Abstract

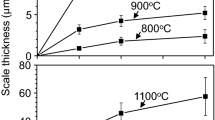

A multilayered TiAlSiN thin film consisting of alternating nanocrystalline Ti(Si)N and Al(Si)N nanolayers was deposited on steel by arc ion plating. The film composition was 26Ti–16.3Al–1.2Si–56.50N in at%. The film was corroded at 800–1000 °C for 4–100 h in N2/0.1%H2S gas to study its corrosion behavior in hostile (H, S)-containing environments. The corrosion was primarily governed by oxidation, because oxides of Ti and Al were much more stable than the corresponding sulfides. The oxygen source for oxidation was impurity oxygen in N2/0.1%H2S gas. Initially, a superficial Al2O3 scale formed. Soon, the scale developed into the outer TiO2-rich layer and the inner Al2O3-rich layer, beneath which formed an oxygen affected zone. As corrosion progressed, Si tended to accumulate in the lower part of the inner Al2O3-rich layer owing to its thermodynamic nobility. Preferential oxidation of Al to Al2O3, formation of fine, dense Al2O3 and TiO2 grains in the oxide scale, and strong Ti–Si, Al–N and Ti–N bonds in the TiAlSiN film caused the scale to grow quite slowly and suppressed fast inward diffusion of sulfur and hydrogen as well as fast outward diffusion of Ti, Al, and Si. Therefore, the film displayed good corrosion resistance at 800–900 °C for up to 100 h. However, it corroded completely, with partial scale spallation and whisker growth at 1000 °C for 50 h.

Graphic Abstract

Similar content being viewed by others

References

H. Ichimura, A. Kawana, J. Mater. Res. 8, 1093 (1993)

S.H. Yao, Y.L. Su, W.H. Kao, T.H. Liu, Tribol. Int. 39, 332 (2006)

W.J. Cho, I.J. Shon, Korean J. Met. Mater. 56, 658 (2018)

S.K. Kim, V. Van Le, Thin Solid Films 518, 7483 (2010)

F. Pei, H.J. Liu, L. Chen, Y.X. Xu, Y. Du, J. Alloys Compd. 790, 909 (2019)

H. Chen, B.C. Zheng, Y.G. Li, Z.L. Wu, M.K. Lei, Thin Solid Films 669, 377 (2019)

F. Cao, P. Munroe, Z. Zhou, Z. Xie, Thin Solid Films 639, 137 (2017)

O. Nakonechna, T. Cselle, M. Morstein, A. Karimi, Thin Solid Films 447, 406 (2004)

L. Chen, S.Q. Wang, Y. Du, S.Z. Zhou, T. Gang, J.C. Fen, K.K. Chang, Y.W. Li, X. Xiong, Surf. Coat. Technol. 205, 582 (2010)

Y.Y. Chang, H.M. Lai, Surf. Coat. Technol. 259, 152 (2014)

W. Tillmann, M. Dildrop, Surf. Coat. Technol. 321, 448 (2017)

X. Sui, G. Li, X. Qin, H. Yu, X. Zhou, K. Wang, Q. Wang, Ceram. Int. 42, 7524 (2016)

C.L. Chang, J.W. Lee, M.D. Tseng, Thin Solid Films 517, 5231 (2009)

H.C. Barshilia, M. Ghosh, Shashidhara, R. Ramakrishna, K.S. Rajam, Appl. Surf. Sci. 256, 6420 (2010)

Y.Y. Chang, S.M. Yang, Thin Solid Films 518, s34 (2010)

L. Zhu, M. Hu, W. Ni, Y. Liu, Vacuum 86, 1795 (2012)

Z.W. Xie, L.P. Wang, X.F. Wang, L. Huang, Y. Lu, J.C. Yan, Nucl. Instrum. Methods B 271, 1 (2012)

S. Zhang, F. Cai, M. Li, Surf. Coat. Technol. 206, 3572 (2012)

L. Xin, Q. Chen, Y. Teng, W. Wang, A. Sun, S. Zhu, F. Wang, Surf. Coat. Technol. 228, 48 (2013)

C. Feng, M. Li, L. Xin, S. Zhu, Z. Shao, Q. Zhao, F. Wang, Surf. Coat. Technol. 232, 88 (2013)

T. Chen, Z. Xie, F. Gong, Z. Luo, Z. Yang, Appl. Surf. Sci. 314, 735 (2014)

S.H. Bak, D.B. Lee, Oxid. Met. 84, 345 (2015)

M. Parlinska-Wojtan, Thin Solid Films 616, 437 (2016)

J.H. Lee, H.K. Park, J.H. Jang, I.H. Oh, Met. Mater. Int. 25, 268 (2019)

G.Y. Lai, High-Temperature Corrosion and Materials Applications (ASM International, Cleveland, 1990), pp. 201–234

N.J. Simms, J.F. Norton, T.M. Lowe, J. Phys. IV 3, 807 (1993)

R. John, in Shreir’s Corrosion, vol. 1, 4th edn., ed. by R.A. Cottis, M.J. Graham, R. Lindsay, S.B. Lyon, J.A. Richardson, J.D. Scantlebury, F.H. Stott (Elsevier, London, 2010), pp. 240–271

Y. Feng, J. Wen, Y. Hu, B. Wu, M. Wua, J. Mi, Chem. Eng. J. 326, 1255 (2017)

N. Birks, G.H. Meier, F.S. Pettit, Introduction to the High-Temperature Oxidation of Metals, 2nd edn., (Cambridge University Press, Cambridge, 2006), pp. 195–197. 62, 63–204

E. Godlewska, Mater. Corros. 48, 687 (1997)

M.G. Hebsur, Appl. Energy 15, 99 (1983)

M.W. Brumm, H.J. Grabke, Corros. Sci. 33, 1677 (1992)

P. Kofstad, J. Less-Common Met. 12, 449 (1967)

S. Mrowec, M. Zastawnik, J. Phys. Chem. Solids 27, 1027 (1966)

Y.J. Kim, P. Yadav, J. Hahn, X. Xiao, D.B. Lee, Met. Mater. Int. 25, 627 (2019)

I. Barin, Thermochemical Data of Pure Substances (VCH, Germany, 1989)

A. Rahmel, P.J. Spencer, Oxid. Met. 35, 53 (1991)

A. Vennemann, H.R. Stock, J. Kohlscheen, S. Rambadt, G. Erkens, Surf. Coat. Technol. 174, 408 (2003)

M. Pfeiler, J. Zechner, M. Penoy, C. Michotte, C. Mitterer, M. Kathrein, Surf. Coat. Technol. 203, 3104 (2009)

H. Holleck, V. Schier, Surf. Coat. Technol. 76, 328 (1995)

Y.M. Chiang, D.P. Birnie III, W.D. Kingery, Physical Ceramics (Wiley, New York, 1996), p. 109

Acknowledgements

This work was supported by the National Research Council of Science and Technology (NST) Grant by the Korea government (MSIT) (No. CRC-15-07-KIER).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hahn, J., Abro, M.A., Xiao, X. et al. Corrosion of Multilayered TiAlSiN Films at 800–1000 °C in N2/0.1%H2S Gas. Met. Mater. Int. 27, 3260–3268 (2021). https://doi.org/10.1007/s12540-020-00665-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00665-1