Abstract

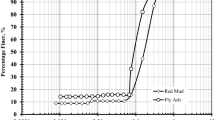

The storage of red mud has seriously damaged the ecological environment, and its utilization is urgent. The roles of particle size fraction of red mud on the geopolymer properties was investigated, to provide guidance for the preparation of red mud-based geopolymer. The composition variation, workability, mechanical strength, and microstructure of each red mud fraction were analyzed, and the results show that the chemical composition changed with the classification. The fluidity decreased first and then increased with the decrement of particle fraction, and all the specimens showed the rheological characteristics of Herschel–Buckley model. The specimens with coarser and finer particles both had excellent mechanical strength and lower porosity. The microstructure of red mud-based geopolymer with different red mud particle fractions was analyzed by FTIR, XRD and SEM–EDS. The results showed that the main hydration products were geopolymer gel (N-A-C-S-H). And the particle fraction has a little effect on the kinds of hydration products. Finally, the particle fraction of red mud was classified according to the properties of red mud-based geopolymer.

Similar content being viewed by others

References

Davidovits J (1989) Geopolymers and geopolymeric new materials. J Therm Anal Calorm 35:429–441

Zhang P, Zheng Y, Wang K, Zhang J (2018) A review on properties of fresh and hardened geopolymer mortar. Compos Part B: Eng 152:79–95

Ma C-K, Awang AZ, Omar W (2018) Structural and material performance of geopolymer concrete: a review. Constr Build Mater 186:90–102

Rożek P, Król M, Mozgawa W (2019) Geopolymer-zeolite composites: a review. J Clean Prod 230:557–579

Hassan A, Arif M, Shariq M (2019) Use of geopolymer concrete for a cleaner and sustainable environment—a review of mechanical properties and microstructure. J Clean Prod 223:704–728

Asim N, Alghoul M, Mohammad M, Amin MH, Akhtaruzzaman M, Amin N, Sopian K (2019) Emerging sustainable solutions for depollution: geopolymers. Constr Build Mater 199:540–548

Zongjin Li and Sifeng Liu (2007) Influence of slag as additive on compressive strength of fly ash-based geopolymer. J Mater Civ Eng 19:470–474

Kinnunen P, Yliniemi J, Talling B, Illikainen M (2017) Rockwool waste in fly ash geopolymer composites. J Mater Cycles Waste Manag 19:1220–1227

Khairul MA, Zanganeh J, Moghtaderi B (2019) The composition, recycling and utilisation of Bayer red mud. Resour Conserv Recycl 141:483–498

Emile M, Zhang LingLing, Liu X, Zhang Na (2019) Utilization of red mud in road base and subgrade materials: a review. Resour Conserv Recycl 141:187–199

Wang W, Jiang J, Xuelong Wu, Liang S (2000) The current situation of solid waste generation and its environmental contamination in China. J Mater Cycles Waste Manag 2:65–69

Verma AS, Verma AS, Kant S (2017) Applications of bauxite residue: a mini-review. Waste Manag Res 35(10):999–1012

Ihsan Cakici A, Yanik J, Uçar S, Karayildirim T, Anil H (2004) Utilization of red mud as catalyst in conversion of waste oil and waste plastics to fuel. J Mater Cycles Waste Manag 2004(6):20–26

Nie Q, Wei H, Tao A et al (2016) Strength properties of geopolymers derived from original and desulfurized red mud cured at ambient temperature. Constr Build Mater 125:905–911

Kaya K, Soyer-Uzun S (2016) Evolution of structural characteristics and compressive strength in red mud-metakaolin based geopolymer systems. Ceram Int 42:7406–7413

Smita Singh M, Aswath U, Ranganath RV (2018) Effect of mechanical activation of red mud on the strength of geopolymer binder. Constr Build Mater 177:91–101

Kaituo W, Lemougna PN, Qing T et al (2017) Low temperature depolymerization and polycondensation of a slag-based inorganic polymer. Ceram Int 43:9067–9076

Ye J, Zhang W, Shi Di (2017) Properties of an aged geopolymer synthesized from calcined ore-dressing tailing of bauxite and slag. Cem Concr Res 100:23–31

NanYe YeChen, Yang J, Liang S, Yong Hu, Jingping Hu, Zhu S, Fan W, Xiao Bo (2017) Transformations of Na, Al, Si and Fe species in red mud during synthesis of one-part geopolymers. Cem Concr Res 101:123–130

NanYe JY, Liang S, Yong Hu, Jingping Hu, Xiao Bo, Huang Q (2016) Synthesis and strength optimization of one-part geopolymer based on red mud. Constr Build Mater 111:317–325

Ye N, Chen Ye, Yang J, Liang S, Hu Y, Xiao B, Huang Q, Shi Y, Hua J, Wua X (2016) Co-disposal of MSWI fly ash and Bayer red mud using an one-part geopolymeric system. J Hazard Mater 318:70–78

Ye N, Yang J, Liang S, Yong Hu, Jingping Hu, Xiao Bo, Huang Q (2016) Synthesis and strength optimization of one-part geopolymer based on red mud. Constr Build Mater 111:317–325

Ye N, Yang J, Ke X, Zhu J, Li Y, Xiang C, Wang H, Li L, Xiao Bo (2014) Synthesis and characterization of geopolymer from Bayer red mud with thermal pretreatment. J Am Ceram Soc 97(5):1652–1660

Liu W, Zhang X, Jiang W, Xinfeng Z, Jiakuan Y (2011) Study on particle-size separation pretreatment of Bayer red mud. Chin J Environ Eng 5(4):521–524

Zhu F, Xue SG, William H, Huang L, Wu C, Li XF (2016) Novel predictors of soil genesis following natural weathering processes of bauxite residues. Environ Sci Pollut R 23:2856–2863

Assi LN, Deaver EE, Ziehl P (2018) Effect of source and particle size distribution on the mechanical and microstructural properties of fly ash-based geopolymer concrete. Constr Build Mater 167:372–380

Zhang D, Wang D, Liu Ze, Xie F (2018) Rheology, agglomerate structure, and particle shape of fresh geopolymer pastes with different NaOH activators content. Constr Build Mater 187:674–680

Özer Sevim and İlhami Demir (2019) Optimization of fly ash particle size distribution for cementitious systems with high compactness. Constr Build Mater 195:104–114

Frigioine G, Marra S (1976) Relationship between particle size distribution and compressive strength in Portland cement. Cem Concr Res 6:113–128

Zhang YM, Napier-Munn TJ (1995) Effects of particle size distribution, surface area and chemical composition on Portland cement strength. Powder Technol 83:245–252

Bentz DP, Conway JT (2001) Computer modeling of the replacement of ‘‘coarse’’ cement particles by inert fillers in low w/c ratio concretes: hydration and strength. Cem Concr Res 31:503–506

Zhang T, Qijun Yu, Wei J, Zhang P (2011) Effects of size fraction on composition and fundamental properties of Portland cement. Constr Build Mater 25:3038–3043

Furlani E, Maschio S, Magnan M et al (2018) Synthesis and characterization of geopolymers containing blends of unprocessed steel slag and metakaolin: the role of slag particle size. Ceram Int 44:5226–5232

Wallevik OH, Feys D, Wallevik JE, Khayat KH (2015) Avoiding inaccurate interpretations of rheological measurements for cement-based materials. Cem Concr Res 78:100–109

Daddy Kabagire K, Diederich P, Yahia A, Chekired M (2017) Experimental assessment of the effect of particle characteristics on rheological properties of model mortar. Constr Build Mater 151:615–624

HaoLiang W, Jing Y, Duo Z et al (2019) Effect of morphological parameters of natural sand on mechanical properties of engineered cementitious composites. Cem Concr Comp 100:108–119

Wan Q, Rao F, Song S et al (2017) Geopolymerization reaction, microstructure and simulation of metakaolin-based geopolymers at extended Si/Al ratios. Cem Concr Comp 79:45–52

Hua W, Nie Q, Huang B, Shu X, He Q (2018) Mechanical and microstructural characterization of geopolymers derived from red mud and fly ashes. J Clean Prod 186:799–806

El-Naggar MR, El-Dessouky MI (2017) Re-use of waste glass in improving properties of metakaolin-basedgeopolymers: mechanical and microstructure examinations. Constr Build Mater 132:543–555

Zhang Z, Li L, Ma X, Wang H (2016) Compositional, microstructural and mechanical properties of ambient condition cured alkali-activated cement. Constr Build Mater 113:237–245

Acknowledgements

This study was financially supported by the Young Scientists Funds of National Natural Science Foundation of China (Grants nos. 51709158), the Major Project of Chinese National Programs for Fundamental Research and Development (Project no. 2017YFC0703100), the Major Basic Project of Shandong Provincial Natural Science Foundation of China (Project no. ZR2017ZC0734), and the China Postdoctoral Science Foundation Funded Project (no. 2018M632676).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, J., Li, S., Li, Z. et al. Feasibility study of red mud for geopolymer preparation: effect of particle size fraction. J Mater Cycles Waste Manag 22, 1328–1338 (2020). https://doi.org/10.1007/s10163-020-01023-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-020-01023-4