Abstract

Manufacture of green building materials has been increasing recently. There are many scientific publications related to lignocellulosic waste incorporation in Portland cement systems, but only few research works on the waste recovery in alkali-activated binders can be found. Alkali-activated materials could be a choice of ecological and renewable materials due to good durability, as well as mechanical and thermal properties. The paper analyses the performance of bio-composite material made of alkali-activated slag with the addition of phosphogypsum at 5 wt% by weight of slag or at 3.6 wt% by weight of other bio-composite components including softwood shavings (WS). Relationships between density, compressive and flexural strength, thermal conductivity and WS content were observed. The microstructure of bio-composite specimens was also examined. Usually, alkali-activated binders have relatively low flexural strength, which limits their application possibilities. In this work, it was succeeded to increase the flexural strength by incorporating wood shavings (WS) in this binder. According to the results, the appropriate addition of WS can improve the flexural properties of alkali-activated slag bio-composites, especially at later ages of 28 days. It is concluded that bio-composite from alkali-activated slag blended with WS has a great potential in construction materials industry. Depending on the composition, this bio-composite had flexural strength of 10.7 MPa, compressive strength of 11.5 MPa, and thermal conductivity of 0.30 W (mK)−1. The main practical advantages of this bio-composite are based on practical demand: the mechanical, thermal properties and waste utilization aspects are balanced.

Similar content being viewed by others

References

Ahmed W, Khushnood RA, Memon SA, Ahmad S, Baloch WL, Usman M (2018) Effective use of sawdust for the production of eco-friendly and thermal-energy efficient normal weight and lightweight concretes with tailored fracture properties. J Clean Prod 184:1016–1027

Asadi I, Shafigh P, Fitri Bin Abu Hassan Z, Binti Mahyuddin N (2018) Thermal conductivity of concrete – a review. J Build Eng 20:81–93

Awal AS, M A, Mariyana A, Hossain M (2016) Some aspects of physical and mechanical properties of sawdust concrete. Int J 10(21):1918–1923

Bederina M, Marmoret Mezreb LK, Khenfer MM, Bali A, Queneudec M (2007) Effect of the addition of wood shavings on thermal conductivity of sand concretes: Experimental study and modelling. Constr Build Mater 21:662–668

Belhadj B, Bederina M, Montrela N, Houessou J, Quéneudec M (2014) Effect of substitution of wood shavings by barley straws on the physico-mechanical properties of lightweight sand concrete. Constr Build Mater 66:247–258

Berzins A, Morozovs A, Gross U, Iejavs J (2017) Mechanical properties of wood-geopolymer composite. In: Proceedings of the international scientific conference. Latvia University of Agriculture

Douglas E, Brandstetr J (1990) A preliminary study on the alkali activation of ground granulated blast-furnace slag. Cem Concr Res 20(5):746–756

Duan P, Yan C, Zhou W, Luo W (2016) Fresh properties, mechanical strength and microstructure of fly ash geopolymer paste reinforced with sawdust. Constr Build Mater 111:600–661

Fongang RT, Pemndje J, Lemougna PN et al (2015) Cleaner production of the lightweight insulating composites: Microstructure, pore network and thermal conductivity. Energy Build 107:113–122

Hak-Chul Shin A, Kodide U (2012) Thermal conductivity of ternary mixtures for concrete pavements. Cem Concr Compos 34:575–582

Halas O, Benes L, Minar L (2011) Sawdust as a filler to alkali-activated fly-ash. In: Annals of DAAAM and proceedings of the 22nd international DAAAM symposium, pp 797–799

Korjenic A, Petránek V, Zach J, Hroudová J (2011) Development and performance evaluation of natural thermal-insulation materials composed of renewable resources. Energy Build 43(9):2518–2523

LST EN 12667:2002 Thermal performance of building materials and products - Determination of thermal resistance by means of guarded hot plate and heat flow meter methods - Products of high and medium thermal resistance. LST - Lithuanian Standards Board

Palacios M, Puertas F (2007) Effect of shrinkage-reducing admixtures on the properties of alkali-activated slag mortars and pastes. Cem Concr Res 37(5):691–702

Plötze M, Niemz P (2011) Porosity and pore size distribution of different wood types as determined by mercury intrusion porosimetry. Eur J Wood Prod 69(4):649–657

Rashad AM (2015) Potential use of phosphogypsum in alkali-activated fly ash under the effects of elevated temperatures and thermal shock cycles. J Clean Prod 87(15):717–725

Sá Ribeiro RA, Sá Ribeiro MG, Sankar K, Kriven WM (2016) Geopolymer-bamboo composite–a novel sustainable construction material. Constr Build Mater 123:501–507

Sarmin SN (2015) Lightweight building materials of geopolymer reinforced wood particles aggregate–a review. Appl Mech Mater 802:220–224

Sarmin SN, Welling J, Krause A, Shalbafan A (2014) Investigating the possibility of geopolymer to produce inorganic-bonded wood composites for multifunctional construction material – a review. Bioresour Technol 9(4):7941–7950

Shalbafan A, Welling J, Hasch J (2016) Geopolymers as potential new binder class for the wood based composite industry. Holzforschung 70(8):755–761

Skripkiunas G, Yakovlev G, Karpova E, Ng PL (2019) Hydration process and physical properties of cement systems modified by calcium chloride and multi-walled carbon nanotubes. Rev Rom Mater 49:58–67

Steins P, Poulesquen A, Frizon F et al (2014) Effect of aging and alkali activator on the porous structure of a geopolymer. J Appl Crystallogr 47(1):316–324

Taoukill D, Abdelmajid El B, Sick F, Mimet A, Ezbakhe H, Ajzoul T (2013) Moisture content influence on the thermal conductivity and diffusivity of wood–concrete composite. Constr Build Mater 48:104–115

Trombetta E, Flores-Sahagun T, Satyanarayana KG (2010) Evaluation of polypropylene/saw dust composites prepared with maleated polypropylene (mapp) produced by reactive extrusion. Matér (Rio de Janeiro) 15(2):309–318

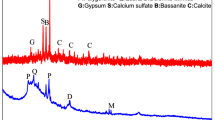

Vaičiukynienė D, Nizevičienė D, Kielė A, Janavičius E, Pupeikis D (2018) Effect of phosphogypsum on the stability upon firing treatment of alkali-activated slag. Constr Build Mater 184:485–491

Zollo RF (1997) Fiber-reinforced concrete: an overview after 30 years of development. Cem Concr Compos 19(2):107–122

Acknowledgement

This research work was supported by the Lithuanian Research Council project “The utilization of industrial waste in alkali-activated concrete”, project code S-MIP-17-363.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kielė, A., Vaičiukynienė, D., Tamošaitis, G. et al. Wood shavings and alkali-activated slag bio-composite. Eur. J. Wood Prod. 78, 513–522 (2020). https://doi.org/10.1007/s00107-020-01516-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-020-01516-x