Abstract

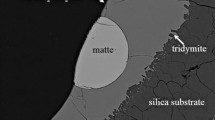

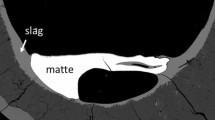

Understanding the significance of magnesia as a common component in copper processing slags is essential for optimisation of the industrial copper production. Fundamental experimental studies have been undertaken to determine the effect of MgO on the equilibria between the gas phase (CO-CO2-SO2-Ar) and slag-matte-tridymite phases in the Cu-Fe-O-S-Si-Mg system at 1473 K (1200 °C) and 1573 K (1300 °C), and P(SO2) = 0.25 atm. The experimental methodology used was based on equilibration, quenching and microanalysis. New experimental data have been obtained for the four-phase gas–slag–matte–tridymite equilibria system for a range of MgO concentrations up to 3.1 wt pct in the slag phase as a function of matte grade, including the concentrations of dissolved sulphur and copper in slag, and Fe/SiO2 ratios in slag. The results are also used to analyse the effect of temperature on phase equilibria in the range investigated. The results obtained showed that dissolution of sulphur, copper and “FeO” in slag decreases with increase of MgO in slag while it has no detectable effect on concentration of sulphur in matte. Also, dissolved copper and sulphur in slag increases when temperature increases while the Fe/SiO2 ratio in slag is greater at 1473 K (1200 °C) than 1573 K (1300 °C). The new data provided in the present study are of direct relevance to the pyrometallurgical processing of copper and will be used as an input for optimization of the FactSage thermodynamic database for the copper-containing multi-component multi-phase system.

Similar content being viewed by others

References

W.G.I. Davenport, M. King, M. Schlesinger, and A.K. Biswas, Extractive Metallurgy of Copper, 4th ed., Pergamon, Oxford, 2002

A. Fallah-Mehrjardi, P.C. Hayes, T. Azekenov, L. Ushkov, E. Jak, Presented at 9th International Copper Conference, The Mining and Materials Processing Institute of Japan, Japan, 13–16 November, p. 713 (2016)

A. Fallah Mehrjardi, P.C. Hayes, T. Azekenov, L.A. Ushkov, E. Jak, Presented at 10th International Copper on Molten Slags, Fluxes and Salts (Molten 2016), Springer, USA, 22–25 May, p. 1071 (2016)

W.E. Lee and S. Zhang, Int. Mater. Rev., 1999, 44(3), p 77

W.E. Lee, B.B. Argent, and S.W. Zhang, J. Am. Ceram. Soc., 2002, 85(12), p 2911

I. Ganesha, S. Bhattacharjeea, B.P. Sahaa, R. Johnsona, K. Rajeshwarib, R. Senguptab, M.V. Ramana Raob, and Y.R. Mahajana, Ceram. Int., 2002, 28, p 245

F.J. Tavera and E. Bedolla, Int. J. Miner. Process., 1990, 29(3–4), p 289

A. Geveci and T. Rosenqvist, Trans. Inst. Min. Metall., 1973, 82, p C193

R. Shimpo, S. Goto, O. Ogawa, and I. Asakura, Can. Metall. Q., 1986, 25(2), p 113

M. Nagamori, Metall. Trans. B, 1974, 5(3), p 531

A. Yazawa, S. Nakazawa, Y. Takeda, Presented at Proceedings of International Sulfide Smelting Symposium, Metall. Soc. AIME, USA, 6-9 November, p. 99 (1983)

G.H. Kaiura, K. Watanabe, and A. Yazawa, Can. Metall. Q., 1980, 19(2), p 191

H. Jalkanen, Scand. J. Metall., 1981, 10(4), p 177

A. Yazawa, Can. Metall. Q., 1974, 13(3), p 443

Y. Takeda, Presented at 5th International Conference Molten Slags, Fluxes Salts (Molten 1997), Iron and Steel Society Warrendale—PA, Australia, 5-7 January, p. 735 (1997)

U. Kuxmann and F.Y. Bor, Erzmetall, 1965, 18, p 441

N. Korakas, Etude thermodynamic de l’équilibre entre scories ferro-siliceuses et mattes de cuivre. Application aux problèmes posés par la formation de magnetite lors du traitement des minerais sulfurés de cuivre, Univirsité de Liège, Belgium, (1964)

F.J. Tavera and W.G. Davenport, Metall. Trans. B, 1979, 10B(2), p 237

J.M. Font, G. Roghani, M. Hino, and K. Itagaki, Metall. Rev. MMIJ, 1998, 15(1), p 75

H.M. Henao, L.A. Ushkov, E. Jak, Presented at 9th International Conference on Molten Slags, Fluxes and Salts (Molten 2012), The Chinese Society for Metals, China, 27-31 May, p. 1 (2012)

H. Li and W.J. Rankin, Metall. Trans. B, 1994, 25B(1), p 79

Z. Sun, T. Hidayat, P.C. Hayes, E. Jak, Presented at 8th International Copper Conference, The Institute of Materials, Minerals and Mining, Chile, 1-4 December, p. 33 (2013)

A. Fallah-Mehrjardi, T. Hidayat, P.C. Hayes, and E. Jak, Metall. Mater. Trans. B, 2017, 48(6), p 3017

A. Fallah-Mehrjardi, T. Hidayat, P.C. Hayes, and E. Jak, Metall. Mater. Trans. B, 2017, 48(6), p 3002

R. Sridhar, J.M. Toguri, and S. Simeonov, JOM, 1997, 49(4), p 48

A. Fallah-Mehrjardi, T. Hidayat, P.C. Hayes, and E. Jak, Metall. Mater. Trans. B, 2017, 49(4), p 1732

Y. Takeda, Presented at 5th International Conference Molten Slags, Fluxes Salts (Molten 1997), Iron and Steel Society Warrendale - PA, Australia, 5-7 January, p. 329 (1997)

G. Roghani, Y. Takeda, and K. Itagaki, Metall. Mater. Trans. B, 2000, 31B(4), p 705

E. Jak, P.C. Hayes, and H.-G. Lee, Korean J. Miner. Mater. Inst. (Seoul), 1995, 1(1), p 1

E. Jak, Presented at 9th International Conference on Molten Slags, Fluxes and Salts (Molten 2012), The Chinese Society for Metals, China, 27-31 May, (2012)

FactSage ver. 6.2. CRCT-Thermfact Inc & GTT-Technologies: Montreal, Canada (2010)

D. Shishin, T. Hidayat, A. Fallah Mehrjardi, P.C. Hayes, S.A. Decterov, and E. Jak, J. Phase Equilib. Differ., 2019, 40(4), p 445

D. Shishin, S.A. Decterov, and E. Jak, J. Phase Equilib. Diff., 2018, 39(5), p 456

M. Allibert, H. Gaye, J. Geiseler, D. Janke, B.J. Keene, D. Kirner, M. Kowalski, J. Lehmann, K.C. Mills, D. Neuschutz, R. Parra, C. Saint-Jours, P.J. Spencer, M. Susa, M. Tmar, E. Woermann, Slag Atlas, 2ndEdition, Verlag Stahleisen GmbH, d-Dusseldorf, on behalf of the European Communities, Germany, (1995)

T. Hidayat, D. Shishin, S.A. Decterov, P.C. Hayes and E. Jak, Presented at 1st International Process Metallurgy Conference, IPMC 2016, AIP Publishing LLC, Indonesia, 10-11 November (2016)

Acknowledgments

The authors would like to thank Australian Research Council Linkage program, Altonorte Glencore, Atlantic Copper, Aurubis, Olympic Dam Operation BHP Billiton, Kazzinc Glencore, PASAR Glencore, Outotec Oy (Espoo), Anglo American Platinum, Umicore, and Kennecott Rio Tinto for the financial and technical support for this study. The authors thank Dr. Denis Shishin for assistance and advice in this work. The authors would like to thank the Centre for Microscopy and Microanalysis, University of Queensland for technical support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abdeyazdan, H., Fallah-Mehrjardi, A., Hidayat, T. et al. The Effect of MgO on Gas–Slag–Matte–Tridymite Equilibria in Fayalite-Based Copper Smelting Slags at 1473 K (1200 °C) and 1573 K (1300 °C), and P(SO2) = 0.25 atm. J. Phase Equilib. Diffus. 41, 44–55 (2020). https://doi.org/10.1007/s11669-020-00778-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-020-00778-5