Abstract

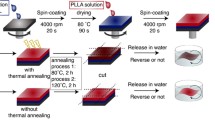

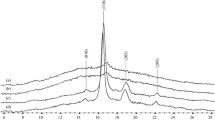

The effect of post-processing annealing beyond the glass transition temperature on optical transparency was studied using poly(lactic acid) (PLA) films containing a nucleating agent such as N,N′-ethylenebis(stearamide) (EBS) or N,N′-ethylenebis(12-hydroxystearamide) (EBHS). Although the PLA films without the nucleating agent became opaque after exposure to annealing, the film with an appropriate amount of the nucleating agent was found to be transparent (the haze value was lower than 10%). Since the crystallinity was enhanced by annealing, the film showed excellent heat resistance. As compared with EBS, moreover, EBHS had a better capability to produce a transparent film because the aggregates, which appeared during cooling from the molten state, were small. In the case of EBHS, a network structure of fibrous EBHS in molten PLA was confirmed, which was responsible for the reduced size of the PLA crystals and prevented spherulite formation.

Similar content being viewed by others

References

Ray SS, Bousmina M (2005) Biodegradable polymers and their layered silicate nanocomposites: in greening the 21st century materials world. Prog. Mater Sci 50:962–1079. https://doi.org/10.1016/j.pmatsci.2005.05.002

R. Auras, L.T. Lim, S.E.M. Selke, H. Tsuji (2010) Poly(lactic acid): synthesis, structures, properties, processing, and applications. Wiley Hoboken

Saeidlou S, Huneault MA, Li HB, Park CB (2012) Poly(lactic acid) crystallization. Prog Polym Sci 37:1657–1677. https://doi.org/10.1016/j.progpolymsci.2012.07.005

A. Jimenez, M. Peltzer, R. Ruseckaite (2014) Poly(lactic acid) science and technology: processing, properties, additives, and applications. RSC Publishing Oxfordshire

M. Yamaguchi (2016) Manufacturing of high-performance biomass-based polyesters by rheological approach, in V.K. Thakur, M.K. Thakur, M.R. Kessler, (Eds.) Handbook of composites from renewable materials. Wiley Hoboken: Chap.2

L.T. Sin, B.S. Tueen (2019) Polylactic acid, 2nd ed. Elsevier Amsterdam

Yokohara T, Nobukawa S, Yamaguchi M (2011) Rheological properties of polymer composites with flexible fine fiber. J Rheol 55:1205–1218. https://doi.org/10.1122/1.3626414

Yamaguchi M, Yokohara T, Ali MABM (2013) Effect of flexible fibers on rheological properties of poly(lactic acid) composites under elongational flow. J Soc Rheol Jpn 41:129–135. https://doi.org/10.1678/rheology.41.129

Yamane H, Sasai K, Takano M, Takahashi M (2004) Poly(D-lactic acid) as a rheological modifier of poly(L-lactic acid): shear and biaxial extensional flow behavior. J Rheol 48:599–609. https://doi.org/10.1122/1.1687736

Yamaguchi M, Wakabayashi T (2006) Rheological properties and processability of chemically modified poly(ethylene terephthalate-co-ethylene isophthalate). Adv Polym Technol 25:236–241. https://doi.org/10.1002/adv.20078

Dhavalikar R, Yamaguchi M, Xanthos M (2003) Molecular and structural analysis of a triepoxide-modified poly(ethylene terephthalate) from rheological data. J Polym Sci Polym Chem 41:958–969. https://doi.org/10.1002/pola.10641

Arruda LC, Magatin M, Bretas RES, Ueki MM (2015) Influence of chain extender on mechanical, thermal and morphological properties of blown films of PLA/PBAT blends. Polym Test 43:27–37. https://doi.org/10.1016/j.polymertesting.2015.02.005

Jiang L, Wolcott MP, Zhang J (2006) Study of biodegradable polylactide/poly(butylene adipate-co-terephthalate) blends. Biomacromolecules 7:199–207. https://doi.org/10.1021/bm050581q

Harada M, Ohya T, Iida K, Hayashi H, Hirano K, Fukuda H (2007) Increased impact strength of biodegradable poly(lactic acid)/poly(butylene succinate) blend composites by using isocyanate as a reactive processing agent. J Appl Polym Sci 106:1813–1820. https://doi.org/10.1002/app.26717

Yokohara T, Yamaguchi M (2008) Structure and properties for biomass-based polyester blends of PLA and PBS. Eur Polym J 44:677–685. https://doi.org/10.1016/j.eurpolymj.2008.01.008

N. Zhang, Q. Wang, J. Ren, L (2009) Wang, preparation and properties of biodegradable poly(lactic acid)/poly(butylene adipate-co-terephthalate) blend with glycidyl methacrylate as reactive processing agent. J Mater Sci 44 : 250–256. https://doi.org/10.1007/s10853-008-3049-4

Li Y, Shimizu H (2009) Improvement in toughness of poly(L-lactide) (PLLA) through reactive blending with acrylonitrile-butadiene-styrene copolymer (ABS): morphology and properties. Eur Polym J 45:738–746. https://doi.org/10.1016/j.eurpolymj.2008.12.010

Kugimoto D, Kouda S, Yamaguchi M (2019) Improvement of mechanical toughness of poly(lactic acid) by addition of ethylene-vinyl acetate copolymer. Polym Test 26:246. https://doi.org/10.1016/j.polymertesting.2019.106021

Han JJ, Huang HX (2011) Preparation and characterization of biodegradable polylactide/thermoplastic polyurethane elastomer blends. J Appl Polym Sci 120:3217–3223. https://doi.org/10.1002/app.33338

Huang T, Miura M, Nobukawa S, Yamaguchi M (2015) Chain packing and its anomalous effect on mechanical toughness for poly(lactic acid). Biomacromolecules 16:1660–1666. https://doi.org/10.1021/acs.biomac.5b00293

Huang T, Yamaguchi M (2017) Effect of cooling conditions on the mechanical properties of crystalline poly(lactic acid). J Appl Polym Sci 134:44960–44966. https://doi.org/10.1002/app.44960

Huang T, Miura M, Nobukawa S, Yamaguchi M (2014) Crystallization behavior and dynamic mechanical properties of poly(L-lactic acid) with poly(ethylene glycol) terminated by benzoate. J Polym Environment 22:183–189. https://doi.org/10.1007/s10924-014-0638-y

Okamoto K, Ichikawa T, Yokohara T, Yamaguchi M (2009) Miscibility, mechanical and thermal properties of poly(lactic acid)/polyester-diol blends. Eur Polym J 45:2304–2312. https://doi.org/10.1016/j.eurpolymj.2009.05.011

Zhaobin T, Zhang C, Liu X, Zhu J (2012) The crystallization behavior and mechanical properties of polylactic acid in the presence of a crystal nucleating agent. J Appl Polym Sci 125:1108–1115. https://doi.org/10.1002/app.34799

Xing Q, Zhang X, Dong X, Liu G, Wang D (2012) Low-molecular weight aliphatic amides as nucleating agents for poly (L-lactic acid): conformation variation induced crystallization enhancement. Polymer 53:2306–2314. https://doi.org/10.1016/j.polymer.2012.03.034

Xiong Z, Zang X, Wang R, Vos S, Wang R, Joziasse CAP, Wang D (2015) Favorable formation of stereocomplex crystals in poly(l-lactide)/poly(d-lactide) blends by selective nucleation. Polymer 76:98–104. https://doi.org/10.1016/j.polymer.2015.08.056

Aliotta L, Cinelli P, Coltelli MB, Righetti MC, Gazzano M, Lazzeri A (2017) Effect of nucleating agents on crystallinity and properties of poly (lactic acid). Eur Polym J 93:823–833. https://doi.org/10.1016/j.eurpolymj.2017.04.041

Feng Y, Ma P, Xu P, Wang R, Dong W, Chen M, Joziasse C (2018) The crystallization behavior of poly(lactic acid) with different types of nucleating agents, intern. J Biological Macromol 106:955–962. https://doi.org/10.1016/j.ijbiomac.2017.08.095

Schüfer H, Pretschuh C, Brüggemann O (2019) Reduction of cycle times in injection molding of PLA through bio-based nucleating agents. Eur Polym J 115:6–11. https://doi.org/10.1016/j.eurpolymj.2019.03.011

Norris FH, Stein RS (1958) The scattering of light from thin polymer films IV. Scattering from oriented polymers J Polym Sci 22:87–114. https://doi.org/10.1002/pol.1958.1202711508

Debye P, Bueche AM (1949) Scattering by an inhomogeneous solid. J Appl Phys 20:518. https://doi.org/10.1063/1.1698419

T.A. Shepard, C. Delsorbo, R. Louth, J.L. Walborn, D. A. Norman, N. G. Harvey, R.J (1997) Spontak, self-organization and polyolefin nucleation efficacy of 1,3;2,4-di-p-dimethylbenzylidene sorbitol. J Polym Sci Part B Polym Phys 35: 2617–2628. https://doi.org/10.1002/(SICI)1099-0488(19971130)35:16<2617::AID-POLB5>3.0.CO;2-M

Tenma M, Yamaguchi M (2007) Structure and properties of injection-molded polypropylene with sorbitol-based clarifier. Polym Eng Sci 47:1441–1446. https://doi.org/10.1002/pen.20839

Tenma M, Mieda N, Takamatsu S, Yamaguchi M (2008) Structure and properties for transparent polypropylene containing sorbitol-based clarifier. J Polym Sci Part B Polym Phys 46:41–47. https://doi.org/10.1002/polb.21340

Baizano L, Rastogi S, Peters GWM (2008) Flow induced crystallization in isotactic popypropylene −1,3:2,4-bis(3,4-dimethylbenzylidene)sorbitol blends: implications on morphology of shear and phase separation. Macromolecules 41:399–408. https://doi.org/10.1021/ma071460g

Roy S, Scionti V, Jana SC, Werdemiotis C, Pischera AM, Espe MP (2011) Sorbitol-POSS interactions on development of isotactic polypropylene composites. Marcomolecules 44:8064–8079. https://doi.org/10.1021/ma201595j

Seemork J, Siriprumpoonthum M, Lee Y, Nobukawa S, Yamaguchi M (2015) Effect of die geometry on drawdown force of polypropylene at capillary extrusion. Adv Polym Technol 34:21477. https://doi.org/10.1002/adv.21477

Phulkerd P, Nakabayashi T, Iwasaki S, Yamaguchi M (2018) Enhancement of drawdown force in polypropylene containing nucleating agent. J Appl Polym Sci 136:47295. https://doi.org/10.1002/app.47295

Tomie S, Tsugawa N, Yamaguchi M (2018) Modifying the thermal and mechanical properties of poly(lactic acid) by adding lithium trifluoromethanesulfonate. J Polym Res 25:206. https://doi.org/10.1007/s10965-018-1605-4

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saitou, Ki., Yamaguchi, M. Transparent poly(lactic acid) film crystallized by annealing beyond glass transition temperature. J Polym Res 27, 104 (2020). https://doi.org/10.1007/s10965-020-02071-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-020-02071-y