Abstract

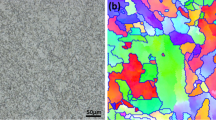

The stress corrosion cracking (SCC) of a simulated weld heat-affected zone (HAZ) in X100 pipeline steel in a carbonate/bicarbonate solution was studied at the open-circuit potential (OCP) and various cathodic potentials. Microstructure of the weld HAZ was simulated by Gleeble processing. Results showed that the steel had a higher sensitivity to SCC at the OCP than at the cathodic potentials. Moreover, the SCC process at − 850 mV was controlled by both anodic dissolution and hydrogen embrittlement (HE), while the SCC was due to HE at − 1200 mV. The SCC occurred at the intercritical HAZ at the cathodic potential because of its lower strength than that of the other weld areas. The fracture modes at the cathodic potentials were all intergranular and transgranular.

Similar content being viewed by others

References

L. Fan, C.W. Du, Z.Y. Liu, and X.G. Li, Stress Corrosion Cracking of X80 Pipeline Steel Exposed to High pH Solutions with Different Concentrations of Bicarbonate, Int J Miner Metall Mater, 2013, 20(7), p 645–652

C.W. Li, G.L. Du, and Y.F. Zhai, Cheng, Stress corrosion Cracking Behavior of X70 Pipe Steel in an Acidic Soil Environment, Corros Sci, 2008, 50(8), p 2251–2257

Z.Y. Liu, X.Z. Wang, C.W. Du, J.K. Li, and X.G. Li, Effect of Hydrogen-Induced Plasticity on the Stress Corrosion Cracking of X70 Pipeline Steel in Simulated Soil Environments, Mater Sci Eng: A, 2016, 658, p 348–354

A.R.H. Far, S.H.M. Anijdan, and S.M. Abbasi, The Effect of Increasing Cu and Ni on a Significant Enhancement of Mechanical Properties of High Strength Low Alloy, Low Carbon Steels of HSLA-100 Type, Mater. Sci. Eng. A, 2019, 746, p 384–393

S.H.M. Anijdan, M. Sabzi, The Evolution of Microstructure of an high Ni HSLA X100 Forged Steel Slab by Thermomechanical Controlled Processing. TMS Ann Meet Exhib, pp. 145–156 (2018)

A.R.H. Far, S.H.M. Anijdan, M. Abbasi, The Effect of Ni and Cu Addition on Mechanical Behavior of Thermomechanically Controlled Processed HSLA X100 Steels, in TMS 2019 148th Annual Meeting & Exhibition Supplemental Proceedings (2019), pp 579–590

M.C. Li and Y.F. Cheng, Mechanistic Investigation of Hydrogen-Enhanced Anodic Dissolution of X-70 Pipe Steel and Its Implication on Near-Neutral pH SCC of Pipelines, Electrochim. Acta, 2007, 52(28), p 8111–8117

Z.Y. Liu, Q. Li, Z.Y. Cui, W. Wu, Z.Z.Y. Liu, Q. Li, Z.Y. Cui, W. Wu, Z. Li, C.W. Du, and X.G. Li, Field Experiment of Stress Corrosion Cracking Behavior of High Strength Pipeline Steels in Typical Soil Environments, Constr. Build. Mater., 2017, 148, p 131–139

M. Zhu, C. Du, X. Li, Z. Liu, S. Wang, T. Zhao, and J. Jia, Effect of Strength and Microstructure on Stress Corrosion Cracking Behavior and Mechanism of X80 Pipeline Steel in High pH Carbonate/Bicarbonate Solution, J. Mater. Eng. Perform., 2014, 23(4), p 1358–1365

X. Li, J. Liu, J. Sun, X. Lin, C. Li, and N. Cao, Effect of Microstructural Aspects in the Heat-Affected Zone of High Strength Pipeline Steels on the Stress Corrosion Cracking Mechanism: Part Iacidic Soil Environment, Corros. Sci., 2019, 160, p 108167

Z. Lu, J. Chen, T. Shoji, Y. Takeda, and S. Yamazaki, Characterization of Microstructure, Local Deformation and Microchemistry in Alloy 690 Heat-Affected Zone and Stress Corrosion Cracking in High Temperature Water, J. Nuclear Mater., 2015, 465, p 471–481

L.W. Wang, C.W. Du, Z.Y. Liu, X.H. Wang, and X.G. Li, Influence of Carbon on Stress Corrosion Cracking of High Strength Pipeline Steel, Corros. Sci., 2013, 76, p 486–493

L.W. Wang, X.H. Wang, Z.Y. Cui, Z.Y. Liu, C.W. Du, and X.G. Li, Effect of Alternating Voltage on Corrosion of X80 and X100 Steels in a Chloride Containing Solution—Investigated by AC Voltammetry Technique, Corros. Sci., 2014, 86, p 213–222

Z. Cui, Z. Liu, L. Wang, X. Li, C. Du, and X. Wang, Effect of Plastic Deformation on the Electrochemical and Stress Corrosion Cracking Behavior of X70 Steel in Near-Neutral pH Environment, Mater. Sci. Eng., A, 2016, 677, p 259–273

C.F. Dong, Z.Y. Liu, X.G. Li, and Y.F. Cheng, Effects of Hydrogen-Charging on the Susceptibility of X100 Pipeline Steel to Hydrogen-Induced Cracking, Int. J. Hydrogen Energy, 2009, 34(24), p 9879–9884

Z.Y. Liu, X.G. Li, and Y.F. Cheng, Effect of Strain Rate on Cathodic Reaction During Stress Corrosion Cracking of X70 Pipeline Steel in a Near-Neutral pH Solution, J. Mater. Eng. Perform., 2010, 20(7), p 1242–1246

A.Q. Fu and Y.F. Cheng, Electrochemical Polarization Behavior of ×70 Steel in Thin Carbonate/Bicarbonate Solution Layers Trapped Under a Disbonded Coating and Its Implication on Pipeline SCC, Corros. Sci., 2010, 52(7), p 2511–2518

M.C. Li and Y.F. Cheng, Corrosion of the Stressed Pipe Steel in Carbonate—Bicarbonate Solution Studied by Scanning Localized Electrochemical Impedance Spectroscopy, Electrochim. Acta, 2008, 53(6), p 2831–2836

Z.Y. Liu, X.G. Li, and Y.F. Cheng, Mechanistic Aspect of Near-Neutral pH Stress Corrosion Cracking of Pipelines Under Cathodic Polarization, Corros. Sci., 2012, 55, p 54–60

Z.Y. Liu, X.G. Li, C.W. Du, and Y.F. Cheng, Local Additional Potential Model for Effect of Strain Rate on SCC of Pipeline Steel in an Acidic Soil Solution, Corros. Sci., 2009, 51(12), p 2863–2871

Z.Y. Liu, L. Lu, Y.Z. Huang, C.W. Du, and X.G. Li, Mechanistic Aspect of Non-Steady Electrochemical Characteristic During Stress Corrosion Cracking of an X70 Pipeline Steel in Simulated Underground Water, Corrosion, 2014, 70(7), p 678–685

Z.H. Fu, T. Li, M.L. Shan, G.Q. Gou, Z.Y. Zhu, C.P. Ma, W. Gao, and Y.C. Hu, Hydrogen Atoms on the SCC Behavior of SUS301L-MT Stainless Steel Laser-Arc Hybrid Welded Joints, Corros. Sci., 2019, 148, p 272–280

Z. Liu, X. Gao, L. Du, J. Li, X. Zhou, X. Wang, Y. Wang, C. Liu, G. Xu, and R.D.K. Misra, Hydrogen Assisted Cracking and CO2 Corrosion Behaviors of Low-Alloy Steel with High Strength Used for Armor Layer of Flexible Pipe, Appl. Surf. Sci., 2018, 440, p 974–991

V. Venegas, F. Caleyo, T. Baudin, J.H. Espina-Hernández, and J.M. Hallen, On the role of Crystallographic Texture in Mitigating Hydrogen-Induced Cracking in Pipeline Steels, Corros. Sci., 2011, 53(12), p 4204–4212

X. Zhong, S.C. Bali, and T. Shoji, Effects of Dissolved Hydrogen and Surface Condition on the Intergranular Stress Corrosion Cracking Initiation and Short Crack Growth Behavior of Non-sensitized 316 Stainless Steel in Simulated PWR priMARY water, Corros. Sci., 2017, 118, p 143–157

H.Y. Tian, X. Wang, Z.Y. Cui, Q.K. Lu, L.W. Wang, L. Li, Y. Li, and D.W. Zhang, Electrochemical Corrosion, Hydrogen Permeation and Stress Corrosion Cracking Behavior of E690 Steel in Thiosulfate-Containing Artificial Seawater, Corros. Sci., 2018, 144, p 145–162

L.W. Wang, Z.Y. Liu, Z.Y. Cui, C.W. Du, X.H. Wang, and X.G. Li, In Situ Corrosion Characterization of Simulated Weld Heat Affected Zone on API, X80 Pipeline Steel, Corros. Sci., 2014, 85, p 401–410

W. Wu, Z. Liu, X. Li, C. Du, and Z. Cui, Influence of Different Heat-Affected Zone Microstructures on the Stress Corrosion Behavior and Mechanism of High-Strength Low-Alloy Steel in a Sulfurated Marine Atmosphere, Mater. Sci. Eng., A, 2019, 759, p 124–141

H. Saffari, M. Shamania, A. Barhrami, and J.A. Szpunar, Effects of ERNiCr-3 Butter Layer on the Microstructure and Mechanical Properties of API, 5L X65/AISI304 Dissimilar Joint, J. Manuf. Processes, 2020, 50, p 305–318

N.N. Tshilwane and J.W. van der Merwe, Stress Corrosion Cracking of Laser Alloyed 304L Stainless Steel with Ru in Hot Chloride Solution, Surf. Coat. Technol., 2018, 347, p 414–419

L. Wang, J. Xin, L. Cheng, K. Zhao, B. Sun, J. Li, X. Wang, and Z. Cui, Influence of Inclusions on Initiation of Pitting Corrosion And Stress Corrosion Cracking of X70 Steel in Near-Neutral pH Environment, Corros. Sci., 2019, 147, p 108–127

H. Ma, Z. Liu, C. Du, X. Li, and Z. Cui, Comparative Study of the SCC Behavior of E690 Steel and Simulated HAZ Microstructures in a SO2-Polluted Marine Atmosphere, Mater. Sci. Eng., A, 2016, 650, p 93–101

H. Ma, Z. Liu, C. Du, H. Wang, C. Li, and X. Li, Effect of Cathodic Potentials on the SCC Behavior of E690 Steel in Simulated Seawater, Mater. Sci. Eng., A, 2015, 642, p 22–31

K.W. Andrews, Empirical Formulae for the Calculation of Some Transformation Temperatures, Iron steel Inst, 1965, 203, p 721–727

S.M. Bruemmer, M.J. Olszta, M.B. Toloczko, and D.K. Schreiber, Grain Boundary Selective Oxidation and Intergranular Stress Corrosion Crack Growth of High-Purity Nickel Binary Alloys in High-Temperature Hydrogenated Water, Corros. Sci., 2018, 131, p 310–323

H. Tian, J. Xin, Y. Li, X. Wang, and Z. Cui, Combined Effect of Cathodic Potential and Sulfur Species on Calcareous Deposition, Hydrogen Permeation, and Hydrogen Embrittlement of a Low Carbon Bainite Steel in Artificial Seawater, Corros. Sci., 2019, 158, p 108089

S.M. Teus, V.G. Gavriljuk, On a correlation between hydrogen effects on atomic interactions and mobility of grain boundaries in the alpha-iron. Stage II. Mobility of grain boundaries in the H-charged α-iron, Mater. Lett. 126859 (2019)

M. Connolly, M. Martin, P. Bradley, D. Lauria, A. Slifka, R. Amaro, C. Looney, and J.-S. Park, In Situ High Energy X-ray Diffraction Measurement of Strain and Dislocation Density Ahead of Crack Tips Grown in Hydrogen, Acta Mater., 2019, 180, p 272–286

A. Nagao, M. Dadfarnia, B.P. Somerday, P. Sofronis, and R.O. Ritchie, Hydrogen-Enhanced-Plasticity Mediated Decohesion for Hydrogen-Induced Intergranular and “Quasi-Cleavage” Fracture of Lath Martensitic Steels, J. Mech. Phys. Solids, 2018, 112, p 403–430

F. Sun, S. Ren, Z. Li, Z. Liu, X. Li, and C. Du, Comparative Study on the Stress Corrosion Cracking of X70 Pipeline Steel in Simulated Shallow and Deep Sea Environments, Mater. Sci. Eng., A, 2017, 685, p 145–153

V. Giorgetti, E.A. Santos, J.B. Marcomini, and V.L. Sordi, Stress Corrosion Cracking and Fatigue Crack Growth of an API, 5L X70 Welded Joint in An Ethanol Environment, Int. J. Press. Vessels Pip., 2019, 169, p 223–229

B.A. Kessal, C. Fares, M.H. Meliani, A. Alhussein, O. Bouledroua, and M. François, Effect of Gas Tungsten Arc Welding Parameters on the Corrosion Resistance and the Residual Stress of Heat Affected Zone, Eng. Fail. Anal., 2020, 107, p 104200

K.E. Nygren, K.M. Bertsch, S. Wang, H. Bei, A. Nagao, and I.M. Robertson, Hydrogen Embrittlement in Compositionally Complex FeNiCoCrMn FCC Solid Solution Alloy, Curr. Opin. Solid State Mater. Sci., 2018, 22(1), p 1–7

K.E. Nygren, S. Wang, K.M. Bertsch, H. Bei, A. Nagao, and I.M. Robertson, Hydrogen Embrittlement of the Equi-Molar FeNiCoCr Alloy, Acta Mater., 2018, 157, p 218–227

S. Wang, M.L. Martin, P. Sofronis, S. Ohnuki, N. Hashimoto, and I.M. Robertson, Hydrogen-Induced Intergranular Failure of Iron, Acta Mater., 2014, 69, p 275–282

Acknowledgements

The authors gratefully acknowledge the financial support of the National Key R&D Program of China (no. 2017YFF0210400) and Open Fund of Shandong Key Laboratory of Corrosion Science (no. KLCS201909).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Longfei, S., Zhiyong, L., Xiaogang, L. et al. Stress Corrosion Cracking of Simulated Weld Heat-Affected Zone on X100 Pipeline Steel in Carbonate/Bicarbonate Solution. J. of Materi Eng and Perform 29, 2574–2585 (2020). https://doi.org/10.1007/s11665-020-04750-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04750-9