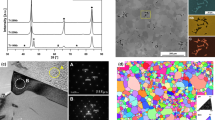

The paper examines how the titanium diboride content of the starting TiH2–TiB2 powder mixture influences basic mechanical properties of the resultant sintered composites in tension and compression tests. The porosity of the compacts sintered at 1250°C increases with greater titanium diboride content of the starting mixture, which is associated with the Frenkel effect that occurs in the sintering process. Although the porosity somewhat increases, the strength, hardness, and elastic modulus in tension become higher when 5% TiB2 powder is introduced into the charge. These characteristics however decrease when the high-modulus component increases to 10% in the charge. The ductility of the sintered alloys monotonically reduces with higher boride content. The yield point and compressive strength monotonically increase with higher TiB2 content of the charge, despite greater porosity. This occurs because porosity has a significantly weaker effect on the strain resistance of the sintered Ti–TiB composites in compression than in tension.

Similar content being viewed by others

References

A.A. Ilyin, B.A. Kolachev, and I.S. Polkin, Titanium Alloys. Composition, Structure, and Properties: Handbook [in Russian], Moscow (2009), p. 520.

A.G. Bratukhin (ed.), B.A. Kolachev, I.S. Eliseev, and V.D. Tatalaev, Titanium Alloy in Aircraft Engines and Aerospace Equipment [in Russian], Moscow (2001), p. 416.

F.H. Froes and D. Eylon, “Powder metallurgy of titanium alloys—A review,” in: Titanium Technology: Present Status and Future Trends, Warrendale (1985), pp. 49–59.

Science and Technology: Proc. 10th World Conf. Titanium’ 2003 (July 13–18, 2003, Gamburg, Germany), Gamburg (2003), Vol. 1–5, p. 3425.

H.W. Wang, J.Q. Qi, C.M. Zou, D.D. Zhu, and Z.J. Wei, “High-temperature tensile strengths of in situ synthesized TiC/Ti-alloy composites,” Mater. Sci. Eng. A, 545, 209–213 (2012).

H.K.S. Rahoma, X.P. Wang, F.T. Kong, Y.Y. Chen, J.C. Han, and M. Derradji, “Effect of (α+β) heat treatment on microstructure and mechanical properties of (TiB+TiC)/Ti–B20 matrix composite,” Mater. Des., 87, 488–494 (2015).

C. Poletti, M. Balog, and T. Schubert, “Production of titanium matrix composites reinforced with SiC particles,” Compos. Sci. Technol., 68, 2171–2177 (2008).

S. Li, K. Kondoh, H. Imai, B. Chen, L. Jia, and J. Umeda, “Microstructure and mechanical properties of P/M titanium matrix composites reinforced by in situ synthesized TiC–TiB,” Mater. Sci. Eng. A, 628, 75–83 (2015).

M. Sumida and K. Kondoh, “In situ synthesis of Ti-matrix composite reinforced with dispersed Ti5Si3 particles via spark plasma sintering,” Mater. Trans., 46, No. 10, 2135–2141 (2005).

O.M. Ivasishin, A.N. Demidik, and D.G. Savvakin, “Use of titanium hydride for the synthesis of titanium aluminides from powder materials,” Powder Metall. Met. Ceram., 38, No. 9–10, 482–487 (1999).

G.A. Baglyuk, O.V. Suprun, and A.A. Mamonova, “Structurization in the thermal synthesis of multicomponent compounds made of TiH2–Fe–Si–Mn–C(B4C) powder mixtures,” Nauk. Not., Issue 58, 27–35 (2017).

O.M. Ivasishin, G.A. Baglyuk, O.O. Stasyuk, and D.G. Savvakin, “Structurization in the sintering of TiH2–TiB2 powder mixtures,” Fiz. Khim. Tverd. Tela, 18, No. 1, 15–20 (2017).

G.A. Baglyuk, O.M. Ivasishin, O.O. Stasyuk, and D.G. Savvakin, “The effect of charge component composition on the structure and properties of titanium matrix sintered composites with high-modulus compounds,” Powder Metall. Met. Ceram., 56, No. 1–2, 45–52 (2017).

O.M. Ivasishin, V.T. Cherepin, V.N. Kolesnik, and N.M. Gumenyak, “Automated dilatometry system,” Prib. Tekh. Eksper., No. 3, 147–151 (2010).

O.M. Ivasishin, O.B. Bondarchuk, M.M. Gumenyak, and D.G. Savvakin, “Surface phenomena in the heating of titanium hydride powder,” Fiz. Khim. Tverd. Tela, 12, No. 4, 900–907 (2011).

Z. Fan, Z.X. Guo, and B. Cantor, “The kinetics and mechanism of interfacial reaction in sigma fibre-reinforced Ti MMCs,” Compos. A: Appl. Sci. Manuf., 131–140 (1997).

N.V. Storozhuk and A.M. Gusak, “Competition of the Frenkel and Kirkendall effect in interdiffusion,” Metallofiz. Noveish. Tekhnol., 36, No. 3, 367–374 (2014).

O.V. Mikhailov and M.B. Shtern, “Allowance for a difference in resistance to extension and compression in theories of plasticity of porous bodies,” Powder Metall. Met. Ceram., 23, No. 5, 339–344 (1984).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 58, Nos. 11–12 (530), pp. 26–36, 2019.

Rights and permissions

About this article

Cite this article

Bagliuk, G.A., Stasiuk, A.A. & Savvakin, D.G. Effect of Titanium Diboride Content on Basic Mechanical Properties of Composites Sintered from TiH2 + TiB2 Powder Mixtures. Powder Metall Met Ceram 58, 642–650 (2020). https://doi.org/10.1007/s11106-020-00120-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-020-00120-1