Abstract

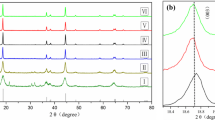

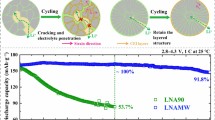

Nickel(Ni)-rich layered materials have attracted considerable interests as promising cathode materials for lithium ion batteries (LIBs) owing to their higher capacities and lower cost. Nevertheless, Mn-rich cathode materials usually suffer from poor cyclability caused by the unavoidable side-reactions between Ni4+ ions on the surface and electrolytes. The design of gradient concentration (GC) particles with Ni-rich inside and Mn-rich outside is proved to be an efficient way to address the issue. Herein, a series of LiNi0.6Co0.2Mn0.2O2 (LNCM622) materials with different GCs (the atomic ratio of Ni/Mn decreasing from the core to the outer layer) have been successfully synthesized via rationally designed co-precipitation process. Experimental results demonstrate that the GC of LNCM622 materials plays an important role in their microstructure and electrochemical properties. The as-prepared GC3.5 cathode material with optimal GC can provide a shorter pathway for lithium-ion diffusion and stabilize the near-surface region, and finally achieve excellent electrochemical performances, delivering a discharge capacity over 176 mAh·g−1 at 0.2 C rate and exhibiting capacity retention up to 94% after 100 cycles at 1 C. The rationally-designed co-precipitation process for fabricating the Ni-rich layered cathode materials with gradient composition lays a solid foundation for the preparation of high-performance cathode materials for LIBs.

Similar content being viewed by others

References

Tang Y, Zhang Y, Li W, Ma B, Chen X. Rational material design for ultrafast rechargeable lithium-ion batteries. Chemical Society Reviews, 2015, 44(17): 5926–5940

Shi J L, Xiao D D, Ge M, Yu X, Chu Y, Huang X, Zhang X D, Yin Y X, Yang X Q, Guo Y G, et al. High-capacity cathode material with high voltage for Li-ion batteries. Advanced Materials, 2018, 30(9): 1705575–1705583

Xu J, Lin F, Doeff M M, Tong W. A review of Ni-based layered oxides for rechargeable Li-ion batteries. Journal of Materials Chemistry. A, Materials for Energy and Sustainability, 2017, 5(3): 874–901

Lin F, Nordlund D, Markus I M, Weng T C, Xin H L, Doeff M M. Profiling the nanoscale gradient in stoichiometric layered cathode particles for lithium-ion batteries. Energy & Environmental Science, 2014, 7(9): 3077–3085

Kim J, Cho H, Jeong H Y, Ma H, Lee J, Hwang J, Park M, Cho J. Self-Induced concentration gradient in nickel-rich cathodes by sacrificial polymeric bead clusters for high-energy lithium-ion batteries. Advanced Energy Materials, 2017, 7(12): 1602559

Liang L, Du K, Peng Z, Cao Y, Duan J, Jiang J, Hu G. Co-precipitation synthesis of Ni0.6Co0.2Mn0.2(OH)2 precursor and characterization of LiNi0.6Co0.2Mn0.2O2 cathode material for secondary lithium batteries. Electrochimica Acta, 2014, 130: 82–89

Ren D, Shen Y, Yang Y, Shen L, Levin B D A, Yu Y, Muller D A, Abruna H D. Systematic optimization of battery materials: Key parameter optimization for the scalable synthesis of uniform, high-energy, and high stability LiNi0.6Mn0.2Co0.2O2 cathode material for lithium-ion batteries. ACS Applied Materials & Interfaces, 2017, 9(41): 35811–35819

Liu S, Zhang C, Su Q, Li L, Su J, Huang T, Chen Y, Yu A. Enhancing electrochemical performance ofLiNi0.6Co0.2Mn0.2O2 by lithium-ion conductor surface modification. Electrochimica Acta, 2017, 224: 171 -177

Zhang T, Paillard E. Recent advances toward high voltage, EC-free electrolytes for graphite-based Li-ion battery. Frontiers of Chemical Science and Engineering, 2018, 12(3): 577–591

Ding R Q, Liu H, Wang L, Liang G C. Effect of spray drying technological conditions on the performance of LiFePO4/C cathode materials with high energy density. Ionics, 2019, 25(12): 5633–5642

Ma Y, Wang L, Zuo X, Nan J. Co-precipitation spray-drying synthesis and electrochemical performance of stabilized LiNi0.5Mn1.5O4 cathode materials. Journal of Solid State Electrochemistry, 2018, 22(7): 1963–1969

Zhang M J, Hu X B, Li M F, Duan Y D, Yang L Y, Yin C, Ge M Y, Xiao X H, Lee W K, Amine K, et al. Cooling induced surface reconstruction during synthesis of high-Ni hayered oxides. Advanced Energy Materials, 2019, 9(43): 1901915

Du H, Zhang X, Chen Z, Wu D, Zhang Z, Li J. Carbon coating and Al-doping to improve the electrochemistry of Li2CoSiO4 polymorphs as cathode materials for lithium-ion batteries. RSC Advances, 2018, 8(40): 22813–22822

Hou P, Zhang H, Zi Z, Zhang L, Xu X. Core-shell and concentration-gradient cathodes prepared via co-precipitation reaction for advanced lithium-ion batteries. Journal of Materials Chemistry. A, Materials for Energy and Sustainability, 2017, 5(9): 4254–4279

Zhao Y, Liu J, Wang S, Ji R, Xia Q, Ding Z, Wei W, Liu Y, Wang P, Ivey D G. Surface structural transition induced by gradient polyanion-doping in Li-rich layered oxides: Implications for enhanced electrochemical performance. Advanced Functional Materials, 2016, 26(26): 4760–4767

Kim U H, Ryu H H, Kim J H, Mücke R, Kaghazchi P, Yoon C S, Sun Y K. Microstructure-controlled Ni-rich cathode material by microscale compositional partition for next-generation electric vehicles. Advanced Energy Materials, 2019, 9(15): 1803902

Kong D F, Hu J T, Chen Z F, Song K P, Li C, Weng M Y, Li M F, Wang R, Liu T C, Liu J J, et al. Ti-gradient doping to stabilize layered surface structure for high performance high-Ni oxide cathode of Li-ion battery. Advanced Energy Materials, 2019, 9(14): 1901756

Pham H Q, Kim G, Jung H M, Song S W. Fluorinated polyimide as a novel high-voltage binder for high-capacity cathode of lithium-ion batteries. Advanced Functional Materials, 2018, 28(2): 1704690

Zhang J, Yang Z, Gao R, Gu L, Hu Z, Liu X. Suppressing the structure deterioration of Ni-rich LiNi0.8Co0.1Mn0.1O2 through atom-scale interfacial integration of self-forming hierarchical spinel layer with Ni gradient concentration. ACS Applied Materials & Interfaces, 2017, 9(35): 29794–29803

Zhang Y, Wang Z B, Nie M, Yu F D, Xia Y F, Liu B S, Xue Y, Zheng L L, Wu J. A simple method for industrialization to enhance the tap density of LiNi0.5Co0.2Mn0.3O2 cathode material for high-specific volumetric energy lithium-ion batteries. RSC Advances, 2016, 6(70): 65941–65949

Liao J Y, Oh S M, Manthiram A. Core/double-shell type gradient Ni-rich LiNi0.76Co0.10Mn0.14O2 with high capacity and long cycle life for lithium-ion batteries. ACS Applied Materials & Interfaces, 2016, 8(37): 24543–24549

Li Y, Xu R, Ren Y, Lu J, Wu H, Wang L, Miller D J, Sun Y K, Amine K, Chen Z. Synthesis of full concentration gradient cathode studied by high energy X-ray diffraction. Nano Energy, 2016, 19: 522–531

Acknowledgements

The authors are grateful to the financial support of the National Natural Science Foundation of China (Grant Nos. 91834301, 91534102 and 21271058). This work is also supported by Science and Technology Project of Anhui Province (Nos. 201903a05020021 and 17030901067).

Author information

Authors and Affiliations

Corresponding authors

Electronic Supplementary Material

11705_2020_1918_MOESM1_ESM.pdf

Effects of gradient concentration on the microstructure and electrochemical performance of LiNi0.6Co0.2Mn0.2O2 cathode materials

Rights and permissions

About this article

Cite this article

Li, W., Tang, W., Qiu, M. et al. Effects of gradient concentration on the microstructure and electrochemical performance of LiNi0.6Co0.2Mn0.2O2 cathode materials. Front. Chem. Sci. Eng. 14, 988–996 (2020). https://doi.org/10.1007/s11705-020-1918-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11705-020-1918-9