Abstract

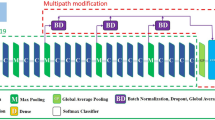

Since small metal cylindrical shell (MCS) is a kind of very important metal object widely used in structure engineering and weapon production, especially in the manufacture of bullets, it is necessary to assure the high-precision surface of MCS. While the detection of MCS is generally done manually. In this paper, a novel automatic defect detection system for MCS is built using transfer learning of Inception-v3 and logistic regression (LR). By using the powerful feature extraction capabilities of Inception-v3 deep convolutional neural network, features are fetched from MCS images firstly and then trained on an LR machine learning classifier to establish a detection model. During the process of detection, five images of one MCS captured by the camera are sent to the computer for detection using the established detection model, with these five images’ composite outcomes representing this MCS’s detection result. Experimental results show that the proposed detection system could reach an accuracy of 97%, meeting the requirements of industrial production.

Similar content being viewed by others

References

Jia, Y., Tang, L., Ming, P., Xie, Y.: Ultrasound-excited thermography for detecting microcracks in concrete materials. NDT E Int. 101, 62–71 (2019)

Yu, Q., Obeidat, O., Han, X.: Ultrasound wave excitation in thermal NDE for defect detection. NDT E Int. 100, 153–165 (2018)

Yoshimura, W., Tanaka, R., Sasayama, T., Enpuku, K.: Detection of slit defects on backside of steel plate using low-frequency eddy-current testing. IEEE Trans. Magn. 54, 1–5 (2018)

Soni, A.K., Rao, B.P.: Lock-in amplifier based eddy current instrument for detection of sub-surface defect in stainless steel plates. Sens. Imaging 19, 32 (2018)

Joung, O.J., Kim, Y.H.: Application of an IR thermographic device for the detection of a simulated defect in a pipe. Sensors 6, 1199–1208 (2006)

Cheng-Wu, Y., Chengchangfeng, L., Tian-Yi, W., Shun-Rong, Q., Zhen-Gang, Y., Ke-Jia, W., Jin-Song, L., Sheng-Lie, W.: Method for defect contour extraction in terahertz non-destructive testing conducted with a raster-scan THz imaging system. Appl. Opt. 57, 4884 (2018)

Jeon, Y.J., Choi, D.C., Lee, S.J., Yun, J.P., Kim, S.W.: Steel-surface defect detection using a switching-lighting scheme. Appl. Opt. 55, 47 (2016)

Son, H., Hwang, N., Kim, C., Kim, C.: Rapid and automated determination of rusted surface areas of a steel bridge for robotic maintenance systems. Autom. Constr. 42, 13–24 (2014)

Liao, K.W., Lee, Y.T.: Detection of rust defects on steel bridge coatings via digital image recognition. Autom. Constr. 71, 294–306 (2016)

Xu, K., Liu, S., Ai, Y.: Application of Shearlet transform to classification of surface defects for metals. Image Vision Comput. 35, 23–30 (2015)

Shen, H., Li, S., Gu, D., Chang, H.: Bearing defect inspection based on machine vision. Measurement 45, 719–733 (2012)

Shanmugamani, R., Sadique, M., Ramamoorthy, B.: Detection and classification of surface defects of gun barrels using computer vision and machine learning. Measurement 60, 222–230 (2015)

Finlayson, G., Hordley, S., Schaefer, G., et al.: Illuminant and device invariant colour using histogram equalisation. Pattern Recogn. 38(2), 179–190 (2005)

Gore, J.C., Ding, Z., Li, C., Kao, C.: Implicit active contours driven by local binary fitting energy. In: IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Minneapolis, pp. 1–7 (2007)

Li, W.-B., Lu, C.-H., Zhang, J.-C.: A local annular contrast based real-time inspection algorithm for steel bar surface defects. Appl. Surf. Sci. 258, 6080–6086 (2012)

Zhou, A., Shao, W., Guo, J.: An image mosaic method for defect inspection of steel rotary parts. J. Nondestr. Eval. 35, 60 (2016)

Zhou, A., Guo, J., Shao, W., Yang, J.: Multipose measurement of surface defects on rotary metal parts with a combined laser-and-camera sensor. Opt. Eng. 52, 104104 (2013)

Zeiler, M.D., Fergus, R. Visualizing and understanding convolutional networks. In: European Conference on Computer Vision (ECCV), pp. 818–833. Springer, Cham (2014).

Yosinski, J., Clune, J., Bengio, Y., Lipson, H.: How transferable are features in deep neural networks? Adv. Neural Inf. Process. 27, 3320–3328 (2014)

Zhang, X.-W., Ding, Y.-Q., Lv, Y.-Y., Shi, A.-Y., Liang, R.-Y.: A vision inspection system for the surface defects of strongly reflected metal based on multi-class SVM. Expert Syst. Appl. 38, 5930–5939 (2011)

Yun, J.P., Kim, D., Kim, K., Lee, S.J., Park, C.H., Kim, S.W.: Vision-based surface defect inspection for thick steel plates. Opt. Eng. 56, 053108 (2017)

Xu, L.M., Yang, Z.Q., Jiang, Z.H., Chen, Y.: Light source optimization for automatic visual inspection of piston surface defects. Int. J. Adv. Manuf. Technol. 91, 2245–2256 (2017)

Li, L., Wang, Z., Pei, F., Wang, X.: Improved illumination for vision-based defect inspection of highly reflective metal surface. Chin. Opt. Lett. 11, 021102 (2013)

Rosati, G., Boschetti, G., Biondi, A., Rossi, A.: Real-time defect detection on highly reflective curved surfaces. Opt. Lasers Eng. 47, 379–384 (2009)

Satorres Martinez, S., Ortega Vazquez, C., Gamez Garcia, J., Gomez Ortega, J.: Quality inspection of machined metal parts using an image fusion technique. Measurement 111, 374–383 (2017)

Pan, S.J., Yang, Q.: A survey on transfer learning. IEEE Trans. Knowl. Data Eng. 22, 1345–1359 (2010)

Xie, D., Zhang, L., Bai, L.: Deep learning in visual computing and signal processing. Appl. Comput. Intell. Soft Comput. 10, 1–13 (2017)

Shin, H.C., Roth, H.R., Gao, M.C., Lu, L., Xu, Z.Y., Nogues, I., Yao, J.H., Mollura, D., Summers, R.M.: Deep convolutional neural networks for computer-aided detection: CNN architectures, dataset characteristics and transfer learning. IEEE Trans. Med. Imaging 35, 1285–1298 (2016)

Donahue, J., Jia, Y., Vinyals, O., Hoffman, J., Zhang, N., Tzeng, E., Darrell, T.: Decaf: a deep convolutional activation feature for generic visual recognition. Int. Conf. Mach. Learn. 50(1), 647 (2013)

Deng, J., Dong, W., Socher, R., Li, L.-J., Li, K., Li, F.-F.: IEEE, ImageNet: a large-scale hierarchical image database. In: CVPR: 2009 IEEE Conference on Computer Vision and Pattern Recognition, vols. 1–4, 2009, pp. 248–255.

Meng, D., Zhang, L., Cao, G., Cao, W., Zhang, G., Hu, B.: Liver fibrosis classification based on transfer learning and FCnet for ultrasound images. IEEE Access 5, 5804–5810 (2017)

Tsai, A., Yezzi, A., Willsky, A.S.: Curve evolution implementation of the mumford-shah functional for image segmentation, denoising, interpolation, and magnification. IEEE Trans. Imag. Proc. 10, 1169–1186 (2001)

ISO 13053-2: Quantitative methods in process improvement—six sigma—part 2: tools and techniques (2010)

ISO 22514-1: Statistical methods in process management, capability and performance—part 1: general principles and concepts (2014)

Automotive Industry Action Group (AIAG): Measurement System Analysis, 4th edn. AIAG, Southfield (2010)

Acknowledgements

This work was supported in part by the Chongqing Changjiang Electrical Industry Co., Ltd. Besides, this work was also supported by the Research on Intelligent Recognition Technology of Spacecraft Composite Defects funded by the Shanghai Institute of Satellite Equipment (No. JG20180209).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gong, Y., Luo, J., Shao, H. et al. Automatic Defect Detection for Small Metal Cylindrical Shell Using Transfer Learning and Logistic Regression. J Nondestruct Eval 39, 24 (2020). https://doi.org/10.1007/s10921-020-0668-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-020-0668-4