Abstract

The application of the agricultural waste of cashew nut shells (CNSs) from the Ivory Coast is proposed for the production of activated carbon (AC) used in water treatment by the physical activation. Washed and crushed CNSs are carbonized at 800°C. The crushed CNS carbonizate is activated by the physical method in a temperature range from 400 to 700°C. The specific surface (SBET) and porous structure of the AC samples are investigated by low-temperature nitrogen desorption and X-ray structural (X-ray phase) analysis. The results show that an increase in the activation temperature at a fixed time leads to an increase in the material specific surface, the development of a microporous structure, and an increase in the summary volume of mesopores and micropores of AC. The X-ray phase analysis data shows that the degree of graphitization, interplanar spacing, and crystallite sizes vary insignificantly. The possibility of using CNSs to fabricate AC no worse in sorption properties than its analogs currently in use to purify water is proven.

Similar content being viewed by others

REFERENCES

Bogayev, A.N., Gorelova, O.M., and Kurochkin, E.S., Study of the regularities of the pyrolysis process of the pine nut shell and the production of activated carbon on the basis of its properties with specified properties, Polzunovsk. Vestn., 2014, no. 3, pp. 217–220.

Pustovaya, L.E., Tyurina, T.A., Talpa, B.V., and Bayan, E.M., Adsorbability of “talpus-ro” and “talpus-kk” mould, Vestn. Donskogo Tech. Univ., 2012, vol. 12, no. 63, pp. 151–152.

Perederiy, Yu.I., Kurakov, I.N., and Malikov, M.V., Adsorbents Based on Carbon-Containing Materials, Moscow: Metallurgizdat, 2014.

Beletskaya, M., Synthesis of carbon adsorbents by thermochemical activation of hydrolytic lignin using sodium hydroxide, Cand. Sci. (Eng.) Dissertation, Arkhangelsk: Northern (Arctic) Federal Univ., 2014.

Kienle, H. and E. Bäder, Aktivkohle und ihre industrielle Anwendung, Stuttgart: Ferdinand Enke Verlag, 1980.

Kishibayev, K.K., Kabulov, A.T., Tokpaev, R.R., Atchabarova, A.A., Nechipurenko, S.V., Yefremov, S.A., Nauryzbaev, M.K., and Mukhin, V.M., IR-spectroscopy of activated carbons based on copolymers of furfural, Vestn. Kaz. Nats. Tekhn. Univ., 2014, no. 4, pp. 344–348.

Butyrin, G.M., Highly Porous Carbon Materials, Moscow: Khimiya, 1976.

Grah Patrick Atheba, Traitement des eaux par action combinée de la photocatalyse solaire et de l’adsorption sur charbon actif: conception et realisation du procédé, These de Doctorat, Metz: Universite Paul Verlaine, 2009.

Pavlenko, V.V., Synthesis and use of multifuncional carbon nanostructured materials based on plant fiber, Cand. Sci. (Eng.) Dissertation, Almaty: Al-Farabi Kazakh National University, 2014.

Bashirov, I.I., Preparation of a molded carbon adsorbent from petroleum feedstocks by steam and alkaline activation, Cand. Sci. (Eng.) Dissertation, Ufa: Ufa State Petroleum Technical Univ., 2016.

Smirnov, A.D., Sorption Cleaning of Water, Leningrad: Khimiya, 1982.

Mukhin, V.M. and Klushin, V.N., Production and Application of Carbon Adsorbents, Moscow: D. Mendeleev University of Chemical Technology of Russia, 2011.

Kolyshkin, D.A. and Mikhailova, K.K., Activated Carbon, Leningrad: Khimiya, 1972.

Lautié, E., Dorniera, M., de Souza Filhoc, M., and Reynesa, M., Les produits de l’anacardier: Caractéristiques, voies de valorisation et marchés, Fruits, 2001, vol. 56, no. 4, pp. 235–248. https://doi.org/10.1051/fruits:200112

Soro Doudjo, Couplage de procédés membranaires pour la clarification et la concentration du jus de pomme de cajou: performances et impacts sur la qualitye des produits, Thèse de Doctorat de Montpellier SupAgro, Institut des Régions Chaudes, 2012.

Tagutchou, J.-P. and Pascale, N., Caractérisation et traitement thermochimique des coques d’anacarde en vue de leur valorisation énergétique dans les procédés de transformation artisanale de noix de cajou, in Colloque Eau, Déchets et Développement Durable, Agadir, March 21–24, 2012, pp. 28–35. https://doi.org/10.4267/dechets-sciences-techniques.2722

Fiche Sectorielle Filière Anacarde, Chambre de commerce et d’industrie de cote d’ivoire; la filiere de l’anacarde en bref. http://www.cci.ci/3.0/component/content/article/133telechargements/683-fichessectorielles. Cited 01.10.2018.

Afrique, J., Côte d’Ivoire: forte poussée de la récolte de noix de cajou en 2015. https://www.jeuneafrique.com/251243/economie/cote-divoire-fortepoussee-de-la-recolte-de-noix-de-cajou-en-2015/. Cited 01.10.2018.

Afrik, F., La Côte d’Ivoire attend une production de 725 000 tonnes de noix de cajou en 2016, soit 24% de l’offre mondiale. https://www.financialafrik.com/2016/ 02/15/la-cote-divoire-attend-uneproduction-de-725-000- tonnes-de-noix-de-cajouen-2016-soit-24-de-loffre-mondiale. Cited 01.10.2018.

Gniré Mariam, O., Analyse de la dynamique de l’offre de noix brutes de cajou en Côte d’Ivoire: une application par l’approche autorégressif à retards échelonnés (ARDL), Eur. Sci. J., 2018, vol. 14, no. 34, pp. 292–306. https://doi.org/10.19044/esj.2018.v14n34p292

Godjo, T., Tagutchou, J.-P., Naquin, P., and Gourdon, R., Valorisation des coques d’anacarde par pyrolyse au Bénin, DéchetsSciences et Techniques, 2015, no. 70, pp. 11–18. https://doi.org/10.4267/dechetssciences-techniques.3282

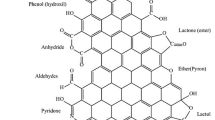

Setianto, W.B., Yoshikawa, S., Smith, R.L., Jr., Inomata, H., Florusse, L.J., and Peters, C.J., Pressure profile separation of phenol c liquid compounds from cashew (Anacardium occidentale) shell with supercritical carbon dioxide and aspects of its phase equilibria, J. Supercrit. Fluids, 2009, vol. 48, pp. 203–210. https://doi.org/10.4267/dechetssciences-techniques.3282

Smith, R.L., Jr., Malaluan, R.M., Setianto, W.B., Inomata, H., and Arai, K., Separation of cashew (Anacardium Occidentale L.) nut shell liquid with supercritical carbon dioxide, Bioresour. Technol., 2003, no. 88(1), pp. 1–7. https://doi.org/10.1016/s0960-8524(02)00271-7

Gedam, P.H. and Sampathkumaran, P.S., Cashew nut shell liquid: extraction, chemistry and applications, Prog. Org. Coat., 1986, no. 14, pp. 115–157. https://doi.org/10.1016/0033-0655(86)80009-7

Gorina, V.A. and Cheblakova, E.G., Influence of activation modes on the specific surface and development of a microporous structure of viscose-based carbon fibers, Izv. VUZov, Poroshk. Metall. Funkts. Pokrytiya, 2015, no. 4, pp. 34–39.

Gregg, S.J. and Sing, K.S.W., Adsorption, Surface Area and Porosity, London: Acad. Press, 1982.

Odintsova, M.V., Physico-chemical characteristics of bifunctional sorbent from the shells of pine nuts, Cand. Sci. (Eng.) Dissertation, Tyumen: Univ. of Tyumen, 2010.

Ul’yanova, V.V., Wastewater treatment from ions of heavy metals by sorbents on the basis of modified wastes of ceramic production and agricultural processing, Cand. Sci. (Eng.) Dissertation, Saratov: Engels Technological Institute, Saratov State Technical Univ., 2015.

Hashemian, S., Salari, K., and Yazdi, Z.A., Preparation of activated carbon from agricultural wastes (almond shell and orange peel) for adsorption of 2-pic from aqueous solution, J. Ind. Eng. Chem., 2014, no. 20, pp. 1892–1900. https://doi.org/10.1016/j.jiec.2013.09.009

Sivaraj, R., Rajendran, V., and Sangeetha Gunalan, G., Preparation and characterization of activated carbons from parthenium biomass by physical and chemical activation techniques, Coden ecjhao. E-J. Chem., 2010, no. 7(4), pp. 1314–1319. https://doi.org/10.1155/2010/948015

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by N. Korovin

About this article

Cite this article

Kouassi Brou Guillaume, Serpokrylov, N.S., Smolyanichenko, A.S. et al. Preparation of Activated Carbon from Cashew Nut Shells for Water Purification. Russ. J. Non-ferrous Metals 61, 112–118 (2020). https://doi.org/10.3103/S1067821220010058

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821220010058