Abstract

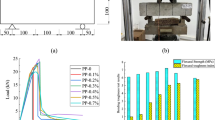

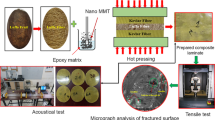

Transverse bending damage morphologies of carbon fiber composite tubes with different ply structures were investigated by the micro-XCT characterization. Structural effects of the plain, twill and winding on the damage mechanism were analyzed. The experimental results present fiber-resin cracking, interlayer delamination and fiber tows breakage with structural deformation from the peak load to final catastrophic failure. Woven fabric plies in the plain and twill composite tubes cannot be effectively slipped because of their tight interlaced structures, which makes the load propagate along the warp and weft fiber tows, resulting in more fiber tows breakage under bending-induced stretching. There is no interlaced effect on the failure mechanism for the winding tubes, resulting in a fact that the bending load can only be transferred from the fiber-resin or the layer-to-layer interface, with more interlaminar slippage and obvious springback behaviors under in-plane shear. For investigating the interlaced effect on failure mechanism, plain and winding models under transverse bending were established using continuous shell elements, and different constitutive description were used to simulate interlayer failure and intra-layer failure behaviors. By comparing the numerical results with the experimental ones, the influence of the fabric structure on the failure behavior of the tube were analyzed.

Similar content being viewed by others

References

B. G. Falzon and P. Apruzzese, Compos. Struct., 93, 1039 (2011).

B. G. Falzon and P. Apruzzese, Compos. Struct., 93, 1047 (2011).

W. Tan, B. G. Falzon, and M. Price, Int. J. Crashworthines, 20, 60 (2015).

G. Zhu, G. Sun, Q. Liu, G. Li, and Q. Li, Compos. Struct., 175, 58 (2017).

S. Boria, A. Scattina, and G. Belingardi, Compos. Struct., 130, 18 (2015).

J. S. Kim, H. J. Yoon, and K. B. Shin, Int. J. Impact. Eng., 38, 198 (2011).

L. Grauers, R. Olsson, and R. Gutkin, Compos. Struct., 110, 110 (2014).

P. H. Thornton and C. L. Magee, J. Eng. Mater.-T. Asme., 99, 114 (1977).

C. Priem, R. Othman, P. Rozycki, and D. Guillon, Compos. Struct., 116, 814 (2014).

A. G. Mamalis, D. E. Manolakos, M. B. Ioannidis, and D. P. Papapostolou, Compos. Struct., 63, 347 (2004).

R. Kalhor and S. W. Case, Compos. Struct., 130, 44 (2015).

E. V. Morozov, Compos. Struct., 76, 123 (2006).

P. Mertiny, F. Ellyin, and A. Hothan, Compos. Sci. Technol., 64, 1 (2004).

M. Y. Huang, Y. S. Tai, and H. T. Hu, Appl. Compos. Mater., 19, 1 (2012).

K. C. Shin, J. J. Lee, K. H. Kim, M. C. Song, and J. S. Huh, Compos. Struct., 57, 279 (2002).

R. A. Eshkoor, S. A. Oshkovr, A. B. Sulong, R. Zulkifli, A. K. Ariffin, and C. H. Azhari, Compos. Part B-Eng., 55, 5 (2013).

G. Sun, S. Li, G. Li, and Q. Li, Compos. Part B-Eng., 145, 47 (2018).

R. Sharma, V. V. Deshpande, A. R. Bhagat, P. Mahajan, and R. K. Mittal, Carbon, 60, 335 (2013).

P. J. Schilling, B. P. R. Karedla, A. K. Tatiparthi, M. A. Verges, and P. D. Herrington, Compos. Sci. Technol., 65, 2071 (2005).

G. A. Schoeppner and S. Abrate, Compos. Part A-Appl. Sci. Manuf., 31, 903 (2000).

D. J. Bull, L. Helfen, I. Sinclair, S. M. Spearing, and T. Baumbach, Compos. Sci. Technol., 75, 55 (2013).

O. Dorival, P. Navarro, S. Marguet, C. Petiot, M. Bermudez, D. Mesnagé, and J. F. Ferrero, Compos. Part B-Eng, 78, 244 (2015).

C. H. Chiu, K. H. Tsai, and W. J. Huang, J. Compos. Mater., 32, 1964 (1998).

R. Seltzer, C. González, R. Muñoz, J. Llorca, and T. Blanco-Varela, Compos. Part A-Appl. Sci. Manuf., 45, 49 (2013).

K. T. Tan, N. Watanabe, and Y. Iwahori, Compos. Part B-Eng., 42, 874 (2011).

D. Li, Z. Lu, J. Li, and L. Chen, J. Aeron. Mater., 29, 82 (2009).

B. Sun, R. Liu, and B. Gu, Compos. Mater. Sci., 65, 239 (2012).

L. Jin, Z. Niu, B. C. Jin, B. Sun, and B. Gu, J. Reinf. Plast. Comp., 31, 935 (2012).

S. Ekşi and K. Genel, Acta Phys. Pol. A, 128, B-59 (2015).

A. Niknejad, A. Moradi, and N. Beheshti, Mater. Lett., 179, 142 (2016).

I. B. Badriev, M. V. Makarov, and V. N. Paimushin, Procedia Eng., 150, 1056 (2016).

M. S. Lee, H. Y. Seo, and C. G. Kang, Int. J. Pr. Eng. Man-GT, 3, 359 (2016).

W. Yuan and Y. Hu, J. Fiber Reinf. Plast/Compos., 2, 64 (2017).

Y. Ma, H. Wang, Z. Shao, Z. Yang, F. Shang, D. Hou, H. Geng, and G. Lv, J. Deep Space Exploration, 4, 346 (2017).

H. Ding, Master’s Thesis, Zhejiang Sci-Tech University, 1, 31 (2017).

Z. Yang, H. Wang, X. Ma, F. Shang, Y. Ma, Z. Shao, and D. Hou, Compos. Struct., 193, 154 (2018).

H. Zhou, C. Li, L. Zhang, B. Crawford, A. S. Milani, and F. K. Ko, Compos. Sci. Technol., 155, 91 (2018).

M. R. Bambach, Compos. Part B-Eng., 41, 550 (2010).

R. A. Eshkoor, A. U. Ude, A. B. Sulong, R. Zulkifli, A. K. Ariffin, and C. H. Azhari, Compos. Part B-Eng., 77, 10 (2015).

M. A. Sofuoğlu, S. Gürgen, F. H. Çakır, and S. Orak, Procedia Engineering, 182, 658 (2017).

X. F. Hu, A. Haris, M. Ridha, V. B. C. Tan, and T. E. Tay, Compos. Struct., 189, 443 (2018).

Dassault Systèmes®, Abaqus 6.14 Documentation: Abaqus Analysis User’s Guide, 2, 11 (2014).

Y. Lin, Y. Huang, T. Huang, B. Liao, D. Zhang, and C. Li, Thin Wall Struct., 135, 494 (2019).

A. Riccio, A. Sellitto, S. Saputo, A. Russo, M. Zarrelli, and V. Lopresto, Compos. Part B-Eng., 126, 60 (2017).

A. Riccio, A. Raimondo, F. Di Caprio, M. Fusco, and P. Sanità, Compos. Part B-Eng., 150, 93 (2018).

D. Cao, Q. Duan, H. Hu, Y. Zhong, and S. Li, Compos. Struct., 192, 300 (2018).

E. J. Pineda and A. M. Waas, Int. J. Fracture, 182, 93 (2013).

A. F. Johnson, Compos. Part A-Appl. Sci. Manuf., 32, 1197 (2001).

F. K. Chang and G. S. Spring, J. Compos. Mater., 20, 30 (1986).

M. L. Benzeggagh and M. Kenane, Compos. Sci. Technol., 56, 439 (1996).

M. Schwab, M. Todt, M. Wolfahrt, and H. E. Pettermann, Compos. Sci. Technol., 128, 131 (2016).

G. Wimmer and H. E. Pettermann, J. Compos. Mater., 43, 3303 (2009).

J. Tao and C. T. Sun, J. Compos. Mater., 32, 1933 (1998).

Acknowledgement

The authors gratefully acknowledge the great support from the National Natural Science Foundation of China (11702249), and Zhejiang Provincial Natural Science Foundation of China (LGG19E050028).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pan, Z., Ma, H., Wu, Z. et al. Micro-XCT Characterization and Numerical Analysis of Bending Damage Mechanism in Carbon Fiber Plain, Twill and Winding Composite Tubes. Fibers Polym 21, 874–897 (2020). https://doi.org/10.1007/s12221-020-9274-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-020-9274-4