Abstract

Secondary resources (i.e., wastes) contain a wide variety of materials (e.g., plastics, metals, and wood) of various sizes and shapes that complicate separation especially when using gravity-based separation techniques. In this study, the effects of particle geometry (i.e., size and shape) on jig separation of crushed plastics were investigated. Plastic boards with 2-mm and 3-mm thicknesses of acrylonitrile butadiene styrene (ABS, specific gravity (SG) = 1.03) and polystyrene (PS, SG = 1.06) were crushed to obtain a size fraction of + 2.0–8.0 mm. The shape distribution in each size fraction (+ 2.0–2.8, + 2.8–4.0, + 4.0–5.6, and + 5.6–8.0 mm) showed the strong effects of crushing on particle shape; that is, particles are more disk-like at coarser size fraction but becomes more sphere-like at finer size fraction. Settling velocity of sphere-like PS increased with increasing particle size while those of disk-like ABS had similar values regardless of the size, which were consistent with the results of jig separation of single-type plastics. The results of jig separation of mixed-type plastics showed that separation efficiency was higher for the mixture of light, disk-like particles (ABS) and heavy, sphere-like particles (PS).

Similar content being viewed by others

References

Laner D, Crest M, Scharff H, Morris JW, Barlaz MA (2012) A review of approaches for the long-term management of municipal solid waste landfills. Waste Manag 32(3):498–512. https://doi.org/10.1016/j.wasman.2011.11.010

Tabelin CB, Igarashi T (2009) Mechanisms of arsenic and lead release from hydrothermally altered rock. J Hazard Mater 169:980–990. https://doi.org/10.1016/j.jhazmat.2009.04.049

Tabelin CB, Hashimoto A, Igarashi T, Yoneda T (2014) Leaching of boron, arsenic and selenium from sedimentary rocks: I. Effects of contact time, mixing speed and liquid-to-solid ratio. Sci Total Environ 472:620–629. https://doi.org/10.1016/j.scitotenv.2013.11.006

Tabelin CB, Sasaki R, Igarashi T, Park I, Tamoto S, Arima T, Ito M, Hiroyoshi N (2017) Simultaneous leaching of arsenite, arsenate, selenite and selenate, and their migration in tunnel-excavated sedimentary rocks: I. Column experiments under intermittent and unsaturated flow. Chemosphere 186:558–569. https://doi.org/10.1016/j.chemosphere.2017.07.145

Tabelin CB, Sasaki R, Igarashi T, Park I, Tamoto S, Arima T, Ito M, Hiroyoshi N (2017) Simultaneous leaching of arsenite, arsenate, selenite and selenate, and their migration in tunnel-excavated sedimentary rocks: II. Kinetic and reactive transport modeling. Chemosphere 188:444–454. https://doi.org/10.1016/j.chemosphere.2017.08.088

Aseniero JPJ, Opiso EM, Banda MHT, Tabelin CB (2019) Potential utilization of artisanal gold-mine tailings as geopolymeric source material: preliminary investigation. SN Appl Sci 1:35. https://doi.org/10.1007/s42452-018-0045-4

Opiso EM, Aseneiro JPJ, Banda MHT, Tabelin CB (2018) Solid-phase partitioning of mercury in artisanal gold mine tailings from selected key areas in Mindanao, Philippines, and its implications for mercury detoxification. Waste Manag Res 36:269–276. https://doi.org/10.1177/0734242X17753534

Park I, Tabelin CB, Jeon S, Li X, Seno K, Ito M, Hiroyoshi N (2019) A review of recent strategies for acid mine drainage prevention and mine tailings recycling. Chemosphere 219:588–606. https://doi.org/10.1016/j.chemosphere.2018.11.053

Eang KE, Igarashi T, Kondo M, Nakatani T, Tabelin CB, Fujinaga R (2018) Groundwater monitoring of an open-pit limestone quarry: Water–rock interaction and mixing estimation within the rock layers by geochemical and statistical analyses. Int J Min Sci Technol 28:849–857. https://doi.org/10.1016/j.ijmst.2018.04.002

Oller I, Malato S, Sánchez-Pérez J (2011) Combination of advanced oxidation processes and biological treatments for wastewater decontamination—a review. Sci Total Environ 409:4141–4166. https://doi.org/10.1016/j.scitotenv.2010.08.061

Tabelin CB, Corpuz RD, Igarashi T, Villacorte-Tabelin M, Ito M, Hiroyoshi N (2019) Hematite-catalysed scorodite formation as a novel arsenic immobilisation strategy under ambient conditions. Chemosphere 233:946–953. https://doi.org/10.1016/j.chemosphere.2019.06.020

Tomiyama S, Igarashi T, Tabelin CB, Tangviroon P, Ii H (2019) Acid mine drainage sources and hydrogeochemistry at the Yatani mine, Yamagata, Japan: a geochemical and isotopic study. J Contam Hydrol 225:103502. https://doi.org/10.1016/j.jconhyd.2019.103502

Burdin J, Monin N (2009) The management of excavated materials from the Lyon–Turin rail link project. Geomech Tunn 2:652–662. https://doi.org/10.1002/geot.200900048

Tatsuhara T, Arima T, Igarashi T, Tabelin CB (2012) Combined neutralization–adsorption system for the disposal of hydrothermally altered excavated rock producing acidic leachate with hazardous elements. Eng Geol 139:76–84. https://doi.org/10.1016/j.enggeo.2012.04.006

Tamoto S, Tabelin CB, Igarashi T, Ito M, Hiroyoshi N (2015) Short and long term release mechanisms of arsenic, selenium and boron from a tunnel-excavated sedimentary rock under in situ conditions. J Contam Hydrol 175:60–71. https://doi.org/10.1016/j.jconhyd.2015.01.003

Tabelin CB, Igarashi T, Villacorte-Tabelin M, Park I, Opiso EM, Ito M, Hiroyoshi N (2018) Arsenic, selenium, boron, lead, cadmium, copper, and zinc in naturally contaminated rocks: a review of their sources, modes of enrichment, mechanisms of release, and mitigation strategies. Sci Total Environ 645:1522–1553. https://doi.org/10.1016/j.scitotenv.2018.07.103

United Nations Department of Public Information (2019) Sustainable development goals. https://sustainabledevelopment.un.org/?menu=1300. Accessed 23 February 2019

Phengsaart T, Ito M, Hamaya N, Tabelin CB, Hiroyoshi N (2018) Improvement of jig efficiency by shape separation, and a novel method to estimate the separation efficiency of metal wires in crushed electronic wastes using bending behavior and “entanglement factor”. Miner Eng 129:54–62. https://doi.org/10.1016/j.mineng.2018.09.015

Jeon S, Tabelin CB, Takahashi H, Park I, Ito M, Hiroyoshi N (2020) Enhanced cementation of gold via galvanic interactions using activated carbon and zero-valent aluminum: a novel approach to recover gold ions from ammonium thiosulfate medium. Hydrometallurgy 191:105165. https://doi.org/10.1016/j.hydromet.2019.105165

Jeon S, Tabelin CB, Park I, Nagata Y, Ito M, Hiroyoshi N (2020) Ammonium thiosulfate extraction of gold from printed circuit boards (PCBs) of end-of-life mobile phones and its recovery from pregnant leach solution by cementation. Hydrometallurgy 191:105214. https://doi.org/10.1016/j.hydromet.2019.105214

Ongondo FO, Williams ID, Cherrett TJ (2011) How are WEEE doing? A global review of the management of electrical and electronic wastes. Waste Manag 31(4):714–730. https://doi.org/10.1016/j.wasman.2010.10.023

PlasticsEurope (2015) Plastics—the Facts 2014/2015. An Analysis of European Plastics Production, Demand and Waste Data. https://www.plasticseurope.org/application/files/5515/1689/9220/2014plastics_the_facts_PubFeb2015.pdf. Accessed 20 June 2018

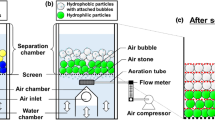

Ito M, Takeuchi M, Saito A, Murase N, Phengsaart T, Tabelin CB, Hiroyoshi N, Tsunekawa M (2019) Improvement of hybrid jig separation efficiency using wetting agents for the recycling of mixed-plastic wastes. J Mater Cycles Waste Manag 21:1376–1383. https://doi.org/10.1007/s10163-019-00890-w

Kuwayama Y, Ito M, Hiroyoshi N, Tsunekawa M (2011) Jig separation of crushed automobile shredded residue and its evaluation by float and sink analysis. J Mater Cycles Waste Manag 13:240–246. https://doi.org/10.1007/s10163-011-0008-y

Ito M, Saito A, Murase N, Phengsaart T, Kimura S, Tabelin CB, Hiroyoshi N (2019) Development of suitable product recovery systems of continuous hybrid jig for plastic-plastic separation. Miner Eng 141:105839. https://doi.org/10.1016/j.mineng.2019.105839

Truc NTT, Lee B (2017) Combining ZnO/microwave treatment for changing wettability of WEEE styrene plastics (ABS and HIPS) and their selective separation by froth flotation. Appl Surf Sci 420:746–752. https://doi.org/10.1016/j.apsusc.2017.04.075

Guo C, Zou Q, Wang J, Wanga H, Chen S, Zhong Y (2018) Application of surface modification using sodium hypochlorite for helping flotation separation of acrylonitrile-butadiene-styrene and polystyrene plastics of WEEE. Waste Manag 82:167–176. https://doi.org/10.1016/j.wasman.2018.10.031

Hori K, Tsunekawa M, Hiroyoshi N, Ito M (2009) Optimum water pulsation of jig separation for crushed plastic particles. Int J Miner Process 92:103–108. https://doi.org/10.1016/j.minpro.2009.01.001

Pongstabodee S, Kunachitpimol B, Damronglerd S (2008) Combination of three-stage sink-float method and selective flotation technique for separation of mixed post-consumer plastic waste. Waste Manag 28:475–483. https://doi.org/10.1016/j.wasman.2007.03.005

Barton AFM (1979) Resources recovery and recycling. Wiley, New York

Tsunekawa M, Naoi B, Ogawa S, Hori K, Hiroyoshi N, Ito M, Hirajima T (2005) Jig separation of plastics from scrapped copy machines. Int J Miner Process 76:67–74. https://doi.org/10.1016/j.minpro.2004.12.001

Pita F, Castilho A (2016) Influence of shape and size of the particles on jigging separation of plastics mixture. Waste Manag 48:89–94. https://doi.org/10.1016/j.wasman.2015.10.034

Richard GM, Mario M, Javier T, Susana T (2011) Optimization of the recovery of plastics for recycling by density media separation cyclones. Resour Conserv Recycl 55:472–482. https://doi.org/10.1016/j.resconrec.2010.12.010

Zhao P, Xie J, Gua F, Sharmin N, Hall P, Fu J (2018) Separation of mixed waste plastics via magnetic levitation. Waste Manag 76:46–54. https://doi.org/10.1016/j.wasman.2018.02.051

Zhang X, Gua F, Xie J, Zhang C, Fu J, Zhao P (2019) Magnetic projection: a novel separation method and its first application on separating mixed plastics. Waste Manag 87:805–813. https://doi.org/10.1016/j.wasman.2019.03.008

Dodbiba G, Shibayama A, Miyazaki T, Fujita T (2003) Triboelectrostatic separation of ABS, PS and PP plastic mixture. Mater Trans 44(1):161–166. https://doi.org/10.2320/matertrans.44.161

Dodbiba G, Shibayama A, Miyazaki T, Fujita T (2003) Electrostatic separation of the shredded plastic mixtures using a tribo-cyclone. Magn Electr Sep 11(1–2):63–92. https://doi.org/10.1080/07313630290002626

Zhang H, Chen M (2017) Triboelectrostatic separation for PP and ABS plastics in end of life passenger vehicles. J Mater Cycles Waste Manag 19:884–897. https://doi.org/10.1007/s10163-016-0490-3

Saisinchai S (2013) Separation of PVC from PET/PVC mixtures using flotation by calcium lignosulfonate depressant. Eng J 18:45–54. https://doi.org/10.4186/ej.2014.18.1.45

Wang C, Wang H, Wu B, Liu Q (2014) Boiling treatment of ABS and PS plastics for flotation separation. Waste Manag 34:1206–1210. https://doi.org/10.1016/j.wasman.2014.02.005

Truc NTT, Le HA, Nguyen DT, Pham T (2019) Novel method for sustainable and selective separation of PVC and PET by the homogeneous dissociation of H2O2 using ultrasonication. J Mater Cycles Waste Manag 21:1085–1094. https://doi.org/10.1007/s10163-019-00861-1

Wang C, Wang H, Liu Y (2015) Separation of polyethylene terephthalate from municipal waste plastics by froth flotation for recycling industry. Waste Manag 35:42–47. https://doi.org/10.1016/j.wasman.2014.09.025

Censori M, Marca FL, Carvalho MT (2016) Separation of plastics: the importance of kinetics knowledge in the evaluation of froth flotation. Waste Manag 54:39–43. https://doi.org/10.1016/j.wasman.2016.05.021

Mallampati SR, Lee C, Park MH, Lee BK (2018) Processing plastics from ASR/ESR waste: separation of poly vinyl chloride (PVC) by froth flotation after microwave-assisted surface modification. J Mater Cycles Waste Manag 20:91–99. https://doi.org/10.1007/s10163-016-0546-4

Wang C, Wang H, Huang L, Wang C (2017) Surface treatment with Fenton for separation of acrylonitrile-butadiene styrene and polyvinylchloride waste plastics by flotation. Waste Manag 67:20–26. https://doi.org/10.1016/j.wasman.2017.05.009

Wills BA, Napier-Munn TJ (2006) Mineral processing technology, 7th edn. Pergamon press, Oxford

Beunder EM (2000) Influence of shape on particle behaviour in recycling techniques. Dissertation, Delft University of Technology

Jeon S, Ito M, Tabelin CB, Pongsumrankul R, Kitajima N, Hiroyoshi N (2018) Gold recovery from shredder light fraction of E-waste recycling plant by flotation-ammonium thiosulfate leaching. Waste Manag 77:195–202. https://doi.org/10.1016/j.wasman.2018.04.039

Jeon S, Tabelin CB, Takahashi H, Park I, Ito M, Hiroyoshi N (2018) Interference of coexisting copper and aluminum on the ammonium thiosulfate leaching of gold from printed circuit boards of waste mobile phones. Waste Manag 81:148–156. https://doi.org/10.1016/j.wasman.2018.09.041

Jeon S, Ito M, Tabelin C, Pongsumrankul R, Tanaka S, Kitajima N, Saito A, Park I, Hiroyoshi N (2019) A physical separation scheme to improve ammonium thiosulfate leaching of gold by separation of base metals in crushed mobile phones. Miner Eng 138:168–177. https://doi.org/10.1016/j.mineng.2019.04.025

Brozek M, Surowiak A (2007) Effect of particle shape on jig separation efficiency. Physicochem Probl Miner 41:397–413

Woollacott LC, Silwamba M (2016) An experimental study of size segregation in a batch jig. Miner Eng 94:41–50. https://doi.org/10.1016/j.mineng.2016.04.003

Wadell H (1932) Volume, shape, and roundness of rock particles. J Geol 40:443–451

Mora CF, Kwan AKH (2000) Sphericity, shape factor, and convexity measurement of coarse aggregate for concrete using digital image processing. Cem Concr Res 30:351–358. https://doi.org/10.1016/S0008-8846(99)00259-8

Zingg T (1935) Bietrahe zur Schotteranalyse. Schweiz Miner Petrog 15:139–140

Arasan S, Akbulut S, Hasiloglu AS (2011) Effect of particle size and shape on the grain-size distribution using Image analysis. Int J Civil Struct Eng 1:968–985. https://doi.org/10.6088/ijcser.00202010083

Concha F (2013) Solid–liquid separation in the mining industry. Springer International Publishing, Switzerland

Gabitto J, Tsouris C (2008) Drag coefficient and settling velocity for particles of cylindrical shape. Powder Technol 183:314–322. https://doi.org/10.1016/j.powtec.2007.07.031

Ito M, Tsunekawa M, Ishida E, Kawai K, Takahashi T, Abe N, Hiroyoshi N (2010) Reverse jig separation of shredded floating plastic—separation of polypropylene and high density polyethylene. Int J Miner Process 97:96–99. https://doi.org/10.1016/j.minpro.2010.08.007

Dharmarajah AH (1982) Effect of particle shape on prediction of velocity voidage relationship in fluidized solid–liquid systems. Dissertation, Iowa State University

Masuda H, Higashitani K, Yoshida H (2006) Powder technology handbook, 3rd edn. Taylor & Francis Group, Florida

Yang WC (2013) Handbook of fluidization and fluid-particle systems. Marcel Dekker Inc, New York

Beunder EM, Rem PC (1999) Screening kinetics of cylindrical particles. Int J Miner Process 57:73–81. https://doi.org/10.1016/S0301-7516(99)00007-1

Acknowledgements

The authors wish to thank the editor and the anonymous reviewers for their valuable inputs to this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Phengsaart, T., Ito, M., Azuma, A. et al. Jig separation of crushed plastics: the effects of particle geometry on separation efficiency. J Mater Cycles Waste Manag 22, 787–800 (2020). https://doi.org/10.1007/s10163-019-00967-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-019-00967-6