Abstract

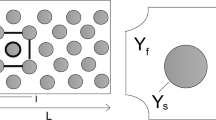

A new stabilized method is presented for coupled chemo-mechanical problems involving chemically reacting fluids flowing through deformable elastic solids. A mixture theory model is employed wherein kinematics is represented via an independent set of balance laws for each of the interacting constituents. A significant feature of the mixture model is the interactive force field in the momentum balance equations that couples the constituents implicitly at the level of the governing system of equations. The constitutive relations for the constituents in the mixture model are based on maximization of the rate of entropy production. Since each constituent is not discretely modeled and the interactive effects are mathematically coupled at the local continuum level, the resulting system serves as a physics-based reduced-order model for the complex microstructure of the material system. When constitutive equations are substituted into the balance laws, they give rise to a system of coupled nonlinear PDEs. Evolving nonlinearity and coupled chemo-mechanical effects give rise to spatially localized phenomena, namely boundary layers, shear bands, and steep gradients that appear at the reaction fronts. For large reaction rates, the balance of mass of the fluid becomes a singularly perturbed equation (reaction-dominated), which may exhibit boundary and/or internal layers. Likewise, for large reaction rates and/or low diffusivity, the balance of linear momentum for the fluid constituent also becomes a singularly perturbed PDE. Presence of these features in the solution requires stable numerical methods, and we present a variational multiscale (VMS)-based stabilized finite element method for the initial-boundary value problem. Mathematical attributes of the method are investigated via a range of numerical test cases that involve diffusion of chemically reacting fluids through nonlinear elastic solids. Enhanced stabilization features and higher spatial accuracy of the models and the methods are highlighted.

Similar content being viewed by others

References

Truster, T.J., Masud, A.: A unified mixture formulation for density and volumetric growth of multi-constituent solids in tissue engineering. Comput. Methods Appl. Mech. Eng. 314, 222–268 (2017)

Humphrey, J.D., Rajagopal, K.R.: A constrained mixture model for growth and remodeling of soft tissues. Math. Model. Methods Appl. Sci. 12, 407–430 (2002)

Humphrey, J.D., Rajagopal, K.R.: A constrained mixture model for arterial adaptations to a sustained step change in blood flow. Biomech. Model. Mechanobiol. 2, 109–126 (2003)

Yuan, P., McCracken, J.M., Gross, D.E., Braun, P.V., Moore, J.S., Nuzzo, R.G.: A programmable soft chemo-mechanical actuator exploiting a catalyzed photochemical water-oxidation reaction. Soft Matter 13, 7312–7317 (2017)

Haberman, B.A., Young, J.B.: Three-dimensional simulation of chemically reacting gas flows in the porous support structure of an integrated-planar solid oxide fuel cell. Int. J. Heat Mass Transf. 47, 3617–3629 (2004)

Bishop, S.R.: Chemical expansion of solid oxide fuel cell materials: a brief overview. Acta Mech. Sin. 29, 312–317 (2013)

Rao, V.S., Hughes, T.J.R.: On modelling thermal oxidation of silicon I: theory. Int. J. Numer. Methods Eng. 47, 341–358 (2000)

Lofaj, F., Kaganovskii, Y.S.: Kinetics of WC-Co oxidation accompanied by swelling. J. Mater. Sci. 30, 1811–1817 (1995)

Merzouki, T., Blond, E., Schmitt, N., Bouchetou, M.-L., Cutard, T., Gasser, A.: Modelling of the swelling induced by oxidation in SiC-based refractory castables. Mech. Mater. 68, 253–266 (2014)

Merzouki, T., Blond, E., Schmitt, N.: Numerical study of the effects of refractory lining geometries on the swelling induced by oxidation. Finite Elem. Anal. Des. 108, 66–80 (2016)

Munro, R.G., Dapkunas, S.J.: Corrosion characteristics of silicon carbide and silicon nitride. J. Res. Natl. Inst. Stand. Technol. 98, 607–631 (1993)

Yang, H., Fan, F., Liang, W., Guo, X., Zhu, T., Zhang, S.: A chemo-mechanical model of lithiation in silicon. J. Mech. Phys. Solids. 70, 349–361 (2014)

Hall, R., Gajendran, H., Masud, A.: Diffusion of chemically reacting fluids through nonlinear elastic solids: mixture model and stabilized methods. Math. Mech. Solids 20, 204–227 (2015)

Hughes, T.J.R.: Multiscale phenomena: Green’s functions, the Dirichlet-to-Neumann formulation, subgrid scale models, bubbles and the origins of stabilized methods. Comput. Methods Appl. Mech. Eng. 127, 387–401 (1995)

Hughes, T.J.R., Feijóo, G.R., Mazzei, L., Quincy, J.-B.: The variational multiscale method–a paradigm for computational mechanics. Comput. Methods Appl. Mech. Eng. 166, 3–24 (1998)

Brezzi, F., Franca, L.P., Hughes, T.J.R., Russo, A.: \(b = int( g )\). Comput. Methods Appl. Mech. Eng. 145, 329–339 (1997)

Truesdell, C.: Rational Thermodynamics, 2nd edn. Springer, New York (1984)

Bowen, R.M.: Theory of mixtures. In: Eringen, A.C. (ed.) Continuum Physics, vol. III, pp. 1–127. Elsevier, Amsterdam (1976)

Atkin, R.J., Craine, R.E.: Continuum theories of mixtures: basic theory and historical development. Q. J. Mech. Appl. Math. 29, 209–244 (1976)

Rajagopal, K.R., Tao, L.: Mechanics of Mixtures. World scientific, Singapore (1995)

Samohýl, I.: Thermodynamics of Irreversible Processes in Fluid Mixtures: Approached by Rational Thermodynamics, 1st edn. B.G. Teubner, Leipzig (1987)

Franca, L.P., Dutra Do Carmo, E.G.: The Galerkin gradient least-squares method. Comput. Methods Appl. Mech. Eng. 74, 41–54 (1989)

Codina, R.: Comparison of some finite element methods for solving the diffusion-convection-reaction equation. Comput. Methods Appl. Mech. Eng. 156, 185–210 (1998)

Hauke, G., García-Olivares, A.: Variational subgrid scale formulations for the advection-diffusion-reaction equation. Comput. Methods Appl. Mech. Eng. 190, 6847–6865 (2001)

Fernando, H., Harder, C., Paredes, D., Valentin, F.: Numerical multiscale methods for a reaction-dominated model. Comput. Methods Appl. Mech. Eng. 201–204, 228–244 (2012)

Dutra do Carmo, E.G., Alvarez, G.B., Rochinha, F.A., Loula, A.F.D.: Galerkin projected residual method applied to diffusion–reaction problems. Comput. Methods Appl. Mech. Eng. 197, 4559–4570 (2008)

Masud, A.: Preface. Comput. Methods Appl. Mech. Eng. 193, iii–iv (2004)

Hall, R., Rajagopal, K.R.: Diffusion of a fluid through an anisotropically chemically reacting thermoelastic body within the context of mixture theory. Math. Mech. Solids 17, 131–164 (2012)

Masud, A., Khurram, R.A.: A multiscale finite element method for the incompressible Navier–Stokes equations. Comput. Methods Appl. Mech. Eng. 195, 1750–1777 (2006)

Masud, A., Calderer, R.: A variational multiscale method for incompressible turbulent flows: bubble functions and fine scale fields. Comput. Methods Appl. Mech. Eng. 200, 2577–2593 (2011)

Hay, R.S.: Growth stress in \(\text{ SiO }_2\) during oxidation of SiC fibers. J. Appl. Phys. 111, 063527 (2012)

Snead, L.L., Nozawa, T., Katoh, Y., Byun, T.S., Kondo, S., Petti, D.A.: Handbook of SiC properties for fuel performance modeling. J. Nucl. Mater. 371, 329–377 (2007)

Kajihara, K., Kamioka, H., Hirano, M., Miura, T., Skuja, L., Hosono, H.: Interstitial oxygen molecules in amorphous \(\text{ SiO }_2\). III. Measurements of dissolution kinetics, diffusion coefficient, and solubility by infrared photoluminescence. J. Appl. Phys. 98, 013529 (2005)

Song, Y., Dhar, S., Feldman, L.C., Chung, G., Williams, J.R.: Modified Deal Grove model for the thermal oxidation of silicon carbide. J. Appl. Phys. 95, 4953–4957 (2004)

Rao, V.S., Hughes, T.J.R., Garikipati, K.: On modelling thermal oxidation of silicon II: numerical aspects. Int. J. Numer. Methods Eng. 47, 359–377 (2000)

Brooks, A.N., Hughes, T.J.R.: Streamline upwind/Petrov–Galerkin formulations for convection dominated flows with particular emphasis on the incompressible Navier-Stokes equations. Comput. Methods Appl. Mech. Eng. 32, 199–259 (1982)

Hughes, T.J.R., Mallet, M., Akira, M.: A new finite element formulation for computational fluid dynamics: II. beyond SUPG. Comput. Methods Appl. Mech. Eng. 54, 341–355 (1986)

Rao, V.S.: On numerical modeling of thermal oxidation in silicon. Stanford University, Stanford (1997)

Acknowledgements

This work was partially supported by the Air Force Research Laboratory (AFRL) Grant 18F5828-19-15-C1. This support is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A. Tables of material properties

Appendix A. Tables of material properties

Remark:

The value of the coefficient for viscosity of oxygen as presented in Table 1 corresponds to the temperature of 1373 K and partial pressure 1 atm of pure oxygen. As oxygen permeates through the solid, the jump in concentration of oxygen between the solid and the ambient surrounding is given by Henry’s law. Accordingly, the coefficient used in the numerical calculation is 2.792e\(-\)7.

Remark:

In Table 2, the value of the reacted shear modulus is determined such that the “effective” shear modulus of the reacted material \(\mu _{2}^{s} -\frac{\mu ^{\mathrm{L}}}{3}\gamma _{\mathrm{max}}^{3} \bar{{c}}^{0}\) in Eq. (28) corresponds to the shear modulus of silicon dioxide employed in [35], which is 40.921 GPa.

Rights and permissions

About this article

Cite this article

Anguiano, M., Gajendran, H., Hall, R.B. et al. Chemo-mechanical coupling and material evolution in finitely deforming solids with advancing fronts of reactive fluids. Acta Mech 231, 1933–1961 (2020). https://doi.org/10.1007/s00707-020-02617-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-020-02617-7