Abstract

In the present study, a simple in situ hydrothermal method was used to fabricate Layered Double Hydroxide conversion coating at different treatment temperatures, times and pH values on the surface of AZ31 magnesium alloy. The films were characterized using XRD, FTIR, XPS, EDS and FESEM. The corrosion resistance of the coatings was evaluated by potentiodynamic polarization, electrochemical impedance spectroscopy and electrochemical noise techniques. The results confirmed the anion exchange ability of the LDH film. Moreover, the best results were obtained at 160 °C, 8 h and pH of 10. Dense and compact blade-like structures were obtained which exhibited appropriate corrosion resistance. The self-healing ability of the films was improved by increasing the LDH content of the film.

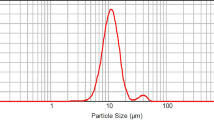

Graphic Abstract

Similar content being viewed by others

References

H. Pan et al., Recent developments in rare-earth free wrought magnesium alloys having high strength: a review. J. Alloy. Compd. 663, 321–331 (2016)

D. Wan et al., The damping and mechanical properties of magnesium alloys balanced by aluminum addition. J. Alloys Compd. 782, 421–426 (2018)

G.P. Abatti et al., Conversion coating on magnesium alloy sheet (AZ31) by vanillic acid treatment: preparation, characterization and corrosion behavior. J. Alloy. Compd. 738, 224–232 (2018)

L. Guo et al., Layered double hydroxide coatings on magnesium alloys: a review. J. Mater. Sci. Technol. 34(9), 1455–1466 (2018)

M. Gobara, M. Shamekh, R. Akid, Improving the corrosion resistance of AZ91D magnesium alloy through reinforcement with titanium carbides and borides. J. Magnes. Alloys 3(2), 112–120 (2015)

C. Blawert et al., Anodizing treatments for magnesium alloys and their effect on corrosion resistance in various environments. Adv. Eng. Mater. 8(6), 511–533 (2006)

Y. Zhang et al., Study on the environmentally friendly anodizing of AZ91D magnesium alloy. Surf. Coat. Technol. 161(1), 36–43 (2002)

C. Wu et al., Study on the anodizing of AZ31 magnesium alloys in alkaline borate solutions. Appl. Surf. Sci. 253(8), 3893–3898 (2007)

M.C.L. de Oliveira et al., Corrosion performance of anodized AZ91D magnesium alloy: effect of the anodizing potential on the film structure and corrosion behavior. J. Mater. Eng. Perform. 23(2), 593–603 (2014)

B.-S. Lou et al., Mechanical property and corrosion resistance evaluation of AZ31 magnesium alloys by plasma electrolytic oxidation treatment: effect of MoS2 particle addition. Surf. Coat. Technol. 350, 813–822 (2018)

Shahri, Z. et al., Optimization of plasma electrolyte oxidation process parameters for corrosion resistance of Mg alloy. J. Magn. Alloys (2018)

Z. Qiu et al., Study of coating growth behavior during the plasma electrolytic oxidation of magnesium alloy ZK60. J. Mater. Eng. Perform. 24(4), 1483–1491 (2015)

X. Jiang, R. Guo, S. Jiang, Evaluation of self-healing ability of Ce–V conversion coating on AZ31 magnesium alloy. J. Magn. Alloys 4(3), 230–241 (2016)

M. Dabala et al., Cerium-based chemical conversion coating on AZ63 magnesium alloy. Surf. Coat. Technol. 172(2–3), 227–232 (2003)

M. Montemor, A. Simoes, M. Carmezim, Characterization of rare-earth conversion films formed on the AZ31 magnesium alloy and its relation with corrosion protection. Appl. Surf. Sci. 253(16), 6922–6931 (2007)

F.R. Costa et al., Intercalation of Mg–Al layered double hydroxide by anionic surfactants: preparation and characterization. Appl. Clay Sci. 38(3–4), 153–164 (2008)

J. Wang et al., Hydrotalcite conversion coating on Mg alloy and its corrosion resistance. J. Alloy. Compd. 494(1–2), 271–274 (2010)

Q.-S. Yao et al., Corrosion resistance of a ceria/polymethyltrimethoxysilane modified Mg-Al-layered double hydroxide on AZ31 magnesium alloy. J. Alloy. Compd. 764, 913–928 (2018)

F. Wang, Z. Guo, Insitu growth of durable superhydrophobic Mg–Al layered double hydroxides nanoplatelets on aluminum alloys for corrosion resistance. J. Alloy. Compd. 767, 382–391 (2018)

F. Cavani, F. Trifiro, A. Vaccari, Hydrotalcite-type anionic clays: preparation, properties and applications. Catal. Today 11(2), 173–301 (1991)

L. Mohapatra, K. Parida, A review on the recent progress, challenges and perspective of layered double hydroxides as promising photocatalysts. J. Mater. Chem. A 4(28), 10744–10766 (2016)

W. Zheng et al., Facile synthesis of NiAl-LDH/MnO2 and NiFe-LDH/MnO2 composites for high-performance asymmetric supercapacitors. J. Alloy. Compd. 768, 240–248 (2018)

S. Bagherifam et al., Evaluation of Zn–Al–SO4 layered double hydroxide for the removal of arsenite and arsenate from a simulated soil solution: isotherms and kinetics. Appl. Clay Sci. 95, 119–125 (2014)

K. Lin et al., Enhanced corrosion resistance of LiAl-layered double hydroxide (LDH) coating modified with a Schiff base salt on aluminum alloy by one step in situ synthesis at low temperature. Appl. Surf. Sci. 463, 1085–1096 (2019)

J.L. Guimarães et al., Covalent grafting of ethylene glycol into the Zn–Al–CO3 layered double hydroxide. J. Colloid Interface Sci. 227(2), 445–451 (2000)

Y. Zhang et al., Fabrication of inhibitor anion-intercalated layered double hydroxide host films on aluminum alloy 2024 and their anticorrosion properties. J. Coat. Technol. Res. 12(2), 293–302 (2015)

Y. Zhang et al., Enhancement of anticorrosion protection via inhibitor-loaded ZnAlCe-LDH nanocontainers embedded in sol–gel coatings. J. Coat. Technol. Res. 15(2), 303–313 (2018)

H.-W. Olfs et al., Comparison of different synthesis routes for Mg–Al layered double hydroxides (LDH): characterization of the structural phases and anion exchange properties. Appl. Clay Sci. 43(3–4), 459–464 (2009)

A.I. Khan, D. O’Hare, Intercalation chemistry of layered double hydroxides: recent developments and applications. J. Mater. Chem. 12(11), 3191–3198 (2002)

Y. Dong, F. Wang, Q. Zhou, Protective behaviors of 2-mercaptobenzothiazole intercalated Zn–Al-layered double hydroxide coating. J. Coat. Technol. Res. 11(5), 793–803 (2014)

H. Chen et al., In situ microstructure control of oriented layered double hydroxide monolayer films with curved hexagonal crystals as superhydrophobic materials. Adv. Mater. 18(23), 3089–3093 (2006)

J. Wang et al., In situ Ni/Al layered double hydroxide and its electrochemical capacitance performance. Energy Fuels 24(12), 6463–6467 (2010)

Y. Zhang et al., A facile approach to superhydrophobic LiAl-layered double hydroxide film on Al–Li alloy substrate. J. Coat. Technol. Res. 12(3), 595–601 (2015)

F. Zhang et al., Corrosion resistance of Mg–Al-LDH coating on magnesium alloy AZ31. Surf. Coat. Technol. 258, 1152–1158 (2014)

T. Ishizaki et al., Corrosion resistance of Mg (OH) 2/Mg–Al layered double hydroxide composite film formed directly on combustion-resistant magnesium alloy AMCa602 by steam coating. Corros. Sci. 92, 76–84 (2015)

K. Nakamura et al., Formation mechanism of Mg-Al layered double hydroxide-containing magnesium hydroxide films prepared on Ca-added flame-resistant magnesium alloy by steam coating. Surf. Coat. Technol. 328, 436–443 (2017)

G. Zhang et al., A novel approach to fabricate protective layered double hydroxide films on the surface of anodized Mg-Al alloy. Adv. Mater. Interfaces 4(12), 1700163 (2017)

Q. Wu et al., Delamination and restacking of a layered double hydroxide with nitrate as counter anion. J. Mater. Chem. 15(44), 4695–4700 (2005)

Y. Feng et al., Synthesis and characterization of a UV absorbent-intercalated Zn–Al layered double hydroxide. Polym. Degrad. Stab. 91(4), 789–794 (2006)

J.-Y. Uan, J.-K. Lin, Y.-S. Tung, Direct growth of oriented Mg–Al layered double hydroxide film on Mg alloy in aqueous HCO 3 −/CO 3 2 − solution. J. Mater. Chem. 20(4), 761–766 (2010)

X. Zhang et al., Mitigation of corrosion on magnesium alloy by predesigned surface corrosion. Sci Rep. 5, 17399 (2015)

G. Song, Recent progress in corrosion and protection of magnesium alloys. Adv. Eng. Mater. 7(7), 563–586 (2005)

A. Frignani et al., Inhibition of AZ31 Mg alloy corrosion by anionic surfactants. Corros. Sci. 63, 29–39 (2012)

J. Lin, C. Hsia, J. Uan, Characterization of Mg, Al-hydrotalcite conversion film on Mg alloy and Cl − and CO32-anion-exchangeability of the film in a corrosive environment. Script. Mater. 56(11), 927–930 (2007)

K. Liu et al., Study of behaviors of aluminum overlayers deposited on uranium via AES, EELS, and XPS. Appl. Surf. Sci. 270, 184–189 (2013)

A.I. Ikeuba et al., Electrochemical, TOF-SIMS and XPS studies on the corrosion behavior of Q-phase in NaCl solutions as a function of pH. Appl. Surf. Sci. 490, 535–545 (2019)

J. Smulko, Methods of trend removal in electrochemical noise data—overview. Measurement 131, 569–581 (2019)

S. Zhang et al., Study on the corrosion behavior of steel Q315NS heat-affected zone in a HCl solution using electrochemical noise. RSC Adv. 8(1), 454–463 (2018)

K. Jung et al., Alloy design employing high Cr concentrations for Mo-free stainless steels with enhanced corrosion resistance. Corros. Sci. 140, 61–72 (2018)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hasanbeigi, S., Tabaian, S. & Yazdani, S. Effect of Manufacturing Parameters on the Corrosion Behavior of AZ31 Coated by Mg–Al Layered Double Hydroxide. Met. Mater. Int. 27, 4441–4454 (2021). https://doi.org/10.1007/s12540-020-00692-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00692-y