Abstract

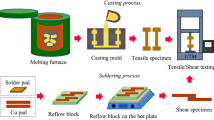

This paper presents an investigation of the effects of aging temperature on the microstructure and shear strength of SAC0307-0.1Ni/Cu solder joints. Single-overlap shear solder joints were aged for 1 h at 80, 130, and 180°C. The microstructure of the interface between the solder and the Cu substrate contained phase of the intermetallic compounds (IMCs) (Cu,Ni)6Sn5 formed along the interface. The shape of scallop-like (Cu,Ni)6Sn5 IMCs changed to the long dendrite and grew larger at the interface of solder joints after increased aging temperature. In addition, a phase of particle-like Ag3Sn IMCs was formed in the solder matrix. The growth of the interfacial IMC layer in the solder joints increased with increasing the aging temperature. The thickness of this layer was controlled by diffusion mechanism. The shear strength of the as-reflowed solder joints was greater than that of the aged solder joints, and the shear strength of all the aged solder joints decreased with increasing the aging temperatures. Therefore, the aging temperature mainly affected the thickness of the interfacial layer of IMCs and the shear strength of the solder joints.

Similar content being viewed by others

REFERENCES

Tao, Q.B., Benabou, L., Vivet, L., Le, V.N., and Ouezdou, F.B., Effect of Ni and Sb additions and testing conditions on the mechanical properties and microstructures of lead-free solder joints, Mater. Sci. Eng. A, 2016, vol. 669, pp. 403–416.

El-Daly, A.A., Hammad, A.E., Fawzy, A., and Nasrallh, D.A., Microstructure, mechanical properties, and deformation behavior of Sn–1.0Ag–0.5Cu solder after Ni and Sb additions, Mater. Design, 2013, vol. 43, pp. 40–49.

Abtew, M. and Selvaduray, G., Lead-free solders in microelectronics, Mater. Sci. Eng. R, 2000, vol. 27, pp. 95–141.

Frear, D.R., Issues related to the implementation of Pb-free electronic solders in consumer electronics, J. Mater. Sci. Mater. Electron., 2007, vol. 18, pp. 319–330.

Sharif, A. and Chan, Y.C., Effect of indium addition in Sn-rich solder on the dissolution of Cu metallization, J. Alloys Compd., 2005, vol. 390, pp. 67–73.

Mehrabi, K., Khodabakhshi, F., Zareh, E., Shahbazkham, A., and Simchi, A., Effect of alumina nanoparticles on the microstructure and mechanical durability of meltspun lead-free solders based on tin alloys, J. Alloys Compd., 2016, vol. 688, pp.143–155.

Lee, H., Chen, M., Jao, H., and Liao, T., Influence of interfacial intermetallic compound on fracture behavior of solder joints, Mater. Sci. Eng. A, 2003, vol. 358, pp. 134–141.

Chan, Y.C., So, A.C.K., and Lai, J.K.L., Growth kinetic studies of Cu–Sn intermetallic compound and its effect on shear strength of LCCC SMT solder joints, Mater. Sci. Eng. B, 1998, vol. 55, pp. 5–13.

Pang, H.L.J., Tan, K.H., Shi, X.W., and Wang, Z.P., Microstructure and intermetallic growth effects on shear and fatigue strength of solder joints subjected to thermal cycling aging, Mater. Sci. Eng. A, 2001, vol. 307, pp. 42–50.

Miao, H.W. and Duh, J.G., Microstructure evolution in Sn–Bi and Sn–Bi–Cu solder joints under thermal aging, Mater. Chem. Phys., 2001, vol. 71, pp. 255–271.

Kim, K.S., Huh, S.H., and Suganuma, K., Effects of intermetallic compounds on properties of Sn–Ag–Cu lead-free soldered joints, J. Alloys Compd., 2003, vol. 352, pp. 226–236.

Deng, X., Shidhu, R.S., Johnson, P., and Chawla, N., Influence of reflow and thermal aging on the shear strength and fracture behavior of Sn–3.5Ag solder/Cu joints, Metall. Mater. Trans. A, 2005, vol. 36, pp. 55–64.

Ahat, S., Sheng, M., and Luo, L., Microstructure and shear strength evolution of SnAg/Cu surface mount solder joint during aging, J. Electron. Mater., 2001, vol. 30, pp.1317–1322.

Hu, X., Li, Y., Liu, Y., Liu, Y., and Min, Z., Microstructure and shear strength of Sn37Pb/Cu solder joints subjected to isothermal aging, Microelectron. Reliab., 2014, vol. 54, pp. 1575–1582.

Deng, X., Piotrowski, G., Williams, J.J., and Chawla, N., Influence of initial morphology and thickness of Cu6Sn5 and Cu3Sn intermetallics on growth and evolution during thermal aging of Sn–Ag solder/Cu joints, J. Electron. Mater., 2003, vol. 32, pp. 1403–1413.

Ochoa, F., Williams, J.J., and Chawla, N., Effects of cooling rate on the microstructure and tensile behavior of a Sn–3.5 wt % Ag solder, J. Electron. Mater., 2003, vol. 32, pp. 1414–1420.

Tang, Y., Luo, S.M., Huang, W.F., Pan, Y.C., and Li, G.Y., Effects of Mn nanoparticles on tensile properties of low-Ag Sn–0.3Ag–0.7Cu–xMn solder alloys and joints, J. Alloys Compd., 2017, vol. 719, pp. 365–375.

Hammad, A.E., Evolution of microstructure, thermal and creep properties of Ni-doped Sn–0.5Ag–0.7Cu low-Ag solder alloys for electronic applications, Mater. Design, 2013, vol. 52, pp. 663–670.

Lee, H.T., Lee, C.Y., Lee, F.F., Chen, Y.F., and Lee, Y.H., Microstructural evolution of Sn–Ag–Sb solder with indium additions, J. Electron. Mater., 2009, vol. 38, pp. 2112–2121.

Tomlinson, W.J. and Fullylove, A., Strength of tin-based soldered joints, J. Mater. Sci., 1992, vol. 27, pp. 5777–5782.

Hu, X., Xu, T., Keer, L.M., Li, Y., and Jiang, X., Shear strength and fracture behavior of reflowed Sn3.0Ag0.5Cu/Cu solder joints under various strain rates, J. Alloys Compd., 2017, vol. 690, pp. 720–729.

Hammad, A.E., Investigation of microstructure and mechanical properties of novel Sn–0.5Ag–0.7Cu solder containing small amount of Ni, Mater. Design, 2013, vol. 50, pp. 108–116.

Hodulova, E., Palcut, M., Lechovic, E., Simekova, B., and Ulrich, K., Kinetics of intermetallic phase formation at the interface of Sn–Ag–Cu–X (X = Bi, In) solders with Cu substrate, J. Alloys Compd., 2011, vol. 509, pp. 7052–7059.

Teo, J.W.R. and Sun, Y.F., Spalling behavior of interfacial intermetallic compounds in Pb-free solder joints subjected to temperature cycling loading, Acta Mater., 2008, vol. 56, pp. 242–249.

Abdelhadi, O.M. and Ladani, L., IMC growth of Sn‒3.5Ag/Cu system: combined chemical reaction and diffusion mechanisms, J. Alloys Compd., 2012, vol. 537, pp. 87–99.

Lee, Y.H. and Lee, H.T., Shear strength and interfacial microstructure of Sn–Ag–xNi/Cu single shear lap solder joints, Mater. Sci. Eng. A, 2007, vol. 444, pp. 75–83.

Chen, W.L., Yu, C.Y., Ho, C.Y., and Duh, J.G., Effect of thermal annealing in the post-reflow process on microstructure tin crystallography and impact reliability of Sn–Ag–Cu solder joints, Mater. Sci. Eng. A, 2014, vol. 613, pp. 193–200.

Nogita, K., Stabilisation of Cu6Sn5 by Ni in Sn–0.7Cu-0.05Ni lead-free solder alloys, Intermetallics, 2010, vol. 18, pp. 145–149.

Han, Y.D., Jing, H.Y., Nai, S.M.L., Xu, L.Y., Tan, C.M., and Wei, J., Effect of Ni-coated carbon nanotubes on interfacial reaction and shear strength of Sn–Ag–Cu solder joints, J. Electron. Mater., 2012, vol.41, pp. 2478–2486.

Hu, X., Xu, T., Keer, L.M., Li,Y., and Jiang, X., Microstructure evolution and shear fracture behavior of aged Sn3Ag0.5Cu/Cu solder joints, Mater. Sci. Eng. A, 2016, vol. 673, pp. 167–177.

Chen, G., Peng, H., Silberschmidt, V.V., Chan, Y.C., and Liu, C., Performance of Sn–3.0Ag–0.5Cu composite solder with TiC reinforcement: Physical properties, solderability and microstructural evolution under isothermal ageing, J. Alloys Compd., 2016, vol. 685, pp. 680–689.

Adawiyah, M.A.R. and Azlina, O.S., Comparative study on the isothermal aging of bare Cu and ENImAg surface finish for Sn–Ag–Cu solder joints, J. Alloys Compd., 2018, vol. 740, pp. 958–966.

ACKNOWLEDGMENTS

This work has been supported by Prince of Songkla University Research Fund (Fiscal Year 2016) under the contract number SCI590647S. We would like to thank academician Thomas Duncan Coyne for commenting and improving the English in the manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors claim that they have no conflict of interest.

About this article

Cite this article

Phairote Sungkhaphaitoon, Suchart Chantaramanee Effect of Aging Temperature on the Microstructure and Shear Strength of SAC0307-0.1Ni Lead-Free Solders in Copper Joints. Russ. J. Non-ferrous Metals 61, 89–98 (2020). https://doi.org/10.3103/S1067821220010162

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821220010162