Abstract

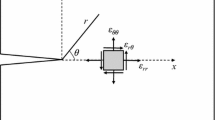

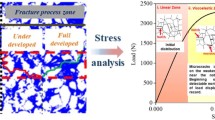

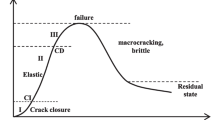

Mode I fracture toughness (KIC) quantifies the ability of a material to withstand crack initiation and propagation due to tensile loads. The International Society for Rock Mechanics (ISRM) has proposed four suggested methods for determining KIC. However, these methods present some drawbacks such as insufficient post-peak control, complex sample preparation and considerable material requirements. Here we present an alternative approach, called the pseudo-compact tension (pCT) method, to measure KIC in rocks using disc-shaped specimens loaded in pure tension. The pCT specimen has favourable features such as a simple geometry, small sample volume and minimal machining requirement. The tensile load is transmitted to the specimen through two high-strength, high-stiffness steel jaws that fit into a U-shaped groove cut in the specimen. An additional thin straight notch is introduced to act as a stress concentrator. The crack propagates from the notch tip along the ligament plane, splitting the specimen into two halves. The effects of specimen size and notch length on KIC are determined by testing specimens 100, 50 and 38 mm in diameter with different notch length ratios (0.1 ≤ a/b ≤ 0.4). Tests were performed under ambient conditions and a slow loading rate (0.1 mm/min). Our results show that the pCT method is convenient for the assessment of KIC of both fragile and ductile rocks. The method offers good control even beyond the maximum load, making it possible to study the post-peak behaviour of the material.

Similar content being viewed by others

Abbreviations

- E :

-

Young’s modulus

- ν :

-

Poisson’s ratio

- σ c :

-

Compressive strength

- σ t :

-

Tensile strength

- σ yield :

-

Yield stress

- n e :

-

Effective porosity

- ρ bulk :

-

Bulk density

- ρ :

-

Mass density

- V p :

-

Ultrasonic P-wave velocity

- V s :

-

Ultrasonic S-wave velocity

- K C :

-

Fracture toughness

- K IC :

-

Mode I fracture toughness

- K I :

-

Mode I stress intensity factor

- Y’ :

-

Dimensionless stress intensity factor

- C i :

-

Coefficients of the Y’ expression (i = 0–4)

- SR:

-

Short rod

- CB:

-

Chevron bend

- CCNBD:

-

Cracked chevron notched Brazilian disc

- SCB:

-

Semi-circular bend

- CT:

-

Compact tension

- pCT:

-

Pseudo-compact tension

- WS:

-

Wedge splitting

- MDCT:

-

Modified disk-shaped compact tension

- R :

-

Specimen radius

- B :

-

Specimen thickness

- D :

-

Specimen diameter

- G w :

-

U-shaped groove width

- G d :

-

U-shaped groove depth

- a :

-

Notch length

- b :

-

Distance from the base of the groove to the bottom of the specimen

- a/b :

-

Notch length ratio

- P :

-

Load

- P max :

-

Maximum (peak) load

- d :

-

Displacement

- d peak :

-

Displacement at the peak load

- σ max :

-

Applied stress at the maximum load

- σ 0 :

-

Applied stress

- COD:

-

Crack opening displacement

- CMOD:

-

Crack mouth opening displacement

- LPD:

-

Load point displacement

- LVDT:

-

Linear variable differential transducer

- AE:

-

Acoustic emission

- FE:

-

Finite element

- FPZ:

-

Fracture process zone

References

ABAQUS (2014) ABAQUS Version 6.14/analysis user’s guide. Dassault Systemes Simulia Corporation, Providence, Rhode Island, USA

Al-Rkaby AHJ, Alafandi ZMS (2015) Size effect on the unconfined compressive strength and modulus of elasticity of limestone rock. Electron J Geotech Eng 20:5143–5149

Alber M, Brardt A (2003) Factors influencing fracture toughness KIC from simple screening tests. Int J Rock Mech Min Sci 40:779–784. https://doi.org/10.1016/S1365-1609(03)00065-0

Aliha MRM, Mahdavi E, Ayatollahi MR (2017) The influence of specimen type on tensile fracture toughness of rock materials. Pure Appl Geophys 174:1237–1253. https://doi.org/10.1007/s00024-016-1458-x

Aliha MRM, Sistaninia M, Smith DJ et al (2012) Geometry effects and statistical analysis of mode I fracture in guiting limestone. Int J Rock Mech Min Sci 51:128–135. https://doi.org/10.1016/j.ijrmms.2012.01.017

Alkiliçgil C (2010) Development of specimen geometries for mode I fracture toughness testing with disc type rock specimens. PhD thesis, Middle East Technical University, Ankara, Turkey

Anderson TL (2005) Fracture mechanics: fundamentals and applications, 3rd edn. CRC Press, Boca Raton

ANSYS (2012) ANSYS User’s Manual Revision 12.1. ANSYS, Inc., Canonsburg, Pennsylvania, USA

Arzúa J, Alejano LR (2013) Dilation in granite during servo-controlled triaxial strength tests. Int J Rock Mech Min Sci 61:43–56. https://doi.org/10.1016/j.ijrmms.2013.02.007

ASTM D3967-05 (2008) Standard test method for splitting tensile strength of intact rock core specimens. In: Annual Book of ASTM Standards. ASTM International, West Conshohocken, PA, USA

ASTM E999-90 (1997) Standard test method for plane-strain fracture toughness of metallic materials. In: Annual Book of ASTM Standards. ASTM International, West Conshohocken, PA, USA

Ayatollahi MR, Mahdavi E, Alborzi MJ, Obara Y (2016) Stress intensity factors of semi-circular bend specimens with straight-through and chevron notches. Rock Mech Rock Eng 49:1161–1172. https://doi.org/10.1007/s00603-015-0830-y

Backers T (2004) Fracture toughness determination and micromechanics of rock under mode I and mode II loading. PhD thesis, University of Potsdam, Potsdam, Germany

Backers T, Fardin N, Dresen G, Stephansson O (2003) Effect of loading rate on mode I fracture toughness, roughness and micromechanics of sandstone. Int J Rock Mech Min Sci 40:425–433. https://doi.org/10.1016/S1365-1609(03)00015-7

Backers T, Stephansson O (2012) ISRM suggested method for the determination of mode II fracture toughness. Rock Mech Rock Eng 45:1011–1022. https://doi.org/10.1007/s00603-012-0271-9

Balme MR, Rocchi V, Jones C et al (2004) Fracture toughness measurements on igneous rocks using a high-pressure, high-temperature rock fracture mechanics cell. J Volcanol Geotherm Res 132:159–172. https://doi.org/10.1016/S0377-0273(03)00343-3

Bearman RA (1999) The use of the point load test for the rapid estimation of mode I fracture toughness. Int J Rock Mech Min Sci 36:257–263. https://doi.org/10.1016/S0148-9062(99)00015-7

Brevik NØ (2016) Experimental study of fracture toughness in sedimentary rocks. PhD thesis, Norwegian University of Science and Technology, Trondheim, Norway

Brown GJ, Reddish DJ (1997) Experimental relations between rock fracture toughness and density. Int J Rock Mech Min Sci 34:153–155. https://doi.org/10.1016/S1365-1609(97)80042-1

Canal-Vila J (2016) Experimental study of effect of CO2 injection on rocks: coupling hydrodynamic, mechanical and geochemical processes. PhD thesis, University of A Coruña, A Coruña, Spain

Chandler et al (2016) Fracture toughness anisotropy in shale J Geophys Res Solid Earth 121(3):1706–1729. https://doi.org/10.1002/2015JB012756

Chang SH, Lee CI, Jeon S (2002) Measurement of rock fracture toughness under modes I and II and mixed-mode conditions by using disc-type specimens. Eng Geol 66:79–97. https://doi.org/10.1016/S0013-7952(02)00033-9

Cifuentes H, Lozano M, Holušová T et al (2017) Modified disk-shaped compact tension test for measuring concrete fracture properties. Int J Concr Struct Mater 11:215–228. https://doi.org/10.1007/s40069-017-0189-4

Dwivedi R, Soni A, Goel R, Dube A (2000) Fracture toughness of rocks under sub-zero temperature conditions. Int J Rock Mech Min Sci 37:1267–1275. https://doi.org/10.1016/S1365-1609(00)00051-4

Erarslan N (2016) Microstructural investigation of subcritical crack propagation and Fracture Process Zone (FPZ) by the reduction of rock fracture toughness under cyclic loading. Eng Geol 208:181–190. https://doi.org/10.1016/j.enggeo.2016.04.035

Falcon-Suarez I, Canal-Vila J, Delgado-Martin J et al (2017) Characterisation and multifaceted anisotropy assessment of Corvio sandstone for geological CO2 storage studies. Geophys Prospect 65:1293–1311. https://doi.org/10.1111/1365-2478.12469

Fett T, Munz D (1997) Stress intensity factors and weight functions. Computational Mechanics Publications, Southampton

FITNET (2006) Fitness-for-Service (FFS)—final draft MK7 (Vol. III). Annex A: stress intensity factor (SIF) solutions. pp A1–A149

Fowell RJ, Hudson JA, Xu C, Chen JF (1995) Suggested method for determining mode-I fracture-toughness using cracked chevron-notched brazilian disc (CCNBD) Specimens. Int J Rock Mech Min Sci Geomech Abstr 32:57–64

Funatsu T, Seto M, Shimada H et al (2004) Combined effects of increasing temperature and confining pressure on the fracture toughness of clay bearing rocks. Int J Rock Mech Min Sci 41:927–938. https://doi.org/10.1016/j.ijrmms.2004.02.008

Funatsu T, Shimizu N, Kuruppu M, Matsui K (2015) Evaluation of mode I fracture toughness assisted by the numerical determination of K-resistance. Rock Mech Rock Eng 48:143–157. https://doi.org/10.1007/s00603-014-0550-8

Gao F, Cai C, Yang Y (2018) Experimental research on rock fracture failure characteristics under liquid nitrogen cooling conditions. Results Phys 9:252–262. https://doi.org/10.1016/j.rinp.2018.02.061

Guan JF, Hu XZ, Xie CP et al (2018) Wedge-splitting tests for tensile strength and fracture toughness of concrete. Theor Appl Fract Mech 93:263–275. https://doi.org/10.1016/j.tafmec.2017.09.006

Han Q, Wang Y, Yin Y, Wang D (2015) Determination of stress intensity factor for mode I fatigue crack based on finite element analysis. Eng Fract Mech 138:118–126. https://doi.org/10.1016/j.engfracmech.2015.02.019

Hoek E, Brown ET (1997) Practical estimates of rock mass strength. Int J Rock Mech Min Sci 34:1165–1186. https://doi.org/10.1016/S1365-1609(97)80069-X

Iesulauro E (2009) FRANC2D/L: A crack propagation simulator for plane layered structures. Version 1.5 User’s Guide. Ithaca, NY, USA

Ingraffea AR (2007) Computational fracture mechanics In Encyclopedia of Computational Mechanics. Wiley, New York

Iqbal MJ, Mohanty B (2007) Experimental calibration of ISRM suggested fracture toughness measurement techniques in selected brittle rocks. Rock Mech Rock Eng 40:453–475. https://doi.org/10.1007/s00603-006-0107-6

Iqbal MJ, Mohanty B (2006) Experimental calibration of stress intensity factors of the ISRM suggested cracked chevron-notched Brazilian disc specimen used for determination of mode-I fracture toughness. Int J Rock Mech Min Sci 43:1270–1276. https://doi.org/10.1016/j.ijrmms.2006.04.014

Irwin GR (1958) Fracture. Handbook on physics. Springer, Berlin, pp 551–590

ISRM (1988) Suggested methods for determining the fracture toughness of rock. Int J Rock Mech Min Sci Geomech Abstr 25:71–96

ISRM (1978) Suggested methods for determining tensile strength of rock materials. Int J Rock Mech Min Sci Geomech Abstr 15:99–103. https://doi.org/10.1016/0148-9062(78)90003-7

Jameel A, Harmain GA (2015) Fatigue crack growth in presence of material discontinuities by EFGM. Int J Fatigue 81:105–116. https://doi.org/10.1016/j.ijfatigue.2015.07.021

Jeong SS, Nakamura K, Yoshioka S et al (2017) Fracture Toughness of Granite Measured Using Micro to Macro Scale Specimens. Procedia Eng 191:761–767. https://doi.org/10.1016/j.proeng.2017.05.242

Jian-An H, Sijing W (1985) An experimental investigation concerning the comprehensive fracture toughness of some brittle rocks. Int J Rock Mech Min Sci 22:99–104. https://doi.org/10.1016/0148-9062(85)92331-9

Kataoka M, Mahdavi E, Funatsu T et al (2017) Estimation of mode I fracture toughness of rock by semi-circular bend test under confining pressure condition. Procedia Eng 191:886–893. https://doi.org/10.1016/j.proeng.2017.05.258

Kataoka M, Obara Y (2015a) Size Effect in Fracture Toughness of Sandstone. In: 13th ISRM International Congress on Rock Mechanics. 10–14 May, Montréal, Canada

Kataoka M, Obara Y (2015b) Anisotropy in fracture toughness of sedimentary and crystalline rocks estimated by semi-circular bend test. In: ISRM Regional Symposium, EUROCK 2015, Salzburg, Austria. pp 695–700

Kataoka M, Yoshioka S, Cho S-H, et al (2015) Estimation of fracture toughness of sandstone by three testing methods. In: Vietrock2015: an ISRM specialized conference, Hanoi, Vietnam

Khan K, Al-Shayea NA (2000) Effect of specimen geometry and testing method on mixed Mode I-II fracture toughness of a limestone rock from Saudi Arabia. Rock Mech Rock Eng 33:179–206. https://doi.org/10.1007/s006030070006

Khayal OMES (2017) Literature review on imperfection of composite laminated plates. J Microsc Ultrastruct 5:119–122. https://doi.org/10.1016/j.jmau.2017.01.001

Ko TY, Kemeny J (2013) Determination of the subcritical crack growth parameters in rocks using the constant stress-rate test. Int J Rock Mech Min Sci 59:166–178. https://doi.org/10.1016/j.ijrmms.2012.11.006

Kozak D, Blaj L, Matejiček F (2003) State of stress modelling by 2-D finite element analysis of fracture toughness specimens. In: Dobre I, Faur N (eds) Proceedings of the 6th International Conference on Boundary and Finite Element. Timisoara: Editura Politehnica, pp 303–312

Kuruppu MD, Obara Y, Ayatollahi MR et al (2014) ISRM-suggested method for determining the mode I static fracture toughness using semi-circular bend specimen. Rock Mech Rock Eng 47:267–274. https://doi.org/10.1007/s00603-013-0422-7

Levén M, Rickert D (2012) Stationary 3D crack analysis with Abaqus XFEM for integrity assessment of subsea equipment. Chalmers University of Technology, Göteborg

Lim IL, Johnston IW, Choi SK, Boland JN (1994) Fracture testing of a soft rock with semi-circular specimens under three-point bending. Part 1—mode I. Int J Rock Mech Min Sci Geomech Abstr 31:185–197. https://doi.org/10.1016/0148-9062(94)90463-4

Linsbauer HN, Tschegg EK (1986) Fracture energy determination of concrete with cube shaped specimens. Zement Bet 31:38–40

Liu A (1996) Summary of stress-intensity factors. In: ASM handbook. Fatigue and fracture. Vol. 19. ASM International, pp 980–1000

Major JR, Eichhubl P, Dewers TA, et al (2014) The effect of CO2-related diagenesis on geomechanical failure parameters; fracture testing of CO2-altered reservoir and seal rocks from a natural analog at Crystal Geyser, Utah. 48th US Rocks Mech Symp 14–7463:1–5

Matsuki K, Aoki T (1990) The effect of confining and pore pressures on fracture toughness of rocks. Shigen-to-Sozai 106:713–718. https://doi.org/10.2473/shigentosozai.106.713

Müller W, Rummel F (1984) Bruchzähigkeitsmessungen an Gesteinen. Bericht zu den BMFT-FE-Vorhaben 03E-3068-B

Nara Y, Morimoto K, Hiroyoshi N et al (2012) Influence of relative humidity on fracture toughness of rock: Implications for subcritical crack growth. Int J Solids Struct 49:2471–2481. https://doi.org/10.1016/j.ijsolstr.2012.05.009

Nasseri MHB, Schubnel A, Young RP (2007) Coupled evolutions of fracture toughness and elastic wave velocities at high crack density in thermally treated Westerly granite. Int J Rock Mech Min Sci 44:601–616. https://doi.org/10.1016/j.ijrmms.2006.09.008

Oliveira FXGZ de O (2013) Crack modelling with the eXtended finite element method. Master thesis, Instituto Superior Técnico, Lisboa, Portugal

Ouchterlony F (1987) A presentation of the ISRM suggested methods for determining fracture toughness of rock material. Proc 6th Int Congr Rock Mech 2:1181–1186

Perez N (2004) Fracture mechanics. Kluwer Academic Publishers, Boston

Qian G, González-Albuixech VF, Niffenegger M, Giner E (2016) Comparison of KI calculation methods. Eng Fract Mech 156:52–67. https://doi.org/10.1016/j.engfracmech.2016.02.014

Sato N, Takahashi K (2018) Evaluation of fracture strength of ceramics containing small surface defects introduced by focused ion beam. Materials (Basel) 11:457. https://doi.org/10.3390/ma11030457

Schreurs PJG (2012) Fracture Mechanics. Lecture notes—course 4A780. Concept version. Eindhoven University of Technology. Department of Mechanical Engineering

Simulia (2007) Abaqus technology brief. Fracture mechanics study of a compact tension specimen using abaqus/CAE. Dassault Systemes, Vélizy-Villacoublay

Simulia (2009) Modeling fracture and failure with abaqus. Dassault Systemes, Vélizy-Villacoublay

Singh RN, Sun GX (1990) An investigation into factors affecting fracture toughness of coal measures sandstones. J Mines Met Fuels 38:111–118

Sun Z, Ouchterlony F (1986) Fracture toughness of stripa granite cores. Int J Rock Mech Min Sci Geomech Abstr 23:399–409. https://doi.org/10.1016/0148-9062(86)92305-3

Takahashi K, Osedo H, Suzuki T, Fukuda S (2018) Fatigue strength improvement of an aluminum alloy with a crack-like surface defect using shot peening and cavitation peening. Eng Fract Mech 193:151–161. https://doi.org/10.1016/j.engfracmech.2018.02.013

Talukdar M, Guha Roy D, Singh TN (2018) Correlating mode-I fracture toughness and mechanical properties of heat-treated crystalline rocks. J Rock Mech Geotech Eng 10:91–101. https://doi.org/10.1016/j.jrmge.2017.09.009

Thuro K, Plinninger R, Zah S, Schutz S (2001) Scale effects in rock strength properties. Part 1: Unconfined compressive test and Brazilian test. In: Elorante P, Sarkka P (eds) Rock mechanics : a challenge for society: proceedings of the ISRM Regional Symposium Eurock 2001, Swets & Zeitlinger Lisse, Espoo, Finland, pp 169–174

Tutluoglu L, Keles C (2011) Mode I fracture toughness determination with straight notched disk bending method. Int J Rock Mech Min Sci 48:1248–1261. https://doi.org/10.1016/j.ijrmms.2011.09.019

Ueno K, Funatsu T, Shimada H, et al (2013) Effect of specimen size on mode I fracture toughness by SCB test. In: The 11th International conference on Mining, Materials and Petroleum Engineering; the 7th International Conference on Mining, Materials and Petroleum Engineering, Chiang Mai, Thailand

Veselý V, Holusová T, Seitl S (2012) Numerical prediction of parasitic energy dissipation in wedge splitting tests on concrete specimens. In: 18th International Conference Engineering Mechanics, Svratka, Czech Republic. pp 1497–1504

Wang Q-Z (1998) Stress intensity factors of the ISRM suggested CCNBD specimen used for mode-I fracture toughness determination. Int J Rock Mech Min Sci 35:977–982. https://doi.org/10.1016/S0148-9062(98)00010-2

Wang QZ, Fan H, Gou XP, Zhang S (2013) Recalibration and clarification of the formula applied to the ISRM-suggested CCNBD specimens for testing rock fracture toughness. Rock Mech Rock Eng 46:303–313. https://doi.org/10.1007/s00603-012-0258-6

Wang QZ, Jia XM, Kou SQ et al (2003) More accurate stress intensity factor derived by finite element analysis for the ISRM suggested rock fracture toughness specimen—CCNBD. Int J Rock Mech Min Sci 40:233–241. https://doi.org/10.1016/S1365-1609(02)00131-4

Wei MD, Dai F, Xu NW et al (2016a) Experimental and numerical study on the fracture process zone and fracture toughness determination for ISRM-suggested semi-circular bend rock specimen. Eng Fract Mech 154:43–56. https://doi.org/10.1016/j.engfracmech.2016.01.002

Wei MD, Dai F, Xu NW et al (2016) Experimental and numerical study on the cracked chevron notched semi-circular bend method for characterizing the mode I fracture toughness of rocks. Rock Mech Rock Eng 49:1595–1609. https://doi.org/10.1007/s00603-015-0855-2

Whittaker BN, Singh RN, Sun G (1992) Rock fracture mechanics: principles, design, and applications. Elsevier, Amsterdam

Yu Y, Yin J, Zhong Z (2006) Shape effects in the Brazilian tensile strength test and a 3D FEM correction. Int J Rock Mech Min Sci 43:623–627. https://doi.org/10.1016/j.ijrmms.2005.09.005

Zalnezhad E, Sarhan AAD, Hamdi M et al (2012) A FUZZY logic based model to predict the fretting fatigue life of aerospace Al7075-T6 alloy. Casp J Appl Sci Res 2012:39–48

Zhang J, Little DN, Grajales J et al (2017) Use of semicircular bending test and cohesive zone modeling to evaluate fracture resistance of stabilized soils. Transp Res Rec J Transp Res Board 2657:67–77. https://doi.org/10.3141/2657-08

Zhang K, Fan F, Li C et al (2016) Experimental investigations on the relationships between rock toughness and physical properties of shale. Int J Simul Syst Sci Technol. https://doi.org/10.5013/IJSSST.a.17.49.54

Zhang ZX (2002) An empirical relation between mode I fracture toughness and the tensile strength of rock. Int J Rock Mech Min Sci 39:401–406. https://doi.org/10.1016/S1365-1609(02)00032-1

Acknowledgements

This work was funded by Repsol S.A., and the support from the Xunta de Galicia, the European Union (European Social Fund—ESF) and the MINECO/AEI/FEDER, UE project BIA2017- 87066-R. The authors would like to thank Dr. Manika Prasad and Kurt Livo (Petroleum Engineering Department, Colorado School of Mines) for their advice and assistance with the micro X-ray computed tomography work. The authors would also like to thank the reviewers for their comments and suggestions that helped to improve the manuscript.

Author information

Authors and Affiliations

Contributions

JDM, JAI and JCV devised the project and conceptualized the main ideas. JRD designed the electronics and software of the experimental device. MC created the numerical model of the device. AMI performed the experiments and, in cooperation with the rest of the authors, analysed the data. The first draft of the manuscript was written by AMI, and all the authors commented on previous versions of the manuscript. All the authors have read and approved the final version of the manuscript.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Muñoz-Ibáñez, A., Delgado-Martín, J., Costas, M. et al. Pure Mode I Fracture Toughness Determination in Rocks Using a Pseudo-Compact Tension (pCT) Test Approach. Rock Mech Rock Eng 53, 3267–3285 (2020). https://doi.org/10.1007/s00603-020-02102-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-020-02102-6