Abstract

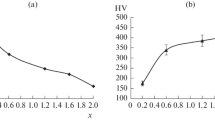

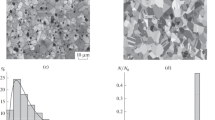

The influence of different methods of producing alloys of the Fe–Cu system from immiscible components is studied. Alloys with limited solubility (LS) in liquid and solid states are impossible to fabricate by conventional metallurgy. This is why developing low-cost and simple technologies for fabricating such alloys and materials based in them, making it possible to specify the necessary level of physicomechanical properties, is currently a relevant problem. Energy-effective SHS metallurgy is used for the first timchemical scheme of the synthesis ofe in this work to prepare a pseudoalloy with a composition, wt %, of 70Cu–30Fe from oxide materials. This technology offers the use of chemical energy liberated during the interaction of highly exothermic thermite compositions (in a combustion mode), which makes this method one of most energy-efficient for cast material production. The short synthesis time (tens of seconds) and protection of the top ingot surface by the oxide melt (Al2O3) against oxidation make it possible to perform the process in atmospheric conditions. Rods with the same composition have been fabricated by vacuum induction smelting from pure (impurity-free) components Fe and Cu for a comparative analysis of structural components of alloy samples. It is revealed that the high temperatures of the melt of the SHS alloy provide an increased solubility of Cu in Fe. Then structural components are isolated during the crystallization in the form of finely dispersed particles over the entire volume, forming the hierarchical structure characteristic for the SHS alloy only. The 70Cu–30Fe alloys formed in the combustion mode (SHS) have a uniform homogeneous structure with a uniform distribution of all structural components over the sample volume, which can be of great practical interest, in particular, when developing isotropic and anisotropic hard-magnetic materials with high magnetic energy.

Similar content being viewed by others

REFERENCES

Livshits, B.G., Linetskii, Ya.L., and Kraposhin, V.S., Physical Properties of Metals and Alloys, Moscow: Metallurgiya, 1980.

Avraamov, Yu.S. and Shlyapin, A.D., Alloys Based on Systems with Limited Solubility in the Liquid State, Moscow: Intercontact Nauka, 1980.

Bachmaier, A., Schmauch, J., Aboulfadl, H., Verch, A., and Motz, C., On the process of co-deformation and phase dissolution in a hard-soft immiscible Cu single bond Co alloy system during high-pressure torsion deformation, Acta Mater., 2016, vol. 115, pp. 333–346.

Zhou, Sh., Lei, J., Xiong, Z., Guo, J., Gu, Z., and Pan, H., Effect of Fe content on microstructure and mechanical properties of Cu–Fe-based composite coatings by laser induction hybrid rapid cladding, Trans. Nonferrous Met. Soc. China, 2016, vol. 26, no. 12, pp. 3196–3204. https://doi.org/10.1016/S1003-6326(16)64452-7

Dublon, G., Habbal, F., and Bell, J.L., Permanent magnet properties of in situ formed multifilamentary composites, J. Appl. Phys., 1982, vol. 53, no. 11, pp. 8333–8337.

Shi, G., Chen, H., Jiang, H., Wang, Z., Tang, H., and Fan, Y., Strengthening mechanisms of Fe nanoparticles for single crystal Cu-Fe alloy, Mater. Sci. Eng. A, 2015, vol. 636, pp. 43–47. https://doi.org/10.1016/j.msea.2015.03.081

Prokoshkina, D., Esin, V., and Divinski, S., Experimental evidence for anomalous grain boundary diffusion of Fe in Cu and Cu–Fe alloys, Acta Mater., 2017, vol. 133, pp. 240–246. https://doi.org/10.1016/j.actamat.2017.05.024

Mina, R., Hamed, M., and Abolghasem, A., Processing of Cu–Fe and Cu–Fe–SiC nanocomposites by mechanical alloying, Adv. Powder Technol., 2017, vol. 28, no. 8, pp. 1882–1887. https://doi.org/10.1016/j.apt.2017.04.023

Dong, Q., Wanga, M., Shen, L., Jia, Y., and Li, Z., Diffraction analysis of α-Fe precipitates in a polycrystalline Cu–Fe alloy, Mater. Charact., 2015, vol. 105, pp. 129–135. https://doi.org/10.1016/j.matchar.2015.05.012

Fenglin, W., Wakoh, K., Li, Y., Ito, Sh., Yamanaka, K., Koizumi, Y., and Chiba, A., Study of microstructure evolution and properties of Cu–Fe microcomposites produced by a prealloyed powder method, Mater. Design, 2017, vol. 126, pp. 64–72. https://doi.org/10.1016/j.matdes.2017.04.017

Cutrano, C.S. and Lekka, Ch.E., Structural, magnetic and electronic properties of Cu-Fe nanoclusters by density functional theory calculations, J. Alloys Compd., 2017, vol. 707, pp. 114–119. https://doi.org/10.1016/j.jallcom.2016.11.425

Yufei, W., Haiyan, G., Yanfeng, H., Yongbing, D., Jun, W., and Baode, S., First-principles study on the solubility of iron in dilute Cu-Fe-X alloys, J. Alloys Compd., 2017, vol. 691, pp. 992–996. https://doi.org/10.1016/j.jallcom.2016.08.247

Elofsson, V., Almyras, G.A., Lu, B., Boy, R.D., and Sarakinos, K., Atomic arrangement in immiscible Ag‒Cu alloys synthesized far-from-equilibrium, Acta Mater., 2016, vol. 110, pp. 114–121. https://doi.org/10.1016/j.actamat.2016.03.023

Yanhui, L., Xingjie, J., Yongqiang, X., Chuntao, C., Guoqiang, X., and Wei, Z., Soft magnetic Fe–Si–B–Cu nanocrystalline alloys with high Cu concentrations, J. Alloys Compd., 2017, vol. 722, pp. 859–863. https://doi.org/10.1016/j.jallcom.2017.06.128

Ghannami, M.E., Gomez-Polo, C., Rivero, G., and Hernando, A., Exchange correlation length and magnetoresistance in Fe–Cu and Fe–Cu–Ni melt-spun ribbons, Eur. Lett., 1994, vol. 26, no. 9, pp. 701–706.

Zhiliang, P., Timothy, J., and Rupert, D., Formation of ordered and disordered interfacial films in immiscible metal alloys, Scr. Mater., 2017, vol. 130, pp. 91–95. https://doi.org/10.1016/j.scriptamat.2016.11.025

Jo, H.R., Kim, J.T., Hong, S.H., Kim, Yo.S., Park, H.J., Park, W.J., Park, J.M., and Kim, K.B., Effect of silicon on microstructure and mechanical properties of Cu–Fe alloys, J. Alloys Compd., 2017, vol. 707, pp. 184–188. https://doi.org/10.1016/j.jallcom.2016.12.352

Chen, Y., Li, N., Bufford, D.C., Li, J., Hattar, K., Wang, H., and Zhang, X., In situ study of heavy ion irradiation response of immiscible Cu/Fe multilayers, J. Nucl. Mater., 2016, vol. 475, pp. 274–279.

Yang Ya, Wang, D., Lin, J., Khan, D.F., Lin, G., and Jidong Ma, Evolution of structure and fabrication of Cu/Fe multilayered composites by a repeated diffusion-rolling procedure, Mater. Design, 2015, vol. 85, pp. 635–639. https://doi.org/10.1016/j.matdes.2015.07.082

Merzhanov, A.G., Combustion Processes and Synthesis of Materials, Chernogolovka: ISMAN, 1998.

Sanin, V.N., Ikornikov, D.M., Andreev, D.E., and Yukhvid, V.I., Centrifugal SHS-metallurgy of eutectic alloys based on nickel aluminum, Izv. VUZov, Poroshk. Metall. Funkts. Pokrytiya, 2013, no. 3, pp. 35–42.

Sanin, V.N., Yukhvid, V.I., and Merzhanov, A.G., The influence of high-temperature melt infiltration under centrifugal forces on SHS processes in gasless systems, Int. J. Self-Propag. High-Temp. Synth., 2002, vol. 11, no. 1, pp. 31–44.

Shiryaev, A.A., Thermodynamics of SHS processes: an advanced approach, Int. J. Self-Propag. High-Temp. Synth., 1995, vol. 2, no. 4, pp. 351–362.

Funding

This study was supported by the Russian Foundation for Basic Research, project no. 18-38-00932.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by N. Korovin

About this article

Cite this article

Sanin, V.V., Filonov, M.R., Yukhvid, V.I. et al. Production of the 70% Cu–30% Fe Alloy by SHS Metallurgy and Electrometallurgy: Comparative Analysis of Microstructures. Russ. J. Non-ferrous Metals 61, 119–125 (2020). https://doi.org/10.3103/S1067821220010137

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821220010137