Abstract

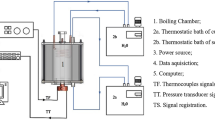

The current study presents an artificial neural network model used to predict the boiling heat transfer coefficient of different coating thicknesses of a graphene-coated copper surface in the pool boiling experimental setup for deionized water. The surface characterization has been carried out to study the structure, morphology and surface behavior. The investigations are carried out to evaluate the boiling heat transfer coefficient, heat flux and wall superheat for various thicknesses of nano-coated surfaces experimentally, and the obtained results are compared with those of the reported studies and existing empirical correlations. After that, these results are compared with the outputs such as current, heat flux, wall superheat and boiling heat transfer coefficient obtained using a MATLAB-based artificial neural network model with coating thickness, surface roughness and voltage as input variables. The admirable accuracies are obtained with the predicted optimal model outputs with experimental observation in each test case.

Similar content being viewed by others

Abbreviations

- HTC:

-

Heat transfer coefficient (h) (kW m−2 K−1)

- CHF:

-

Critical heat flux (W m−2)

- Tn, To, Tp :

-

Temperature of copper heating block (°C)

- Tq, Tr, Ts :

-

Calculated temperature of sample at different sections (°C)

- T l :

-

Temperature of base fluid (°C)

- T s :

-

Surface temperature of specimen (°C)

- ∆T :

-

Wall superheat (°C)

- Qpq, Qqr, Qrs :

-

Heat flux at various sections (W m−2)

- Kpq, Kqr, Krs :

-

Thermal conductivity of copper material at various sections (W m−1 K−1)

- Apq, Aqr, Ars :

-

Cross-sectional area at various sections (m2)

- ∆xpq, ∆xrs, ∆xrs :

-

Thickness of surface at various sections (m)

- k :

-

Thermal conductivity of the working fluid (W m−1 K−1)

- Pr :

-

Prandtl number \(\left( {\frac{{\mu C_{\text{p}} }}{K}} \right)\)

- C p :

-

Specific heat of the working fluid (kJ kg−1 K−1)

- h fg :

-

Latent heat of vaporization of the working fluid (kJ kg−1)

- q :

-

Pool boiling heat transfer (W m−2)

- I :

-

Current (A)

- AI:

-

Artificial intelligence

- ANN:

-

Artificial neural networks

- GEP:

-

Gene expression programming

- SVR:

-

Support vector regression

- IVR-ERVC:

-

In-vessel retention through extend reaction vessel cooling

- CNT:

-

Carbon nanotubes

- PEG:

-

Polyethylene glycol

- Cu:

-

Copper

- XRD:

-

X-ray diffraction

- AFM:

-

Atomic force microscopy

- SEM:

-

Scanning electron microscopy

- DI:

-

De-ionized

- d :

-

Interplanar spacing

- h, k, l :

-

Miller indices

- a, c :

-

Lattice constants

- g :

-

Acceleration due to gravity (m s−2)

- MLP:

-

Multilayer perceptron

- Trainlm:

-

Levenberg–Marquardt backpropagation

- Trainscg:

-

Scaled conjugate gradient backpropagation

- Trainbfg:

-

BFGS quasi-Newton backpropagation

- Traingda:

-

Gradient descent with adaptive learning rate backpropagation

- Trainsig:

-

Hyperbolic tangent sigmoid transfer function

- Logsig:

-

Log-sigmoid

- MATLAB:

-

Matrix laboratory

- MSE:

-

Mean square error

- R :

-

Regression coefficient

- MAPE:

-

Mean absolute percentage error

- n :

-

Total number of output data

- µ :

-

Viscosity (N s m−2)

- σ :

-

Surface tension (N m−2)

- ρ :

-

Density (kg m−3)

- λ :

-

Wavelength (m)

- s:

-

Surface

- l:

-

Liquid

- v:

-

Vapour

- exp:

-

Experimental values

- opt:

-

Predicted values

References

Nukiyama S. The maximum and minimum values of the heat Q transmitted from metal to boiling water under atmospheric pressure. Int J Heat Mass Transf. 1966;9(12):1419–33.

Dharmendra M, Suresh S, Kumar CS, Yang Q. Pool boiling heat transfer enhancement using vertically aligned carbon nanotube coatings on a copper substrate. Appl Therm Eng. 2016;99:61–71.

Mehrotra AK, Nassar NN, Kasumu AS. A novel laboratory experiment for demonstrating boiling heat transfer. Educ Chem Eng. 2012;7(4):e210–8.

Parveen N, Zaidi S, Danish M. Comparative analysis for the prediction of boiling heat transfer coefficient of R134a in micro/mini channels using artificial intelligence (AI)-based techniques. Int J Model Simul. 2019. https://doi.org/10.1080/02286203.2018.1564809.

Naphon P, Wiriyasart S, Arisariyawong T, Nakharintr L. ANN, numerical and experimental analysis on the jet impingement nanofluids flow and heat transfer characteristics in the micro-channel heat sink. Int J Heat Mass Transf. 2019;131:329–40.

Swain A, Das MK. ANFIS modeling of boiling heat transfer over tube bundles. In: Soft computing for problem solving. Springer; 2019; p. 433–40.

Kim DE, Yu DI, Jerng DW, Kim MH, Ahn HS. Review of boiling heat transfer enhancement on micro/nanostructured surfaces. Exp Therm Fluid Sci. 2015;66:173–96.

Kumar CS, Kumar GU, Arenales MRM, Hsu C-C, Suresh S, Chen P-H. Elucidating the mechanisms behind the boiling heat transfer enhancement using nano-structured surface coatings. Appl Therm Eng. 2018;137:868–91.

Krishnan DV, Kumar GU, Suresh S, Thansekhar M, Iqbal U. Evaluating the scale effects of metal nanowire coatings on the thermal performance of miniature loop heat pipe. Appl Therm Eng. 2018;133:727–38.

Ray M, Bhaumik S. Nucleate pool boiling heat transfer of hydro-fluorocarbon refrigerant R134a on TiO2 nanoparticle coated copper heating surfaces. Heat Transf Eng. 2018;40:1–10.

Ray M, Bhaumik S. Structural properties of glancing angle deposited nanostructured surfaces for enhanced boiling heat transfer using refrigerant R-141b. Int J Refrig. 2018;88:78–90.

Jaikumar A, Kandlikar SG, Gupta A. Pool boiling enhancement through graphene and graphene oxide coatings. Heat Transf Eng. 2017;38(14–15):1274–84.

Seo H, Chu JH, Kwon S-Y, Bang IC. Pool boiling CHF of reduced graphene oxide, graphene, and SiC-coated surfaces under highly wettable FC-72. Int J Heat Mass Transf. 2015;82:490–502.

Lee MH, Heo H, Bang IC. Effect of thermal activity on critical heat flux enhancement in downward-hemispherical surface using graphene oxide coating. Int J Heat Mass Transf. 2018;127:1102–11.

Rishi AM, Gupta A, Kandlikar SG, editors. Improving liquid supply pathways on graphene oxide coated surfaces for enhanced pool boiling heat transfer performance. In: ASME 2018 16th international conference on nanochannels, microchannels, and minichannels. American Society of Mechanical Engineers; 2018.

Ujereh S, Fisher T, Mudawar I. Effects of carbon nanotube arrays on nucleate pool boiling. Int J Heat Mass Transf. 2007;50(19–20):4023–38.

Park SD, Won Lee S, Kang S, Bang IC, Kim JH, Shin HS, et al. Effects of nanofluids containing graphene/graphene-oxide nanosheets on critical heat flux. Appl Phys Lett. 2010;97(2):023103.

Kim JM, Kim T, Kim J, Kim MH, Ahn HS. Effect of a graphene oxide coating layer on critical heat flux enhancement under pool boiling. Int J Heat Mass Transf. 2014;77:919–27.

Ahn HS, Kim JM, Kim MH. Experimental study of the effect of a reduced graphene oxide coating on critical heat flux enhancement. Int J Heat Mass Transf. 2013;60:763–71.

Su G, Fukuda K, Morita K, Pidduck M, Jia D, Matsumoto T, Akasaka R. Applications of artificial neural network for the prediction of flow boiling curves. J Nucl Sci Technol. 2002;39(11):1190–8.

Ertunc HM. Prediction of the pool boiling critical heat flux using artificial neural network. IEEE Trans Compon Packag Technol. 2006;29(4):770–7.

Das MK, Kishor N. Determination of heat transfer coefficient in pool boiling of organic liquids using fuzzy modeling approach. Heat Transf Eng. 2010;31(1):45–58.

Kishor N, Das MK. Soft computing techniques for prediction of boiling heat transfer coefficient of liquids on copper-coated tubes. Appl Artif Intell. 2010;24(3):210–32.

Hernandez Y, Lotya M, Rickard D, Bergin SD, Coleman JN. Measurement of multicomponent solubility parameters for graphene facilitates solvent discovery. Langmuir. 2009;26(5):3208–13.

Balandin AA, Ghosh S, Bao W, Calizo I, Teweldebrhan D, Miao F, Lau CN. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008;8(3):902–7.

Arao Y, Kubouchi M. High-rate production of few-layer graphene by high-power probe sonication. Carbon. 2015;95:802–8.

Jabbarzadeh F, Siahsar M, Dolatyari M, Rostami G, Rostami A. Fabrication of new mid-infrared photodetectors based on graphene modified by organic molecules. IEEE Sens J. 2014;15(5):2795–800.

Gupta S, Irihamye A. Probing the nature of electron transfer in metalloproteins on graphene-family materials as nanobiocatalytic scaffold using electrochemistry. AIP Adv. 2015;5(3):037106.

Jabbarzadeh F, Siahsar M, Dolatyari M, Rostami G, Rostami A. Modification of graphene oxide for applying as mid-infrared photodetector. Appl Phys B. 2015;120(4):637–43.

Siahsar M, Dolatyari M, Rostami A, Rostami G. Surface-modified graphene for mid-infrared detection. Graphene Mater Adv Appl. 2017. https://doi.org/10.5772/67490.

Si Y, Samulski ET. Synthesis of water soluble graphene. Nano Lett. 2008;8(6):1679–82.

Alaferdov AV, Gholamipour-Shirazi A, Canesqui MA, Danilov YA, Moshkalev SA. Size-controlled synthesis of graphite nanoflakes and multi-layer graphene by liquid phase exfoliation of natural graphite. Carbon. 2014;69:525–35.

Konios D, Stylianakis MM, Stratakis E, Kymakis E. Dispersion behaviour of graphene oxide and reduced graphene oxide. J Colloid Interface Sci. 2014;430:108–12.

Johnson DW, Dobson BP, Coleman KS. A manufacturing perspective on graphene dispersions. Curr Opin Colloid Interface Sci. 2015;20(5–6):367–82.

Ayan-Varela M, Paredes JI, Guardia L, Villar-Rodil S, Munuera JM, Díaz-González M, Fernández-Sánchez CE, Martínez-Alonso A, Tascón JM. Achieving extremely concentrated aqueous dispersions of graphene flakes and catalytically efficient graphene-metal nanoparticle hybrids with flavin mononucleotide as a high-performance stabilizer. ACS Appl Mater Interfaces. 2015;7(19):10293–307.

Hung YF, Cheng C, Huang CK, Yang CR. A facile method for batch preparation of electrochemically reduced graphene oxide. Nanomaterials. 2019;9(3):376.

Kang DW, Shin HS. Control of size and physical properties of graphene oxide by changing the oxidation temperature. Carbon Lett. 2012;13(1):39–43.

Zhang TY, Zhang D. Aqueous colloids of graphene oxide nanosheets by exfoliation of graphite oxide without ultrasonication. Bull Mater Sci. 2011;34(1):25–8.

Ying JY, Benziger JB, Navrotsky A. Structural evolution of colloidal silica gels to glass. J Am Ceram Soc. 1993;76(10):2561–70.

Rivero PJ, Urrutia A, Goicoechea J, Zamarreño CR, Arregui FJ, Matías IR. An antibacterial coating based on a polymer/sol–gel hybrid matrix loaded with silver nanoparticles. Nanosc Res Lett. 2011;6(1):305.

Kline SJ. Describing uncertainty in single sample experiments. Mech Eng. 1953;75:3–8.

Andonovic B, Ademi A, Grozdanov A, Paunović P, Dimitrov AT. Enhanced model for determining the number of graphene layers and their distribution from X-ray diffraction data. Beilstein J Nanotechnol. 2015;6(1):2113–22.

Andonovic B, Grozdanov A, Paunović P, Dimitrov AT. X-ray diffraction analysis on layers in graphene samples obtained by electrolysis in molten salts: a new perspective. Micro Nano Lett. 2015;10(12):683–5.

Amaro-Gahete J, Benítez A, Otero R, Esquivel D, Jiménez-Sanchidrián C, Morales J, Caballero A, Romero-Salguero FJ. A comparative study of particle size distribution of graphene nanosheets synthesized by an ultrasound-assisted method. Nanomaterials. 2019;9(2):152.

Simón M, Benítez A, Caballero A, Morales J, Vargas O. Untreated natural graphite as a graphene source for high-performance li-ion batteries. Batteries. 2018;4(1):13.

Jaikumar A. Multiscale mechanistic approach to enhance pool boiling performance for high heat flux applications; 2017. Thesis. Rochester Institute of Technology.

Das S, Saha B, Bhaumik S. Experimental study of nucleate pool boiling heat transfer of water by surface functionalization with crystalline TiO2 nanostructure. Appl Therm Eng. 2017;113:1345–57.

Suryanarayana C. Experimental techniques in materials and mechanics. Boca Raton: CRC Press; 2011.

Suryanarayana C, Norton MG. X-ray diffraction: a practical approach. Berlin: Springer; 2013.

Zhang BJ, Kim KJ. Nucleate pool boiling heat transfer augmentation on hydrophobic self-assembly mono-layered alumina nano-porous surfaces. Int J Heat Mass Transf. 2014;73:551–61.

Jo H, Ahn HS, Kang S, Kim MH. A study of nucleate boiling heat transfer on hydrophilic, hydrophobic and heterogeneous wetting surfaces. Int J Heat Mass Transf. 2011;54(25–26):5643–52.

Jo H, Kim S, Kim H, Kim J, Kim MH. Nucleate boiling performance on nano/microstructures with different wetting surfaces. Nanosc Res Lett. 2012;7(1):242.

Das S, Saha B, Bhaumik S. Experimental study of nucleate pool boiling heat transfer of water by surface functionalization with SiO2 nanostructure. Exp Therm Fluid Sci. 2017;81:454–65.

Rohsenow WM. A method of correlating heat transfer data for surface boiling of liquids. Cambridge: MIT Division of Industrial Corporation; 1951.

Li Y-Y, Chen Y-J, Liu Z-H. A uniform correlation for predicting pool boiling heat transfer on plane surface with surface characteristics effect. Int J Heat Mass Transf. 2014;77:809–17.

Li N, Betz AR. Boiling performance of graphene oxide coated copper surfaces at high pressures. J Heat Transf. 2017;139(11):111504.

Akbari A, Fazel SAA, Maghsoodi S, Kootenaei AS. Pool boiling heat transfer characteristics of graphene-based aqueous nanofluids. J Therm Anal Calorim. 2019;135(1):697–711.

Basheer IA, Hajmeer M. Artificial neural networks: fundamentals, computing, design, and application. J Microbiol Methods. 2000;43(1):3–31.

Najafi G, Ghobadian B, Tavakoli T, Buttsworth D, Yusaf T, Faizollahnejad M. Performance and exhaust emissions of a gasoline engine with ethanol blended gasoline fuels using artificial neural network. Appl Energy. 2009;86(5):630–9.

Ismail HM, Ng HK, Queck CW, Gan S. Artificial neural networks modelling of engine-out responses for a light-duty diesel engine fuelled with biodiesel blends. Appl Energy. 2012;92:769–77.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gajghate, S.S., Barathula, S., Das, S. et al. Experimental investigation and optimization of pool boiling heat transfer enhancement over graphene-coated copper surface. J Therm Anal Calorim 140, 1393–1411 (2020). https://doi.org/10.1007/s10973-019-08740-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08740-5