Abstract

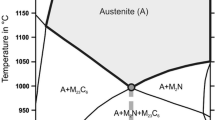

The microstructures of additively manufactured (AM) precipitation-hardenable stainless steels 17-4 and 15-5 were investigated and compared to those of conventionally produced materials. The residual N found in N2-atomized 17-4 powder feedstock is inherited by the additively produced material, and has dramatic effects on phase stability, microstructure, and microstructural evolution. Nitrogen is a known austenite stabilizing element, and the as-built microstructure of AM 17-4 can contain up to 90 pct or more retained austenite, compared to the nearly 100 pct martensite structure of wrought 17-4. Even after homogenization and solutionization heat treatments, AM 17-4 contains 5 to 20 pct retained austenite. In contrast, AM 15-5 and Ar-atomized AM 17-4 contain < 5 pct retained austenite in the as-built condition, and this level is further decreased following post-build thermal processing. Computational thermodynamics-based calculations qualitatively describe the observed depression in the martensite start temperature and martensite stability as a function of N-content, but require further refinements to become quantitative. A significant increase in the volume fraction of fine-scale carbide precipitates attributed to the high N-content of AM 17-4 is also hypothesized to give rise to additional activation barriers for the dislocation motion required for martensite nucleation and subsequent growth. An increase in the volume fraction of carbide/nitride precipitates is observed in AM 15-5, although they do not inhibit martensite formation to the extent observed in AM 17-4.

Similar content being viewed by others

Notes

All compositions are given in mass fraction times one hundred unless otherwise stated. For example, an alloy with a N-content of 0.15 pct, contains a mass fraction of N of 0.0015.

Mention of commercial products does not imply endorsement by NIST, nor does it imply that such products or services are necessarily the best available for the purpose.

The tetragonality (i.e., c/a lattice parameter ratio) of the martensite was found to be very close to one, making the distinction between BCT-martensite and BCC-δ-ferrite impossible using X-ray techniques. Because of this BCC/martensite is used when discussing XRD results.

References

AK Steel Product Data Bulletin, 17-4 PH Stainless Steel, AK Steel Corporation, West Chester, OH, December 2016.

ATI Technical Data Sheet, ATI 17-4 Precipitation Hardening Stainless Steel, Allegheny Technologies Incorporated, Pittsburgh, PA, August 2016.

AK Steel Product Data Bulletin, 15-5 PH Stainless Steel, AK Steel Corporation, West Chester, OH, July 2007.

ATI Technical Data Sheet, ATI 15-5 Precipitation Hardening Stainless Steel, Allegheny Technologies Incorporated, Pittsburgh, PA, March 2012.

Aerospace Material Specification 5355J, Steel, Corrosion Resistant, Investment Castings, 16Cr-4.1Ni-0.28Nb-3.2Cu, Homogenization and Solution Heat Treated or Homogenization, Solution, and Precipitation Heat Treated. SAE Aerospace, SAE International, 2009.

T.L. Starr, K. Rafi, B. Stucker, C.M. Scherzer, 23rd Annual Solid Freeform Fabrication Symposium, 2012, pp. 439–46.

L.E. Murr, E. Martinez, J. Hernandez, S. Collins, K.N. Amato, S.M. Gaytan, P.W. Shindo, J. Mater. Res. Technol., 2012, vol. 1, pp. 167-77.

S.D. Meredith, J.S. Zuback, J.S. Keist, T.A. Palmer, Mater. Sci. Eng. A, 2018, vol. 738, pp. 44-56.

S. Cheruvathur, E.A. Lass, C.E. Campbell, JOM, 2016, vol. 68, pp. 930-42.

E.A. Lass, M.R. Stoudt, M.E. Williams, Metall. Mater. Trans. A, 2019, vol. 50A, pp. 1619-24.

M.R. Stoudt, R.E. Ricker, E.A. Lass, L.E. Levine, JOM, 2017, vol. 69, pp. 506-15.

B.D. Salzbrenner, M.S. Thesis, The University of New Mexico, Albuquerque, New Mexico, 2017.

A.B. Lass, G. Welsh, U.S. Naval Air Systems Command (NAVAIR), private communication, 2017.

J.S. Keist, T.A. Palmer, Pennsylvania State University, private communication, 2017.

Additive Manufacturing Benchmark Test Series (AM-Bench). https://www.nist.gov/ambench. Accessed 12 Dec 2018.

K.M. Coffy, M.S. Thesis, University of Central Florida, Orlando, Florida, 2014.

E.W. Lum, M.S. Thesis, Air Force Institute of Technology, Wright-Patterson Air Force Base, Ohio, 2017.

W.E. Luecke, J.A. Slotwinski, J. Res. Natl. Inst. Stand. Technol., 2014, vol. 119, pp. 398-418.

H.K. Rafi, D. Pal, N. Patil, T.L. Starr, B.E. Stucker, J. Mater. Eng. Perf., 2014, vol. 23, pp. 4421-8.

B. Clausen, D.W. Brown, J.S. Carpenter, K.D. Clarke, A.J. Clarke, S.C. Vogel, J.D. Bernardin, D. Spernjak, J.M. Thompson, Mater. Sci. Eng. A, 2017, vol. 696, pp. 331-40.

D.W. Brown, J.D. Bernardin, J.S. Carpenter, B. Clausen, D. Spernjak, J.M. Thompson, Mater. Sci. Eng. A, 2016, vol. 678, pp. 291-8.

G.E. Dieter, Mechanical Metallurgy, 3rd Edition. McGraw Hill, Boston, Massachusetts, 1986.

A. Yadollahi, N. Shamsaei, S.M. Thompson, A. Elwany, L. Bian, Int. J. Fatigue, 2017, vol. 94, pp. 218-35.

B. AlMangour, J.-M. Yang, Int. J. Adv. Manuf. Technol., 2017, vol. 90, pp. 119-26.

H.K. Rafi, T.L. Starr, B.E. Stucker, Int. J. Adv. Manuf. Technol., 2013, vol. 69, pp. 1299-1309.

C. Buchannan, V.-P. Matilainen, A. Salminen, L. Gardner, J. Constr. Steel Res., 2017, vol. 136, pp. 35-48.

D. Roberts, Y. Zhang, I. Charit, J. Zhang, Prog. Add. Manuf., 2018, vol. 3, pp. 183-90.

T. LeBrun, T. Nakamoto, K. Horikawa, H. Kobayashi, Mater. Des., 2015, vol. 81, pp. 44-53.

H.Ö. Gülsoy, S. Özbek, T. Baykara, Powder Metall., 2007, vol. 50, pp. 120-26.

R. Gerling, R. Leitgeb, F.-P. Schimansky, Mater. Sci. Eng. A, 1998, vol. 252A, pp. 239-47.

G. Wegmann, R. Gerling, F.-P. Schimansky, Acta Mater., 2003, vol. 51, pp. 741-52.

B.D. Cullity, “Elements of X-ray Diffraction”, 2nd Edition. Addison-Wesley Publishing Company, Inc., Philippines, 1978.

P.L. Lee, D. Shu, M. Ramanathan, C. Preissner, J. Wang, M.A. Beno, R.B. Von Dreele, L. Ribaud, C. Kurtz, S.M. Antao, J. Synchrotron Radiat., 2008, vol. 15, pp. 427-32.

B.H. Toby, R.B. Von Dreele, J. Appl. Crystallogr., 2013, vol. 46, pp. 544-49

F. Zhang, L.E. Levine, A.J. Allen, S.W. Young, M.E. Williams, M.R. Stoudt, K.-W. Moon, J.C. Heigel, J. Ilavsky, IMMI, 2019, submitted

Thermo-Calc 2018b, Themo-Calc Software AB, Stockholm, Sweden, 2018.

TCFE8 Fe-based superalloy database, Themo-Calc Software AB, Stockholm, Sweden, 2016.

G. Ghosh, G.B. Olson, Acta Metall. Mater., 1994, vol. 42, pp. 3361-70.

G. Ghosh, G.B. Olson, Acta Metall. Mater., 1994, vol. 42, pp. 3371-79.

G.B. Olson, M. Cohen, Metall. Trans. A, 1976 vol. 7A, pp. 1897-1904.

G.B. Olson, M. Cohen, Metall. Trans. A, 1976 vol. 7A, pp. 1905-14.

G.B. Olson, M. Cohen, Metall. Trans. A, 1976 vol. 7A, pp. 1915-23.

H.K. Danielsen, Ph.D. Dissertation, Technical University of Denmark, 2007.

H.K. Danielsen, Mater. Sci. Tech., 2016, vol. 32, pp. 126-37.

M. Alnajjar, F. Christien, K. Wolski, C. Bosch, Additive Manuf., 2019, vol. 25, pp. 187-95.

E.A. Lass, M.R. Stoudt, M.E. Williams, M.B. Katz, L.E. Levine, T.Q. Phan, T.H. Gnaeupel-Herold, D.S. Ng: Metall. Mater. Trans. A, vol. 48A, pp. 5547-58 (2017)

M. Wendler, B. Reichel, R. Eckner, O. Fabrichnaya, L. Krüger, A. Weiss, J. Mola, Metall. Mater. Trans. A, 2016, vol. 47A, pp. 139-51.

T. Sawaguchi, L.-G. Bujoreanu, T. Kikuchi, K. Ogawa, F. Yin, ISIJ Int., 2008, vol. 48, pp. 99-106.

M. Grujicic, G.B. Olson, W.S. Owen, Metall. Trans. A, 1985, vol. 16A, pp. 1713-22.

M. Grujicic, G.B. Olson, W.S. Owen, Metall. Trans. A, 1985, vol. 16A, pp. 1723-34.

M. Grujicic, G.B. Olson, W.S. Owen, Metall. Trans. A, 1985, vol. 16A, pp. 1735-44.

Acknowledgments

The authors would like to thank the Engineering Laboratory at the National Institute of Standards and Technology (NIST), the Applied Research Laboratory at Pennsylvania State University, and Naval Air Systems Command (NAVAIR) for providing the N2-atomized AM 17-4, argon-atomized AM 17-4, and AM 15-5 material, respectively. Use of the Advanced Photon Source, an Office of Science User Facility operated for the U.S. Department of Energy (DOE) Office of Science by Argonne National Laboratory, was supported by the U.S. DOE under Contract No. DE-AC02-06CH11357.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 16, 2019.

Rights and permissions

About this article

Cite this article

Lass, E.A., Zhang, F. & Campbell, C.E. Nitrogen Effects in Additively Manufactured Martensitic Stainless Steels: Conventional Thermal Processing and Comparison with Wrought. Metall Mater Trans A 51, 2318–2332 (2020). https://doi.org/10.1007/s11661-020-05703-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05703-6