Abstract

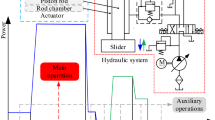

In this study, modifying a constant speed–driven hydraulic press brake machine into a variable speed drive system is examined in terms of electricity saving, CO2 reduction, and economic perspectives. The goal of the modification is to obtain increased efficiency by adding minimum hardware and software tools. For realizing this goal, a hydraulic test rig operated in a manner to represent the cycle of a specified press brake machine is taken into consideration, which is equipped with a frequency controller on an induction motor and an electro-hydraulic load sensing. Then, the amount of electricity saving is determined experimentally under wide-range operating conditions. Besides, an economic analysis is performed based on 5 different scenarios to represent the conditions of the real industry throughout an operation year. As a result, the amount of electricity saving is observed to vary between 3 and 19% depending on the operating conditions. In addition, it is determined that there is 1.75 to 10.5 tons of CO2 reduction potential per year. The payback period of the modification investment is computed between 1.51 and 4.67 years, according to the considered scenarios. In the sensitivity analysis, the most important parameters affecting the economic criteria are discount rate, electricity unit price, and initial investment cost.

Similar content being viewed by others

References

ABB. (2013). Low Voltage AC Drives, 3AFE68375126 Rev o en 7.5.2013 #16710. Zurich: ABB Group.

Akova, H. U., Caliskan, H., Balkan, T., Platin, B. E., & Demirer, S. (2014). Energy efficient hydraulic drive system and control for press brakes. VII. National hydraulic pneumatic congress, Istanbul: Turkish, 22–25 October 2014, pp. 361–376.

Ari, I., & Koksal, M. A. (2011). Carbon dioxide emission from the Turkish electricity sector and its mitigation options. Energ Policy, 39(10), 6120–6135.

Blank, L., & Tarquin, A. (2012). Engineering economy (7th ed.). New York: Mc Graw Hill.

BOSCH REXROTH. (2011). External Gear Pumps, Series F, RA 10089/08.11 Replaces: RA 10097. Lohr: Bosch Rexroth AG..

Bostan, B. (2011). Variable speed pump drive systems in presses. In National Hydraulic Pneumatic Congress (Vol. VI, pp. 37–54). Izmir In Turkish.

Caliskan, H. (2009). Modeling and experimental evaluation of variable speed pump and valve controlled servo drives, MSc Thesis, METU, Natural and applied sciences, Ankara.

Caliskan, O. (2018). Variable speed drive application on a press brake: Energy effıciency and economic analysis. MSc Thesis. YTU, Graduate school of Science enginnering and technology, Istanbul. In Turkish.

EUAS. (2017). Department of environmental and nationalization. Carbon footprint report 2017. http://www.euas.gov.tr/Documents/Karbon_Ayak_izi_Raporu.pdf. Accessed 12 Arpril 2018. In Turkish.

GAMAK. (2016). AGM2E Series General Asynchronous Electric Motors. Istanbul: Gamak Machinery Industry Inc..

Gunkaya, Z., Ozdemir, A., Ozkan, A., & Banar, M. (2016). Environmental performance of electricity generation based on resources: A life cycle assessment case study in Turkey. Sustainability, 8(11), 1–14.

HYDROTECHNIK. (2016). MultiSystem 5060 Plus Technical Data Sheet. Limburg: Hydrotechnik GmbH.

HYDROTECHNIK. (2017a). HySense PR 100 E5 Technical Data Sheet. Limburg: Hydrotechnik GmbH..

HYDROTECHNIK. (2017b). HySense QT 5xx Technical Data Sheet. Limburg: Hydrotechnik GmbH.

Lin, T., Chen, Q., Ren, H., Huang, W., Chen, Q., & Fu, S. (2017). Review of boom potential energy regeneration technology for hydraulic construction machinery. Renewable and Sustainable Energy Reviews, 79, 358–371.

Lovrec, D., & Kastrevc, M. (2011). Modelling and simulating a controlled press-brake supply system. International Journal of Simulation Modelling, 10(3), 133–144.

Lovrec, D., Kastrevc, M., & Ulaga, S. (2009). Electro-hydraulic load sensing with a speed-controlled hydraulic supply system on forming machines. International Journal of Advanced Manufacturing Technology, 41(11–12), 1066–1075.

Lovrec, D., Tic, V., & Tasner, T. (2017). Dynamic behavior of different hydraulic drive concepts-comparison and limits. International Journal of Simulation Modelling, 16(3), 448–457.

Manasek, R. (2000). Simulation of an electro-hydraulic load-sensing system with AC motor and frequency changer. In: Proceeding of the 1st FPNI-PhD Symposium (pp.311–324). Hamburg.

Ozer, B. (2012). Scenario analysis on CO2 emission reduction potential in Turkey electricity sector. Doctor dissertation. ITU, Graduate school of science engineering and technology, Istanbul. In Turkish.

Quan, Z., Quan, L., & Zhang, J. (2014). Review of energy efficient direct pump controlled cylinder electro-hydraulic technology. Renewable and Sustainable Energy Reviews, 35, 336–346.

Ramesh, S., Ashok, S. D., & Nagaraj, S. (2018). An energy conservation strategy using variable frequency drive for a hydraulic clamping system in a CNC machine. Materials Today: Proceedings, 5(5), 13504–135013.

Saidur, R., Mekhilef, S., Ali, M. B., Safari, A., & Mohammed, H. A. (2012). Applications of variable speed drive (VSD) in electrical motors energy savings. Renewable and Sustainable Energy Reviews, 16(1), 543–550.

Stelson, K. A. (2011). Saving the world’s energy with fluid power. In: Proc of the 8th JFPS (pp. 1-7), Okinawa.

TEIAS. (2017), The distribution of Turkey’s gross electricity generation by energy resources in 2017. https://www.teias.gov.tr/tr/iii-electricity-generation-consumption-losses. Accesed 10 December 2018. In Turkish.

Willkomm, J., Wahler, M., Weber, J. (2014). Model predictive control of speed-variable variable-displacement pumps to optimize energy efficiency. In: 9th Int. Fluid Power Conf. (pp.372–385). Aachen.

Xu, M. M., Jin, B., Chen, G., & Ni, J. (2010). Speed-control of energy regulation based variable-speed electrohydraulic drive. Strojniski Vestnik-Journal of Mechanical Engineering, 59(7), 433–442.

Yang, X., Gong, G., Yang, H., Jia, L., & Zhou, J. (2016). An investigation in performance of variable-speed-displacement pump controlled motor system. IEEE/ASME Transactions on Mechatronics, 22(2), 647–656.

Acknowledgments

The authors would like to thank Dr. Muharrem Erdem Bogoclu for allowing the use of hydraulic test rig used in this study and his valuable comments.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Caliskan, O., Akkaya, A.V. Modifying hydraulic press brake by variable speed drive application: energy saving, CO2 reduction, and economic analysis. Energy Efficiency 13, 1031–1046 (2020). https://doi.org/10.1007/s12053-020-09854-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12053-020-09854-8