Abstract

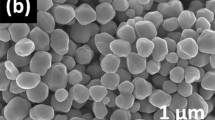

To achieve bondlines with improved heat resistance and thermal conductance during operation, pressure-assisted sinter-bonding was performed in air with bimodal Ag-coated Cu particles for die attachment of the next-generation power devices composed of SiC. The bonding temperature and pressure were 250 °C and 10 MPa, respectively, and the sizes of the bimodal particles were 2 µm and 350 nm. After a short bonding time of 10 min, a paste with a 6:4 mixing ratio showed an average shear strength of > 20 MPa. The dewetting of Ag shells on the particles and void filling by the 350 nm particles induced rapid sintering.

Graphic Abstract

Similar content being viewed by others

References

Kim, J., Park, C., Cho, K.-M., Hong, W., Bang, J.-H., Ko, Y.-H., Kang, N.: Oxidation and repeated-bending properties of Sn-based solder joints after Highly Accelerated Stress Testing (HAST). Electron. Mater. Lett. 14, 678–688 (2018)

Cho, S., Ko, Y.: Finite element analysis for reliability of solder joints materials in the embedded package. Electron. Mater. Lett. 15, 287–296 (2019)

Wang, T., Chen, X., Lu, G.Q., Lei, G.Y.: Low-temperature sintering with nano-silver paste in die attached interconnection. J. Electron. Mater. 36, 1333–1340 (2007)

Siow, K.S., Lin, Y.T.: Identifying the development state of sintered silver (Ag) as a bonding material in the microelectronic packaging via a patent landscape study. J. Electron. Packag. 138, 020804 (2016)

E. Ide, S. Angata, A. Hirose, K.F. Kobayashi: Metal–metal bonding process using Ag metallo-organic nanoparticles. Acta Mater. 53, 2385–2393 (2005)

Noh, S., Choe, C., Chen, C., Zhang, H., Suganuma, K.: Printed wire interconnection using Ag sinter paste for wide band gap power semiconductors. J. Mater. Sci. Mater. Electron. 29, 15223–15232 (2018)

Chang, T.C., Lee, C.C., Hsieh, C.P., Hung, S.C., Cheng, R.S.: Electrical characteristics and reliability performance of IGBT power device packaging by chip embedding technology. Microelectron. Reliab. 55, 2582–2588 (2015)

S. Krishnan, A. Haseeb, M.R. Johan: Preparation and low-temperature sintering of Cu nanoparticles for high-power devices. IEEE Trans. Compon. Packag. Manuf. Technol. 2, 587–592 (2012)

Morisada, Y., Nagaoka, T., Fukusumi, M., Kashiwagi, Y., Yamamoto, M., Nakamoto, M.: A low-temperature bonding process using mixed Cu–Ag nanoparticles. J. Electron. Mater. 39, 1283–1288 (2010)

Noh, B.I., Yoon, J.W., Kim, K.S., Kang, S., Jung, S.B.: Electrochemical migration of directly printed Ag electrodes using Ag paste with epoxy binder. Microelectron. Eng. 103, 1–6 (2013)

Lu, G.Q., Wang, M., Mei, Y., Li, X.: Advanced die-attach by metal-powder sintering: the science and practice. In: Proceedings of 10th International Conference on Integrated Power Electronic System: (CIPS 2018), pp. 594–602 (2018)

Jianfeng, Y., Guisheng, Z., Anming, H., Zhou, Y.N.: Preparation of PVP coated Cu NPs and the application for low-temperature bonding. J. Mater. Chem. 40, 15981–15986 (2011)

Lee, C.H., Choi, E.B., Lee, J.-H.: Characterization of novel high-speed die attachment method at 225 C using submicrometer Ag-coated Cu particles. Scr. Mater. 150, 7–12 (2018)

Chee, S.S., Lee, J.-H.: Preparation and oxidation behavior of Ag-coated Cu nanoparticles less than 20 nm in size. J. Mater. Chem. C 2, 5372–5381 (2014)

Choi, E.B., Lee, J.-H.: Preparation of submicroscale Ag-coated Cu particles by multi-step addition of Ag plating solution and antioxidation properties for different Ag shell thicknesses. Arch. Metall. Mater. 62, 1137–1142 (2017)

Choi, E.B., Lee, J.-H.: Submicron Ag-coated Cu particles and characterization methods to evaluate their quality. J. Alloys Compd. 689, 952–958 (2016)

X. Yu, J. Li, T. Shi, C. Cheng, G. Liao, J. Fan, Z. Tang: A green approach of synthesizing of Cu–Ag core-shell nanoparticles and their sintering behavior for printed electronics. J. Alloys Compd. 724, 365–372 (2017)

P.A. Huttunen, J. Mäkinen, A. Vehanen: Defects in heteroepitaxial structures studied with monoenergetic positrons: large-lattice-mismatch systems Cu/Ag (111) and Ag/Cu (111). Phys. Rev. B 41, 8062–8074 (1990)

Muzikansky, A., Nanikashvili, P., Grinblat, J., Zitoun, D.: Ag dewetting in Cu@Ag monodisperse core–shell nanoparticles. J. Phys. Chem. C 117, 3093–3100 (2013)

Liu, X., Nishikawa, H.: Low-pressure Cu-Cu bonding using in-situ surface-modified microscale Cu particles for power device packaging. Scr. Mater. 120, 80–84 (2016)

J. Li, Q. Liang, T. Shi, J. Fan, B. Gong, C. Feng, J. Fan, G. Liao, Z. Tang: Design of Cu nanoaggregates composed of ultra-small Cu nanoparticles for Cu–Cu thermocompression bonding. J. Alloys Compd. 772, 793–800 (2019)

Acknowledgements

This research was supported by the Commercialization Promotion Agency for R&D Outcomes (COMPA) funded by the Ministry of Science and ICT (MSIT) [Optimization of fabrication processes for the mass production of Ag-coated Cu powder of average size 1.4 m and 400 nm and evaluation of the application properties].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kim, S.Y., Kim, M.I. & Lee, JH. Pressure-Assisted Sinter-Bonding Characteristics at 250 °C in Air Using Bimodal Ag-Coated Cu Particles. Electron. Mater. Lett. 16, 293–298 (2020). https://doi.org/10.1007/s13391-020-00208-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-020-00208-1