Abstract

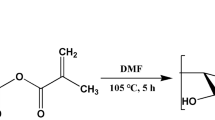

The structure and properties of functional nanoparticles are important for stabilizing Pickering emulsion polymerization. Recently, cellulose nanocrystals (CNCs) are increasingly favored as a bio-based stabilizer for Pickering emulsions. In this study, we reported a novel functionalized polyphosphoester-grafted CNCs for the stabilization of oil-in-water Pickering emulsions and the emulsion polymerization of styrene. First, polyphosphoester containing an amino group at one end of the chain, abbreviated as PBYP-NH2, was prepared by ring-opening polymerization (ROP) and hydrolysis reaction, wherein PBYP represents poly[2-(but-3-yn-1-yloxy)-2-oxo-1,3,2-dioxaphospholane]. Subsequently, CNC-COOH was obtained via 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO) oxidation of CNCs. The functionalized nanocrystals CNC-PBYP-COOH with carboxyl groups and polyphosphoester on the surface were obtained by the amidation reaction of PBYP-NH2 with CNC-COOH. Finally, we used CNC-PBYP-COOH as sole particle emulsifiers to stabilize styrene-in-water Pickering emulsions and studied its effects on the emulsions in details by using dynamic light scattering (DLS). The results indicated that the properties of these emulsions depended on the concentration of hydrophobically modified CNCs, volume ratios of oil to water, and pH values. The modified CNCs had higher ability to stabilize the styrene-in-water emulsions relative to the unmodified CNCs, and a stable oil-in-water (o/w) Pickering emulsion with diameter of hundreds of nanometers could be obtained. The resulting emulsions could be polymerized to yield nanosized latexes. The polyphosphoester-modified CNCs as green particle emulsifiers can efficiently stabilize nanoemulsions and latexes, which would promote the development of novel environmentally friendly materials.

Similar content being viewed by others

References

Ramsden, W. Separation of solids in the surface-layers of solutions and ‘suspensions’ (observations on surface-membranes, bubbles, emulsions, and mechanical coagulation). Preliminary Account. Proc. R. Soc. London1903, 72, 156–164.

Pickering, S. U. CXCVI Emulsions. J. Chem. Soc., Trans.1907, 91, 2001–2021.

Chevalier, Y.; Bolzinger, M. A. Emulsions stabilized with solid nanoparticles: pickering emulsions. Colloids Surf. A: Physicochem. Eng. Aspects.2013, 439, 23–34.

Aveyard, R.; Binks, B. P.; Clint, J. H. Emulsions stabilised solely by colloidal particles. Adv. Colloid Interface Sci.. 2003, 100–102, 503–546.

Zou, Z. M.; Sun, Z. Y.; An, L. J. Studies on droplet size distributions during coalescence in immiscible polymer blends filled with silica nanoparticles. Chinese J. Polym. Sci.2014, 32, 255–267.

Binks, B. P. Particles as surfactants-similarities and differences. Curr. Opin. Colloid Interface Sci.2002, 7, 21–41.

Arditty, S.; Schmitt, V.; Giermanska-Kahn, J.; Leal-Calderon, F. Materials based on solid-stabilized emulsions. J. Colloid Interface Sci.2004, 275, 659–664.

Pang, K.; Ding, B. B.; Liu, X. T.; Wu, H.; Duan, Y. X.; Zhang, J. M. High-yield preparation of a zwitterionically charged chitin nanofiber and its application in a doubly pH-responsive Pickering emulsion. Green Chem.2017, 19, 3665–3670.

Yang, F.; Liu, S. Y.; Xu, J.; Lan, Q.; Wei, F.; Sun, D. J. Pickering emulsions stabilized solely by layered double hydroxides particles: the effect of salt on emulsion formation and stability. J. Colloid Interface Sci.2006, 302, 159–169.

Tang, J. T.; Quinlan, P. J.; Tam, K. C. Stimuli-responsive Pickering emulsions: recent advances and potential applications. Soft Matter.2015, 11, 3512–3529.

Björkegren, S.; Nordstierna, L.; Törncrona, A.; Palmqvist, A. Hydrophilic and hydrophobic modifications of colloidal silica particles for Pickering emulsions. J. Colloid Interface Sci.2017, 487, 250–257.

Kim, J.; Cote, L. J.; Kim, F.; Yuan, W.; Shull, K. R.; Huang, J. X. Graphene oxide sheets at interfaces. J. Am. Chem. Soc.2010, 132, 8180–8186.

Cui, Z. G.; Cui, C. F.; Zhu, Y.; Binks, B. P. Multiple phase inversion of emulsions stabilized by in situ.surface activation of CaCO3 nanoparticles via.adsorption of fatty acids. Langmuir2012, 28, 314–320.

Voorn, D. J.; Ming, W.; van Herk, A. M. Polymer-clay nanocomposite latex particles by inverse Pickering emulsion polymerization stabilized with hydrophobic montmorillonite platelets. Macromolecules2006, 39, 2137–2143.

Wei, D.; Ge, L. L.; Lu, S. H.; Li, J. J.; Guo, R. Janus particles templated by Janus emulsions and application as a Pickering emulsifier. Langmuir2017, 33, 5819–5828.

Wei, W.; Wang, T.; Luo, J.; Zhu, Y.; Gu, Y.; Liu, X. Y. Pickering emulsions stabilized by self-assembled colloidal particles of amphiphilic branched random poly(styrene-co-acrylic acid). Colloids Surf. A: Physicochem. Eng. Aspects2015, 487, 58–65.

Li, C.; Sun, P. D.; Yang, C. Emulsion stabilized by starch nanocrystals. Starch2012, 64, 497–502.

Kalashnikova, I.; Bizot, H.; Cathala, B.; Capron, I. New Pickering emulsions stabilized by bacterial cellulose nanocrystals. Langmuir2011, 27, 7471–7479.

Fratzl, P.; Weinkamer, R. Nature’s hierarchical materials. Prog. Mater. Sci.2007, 52, 1263–1334.

Tang, J. T.; Sisler, J.; Grishkewich, N.; Tam, K. C. Functionalization of cellulose nanocrystals for advanced applications. J. Colloid Interface Sci.2017, 494, 397–409.

Gómez H, C.; Serpa, A.; Velásquez-Cock, J.; Gañán, P.; Castro, C.; Vélez, L.; Zuluaga, R. Vegetable nanocellulose in food science: a review. Food Hydrocolloids2016, 57, 178–186.

Moon, R. J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: structure, properties and nanocomposites. Chem. Soc. Rev.2011, 40, 3941–3994.

Mazeau, K.; Heux, L. Molecular dynamics simulations of bulk native crystalline and amorphous structures of cellulose. J. Phys. Chem. B2003, 107, 2394–2403.

Oza, K. P.; Frank, S. G. Microcrystalline cellulose stabilized emulsions. J. Dispersion Sci. Technol.1986, 7, 543–561.

Li, X.; Ding, L.; Zhang, Y. C.; Wang, B. J.; Jiang, Y.; Feng, X. L.; Mao, Z. P.; Sui, X. F. Oil-in-water Pickering emulsions from three plant-derived regenerated celluloses. Carbohydr. Polym.2019, 207, 755–763.

Saelices, C. J.; Save, M.; Capron, I. Synthesis of latex stabilized by unmodified cellulose nanocrystals: the effect of monomers on particle size. Polym. Chem.2019, 10, 727–737.

Saelices, C. J.; Capron, I. Design of Pickering micro- and nanoemulsions based on the structural characteristics of nanocelluloses. Biomacromolecules2018, 19, 460–469.

Xu, H. N.; Li, Y. H.; Zhang, L. F. Driving forces for accumulation of cellulose nanofibrils at the oil/water interface. Langmuir2018, 34, 10757–10763.

Bai, L.; Huan, S. Q.; Xiang, W. C.; Rojas, O. J. Pickering emulsions by combining cellulose nanofibrils and nanocrystals: phase behavior and depletion stabilization. Green Chem.2018, 20, 1571–1582.

Lee, K. Y.; Blaker, J. J.; Murakami, R.; Heng, J. Y. Y.; Bismarck, A. Phase behavior of medium and high internal phase water-in-oil emulsions stabilized solely by hydrophobized bacterial cellulose nanofibrils. Langmuir2014, 30, 452–460.

Cunha, A. G.; Mougel, J. B.; Cathala, B.; Berglund, L. A.; Capron, I. Preparation of double Pickering emulsions stabilized by chemically tailored nanocelluloses. Langmuir2014, 30, 9327–9335.

Kalashnikova, I.; Bizot, H.; Bertoncini, P.; Cathala, B.; Capron, I. Cellulosic nanorods of various aspect ratios for oil in water Pickering emulsions. Soft Matter2013, 9, 952–959.

Zhang, Y. F.; Karimkhani, V.; Makowski, B. T.; Samaranayake, G.; Rowan, S. J. Nanoemulsions and nanolatexes stabilized by hydrophobically functionalized cellulose nanocrystals. Macromolecules2017, 50, 6032–6042.

Habibi, Y.; Lucia, L. A.; Rojas, O. J. Cellulose nanocrystals: chemistry, self-assembly, and applications. Chem. Rev.2010, 110, 3479–3500.

Kalashnikova, I.; Bizot, H.; Cathala, B.; Capron, I. Modulation of cellulose nanocrystals amphiphilic properties to stabilize oil/water interface. Biomacromolecules2012, 13, 267–275.

Capron, I.; Cathala, B. Surfactant-free high internal phase emulsions stabilized by cellulose nanocrystals. Biomacromolecules2013, 14, 291–296.

Peddireddy, K. R.; Nicolai, T.; Benyahia, L.; Capron, I. Stabilization of water-in-water emulsions by nanorods. ACS Macro Lett. 2016, 5. 283–286.

Cherhal, F.; Cousin, F.; Capron, I. Structural description of the interface of Pickering emulsions stabilized by cellulose nanocrystals. Biomacromolecules2016, 17, 496–502.

Hu, Z.; Ballinger, S.; Pelton, R.; Cranston, E. D. Surfactant-enhanced cellulose nanocrystal Pickering emulsions. J. Colloid Interface Sci.2015, 439, 139–148.

Saidane, D.; Perrin, E.; Cherhal, F.; Guellec, F.; Capron, I. Some modification of cellulose nanocrystals for functional Pickering emulsions. Philos. Trans. R. Soc., A.2016, 374. 20150139.

Zoppe, J. O.; Venditti, R. A.; Rojas, O. J. Pickering emulsions stabilized by cellulose nanocrystals grafted with thermo-responsive polymer brushes. J. Colloid Interface Sci.2012, 369, 202–209.

Tang, J. T.; Lee, M. F. X.; Zhang, W.; Zhao, B. X.; Berry, R. M.; Tam, K. C. Dual responsive pickering emulsion stabilized by poly[2-(dimethylamino)ethyl methacrylate] grafted cellulose nanocrystals. Biomacromolecules2014, 15, 3052–3060.

Gupta, A.; Eral, H. B.; Hatton, T. A.; Doyle, P. S. Nanoemulsions: formation, properties and applications. Soft Matter2016, 12, 2826–2841.

Fryd, M. M.; Mason, T. G. Advanced nanoemulsions. Annu. Rev. Phys. Chem.2012, 63, 493–518.

Arancibia, C.; Navarro-Lisboa, R.; Zúñiga, R. N.; Matiacevich, S. Application of CMC as thickener on nanoemulsions based on olive oil: physical properties and stability. Int. J. Polym. Sci.2016, 2016, 1–10.

Singh, Y.; Meher, J. G.; Raval, K.; Khan, F. A.; Chaurasia, M.; Jain, N. K.; Chourasia, M. K. Nanoemulsion: concepts, development and applications in drug delivery. J. Control. Release. 2017, 252, 28–49.

Sonneville-Aubrun, O.; Simonnet, J. T.; L’Alloret, F. Nanoemulsions: a new vehicle for skincare products. Adv. Colloid Interface Sci.. 2004, 108–109. 145–149.

Bauer, K. N.; Tee, H. T.; Velencoso, M. M.; Wurm, F. R. Main-chain poly(phosphoester)s: history, syntheses, degradation, bio-and flame-retardant applications. Prog. Polym. Sci.2017, 73, 61–122.

Wang, H. R.; He, J. L.; Zhang, M. Z.; Tam, K. C.; Ni, P. H. A new pathway towards polymer modified cellulose nanocrystals via.a “grafting onto” process for drug delivery. Polym. Chem.. 2015, 6, 4206–4209.

Zhang, S. Y.; Li, A.; Zou, J.; Lin, L. Y.; Wooley, K. L. Facile synthesis of clickable, water-soluble and degradable polyphosphoesters. ACS Macro Lett. 2012, 1, 328–333.

Habibi, Y.; Chanzy, H.; Vignon, M. R. TEMPO-mediated surface oxidation of cellulose whiskers. Cellulose. 2006, 13, 679–687.

Way, A. E.; Hsu, L.; Shanmuganathan, K.; Weder, C.; Rowan, S. J. pH-responsive cellulose nanocrystal gels and nanocomposites. ACS Macro Lett.. 2012, 1, 1001–1006.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Nos. 21975169 and 21374066), the Major Program of the Natural Science Project of Jiangsu Higher Education Institutions (No. 15KJA150007), the Natural Science Foundation of Jiangsu Province (No. BK20171212), a Project Funded by the Priority Academic Program Development (PAPD) of Jiangsu Higher Education Institutions, and Soochow-Waterloo University Joint Project for Nanotechnology from Suzhou Industrial Park.

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Information

Rights and permissions

About this article

Cite this article

Che, KM., Zhang, MZ., He, JL. et al. Polyphosphoester-modified Cellulose Nanocrystals for Stabilizing Pickering Emulsion Polymerization of Styrene. Chin J Polym Sci 38, 921–931 (2020). https://doi.org/10.1007/s10118-020-2404-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-020-2404-z