Abstract

Coarse-grained molecular dynamics simulations were carried out to investigate the frictional properties of lubricant molecules on nanostructured metal surfaces. The simulation cell consists of a lubricant film enclosed between two metal surfaces. The attractive potential of specific iron atoms on the surface was modified such that the lubricant molecule adsorb preferentially on these atoms. These particular iron atoms were arranged to reproduce a grain boundary surface nanostructure. It is found that below the critical normal stress, the strength of the interaction between Fe and the lubricant molecule has little effect on the friction coefficient. However, the behavior of the lubricant film on the metal surface is sensitive to the interaction strength. Large attraction forces increase the adherence of the lubricant film.

Similar content being viewed by others

References

Wong, V.W., Tung, S.C.: Overview of automotive engine friction and reduction trends–effects of surface, material, and lubricant-additive technologies. Friction 4(1), 1–28 (2016)

Wang, Z., Tao, N., Li, S.S., Wang, W., Liu, G., Lu, J., Lu, K.: Effect of surface nanocrystallization on friction and wear properties in low carbon steel. Mater. Sci. Eng. A 352(1–2), 144–149 (2003)

Wang, X., Li, D.: Mechanical, electrochemical and tribological properties of nano-crystalline surface of 304 stainless steel. Wear 255(7–12), 836–845 (2003)

Zhang, Y., Han, Z., Wang, K., Lu, K.: Friction and wear behaviors of nanocrystalline surface layer of pure copper. Wear 260(9–10), 942–948 (2006)

Suh, C.M., Song, G.H., Suh, M.S., Pyoun, Y.S.: Fatigue and mechanical characteristics of nano-structured tool steel by ultrasonic cold forging technology. Mater. Sci. Eng. A 443(1–2), 101–106 (2007)

Todaka, Y., Toda, K., Horii, M., Umemoto, M.: Effect of lattice defects on tribological behavior for low friction coefficient under lubricant in nanostructured steels. Tetsu-to-Hagané 101, 530–535 (2015)

Splinter, S., Rofagha, R., McIntyre, N., Erb, U.: XPS characterization of the corrosion films formed on nanocrystalline Ni-P alloys in sulphuric acid. Surf. Interface Anal. 24(3), 181–186 (1996)

Rydel, J.J., Pagkalis, K., Kadiric, A., Rivera-Díaz-del Castillo, P.: The correlation between ZDDP tribofilm morphology and the microstructure of steel. Tribol. Int. 113, 13–25 (2017)

Lobzenko, I., Shiihara, Y., Sakakibara, A., Uchiyama, Y., Umeno, Y., Todaka, Y.: Chemisorption enhancement of single carbon and oxygen atoms near the grain boundary on Fe surface: ab initio study. Appl. Surf. Sci. 493, 1042–1047 (2019)

Berro, H., Fillot, N., Vergne, P.: Molecular dynamics simulation of surface energy and ZDDP effects on friction in nano-scale lubricated contacts. Tribol. Int. 43(10), 1811–1822 (2010)

Savio, D., Fillot, N., Vergne, P.: A molecular dynamics study of the transition from ultra-thin film lubrication toward local film breakdown. Tribol. Lett. 50(2), 207–220 (2013)

Zhu, H., Zheng, X., Kosasih, P., Tieu, A.K.: Tribo-surface charge and polar lubricant molecules on friction and lubrication under multiple 3D asperity contacts. Wear 332, 1248–1255 (2015)

Ewen, J.P., Gattinoni, C., Morgan, N., Spikes, H.A., Dini, D.: Nonequilibrium molecular dynamics simulations of organic friction modifiers adsorbed on iron oxide surfaces. Langmuir 32(18), 4450–4463 (2016)

Ewen, J.P., Restrepo, S.E., Morgan, N., Dini, D.: Nonequilibrium molecular dynamics simulations of stearic acid adsorbed on iron surfaces with nanoscale roughness. Tribol. Int. 107, 264–273 (2017)

Latorre, C.A., Ewen, J.P., Gattinoni, C., Dini, D.: Simulating surfactant-Iron oxide interfaces: from density functional theory to molecular dynamics. J. Phys. Chem. B 123(31), 6870–6881 (2019)

Ewen, J., Heyes, D., Dini, D.: Advances in nonequilibrium molecular dynamics simulations of lubricants and additives. Friction 6(4), 349–386 (2018)

Spikes, H.: Friction modifier additives. Tribol. Lett. 60(1), 5 (2015)

Ashurst, W.T., Hoover, W.: Dense-fluid shear viscosity via nonequilibrium molecular dynamics. Phys. Rev. A 11(2), 658 (1975)

Nosé, S.: A molecular dynamics method for simulations in the canonical ensemble. Mol. Phys. 52(2), 255–268 (1984)

Hoover, W.G.: Canonical dynamics: equilibrium phase-space distributions. Phys. Rev. A 31(3), 1695 (1985)

de Pablo, J.J.: Coarse-grained simulations of macromolecules: from DNA to nanocomposites. Annu. Rev. Phys. Chem. 62, 555–574 (2011)

Plimpton, S.: Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117(1), 1–19 (1995)

Shin, S., Rice, S.A.: Comment on the influence of molecular flexibility on molecular packing in Langmuir monolayers. Langmuir 10(1), 262–266 (1994)

Muthukumar, M., Welch, P.: Modeling polymer crystallization from solutions. Polymer 41(25), 8833–8837 (2000)

Sudo, Y.: Master’s thesis. The University of Tokyo, Institute of Industrial Science, Japan (2018)

Ewen, J., Gattinoni, C., Thakkar, F., Morgan, N., Spikes, H., Dini, D.: A comparison of classical force-fields for molecular dynamics simulations of lubricants. Materials 9(8), 651 (2016)

Lide, D.: CRC handbook of chemistry and physics, 85th edn. Taylor & Francis, Boca Raton (2004)

Wohlfarth, C., Wohlfahrt, B.: References for Pure Organic Liquids: Datasheet from Landolt-Börnstein - Group IV Physical Chemistry 18B (Pure Organic Liquids)

Loehlé, S.: Understanding of adsorption mechanism and tribological behaviors of C18 fatty acids on iron-based surfaces: a molecular simulation approach. PhD thesis, Ecully, Ecole centrale de Lyon (2014)

Loehlé, S., Matta, C., Minfray, C., Le Mogne, T., Iovine, R., Obara, Y., Miyamoto, A., Martin, J.: Mixed lubrication of steel by C18 fatty acids revisited. Part II: Influence of some key parameters. Tribol. Int. 94, 207–216 (2016)

Gee, M.L., McGuiggan, P.M., Israelachvili, J.N., Homola, A.M.: Liquid to solidlike transitions of molecularly thin films under shear. J. Chem. Phys. 93(3), 1895–1906 (1990)

An, R., Zhou, G., Zhu, Y., Zhu, W., Huang, L., Shah, F.U.: Friction of ionic liquid-glycol ether mixtures at titanium interfaces: negative load dependence. Adv. Mater. Interfaces 5(14), 1800263 (2018)

Stevens, M.J., Mondello, M., Grest, G.S., Cui, S., Cochran, H., Cummings, P.: Comparison of shear flow of hexadecane in a confined geometry and in bulk. J. Chem. Phys. 106(17), 7303–7314 (1997)

Thompson, P.A., Troian, S.M.: A general boundary condition for liquid flow at solid surfaces. Nature 389(6649), 360 (1997)

Koike, A., Yoneya, M.: Chain length effects on frictional behavior of confined ultrathin films of linear alkanes under shear. J. Phys. Chem. B 102(19), 3669–3675 (1998)

Gao, J., Luedtke, W., Landman, U.: Structures, solvation forces and shear of molecular films in a rough nano-confinement. Tribol. Lett. 9(1–2), 3–13 (2000)

Das, N.K., Shoji, T.: Early stage oxidation initiation at different grain boundaries of fcc Fe-Cr binary alloy: a computational chemistry study. Oxid. Met. 79(3–4), 429–441 (2013)

Campen, S., Green, J., Lamb, G., Atkinson, D., Spikes, H.: On the increase in boundary friction with sliding speed. Tribol. Lett. 48(2), 237–248 (2012)

Morse, P.M.: Diatomic molecules according to the wave mechanics. II. Vibrational levels. Phys. Rev. 34(1), 57 (1929)

Bernardi, S., Todd, B., Searles, D.J.: Thermostating highly confined fluids. J. Chem. Phys. 132(24), 244706 (2010)

Yong, X., Zhang, L.T.: Thermostats and thermostat strategies for molecular dynamics simulations of nanofluidics. J. Chem. Phys. 138(8), 084503 (2013)

Sun, H.: COMPASS: an ab initio force-field optimized for condensed-phase applications overview with details on alkane and benzene compounds. J. Phys. Chem. B 102(38), 7338–7364 (1998)

Ta, T.D., Tieu, A.K., Zhu, H., Kosasih, B.: Adsorption of normal-alkanes on Fe (110), FeO (110), and \(\text{ Fe }_{2}\text{ O }_{3}\) (0001): Influence of iron oxide surfaces. J. Phys. Chem. C 119(23), 12999–13010 (2015)

Acknowledgements

This study was supported by JST (Japan Science and Technology Agency) through Collaborative Research Based on Industrial Demand Program (Grant No. JPMJSK1511).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendices

Appendix: Coarse-Grained Modeling for the Iron-Lubricant System

Although CG potential parameters for the CH2–CH2, CH2–COOH, and COOH–COOH interactions are available (see Table 2), no CG model for the Fe–CH2 and Fe–COOH interactions has been developed so far.

To address this need, we developed a coarse-grained potential function for the Fe-\({{\hbox{CH}}_2}\) interaction based on the all-atom (AA) potential model for the Fe–C–H system. Details are given in section A1.1. In section A1.2, we show how the CG potential parameters for the Fe–CH2 interaction can be derived from a simple relationship.

\({\hbox{Fe}}{\rm{-}}{{\hbox{CH}}_2}\) interaction

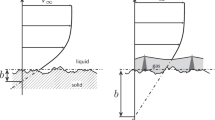

Figure 9 is a schematic illustration of the atomistic structure used for CG modeling. The system consists of an \({\hbox{Fe}}\) surface (bcc {110} plane) and a \({\hbox{CH}}_{4}\) (methane) molecule. An equivalent model for AA and CG simulation was prepared as shown in Fig. 9a, b, respectively. The distance (d) between the \({\hbox{Fe}}\) surface and the \({\hbox{CH}}_{4}\) molecule was varied between 4 Å and 12 Å and the total potential energy of the system E was evaluated as a function of d. The CG potential parameters \(\alpha_{{\text{Fe-CH}}_{2}}\) and \(\beta_{{\text{Fe-CH}}_{2}}\) in the Lennard–Jones potential function (Eq. 1) were determined to reproduce the potential curve E(d) of the \({\hbox{CH}}_{4}\) molecule on the bcc \({\hbox{Fe}}\) {110} surface. We employed the AA models developed in Ref. [42] for the bonding interaction of a \({\hbox{CH}}_{4}\) molecule and Ref. [43] for the non-bond interaction of \({\hbox{Fe}}-{\hbox{H}}\) and \({\hbox{Fe}}-\hbox {C}\). Since there are only two CG potential parameters to be optimized, they were adjusted manually by comparing the CG result (with provisional potential parameter sets) to the AA result. Thermal fluctuations were not considered for the \({\hbox{Fe}}\), \(\hbox {C}\) and \({\hbox{CH}}_{4}\) particles. The dynamics of \({\hbox{H}}\) atoms was controlled by a Nose–Hoover thermostat to keep the temperature constant \((T = 300\,{\rm K})\). Note that this CG simulation is static because there is no degree of freedom to allow thermal fluctuations.

Figure 10 shows the energy profile as a function of d obtained by the AA model and by the optimized CG model. The optimized CG parameters are as follows: \(\alpha _\mathrm{Fe-CH2} =\) 0.2499 kcal/mol and \(\beta _\mathrm{Fe-CH2} = 4.2999\) Å. We confirmed that the optimized CG model reproduces successfully the potential curve obtained from the AA model. The interaction between \({{\hbox{Fe}}^{\mathrm{SP}}}\) and \({{\hbox{CH}}_2}\) was regarded as identical to the \({{\hbox{Fe}}^{\mathrm{SP}}}\)-\({{\hbox{CH}}_2}\) interaction.

1.1 \({\hbox{Fe}}{\rm{-}}{\hbox{COOH}}\) Interaction

To estimate the CG potential parameters \(\alpha _{\mathrm{Fe-COOH}}\) and

\(\beta _{\mathrm{Fe-COOH}}\), we use the geometric mean:

where A and B denote the types of particles (i.e., \({{\hbox{CH}}_2}\), \({\hbox{COOH}}\), \({\hbox{Fe}}\) and \({{\hbox{Fe}}^{\mathrm{SP}}}\)). To derive \(\alpha _{\mathrm{Fe-COOH}}\), we consider two equations as follows:

From these equations, we obtain:

Here, all the parameters on the right side of the equation are known, and thus \(\alpha _{\mathrm{Fe-COOH}}\) can be evaluated.

In a similar way, we obtain:

The evaluation of the aforementioned equations is easily carried out and leads to \(\alpha _{\mathrm{Fe-COOH}} = 0.3658\) kcal/mol and \(\beta _{\mathrm{Fe-COOH}} = 4.5675\) Å. The parameter \(\beta_{\text{Fe}^{\text{SP}}{-}{\text{COOH}}}\) was set to 4.5675 Å as well.

Rights and permissions

About this article

Cite this article

Albina, JM., Kubo, A., Shiihara, Y. et al. Coarse-Grained Molecular Dynamics Simulations of Boundary Lubrication on Nanostructured Metal Surfaces. Tribol Lett 68, 49 (2020). https://doi.org/10.1007/s11249-020-1276-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-020-1276-2