Abstract

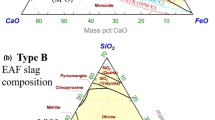

The effect of CaO fluxing on slag morphology was investigated during the reduction of FeO in electric arc furnace slag by aluminum black dross (ABD). Macro- and microscopic observations, by evaluating entrapped gas bubbles and reduced iron droplets related to gas evolution, apparent slag morphologies, and vertical section of slag at different initial CaO contents and reaction times, confirmed that both aluminothermic (dominant reaction) and carbothermic (minor) reduction occurred. Thus, the production of CO(+CO2) gas caused swelling-shrinking phenomena with repeated expansion and collapse of the slag pellet. In addition, macroscopic observation of slag morphologies as a function of the initial CaO content is well associated with quantitative consideration of the apparent viscosity as well as spinel ([Mg,Fe]Al2O4) activity. Consequently, appropriate CaO fluxing is necessary to control the composition of highly fluid slag by changing the slag from a high-alumina system to calcium–aluminosilicate melts when utilizing ABD as a reducing agent.

Similar content being viewed by others

References

J.Y. Hwang, X. Huang and Z. Xu: J. Min. Mater. Charact. Eng., 2006, vol. 5, pp. 47-62.

P.E. Tsakiridis, P. Oustadakis and S. Agatzini-Leonardou: J. Environ. Chem. Eng., 2013, vol. 1, pp. 23-32.

European Waste Catalogue and Hazardous Waste List, Environmental Protection Agency, Ireland, 2002. ISBN: 1-84095-083-8.

F.A. López, E. Sáinz, A. Formoso and I. Alfaro: Can. Metall. Q., 1994, vol. 33, pp. 29-33.

O. Manfredi, W. Wuth and I. Bohlinger: JOM, 1997, vol. 49, pp. 48-51.

E. David and J. Kopac: J. Hazard. Mater., 2013, vol. 261, pp. 316-24.

T. Hashishin, Y. Kodera, T. Yamamoto, M. Ohyanagi and Z.A. Munir: J. Am. Ceram. Soc., 2004, vol. 87, pp. 496-99.

M.C. Shinzato and R. Hypolito: Waste Manag., 2005, vol. 25, pp. 37-46.

B.R. Das, B. Dash, B.C. Tripathy, I.N. Bhattacharya and S.C. Das: Min. Eng., 2007, vol. 20, pp. 252-58.

A. Li, H. Zhang and H. Yang: Ceram. Int., 2014, vol. 40, pp. 12585-90.

J.H. Heo, E.H. Jeong, C.W. Nam, K.H. Park and J.H. Park: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 939-43.

E. David and J. Kopac: J. Hazard. Mater., 2012, vol. 209-210, pp. 501-09.

H. Shen and E. Forssberg: Waste Manag., 2003, vol. 23, pp. 933-49.

H.N. Yoshimura, A.P. Abreu, A.L. Molisani, A.C. de Camargo, J.C.S. Portela and N.E. Narita: Ceram. Int., 2008, vol. 34, pp. 581-91.

E.M.M. Ewais, N.M. Khalil, M.S. Amin, Y.M.Z. Ahmed and M.A. Barakat: Ceram. Int., 2009, vol. 35, pp. 3381-88.

G. Bernardo, M. Marroccoli, M. Nobili, A. Telesca and G.L. Valenti (2007) Resour., Conserv. Recyc. vol. 52, pp. 95-102.

L. Muhmood, S. Vitta and D. Venkateswaran: Cement. Conc. Res., 2009, vol. 39, pp. 102-09.

H.S. Kim, K.S. Kim, S.S. Jung, J.I. Hwang, J.S. Choi and I. Sohn: Waste Manag., 2015, vol. 41, pp. 85-93.

K. Mah, J.M. Toguri and H.W. Smith: Conserv. Recyc., 1986, vol. 9, pp. 325-34.

H. Soto and J.M. Toguri: Conserv. Recyc., 1986, vol. 9, pp. 45-54.

M. Ueda, M. Amemiya, T. Ishikawa and T. Ohtsuka: J. Japan. Inst. Met., 1999, vol. 63, pp. 279-83.

A. Takeuchi, H. Hashimoto, K. Tanaka, N. Tanahashi and K. Nakata: J. Japan. Inst. Light Met. 1996, vol. 46, pp. 592-96.

J.H. Heo and J.H. Park: Calphad, 2017, vol. 58, pp. 219-28.

J.H. Heo and J.H. Park: Calphad, 2017, vol. 58, pp. 229-38.

E.T. Turkdogan: Physical Chemistry of High Temperature Technology, Academic Press, New York, 1980, pp. 1–24.

J.Y. Choi and H.G. Lee: ISIJ Int., 2002, vol. 42, pp. 221-28.

S. Kongkarat, R. Khanna, P. Koshy, P. Okane and V. Sahajwalla (2012) ISIJ Int. vol. 52, pp. 385-93.

U. Kumar, S. Maroufi, R. Rajaro, M. Mayyas, I. Masuri, R.K. Joshi and V. Sahajwalla: J. Clean. Prod. 2017, vol. 158, pp. 218-24.

J.R. Dankwah, P. Koshy, N.M. Saha-Chaudhury, P. O’Kane, C. Skidmore, D. Knights and V. Sahajwalla: ISIJ Int. 2011, vol. 51, pp. 498-07.

S. Maroufi, M. Mayyas, I. Mansuri, P. O’Kane, C. Skidemore, Z. Jin, A. Fontana and V. Sahajwalla: Metall. Mater. Trans. B. 2017, vol. 48, pp. 2316-23

S.L. Teasdale and P.C. Hayes: ISIJ Int., 2005, vol. 45, pp. 634-41.

R. Roscoe: Br. J. Appl. Phys., 1952, vol. 3, pp. 267-69.

S. Wright, L. Zhang, S. Sun and S. Jahanshahi: Metall. Mater. Trans. B, 2000, vol. 31, pp. 97-104.

Acknowledgments

The authors express many thanks to the UNSW Study Abroad Research Practicum Program for JUNG HO HEO’s study at the Centre for SMaRT, UNSW. Also, this work was partly supported by the Korea Evaluation Institute of Industrial Technology (KEIT, with Grant No. 10063056) and Korea Institute of Energy Technology Evaluation and Planning (KETEP, with Grant No. 20172010106310), funded by the Ministry of Trade, Industry & Energy (MOTIE), Korea.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 18, 2019.

Rights and permissions

About this article

Cite this article

Heo, J.H., Kim, T.S., Sahajwalla, V. et al. Observations of FeO Reduction in Electric Arc Furnace Slag by Aluminum Black Dross: Effect of CaO Fluxing on Slag Morphology. Metall Mater Trans B 51, 1201–1210 (2020). https://doi.org/10.1007/s11663-020-01840-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01840-w