Abstract

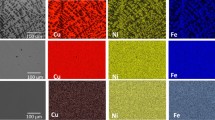

Cu-Ni-Fe-coated and bare aluminum bronze materials are evaluated as O2-evolving anodes for Al production in low-temperature (700 °C) potassium-based cryolite. The Cu-Ni-Fe coating (~ 0.8 mm thick) is obtained by cold spraying of mechanically alloyed Cu65Ni20Fe15 (wt.%) powder and presents a biphase Cu-rich/Ni-Fe-rich structure. The composition and morphology of the scale formed on both anodes are characterized after different electrolysis times (3 to 50 h). In both cases, the formed surface oxide is porous with significant electrolyte infiltration. However, for the Cu-Ni-Fe-coated anode, there is formation of an inner NiFe2O4-rich layer limiting the outward Cu diffusion at the anode surface. As a result after 50 h of electrolysis, a lower anode wear rate (0.37 versus 3.8 cm year−1) and a higher produced Al purity (98.8 versus 95.4 wt.%) are observed with the Cu-Ni-Fe-coated anode compared to the uncoated aluminum bronze anode.

Similar content being viewed by others

References

The Aluminum Association, Inert Anode Roadmap: A Framework for Technology Development, The Aluminum Association, Washington, DC, 1998

I. Galasiu, R. Galasiu, and J. Thonstad, Inert Anodes for Aluminium Electrolysis, 1st ed., GmbH Aluminium-Verlag Marketing & Komuunikation, Düsseldorf, 2007

R.P. Pawlek, Inert Anodes: An Update, Light Metals, J. Grandfield, Ed., Springer, Cham, 2014, p 1309-1313

S.K. Padamata, A.S. Yasinskiy, and P.V. Polyakov, Progress of Inert Anodes in Aluminium Industry: Review, J. Sib. Fed. Univ. Chem., 2018, 1(11), p 18-30

T.R. Beck and R.J. Brooks, Electrolytic Reduction of Alumina, Electrochemical Technology Corp. & Brooks Rand Ltd., Seattle, 1991

J. Yang, D.G. Graczyk, C. Wunsch, and J.N. Hryn, Alumina Solubility in KF–AlF3-Based Low-Temperature Electrolyte System, Light Metals, M. Sorlie, Ed., Springer, Cham, 2007, p 537-541

L. Cassayre, P. Palau, P. Chamelot, and L. Massot, Properties of Low-Temperature Melting Electrolytes for the Aluminum Electrolysis Process: A Review, J. Chem. Eng. Data, 2010, 55, p 4549-4560

E. Kubinakova, V. Danielik, and J. Híves, Electrical Conductivity of Low-Temperature Potassium Cryolite Electrolytes Suitable for Innovation of Aluminum Preparation, J. Electrochem. Soc., 2018, 165(7), p E274-E278

J. Hryn, O. Tkacheva, and J. Spangenberger, Initial 1000A Aluminum Electrolysis Testing in Potassium Cryolite-Based Electrolyte, Light Metals, B.A. Sadler, Ed., Springer, Cham, 2013, p 1289-1294

J. Hryn, O. Tkacheva, and J. Spangenberger, Ultra-High-Efficiency Aluminum Production Cell, Argonne National Lab, Lemont, 2014

J. Yang, J.N. Hryn, and G.K. Krumdick, Aluminum Electrolysis Tests with Inert Anodes in KF–AlF3-Based Electrolytes, Light Metals, T.T. Galloway, Ed., Springer, Cham, 2006, p 421-424

A. Redkin, A. Apisarov, A. Dedyukhin, V. Kovrov, Y. Zaikov, O. Tkachev, and J. Hryn, Recent Developments in Low-Temperature Electrolysis of Aluminum, ECS Trans., 2013, 50(11), p 205-213

J. Yang, J.N. Hryn, B.R. Davis, A. Roy, G.K. Krumdick, and J.A. Pomykala, Jr., New Opportunities for Aluminum Electrolysis with Metal Anodes in a Low Temperature Electrolyte System, Light Metals, A.T. Tabereaux, Ed., Springer, Cham, 2004, p 321-326

S. Helle, B. Davis, D. Guay, and L. Roué, Electrolytic Production of Aluminum Using Mechanically Alloyed Cu–Al–Ni–Fe-Based Materials as Inert Anodes, J. Electrochem. Soc., 2010, 157(11), p E173-E179

S. Helle, M. Pedron, B. Assouli, B. Davis, D. Guay, and L. Roué, Structure and High-Temperature Oxidation Behaviour of Cu–Ni–Fe Alloys Prepared by High-Energy Ball Milling for Application as Inert Anodes in Aluminium Electrolysis, Corr. Sci., 2010, 52, p 3348-3355

S. Helle, B. Brodu, B. Davis, D. Guay, and L. Roué, Influence of the Iron Content in Cu–Ni Based Inert Anodes on Their Corrosion Resistance for Aluminium Electrolysis, Corr. Sci., 2011, 53, p 3248-3253

E. Gavrilova, G. Goupil, B. Davis, D. Guay, and L. Roué, On the Key Role of Cu on the Oxidation Behavior of Cu–Ni–Fe Based Anodes for Al Electrolysis, Corr. Sci., 2015, 101, p 105-113

E. Gavrilova, G. Goupil, B. Davis, D. Guay, and L. Roué, Influence of Partial Substitution of Cu by Various Elements in Cu–Ni–Fe Alloys on Their High-Temperature Oxidation Behavior, Light Metals, M. Hyland, Ed., Springer, Cham, 2015, p 1187-1191

G. Goupil, S. Helle, B. Davis, D. Guay, and L. Roué, Anodic Behavior of Mechanically Alloyed Cu–Ni–Fe and Cu–Ni–Fe–O Electrodes for Aluminum Electrolysis in Low-Temperature KF–AlF3 Electrolyte, Electrochim. Acta, 2013, 112, p 176-182

S. Helle, M. Tresse, B. Davis, D. Guay, and L. Roué, Mechanically Alloyed Cu–Ni–Fe–O Based Materials as Oxygen-Evolving Anodes for Aluminum Electrolysis, J. Electrochem. Soc., 2012, 159(4), p E62-E68

K.P. Gupta, S.B. Rajendraprasad, and A.K. Jena, The Copper–Iron–Nickel System, J. Alloy Phase Diagrams, 1987, 3(2), p 116-127

C.P. Wang, X.J. Liu, I. Ohnuma, R. Kainuma, and K. Ishida, Thermodynamic Database of the Phase Diagrams in Cu–Fe Base Ternary Systems, J. Phase Equilib. Diff., 2004, 25(4), p 320-328

T.R. Beck, C.M. MacRae, and N.C. Wilson, Metal Anode Performance in Low-Temperature Electrolytes for Aluminum Production, Metall. Mater. Trans. B, 2011, 42B, p 807-813

I. Gallino, M.E. Kassner, and R. Busch, Oxidation and Corrosion of Highly Alloyed Cu–Fe–Ni as Inert Anode Material for Aluminum Electrowinning in As-cast and Homogenized Conditions, Corr. Sci., 2012, 63, p 293-303

G. Goupil, G. Bonnefont, H. Idrissi, D. Guay, and L. Roué, Consolidation of Mechanically Alloyed Cu–Ni–Fe Material by Spark Plasma Sintering and Evaluation as Inert Anode for Aluminum Electrolysis, J. Alloys Compd., 2013, 580, p 256-261

A. Papyrin, V. Kosarev, S. Klinkov, A. Alkhimov, and V.M. Fomin, Cold Spray Technology, Elsevier, Amsterdam, 2006

G. Goupil, S. Helle, E. Irissou, D. Poirier, J.G. Legoux, D. Guay, and L. Roué, Cold Spray Deposition of Mechanically Alloyed Cu–Ni–Fe Material for Application as Inert Anodes for Aluminum Production, Light Metals, B.A. Sadler, Ed., Springer, Cham, 2013, p 1283-1287

G. Goupil, S. Jucken, D. Poirier, J.G. Legoux, E. Irissou, B. Davis, D. Guay, and L. Roué, Cold-Sprayed Cu–Ni–Fe Anode for Aluminum Electrolysis, Corr. Sci., 2015, 90, p 259-265

M. Sherif El-Eskandarany, Mechanical Alloying: Nanotechnology, Materials Science and Powder Metallurgy, 2nd ed., William Andrew, Norwich, 2015

I. Gallino, Phase Diagram, Thermal Stability, and High Temperature Oxidation of the Ternary Cu-Ni-Fe System, PhD thesis, Oregon State University, 2003

O.-A. Lorentsen, Behaviour of Nickel, Iron and Copper by Application of Inert Anodes in Aluminium Production, PhD thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2000

M.L. Narula, V.B. Tare, and W.L. Worrell, Diffusivity and Solubility of Oxygen in Solid Copper Using Potentiostatic and Potentiometric Techniques, Metall. Trans. B, 1983, 14B, p 673-677

S.N.S. Reddy and R.A. Rapp, The Solubility and Diffusivity of Fluorine in Solid Copper from Electrochemical Measurements, Metall. Trans. B, 1978, 9, p 559-565

J. Crank, The Mathematics of Diffusion, 2nd ed., Clarendon Press, Oxford, 1975

Acknowledgments

This work was supported by the Natural Sciences and Engineering Research Council of Canada (NSERC) (Grants STPGP 430569—2012 and STPGP 494283—2016), Kingston Process Metallurgy Inc and Metal7 Inc.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jucken, S., Martin, M.H., Irissou, E. et al. Cold-Sprayed Cu-Ni-Fe Anodes for CO2-Free Aluminum Production. J Therm Spray Tech 29, 670–683 (2020). https://doi.org/10.1007/s11666-020-01002-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01002-z