Abstract

A mechanism is proposed for the joint reduction of oxides from multicomponent copper-smelting slag when they are blown with CO–CO2 gas mixtures and an algorithm is developed for its implementation in the form of a mathematical model. The first feature of the proposed mechanism is that the total rate of the overall reduction process is determined by CO consumption in the course of its interaction with oxygen ions formed owing to the dissociation of slag oxides. The second feature is that the equilibrium between the slag, alloy, and gas phase is achieved in accordance with the oxidation potential of the system occurring at each moment of time. It is shown that there is a satisfactory agreement between the calculated and experimental data obtained in the course of the reduction of the industrial copper-smelting slag at a temperature of 1300°C and at a ratio of CO/CO2 = 4, 6, and 156. In this case, a first-order kinetic equation is valid with respect to the difference between the initial and equilibrium CO content in the gas phase. A generalized rate constant for the reduction of multicomponent slag has been calculated amounting to k = 2.6 × 10–7 molCO/(cm2 s%) at a temperature of 1300°С. It is shown that, under the reduction of industrial multicomponent slag, the reduction rates for copper oxide and magnetite are rather high, being close to the maximum value at the very beginning of the slag blowing with the reducing gas. At the same time, the reduction rates for ferrous oxide and for the oxides of zinc and lead in the first minutes of the process are insignificant and exhibit a gradual increase before reaching a maximum, after which they again decrease almost to zero values as the system approaches the equilibrium between the supplied gas and the melt. In general, the reduction rate of oxides decreases when the equilibrium between the initial gas and the liquid phase is approached, and this should be taken into account when organizing the processes of continuous slag depletion.

Similar content being viewed by others

REFERENCES

Komkov, A.A. and Kamkin, R.I., The behavior of copper and impurities during bubbling of copper-smelting slags with CO-CO2 gas mixture, Tsvetn. Met., 2011, no. 6, pp. 26–31.

Romenets, V.A., Valavin, V.S., Usachev, A.B., Karabasov, Yu.S., and Balasanov, A.V., ROMELT Process, Moscow: MISIS, 2005.

Min, D.J., Han, J.W., and Chung, W.S., A study of the reduction rate of FeO in slag by solid carbon, Metal. Mater. Trans. B, 1999, vol. 30, pp. 772–775.

Parra, R., Wilkomirsky, I., and Allibert, M., Direct reduction of copper–iron–silicon oxide melts, in Proc. Int. Conf. “Copper 99 – Cobre 99” (Phoenix, Oct. 10–13 1999), Warrendale: TMS, 1999, vol. 4, pp. 553–570.

Halder, S. and Fruehan, R.J., Reduction of iron-oxide-carbon composites: pt. 1. Estimation of the rate constants, Metal. Mater. Trans. B, 2008, vol. 39, pp. 784–795.

Corbari, R., Matsuura, H., Halder, S., Walker, M., and Fruehan, R.J., Foaming and the rate of the carbon–iron oxide reaction in slag, Metal. Mater. Trans. B, 2009, vol. 40, pp. 772–775.

Madej, P. and Kucharski, M., Influence of temperature on the rate of copper recovery from the slag of the flash direct-to-blister process by a solid carbon reducer, Arch. Metal. Mater., 2015, vol. 60, pp. 1663–1671.

Hayes, P.C., Okongwu, D.A., and Togyri, J.M., Some observation of the reaction between molten oxides and solid carbon, Can. Metal. Quart., 1995, vol. 34, pp. 27–36.

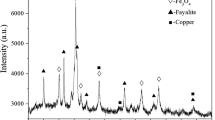

Warczok, A. and Utigard, T.A., Fayalite slag reduction by solid graphite, Can. Metal. Quart., 1998, vol. 37, pp. 27–39.

Huaiwei, Z., Xiaoyan, S., Bo, Z., and Xin, H., Reduction of molten copper slags with mixed CO–C4–Ar gas, Metal. Mater. Trans. B, 2014, vol. 45, pp. 582–589.

Hu, X., Matsuura, H., and Tsukihashi, F., Interfacial reaction between CO2–CO gas and molten iron oxide containing P2O5, Metal. Mater. Trans. B, 2006, vol. 37, pp. 395–401.

Barati, M. and Coley, K.S., Kinetics of CO–CO2 reaction with CaO–SiO2–FeOx melts, Metal. Mater. Trans. B, 2005, vol. 36, pp. 169–178.

Li, Y. and Ratchev, I.P., Rate of interfacial reaction between molten CaO–SiO2–Al2O3–FexO and CO–CO2, Metal. Mater. Trans. B, 2002, vol. 33, pp. 651–660.

Utigard, T., Sanchez, G., Manriquez, J., Luraschi, A., Diaz, C., Cordero, D., and Almendras, E., Reduction kinetics of liquid iron oxide-containing slags by carbon monoxide, Metal. Mater. Trans. B, 1997, vol. 28, pp. 821–826.

Xie, D. and Belton, G.R., Kinetics of reduction of ferric iron in Fe2O3–CaO–SiO2–Al2O3 slags under argon, CO–CO2, or H2–H2O, Metal. Mater. Trans. B, 2003, vol. 34, pp. 225–234.

Sorokin, M.L., Andryushechkin, N.A., and Nikolaev, A.G., Thermodynamics of the Cu-Fe system, Izv. Vyssh. Uchebn. Zaved.,Tsvetn. Metall., 1996, vol. 6, pp. 10–14.

Ladygo, E.A., Copper and nickel distribution patterns between the depleting melt products in reducing conditions, Extended Abstract of Cand. Sci. (Eng.) Dissertation, Moscow: MISIS, 2003.

Cockcroft, S.L., Richards, G.G., and Brimacombe, J.K., Mathematical model of lead behaviour in the zinc slag fuming process, Can. Metal. Quart., 1988, vol. 27, pp. 27–40.

Vanyukov, A.V., Bystrov, V.P., Vaskevich, A.D., Bruek, V.N., Zaitsev, V.Ya., Kirillin, I.I., Komkov, A.A., Mantsevich, N.M., Miklin, N.A., Sorokin, M.L., Fedorov, A.N., Tsesarsky, V.S., and Shubsky, A.G., Smelting in the Liquid Bath, Moscow: Metallurgiya, 1988.

Vaskevich, A.D., Sorokin, M.L., and Kaplan, V.A., General thermodynamic model of copper solubility in slags, Tsvetn. Met., 1982, vol. 10, pp. 22–26.

Komkov, A.A. and Vaskevich, A.D., Model of the biphasic gas-liquid flow, Izv. Akad. Nauk USSR.Met., 1989, vol. 6, pp. 24–29.

Komkov, A.A., Kamkin, R.I., Kuznetsov, A.V., and Karyaev, V.I., Specifics of copper recovery from the slags during reducing in bubbling conditions, Tsvetn. Met., 2018, vol. 11, pp. 21–26.

Thermodynamic database FactSage. http:// www.factsage.com. Cited 17.02.2018.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by O. Polyakov

About this article

Cite this article

Komkov, A.A., Kamkin, R.I. Mechanism for the Reduction of Oxides in Copper-Smelting Slag under Blowing with CO–CO2 Gas Mixtures. Russ. J. Non-ferrous Metals 61, 57–64 (2020). https://doi.org/10.3103/S106782122001006X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S106782122001006X