maitland and J. M. Trusler, J. Chem. Eng. Data, 59, 519 (2014).

J. W. Schmelzer, E. D. Zanotto and V. M. Fokin, J. Chem. Phys., 122, 074511 (2005).

M. D. Rosa, Energy Environ., 31, 60 (2018).

G. Glenk and S. Reichelstein, Nat. Energy, 4, 216 (2019).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jafari, S.A., Osfouri, S. & Azin, R. Modelling of batch biomethanation process for maximizing income based on values of consumed and produced gases. Korean J. Chem. Eng. 37, 815–826 (2020). https://doi.org/10.1007/s11814-020-0501-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-020-0501-x