Abstract

Background

Halomonas boliviensis is a halophilic microorganism that accumulates poly(3-hydroxybutyrate) (PHB) using different carbons sources when nitrogen is depleted from the culture medium. This work presents an improved production of PHB using an air-lift reactor (ALR) that was fed with a concentrated solution of a carbon source, and was supplemented with an adequate airflow rate.

Results

Simple production media were used to study PHB production by H. boliviensis in an ALR. Glucose was first used as the main carbon source and was fed during the exponential phase of cell growth. The maximum CDW and PHB content were 31.7 g/L and 51 wt%, respectively, when the airflow rate entering the reactor varied between 0.5 and 1.2 L/min. Changing the air inflow to 0.5–0.9 L/min resulted in an improvement in PHB accumulation (62 wt%). A cultivation was performed by using the latter range of airflow rate and feeding glucose only when nitrogen was depleted from the medium; a considerable enhancement in PHB content (72 wt%) and CDW (27 g/L) was achieved under these conditions. Moreover, PHB was also produced using molasses as the main carbon source. Residual cell mass was about the same to that achieved with glucose, however the PHB content (52 wt%) was lower.

Conclusions

PHB production by H. boliviensis in an ALR using a simple medium is possible. CDW and PHB content in H. boliviensis can be improved with respect to batch cultivations previously reported when a carbon source is fed to the reactor. The best strategy for the production of PHB consisted of starting the cultivation in a batch mode while glutamate was present in the medium; glucose should be fed when glutamate is depleted from the medium to keep an excess of the carbon source during the synthesis of PHB.

Similar content being viewed by others

Background

From 1950 to 2015, 6300 million tons of plastic waste had been produced, of which only 9% was recycled, 12% was incinerated and 79% was deposited in landfills or the natural environment (Rabnawaz et al. 2017). Furthermore, polypropylene and polyethylene contributed 46% to the global production of plastics in 2015 and it is expected that approximately 12,000 million tons of non-biodegradable polymers waste will be allocated in landfills by 2050 (Rabnawaz et al. 2017). Biodegradable polymers have become an interesting alternative to petrochemical plastics, which are highly persistent in the environment and are produced in large amounts (Geyer et al. 2017). Polyhydroxyalkanoates (PHAs) are intracellular compounds that are stored as carbon and energy reservoirs in several microorganisms (Steinbüchel and Füchtenbusch 1998). PHAs are recognized as non-toxic, biodegradable, completely recyclable into organic waste and resemble many characteristics of petroleum-derived plastics and elastomers (Steinbüchel and Füchtenbusch 1998; Lee 1996). Poly(3-hydroxybutyrate) (PHB) is the most common type of the PHAs and has similar properties to polypropylene (Lee 1996; Harding et al. 2007).

PHB has been industrially produced using bacteria such as Cupriavidus necator (Kim et al. 1994), Azohydromonas lata (Wang and Lee 1997) and recombinant Escherichia coli strains (Liu et al. 1998; Choi et al. 1998), which have attained the highest polymer accumulations and productivities. However, the commercialization of PHB is impaired by its production costs. PHA price varies from 1.5 to 5 € per kg (Chanprateep 2010), whilst polypropylene price varies from 0.2 to 0.4 € per kg (Urtuvia et al. 2014). Moreover, the current industrial production of PHAs is still performed in small-scale (from 1000 to 20,000 tons per year) that also increments the cost of the polymers (Chanprateep 2010). In this respect, the commercialization of PHB may be restricted to applications in tissue engineering and other biomedical appliances (Manavitehrani et al. 2016) in which oil-derived plastics cannot be utilized. The main factors that influence the price of PHAs are the carbon source used in the medium for the production of PHAs, the type of production process and the purification of the polymer (Lee 1996; Chanprateep 2010). Furthermore, the dominant contribution to the environmental deterioration in the production of PHB is the large requirement for energy, particularly steam for sterilization procedures, as well as high requirement of freshwater (Harding et al. 2007).

Research on halophilic microorganisms has shown that their requirement of NaCl for growth facilitates PHB production under non-sterile conditions, which reduces the costs related to the generation of steam for the sterilization of media, reactors, and pipes (Yin et al. 2015; Quillaguamán et al. 2010). Moreover, seawater could be used to dissolve the components of a culture medium; hence the consumption of freshwater could be reduced (Yue et al. 2014). Among halophilic bacteria, some species of the genus Halomonas such as a recombinant H. campaniensis LS21, Halomonas sp. TD01 and H. boliviensis have reached high concentrations and accumulations of PHB in batch, fed-batch and continuous cultures using stirred tank reactors (Yue et al. 2014; Tan et al. 2011; Quillaguamán et al. 2008). Since generally Halomonas species can metabolize several carbon sources, hydrolysates of agro-industrial residues or a mixture of carbohydrates and volatile fatty acids can be used as cheap substrates for the production of PHB (Yin et al. 2015; Quillaguamán et al. 2010). Halomonas sp. TD01 and H. boliviensis have reached PHB contents as high as 80 wt% and a cell dry weight (CDW) of 80 g/L and 44 g/L, respectively, from glucose (Tan et al. 2011; Quillaguamán et al. 2008), whereas a recombinant strain of H. campaniensis has been able to accumulate 70 wt% PHB and a maximum CDW of 73 g/L using substrates that imitated kitchen wastes (Yue et al. 2014). Recently, H. boliviensis was grown on an air-lift reactor (ALR) to produce PHB from starch hydrolysate in a batch culture (Rivera-Terceros et al. 2015). The maximum PHB accumulation attained was 41 wt% with a CDW of 8 g/L (Rivera-Terceros et al. 2015). ALRs have several interesting features, for instance, their design and construction are simple, low energy is required for mass transfer because they are pneumatically mixed by air bubbles and generate low shear stress on cells suspended in the medium (Siege and Robinson 1992). These characteristics have also motivated research on PHB production by non-halophilic bacteria that were grown on ALRs. Azohydromonas australica and C. necator have reached about 72 wt% PHB and a CDW of 10 g/L and 32 g/L, respectively (Gahlawat et al. 2012; Tavares et al. 2004), whilst cultivation of Burkholderia sacchari in an ALR has led to 41 wt% PHB and a maximum CDW of 150 g/L (Pradella et al. 2010).

In this study, we report PHB production by H. boliviensis that was grown in an ALR. The purpose of this study was to investigate cultivation conditions that improve cell growth and PHB accumulation in H. boliviensis using a simple production media in a reactor whose construction, operation and scalability are relatively straightforward. Moreover, the ARL was not operated under strict sterile conditions in our experiments. Some chemical compounds that were previously included in the medium of H. boliviensis were removed because their absence did not show any detrimental effect on cell growth or PHB accumulation in the cells, and should reduce the costs of supplies. Furthermore, a carbon source was fed to the reactor to maintain an excess of the substrate during the cultivation to enhance cell concentration in the medium and PHB content.

Methods

Microorganism and its maintenance

Halomonas boliviensis LC1T = DSM 15516T was used in this study. The strain was maintained at 4 °C on solid TSA (tryptone soy agar) medium containing 5% (w/v) NaCl.

Culture medium with carbohydrates as carbon source

A minimal culture medium was used to determine the optimum concentration of molasses or glucose as a carbon source for the production of PHB. Seed culture medium contained (g/L): molasses 15; glucose 5; monosodium glutamate 6 and NaCl 45, with pH initially adjusted to 7.5 using 3 M NaOH. H. boliviensis was grown in a 100-mL seed culture medium contained in a 1-L Erlenmeyer flask at 180 rpm rotatory shaking at 35 °C for 18 h until the culture broth reached an OD600 = 3 ± 0.4. Subsequently, 5 mL of the seed culture was inoculated in 100 mL of PHB production medium that contained (g/L): monosodium glutamate 2; NaCl 45 and the following carbohydrates were used in 8 different experiments (g/L): (1) molasses 30; (2) molasses 20; (3) molasses 15, glucose 5; (4) molasses 10, glucose 10; (5) molasses 5, glucose 15; (6) molasses 7.5, glucose 2.5; (7) molasses 5, glucose 5; (8) molasses 2.5, glucose 7.5. All media were sterilized at 121 °C for 15 min. These experiments were incubated in a rotary shaker at 180 rpm at 35 °C. Samples were withdrawn at 24 and 30 h.

Production of PHB in an air-lift reactor

For the production of PHB in an air-lift reactor, a medium previously optimized in Erlenmeyer flasks was used. The seed culture medium contained (g/L): molasses 15; glucose 5; monosodium glutamate 6; NaCl 45. Furthermore, a culture medium with glucose as the sole carbohydrate was prepared with (g/L): NaCl 50; KH2PO4 1.6; Na2HPO4 6.6; glucose 20; monosodium glutamate 10. The sterile minimal medium was supplemented with 1 mL/L of trace elements and 1 mL/L of 1 M MgSO4·7H2O, both solutions were filter-sterilized (0.2 μm filter) before they were added to the medium. Composition of trace elements solution was (g/L): CaCl2·2H2O 0.5; FeCl3·6H2O 16.7; ZnSO4·7H2O 0.18; CuSO4·5H2O 0.16; MnSO4·5H2O 0.11; Na-EDTA 20.1. The medium was sterilized at 121 °C for 15 min.

For both media, the seed culture was prepared in 80 mL contained in a 1-L Erlenmeyer flask. In all experiments, the initial pH of the medium was adjusted to 7.5 using 3 M NaOH/H3PO4. The medium was seeded with colonies of H. boliviensis and incubated with shaking at 180 rpm at 35 °C between 16 and 18 h until the culture broth reached an OD600 = 2.9 ± 0.03.

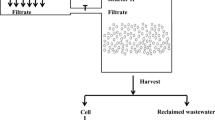

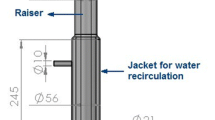

An ALR used in previous studies was also utilized in these experiments (Rivera-Terceros et al. 2015). In our experiments, the reactor was not sterilized and its operation was not kept under strict sterile conditions. Inlets of the ALR for sensors and for the addition of solutions of an acid, a base and carbon sources were open to the environment. The seed culture was added to 1-L ARL containing 720 mL of the culture medium that had the same composition of that used for the seed culture. However, in the bioreactor, the concentration of monosodium glutamate was increased to 15 g/L in all cases to attain high cell density. Four different experiments were carried out for the production of PHB in the ALR varying the air inflow to the reactor between: (1) 0.5–1.2 L/min during the first 18 h afterward the air inflow was kept at 1.2 L/min; glucose was the main carbon source, and was fed to the reactor after 13.5 h of cultivation; (2) 0.5–0.9 L/min (the maximum airflow rate was reached at 13.5 h) and under the same conditions of experiment 1; (3) 0.5–0.9 L/min (the maximum airflow rate was reached at 9 h), with glucose fed after 24 h; (4) 0.5–0.9 L/min (the maximum airflow rate was reached at 30 h), with molasses and glucose used as the main carbon source and molasses fed to the reactor after 14 h of cultivation. In all experiments, the pH of the medium was maintained at 7.5 by the addition of 3 M NaOH/H3PO4 and the temperature was kept at 35 °C using a jacket through which water was recycled from a thermostatic bath. Antifoam (polypropylene glycol 2000) was added to the growth medium as required during cultivation. A volume of 10 mL was taken from the bioreactor approximately every 4.5 h and was analyzed to determine the concentration of carbohydrates, glutamate, cell growth and PHB produced. The cultivations were fed with a concentrated solution of glucose (500 g/L) or molasses (500 g/L) using a peristaltic pump (LAMBDA Multiflow) at a flow rate that ranged between 2.5 and 3 mL/h for 7 h when glucose was fed as carbon source and for 6 h when molasses was fed as carbon source. Subsequently, either glucose or molasses were manually added to the reactor whenever a decrease in the carbohydrate concentration was observed after an HPLC analysis.

Determination of cell growth

Cell growth was monitored by measuring OD600 in a spectrophotometer (Biochrom, Libra S22) after diluting the cultivation broth with saline solution, 0.9% (w/v) NaCl, to an approximate OD600 of 0.1. Cell dry weight (CDW) was obtained by centrifuging 1 mL of culture medium in a 1.5-mL microtube and was centrifuged at 7000×g for 10 min using a microcentrifuge (Thermo scientific). The supernatant was removed, filtered (0.22 μm filter) and stored at − 20 °C for further analyses. The cell pellet obtained was then suspended, washed with 1 mL 0.9% (w/v) NaCl and centrifuged again. The pellet was dried at 85 °C overnight, cooled to room temperature in a desiccator and weighed. All samples were analyzed in triplicate.

Determination of PHB content by gas chromatography

PHB content in the cells was determined by gas chromatography (GC) (Agilent 7890B) following the procedure described by Oehmen et al. (2005). The dried pellets obtained from the determination of CDW were subjected to methanolysis (Oehmen et al. 2005). An HP-INNOWAX (30 m length) capillary column was utilized for the analysis. Poly(3-hydroxybutyrate-co-3-valerate) (Sigma) was used to elaborate a standard curve and benzoic acid was used as an internal standard. Residual cell mass (RCM) was calculated as the difference between the CDW and PHB concentration.

Quantitative analysis of carbohydrates

The concentration of carbohydrates in the medium was analyzed by the dinitrophenol method (Ross 1959). After centrifuging the medium at 7000×g for 10 min, the supernatant was diluted (1:25) in distilled water; 25 mL of the diluted supernatant was clarified by adding 0.5 mL of K4Fe(CN)6·3H2O (150 g/L), 0.5 mL of ZnSO4·7H2O (300 g/L) and 0.1 mL of Na2HPO4 (100 g/L). The solution was then filtered using a filter paper. For the dinitrophenol reagent, solution A was prepared by dissolving 0.3572 g of 2,4-dinitrophenol in 11.5 mL of NaOH 5% (w/v) and then 0.125 g of phenol was added; solution B was prepared by dissolving 5 g of sodium and potassium tartrate in 25 mL of distilled water. Solutions A and B were mixed and completed to 1 L with NaOH 5% (w/v). To determine glucose, 2 mL of the clarified solution was mixed with 6 mL of dinitrophenol reagent. The mixture was heated in a boiling water bath for 6 min, then cooled in a water bath at room temperature and absorbance of the resulting solution was measured using a spectrophotometer (Biochrom, Libra S22) at 560 nm. A calibration curve was built using glucose as standard.

Quantification of total sugars in molasses was performed by clarification followed by acid hydrolysis with 1.5 mL of 9.5% (v/v) HCl. Then 12.5 mL of this solution and distilled water were mixed in a 25-mL volumetric flask. The resulting solution was heated at 70 °C for 10 min in a water bath, was cooled and treated with 4 N NaOH to reach a pH of about 8. Subsequently, 2 mL of this solution was combined with 6 mL of dinitrophenol reagent and the determination was carried out as in the case of glucose. Sucrose was hydrolyzed and used to construct a calibration curve.

Quantification of monosodium glutamate

The concentration of glutamate in the supernatant was determined by high-performance liquid chromatography (HPLC) (Thermo Scientific, UltiMate 3000). The compounds were separated with a C12 RESTEK column. A solution containing 10 mL/L acetonitrile and 340 μL/L H3PO4 dissolved in deionized water was used as the mobile phase at a flow rate of 0.9 mL/min and at 65 °C. All compounds were quantified by a UV diode array detector at 210 nm wavelength at 35 °C. For the analysis, all samples were acidified with 1 μL concentrated (85%) H3PO4.

Determination of metal ions in a culture medium containing molasses

A combined flame and furnace atomic absorption spectrometer (AA500FG model, PG instruments) equipped with deuterium lamp background correction, hollow cathode lamps, and air–acetylene burner was used for the determination of the metals. Moreover, graphite furnace was used to determine metal ions that were not detected by flame quantification. We analyzed lead, iron, potassium, magnesium, manganese, zinc, cadmium and cobalt. The instrumental parameters were those recommended by the manufacturer. Samples were analyzed in triplicate.

Results and discussion

Effect of air inflow rate to the ALR on PHB production using glucose as the main carbon source

Halomonas boliviensis produced PHB in an air-lift reactor operated in a batch mode in which PHB content was 41 wt% and CDW was 8 g/L (Rivera-Terceros et al. 2015). The reactor was not operated under strict sterile conditions. To improve cell growth and accumulation of PHB, we decided to feed the ALR with a concentrated solution of glucose so that glucose is maintained in excess in the medium (Figs. 1 and 2). Moreover, a different medium composition with respect to that previously reported was used in this study (Rivera-Terceros et al. 2015). We found that the magnesium concentration can be reduced 20-fold and ammonium chloride can be removed from the medium composition (data not shown), thereby monosodium glutamate (MSG) is left as the sole nitrogen source in the medium. In the first cultivation, the air inflow rate varied from 0.5 to 1.2 L/min during the first 18 h (Fig. 1). In Fig. 1, the RCM shows that cells grew while there was MSG in the medium and PHB content increased in a linear trend. During the nitrogen depletion phase, RCM was approximately constant denoting that cells reached the stationary phase of growth while PHB was rapidly accumulated in the cells. The maximum PHB accumulation reached was 51 wt% at 50.5 h of cultivation and, at this time, CDW was 28.2 g/L, which increased slightly to 31.7 g/L after 70 h of cultivation.

Production of PHB by H. boliviensis using an air-lift reactor with an air inflow that varied between 0.5 and 1.2 L/min and feed of glucose after 13.5 h of cultivation. The maximum airflow was reached at 18 h, pH was maintained at 7.5 and water at 35 °C was circulated by the jacket of the reactor. Glucose was the main carbon source. A solution of glucose (500 g/L) was fed to the reactor after 13.5 h of cultivation. Experiments were performed in duplicate. CDW, cell dry weight and RCM, residual cell mass

Production of PHB by H. boliviensis using an air-lift reactor with an air inflow that varied between 0.5 and 0.9 L/min and feed of glucose after 13.5 h of cultivation. The maximum airflow rate was reached at 13.5 h, pH was maintained at 7.5 and water at 35 °C was circulated by the jacket of the reactor. Glucose was the main carbon source. A solution of glucose (500 g/L) was fed to the reactor after 13.5 h of cultivation. Experiments were performed in duplicate. CDW, cell dry weight and RCM, residual cell mass

Inducing oxygen limitation during the cultivation of H. boliviensis on starch hydrolysate in a stirred tank reactor quickened PHB accumulation in the cells to some extent (Quillaguamán et al. 2005). Taking this into consideration, we decided to decrease to 0.9 L/min the maximum airflow supplied to the ALR (Fig. 2). Figure 2 shows that PHB accumulation was faster compared to our first experiment before the nitrogen depletion phase. When MSG was depleted from the medium, cells stored the major amount of PHB that was again observed during the stationary phase of growth. At 50.5 h of cultivation, PHB content and CDW were 59 wt% and 24 g/L, respectively, which showed an improvement in PHB accumulation although CDW was slightly lower than that observed in Fig. 1. However, Fig. 2 depicts further that PHB content increased to 62 wt%, which also rose CDW to 28 g/L, at 70 h of cultivation. Although there was an improvement in the PHB content between 50.5 and 70 h of cultivation, PHB volumetric productivity was about 0.25 g/L/h for these cultivation times, which suggested that PHB production could be improved if CDW and PHB synthesis were accelerated in the ALR.

A high intracellular concentration of NAD(P)H induces PHB synthesis in many bacteria (Steinbüchel and Füchtenbusch 1998; Lee 1996). The enzyme acetoacetyl-CoA reductase participates in the synthesis of PHB by oxidizing NAD(P)H (Steinbüchel and Füchtenbusch 1998; Lee 1996). High concentrations of NAD(P)H can be promoted by limiting or depleting an essential nutrient in the medium such as oxygen, nitrogen, phosphorus among others (Steinbüchel and Füchtenbusch 1998; Lee 1996). The activity of acetoacetyl-CoA reductase in H. boliviensis can be triggered by either NADH or NADPH, showing that the synthesis of PHB is adaptable to different conditions in H. boliviensis (Perez-Zabaleta et al. 2016). Nitrogen depletion has been used to favor the production of PHB by H. boliviensis (Quillaguamán et al. 2008), although oxygen limitation can also induce PHB storage in the cells (Quillaguamán et al. 2005). Figures 1 and 2 suggest that a combination of nitrogen depletion in the medium and a reduction in the air inflow to the reactor may lead to intracellular concentrations of NADH and NADPH that direct the carbon flux towards PHB formation in H. boliviensis.

Increasing CDW and PHB content in the ALR

Figures 1 and 2 show that most PHB is accumulated during the cells’ stationary phase of growth; hence, most of the carbon source should be supplied during the nitrogen depletion phase. On the other hand, the cultivation of Burkholderia sacchari in an ALR for PHB production showed that its exponential phase was not affected while sucrose was consumed from 30 to 0.5 g/L, rather CDW was enhanced in a relatively short time of cultivation (Pradella et al. 2010). In this respect, glucose concentration in the medium of H. boliviensis was not replenished during the first 24 h. Glucose was only fed during the nitrogen depletion phase (Fig. 3). Air inflow to the reactor varied between 0.5 and 0.9 L/min and the maximum airflow rate was reached at 9 h to avoid an early limitation of oxygen in the cells. RCM had approximately the same trend as that observed in Fig. 2 while glucose and glutamate were being consumed; however, the PHB content (41 wt%) was higher than those reached in the previous cultivations before the nitrogen depletion phase (Figs. 1, 2, 3). Upon the depletion of MSG, PHB was accumulated rapidly, whereas glucose was being supplemented to the reactor until a PHB content of 72 wt% was reached at 50 h of cultivation (Fig. 3). Moreover, the maximum CDW (27 g/L) and PHB (20 g/L) concentrations were also reached after 50 h. Albeit CDW was similar in all cultivations, the shorter production time and the higher PHB content observed in Fig. 3 than those obtained in the previous experiments (Figs. 1 and 2) resulted in a volumetric productivity of 0.40 g/L/h, which is 1.6-fold higher than those reached in this study.

Production of PHB by H. boliviensis using an air-lift reactor with an air inflow that varied between 0.5 and 0.9 L/min and feed of glucose after 24 h of cultivation. The maximum airflow rate was reached at 9 h, pH was maintained at 7.5 and water at 35 °C was circulated by the jacket of the reactor. Glucose was the main carbon source. A solution of glucose (500 g/L) was fed to the reactor after 24 h of cultivation. Experiments were performed in duplicate. CDW, cell dry weight and RCM, residual cell mass

Moreover, the PHB production attained in this experiment showed a considerable improvement compared to that reached in batch cultivations (i.e., 41 wt% PHB and CDW of 8 g/L) previously reported (Rivera-Terceros et al. 2015). The maximum PHB accumulation in our cultivations is similar to those reported for Azohydromonas australica and C. necator (72 wt% PHB) (Gahlawat et al. 2012; Tavares et al. 2004) and higher than that observed in B. sacchari (41 wt%) (Pradella et al. 2010). CDW of H. boliviensis is higher than that obtained for A. australica (10 g/L), similar to that reached by C. necator (32 g/L) and lower than that observed in B. sacchari (150 g/L) when these bacterial species are grown in ALRs (Gahlawat et al. 2012; Tavares et al. 2004; Pradella et al. 2010). The PHB content of H. boliviensis was also comparable to the highest reported in cultivations performed in stirred tank reactors (i.e., between 70 and 85 wt%) (Steinbüchel and Füchtenbusch 1998); however, CDW of H. boliviensis has to be further improved to be similar to the highest attained so far (i.e., between 40 and 160 g/L) in stirred thank reactors (Steinbüchel and Füchtenbusch 1998). Furthermore, Halomonas sp. Td01 and a recombinant strain of H. campaniensis have reached a CDW of 80 g/L and 73 g/L, respectively, in stirred tank reactors. The results that are shown in Fig. 3 suggest that an adequate combination of glucose, glutamate, and air inflow rate to the ALR could prolong the active cell growth while PHB is being synthesized; perhaps glutamate concentration in the medium could be maintained at a level that delays the stationary phase of cell growth.

PHB production using molasses and glucose as carbon sources

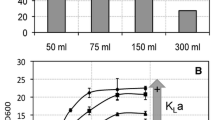

The cultivation medium used in our previous cultivations (Figs. 1, 2, 3) permitted the reduction in the amount of supplies required for PHB production. H. boliviensis, however, also metabolizes other carbohydrates as carbon source, for instance, a combination of molasses and glucose was used before to produce PHB (Guzmán et al. 2012). PHAs have also been produced by other microorganisms such as A. vinelandii UWD, recombinant E. coli and Bacillus megaterium using molasses (Chanprateep 2010). Molasses is an inexpensive carbon source and an industrial by-product (Chanprateep 2010), which contains large amounts of reducing sugars and usually vitamins and trace elements (Crueger and Crueger 1990). In this respect, we decided to further simplify the culture medium for PHB production by H. boliviensis. In shake flasks experiments, glutamate, sodium chloride and different concentrations of glucose and molasses were the only components included in the culture medium. We determined various metals in this medium by atomic absorption spectrometry. We found (mg/L): Pb 0.007, Fe 0.23, K 271.7, Mg 0.0115, Mn 0.252, Zn 0.104 (the maximum standard deviation for the average values was 0.0009 mg/L); cadmium and cobalt were not detected. The medium had indeed various metal ions that we included as trace elements in our previous experiments. Table 1 shows PHB production and CDW obtained from samples taken at 24 and 30 h. In samples taken at 24 h, CDW was about the same when 30 or 20 g/L of molasses was used in the medium, although at 20 g/L both PHB content and concentration improved slightly. Glucose was used to partially substitute molasses while maintaining a total concentration of 20 g/L (Table 1). The maximum CDW, PHB content and PHB concentration were obtained when the concentration of glucose in the medium was between 5 and 10 g/L. Moreover, CDW and PHB production reduced when the total concentration of the carbohydrates was decreased to 10 g/L (Table 1). After 30 h of cultivation, CDW and PHB production improved when the initial concentration of the carbohydrates was 20 g/L, although they declined when the concentration of the carbohydrates was 10 g/L (Table 1).

Cultivation in an ALR was performed using an initial concentration of 15 g/L molasses, 5 g/L glucose, 15 g/L glutamate and 45 g/L NaCl (Fig. 4). When a total sugar concentration of 12 g/L was present in the medium, a concentrated solution of molasses was fed to the reactor (Fig. 4). Most PHB was produced during the nitrogen depletion phase and reached a maximum accumulation of 52 wt% with a concomitant CDW of 16 g/L, PHB concentration of 8 g/L (Fig. 4) and a maximum volumetric productivity of 0.15 g/L/h after 54 h of cultivation. These results show that it is possible to produce PHB using a more economical medium. There was also an improvement in the PHB concentration with respect to those obtained in batch cultivations performed in a stirred tank reactor (c.a. 4.3 g/L) (Guzmán et al. 2012), although the polymer volumetric productivity was about the same (0.13 g/L/h) (Guzmán et al. 2012). Moreover, the production of PHB using molasses (Fig. 4) was lower than that reached using glucose (Fig. 3). Figures 3 and 4 also show that PHB was more rapidly accumulated when only glucose was present in the medium than with the mixture of molasses and glucose. Nevertheless, RCM was about the same (approximately 9.5 g/L) in both cultivations (Figs. 3, 4), implying that cell growth was not inhibited by molasses. Probably there are compounds in the medium containing molasses that hinder the synthesis of PHB or reduce the intracellular levels of NAD(P)H. Additional studies are required to evaluate molasses or other renewable materials as carbon sources for the production of the biopolyester by H. boliviensis.

Production of PHB by H. boliviensis using an air-lift reactor with an air inflow that varied between 0.5 and 0.9 L/min and molasses and glucose used as carbon sources. The maximum airflow rate was reached at 30 h, pH was maintained at 7.5 and water at 35 °C was circulated by the jacket of the reactor. A mixture of molasses (15 g/L) and glucose (5 g/L) was used as carbon source in the medium. A solution of molasses (500 g/L) was fed to the reactor after 14 h of cultivation. Experiments were performed in duplicate. CDW, cell dry weight and RCM, residual cell mass

Conclusions

PHB production by H. boliviensis in an ALR using a simple medium is possible. CDW and PHB content in H. boliviensis can be improved with respect to batch cultivations previously reported when a carbon source is fed to the reactor. The best strategy consisted of starting the cultivation in a batch mode while glutamate is present in the medium; glucose should be fed when glutamate is depleted from the medium to keep an excess of the carbon source during the synthesis of PHB. Moreover, limiting the amount of air inflow rate to the reactor can enhance the accumulation of PHB in the cells. RCM using molasses was as high as that obtained with glucose; however, the PHB content reached using molasses was lower than the maximum reached with glucose. Further research is required to optimize the production process of PHB when molasses is used as the main carbon source.

Availability of data and materials

All data generated or analyzed during this study are included in this article.

Abbreviations

- PHAs:

-

Polyhydroxyalkanoates

- PHB:

-

Poly(3-hydroxybutyrate)

- CDW:

-

Cell dry weight

- RCM:

-

Residual cell mass

- ALR:

-

Air-lift reactor

- MSG:

-

Monosodium glutamate

- TSA:

-

Triptone soy agar

- OD600 :

-

Optical density at 600 nm

- GC:

-

Gas chromatography

- HPLC:

-

High-performance liquid chromatography

References

Chanprateep S (2010) Current trends in biodegradable polyhydroxyalkanoates. J Biosci Bioeng 110:621–632

Choi J, Lee S, Han K (1998) Cloning of the Alcaligenes latus polyhydroxyalkanoate biosynthesis genes and use of these genes for enhanced production of poly(3-hydroxybutyrate) in Escherichia coli. Appl Environ Microbiol 64:4897–4903

Crueger W, Crueger A (1990) Substrates for industrial fermentation. In: Brock T (ed) Biotechnology: a textbook of industrial microbiology. Sinauer Associates, Sunderland, pp 59–62

Gahlawat G, Sengupta B, Srivastava A (2012) Enhanced production of poly(3-hydroxybutyrate) in a novel airlift reactor with in situ cell retention using Azohydromonas australica. J Ind Microbiol Biotechnol 39:1377–1384

Geyer R, Jambeck J, Law K (2017) Production, use, and fate of all plastics ever made. Sci Adv 3:e1700782. https://doi.org/10.1126/sciadv.1700782

Guzmán D, Balderrama-Subieta A, Cardona-Ortuño C, Guevara-Martínez M, Callisaya-Quispe N, Quillaguamán J (2012) Evolutionary patterns of carbohydrate transport and metabolism in Halomonas boliviensis as derived from its genome sequence: influences on polyester production. Aquat Biosyst 8:9. https://doi.org/10.1186/2046-9063-8-9

Harding K, Dennis J, von Blottnitz H, Harrison S (2007) Environmental analysis of plastic production processes: comparing petroleum-based polypropylene and polyethylene with biologically-based poly-beta-hydroxybutyric acid using life cycle analysis. J Biotechnol 130:57–66

Kim B, Lee S, Lee S, Chang H, Chang Y, Woo S (1994) Production of poly(3-hydroxybutyric acid) by fed-batch culture of Alcaligenes eutrophus with glucose concentration control. Biotechnol Bioeng 43:892–898

Lee S (1996) Bacterial polyhydroxyalkanoates. Biotechnol Bioeng 49:1–14

Liu F, Li W, Ridgway D, Gu T (1998) Production of poly-β-hydroxybutyrate on molasses by recombinant Escherichia coli. Biotechnol Lett 20:345–348

Manavitehrani I, Fathi A, Badr H, Daly S, Shirazi A, Dehghani F (2016) Biomedical applications of biodegradable polyesters. Polymers 8:20. https://doi.org/10.3390/polym8010020

Oehmen A, Keller-Lehmann B, Zeng R, Yuan Z, Keller E (2005) Optimisation of poly-β-hydroxyalkanoate analysis using gas chromatography for enhanced biological phosphorus removal systems. J Chromatogr A 1070:131–136

Perez-Zabaleta M, Sjöberg G, Guevara-Martínez M, Jarmander J, Gustavsson M, Quillaguamán J, Larsson G (2016) Increasing the production of (R)-3-hydroxybutyrate in recombinant Escherichia coli by improved cofactor supply. Microb Cell Fact 15:91. https://doi.org/10.1186/s12934-016-0490-y

Pradella J, Taciro M, Mateus A (2010) High-cell-density poly(3-hydroxybutyrate) production from sucrose using Burkholderia sacchari culture in airlift bioreactor. Bioresour Technol 101:8355–8360

Quillaguamán J, Hashim S, Bento F, Mattiasson B, Hatti-Kaul R (2005) Poly(β-hydroxybutyrate) production by a moderate halophile, Halomonas boliviensis LC1 using starch hydrolysate as substrate. J Appl Microbiol 99:151–157

Quillaguamán J, Doan-Van T, Guzmán H, Guzmán D, Martín J, Everest A, Hatti-Kaul R (2008) Poly(3-hydroxybutyrate) production by Halomonas boliviensis in fed-batch culture. Appl Microbiol Biotechnol 78:227–232

Quillaguamán J, Guzmán H, Van-Thuoc D, Hatti-Kaul R (2010) Synthesis and production of polyhydroxyalkanoates by halophiles: current potential and future prospects. Appl Microbiol Biotechnol 85:1687–1696

Rabnawaz M, Wyman I, Aurasa R, Chenga S (2017) A roadmap towards green packaging: the current status and future outlook for polyesters in the packaging industry. Green Chem 19:4737–4753

Rivera-Terceros P, Tito-Claros E, Torrico S, Carballo S, Van-Thuoc D, Quillaguamán J (2015) Production of poly(3-hydroxybutyrate) by Halomonas boliviensis in an air-lift reactor. J Biol Res 22:8. https://doi.org/10.1186/s40709-015-0031-6

Ross A (1959) Dinitrophenol method for reducing sugars. Potato processing. AVI Publishing Co., Inc., Westport, pp 469–470

Siege M, Robinson C (1992) Application of airlift gas-liquid-solid reactors in biotechnology. Chem Eng Sci 47:3215–3229

Steinbüchel A, Füchtenbusch B (1998) Bacterial and other biological systems for polyester production. Trends Biotechnol 16:419–427

Tan D, Xue Y, Aibaidula G, Chen G (2011) Unsterile and continuous production of polyhydroxybutyrate by Halomonas TD01. Bioresour Technol 102:8130–8136

Tavares L, da Silva E, da Cruz Pradella J (2004) Production of poly(3-hydroxybutyrate) in an airlift bioreactor by Ralstonia eutropha. Biochem Eng J 18:21–31

Urtuvia V, Villegas P, González M, Seeger M (2014) Bacterial production of the biodegradable plastics polyhydroxyalkanoates. Int J Biol Macromol 70:208–213

Wang F, Lee S (1997) Poly(3-hydroxybutyrate) production with high productivity and high polymer content by a fed-batch culture of Alcaligenes latus under nitrogen limitation. Appl Environ Microbiol 63:3703–3706

Yin J, Chen J, Wu Q, Chen G (2015) Halophiles, coming stars for industrial biotechnology. Biotechnol Adv 33:1433–1442

Yue H et al (2014) A seawater-based open and continuous process for polyhydroxyalkanoates production by recombinant Halomonas campaniensis LS21 grown in mixed substrates. Biotechnol Biofuels 7:108

Acknowledgements

The authors would like to thank the Swedish International Development Cooperation Agency (Sida) for supporting our research work.

Funding

This work was supported by the Swedish International Development Cooperation Agency (Sida) for supporting our research work.

Author information

Authors and Affiliations

Contributions

NOV and JDQ performed the experimental work. MPZ and MGM contributed to the experimental work and revised the manuscript. JQ and GL were responsible for the original concept, designed the experiments. JQ wrote the manuscript. All authors read and approved the manuscript.

Corresponding author

Ethics declarations

Ethics approval, consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ortiz-Veizán, N., Daga-Quisbert, J., Perez-Zabaleta, M. et al. Improvements of poly(3-hydroxybutyrate) production in an air-lift reactor using simple production media. Bioresour. Bioprocess. 7, 22 (2020). https://doi.org/10.1186/s40643-020-00308-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40643-020-00308-8