Abstract

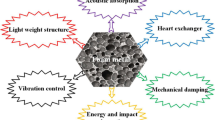

The dynamics of fluid in porous metals has earned growing attention due to the increasing worldwide research and technological advancement in harnessing, processing and the use of materials. In this study, a review on the wide range of different structures that metal foams can show, the range of processing methods that can be used to make them, leading to these different structures and their fluid flow behaviour are presented herein. The fluid section of this investigation covers fluid flow models, boundary conditions, permeability and Form drag estimations, Reynolds number and friction factor determinations, state-of-the-art knowledge of experimental and predictive results. It is the hope that the extended review on processing and fluid flow across monomodal “bottleneck” metallic structures covered herein would lend itself useful to the processing of enhanced bimodal “bottleneck” structures for fluid flow application.

Sourced, Ref. [5]

Sourced from [39]

Sourced from [33]

Sourced from [34]

Sourced from [11]

Sourced from [61]

Adapted from [33]

Sourced from [34]

Similar content being viewed by others

References

P.A. Jorges, J.C. Malcom, Recent-trends in porous sound-absorbing materials. Sound Vib. 44, 12–17 (2010)

B. Koo, Y. Yi, M. Lee, B. Kim, Effect of particle size and forming pressure on pore properties of Fe–Cr–Al porous metal by pressureless sintering. Met. Mater. 23(2), 336–340 (2017)

J.H. Jung, V.D. Krstic, H.K. Cho, Numerical analysis of effective thermal conductivity associated with microstructural changes of porous SiC as an inert-matrix. Met. Mater. 7(1), 21–26 (2001)

A.R. Kennedy, Porous Metals and Metal Foams Made from Powders, Powder Metal. (2012). https://doi.org/10.5772/33060

J. Zhou, Porous metallic materials, in Advanced Structural Materials, ed. by W.O. Soboyejo (CRC Press, Taylor & Francis Group, Boca Raton, 2006), p. 22

M.F. Ashby, L.U. Tianjin, Metal foams: a survey. Sci. China Ser. (b) 46(6), 521–530 (2003)

E.L. Furman, A.B. Finkelstein, M.L. Cherny, The permeability of aluminium foams produced by replicated-casting. Metals 3, 49–57 (2013)

C.Y. Zhao, Review on thermal transport in high porosity cellular metal foams with open cells. Int. J. Heat Mass Transf. 55, 3618–3632 (2012)

A.J. Otaru, H.P. Morvan, A.R. Kennedy, Modelling and optimisation of sound absorption in replicated microcellular metals. Scripta Mater. 150, 152–155 (2018)

N. Dukhan, Analysis of Brinkman-extended Darcy flow in porous media and experimental verification using metal foam. ASME J. Fluids Eng. 134(7), 071201 (2012)

A.R. Siddiq, A.R. Kennedy, A novel method for the manufacture of porous structures with multi-component, coated pores. Mater. Lett. 196, 324–327 (2017)

M.F. Ashby, A. Evans, A.R. Kennedy, The role of oxidation during compaction on the expansion and stability of Al foams made via a PM route. Adv. Eng. Mater. 8, 568–570 (2006)

P. Habisreuther, N. Djordjevic, N. Zarzalis, Statistical distribution of residence time and tortuosity of flow through open-cell foams. Chem. Eng. Sci. (2009). https://doi.org/10.1016/j.ces.2009.07.033

N. Dukhan, O. Bagci, M. Ozdemir, Experimental flow in various porous media and reconciliation of Forchheimer and Ergun relation. Exp. Thermal Fluid Sci. 57, 425–433 (2014)

P. Ranut, E. Nobile, L. Mancini, High resolution microtomography-based CFD simulation of flow and heat transfer in aluminum metal foams. Appl. Thermal Eng. (2013). https://doi.org/10.1016/j.applthermaleng.2013.11.056

F. Garcia-Moreno, Commercial applications of metal foams: their properties and production. Materials 9, 85 (2016)

J. Banhart, Manufacture, characterization, and application of cellular metals and metal foams. Prog. Mater Sci. 46, 559–632 (2001)

B.H. Smith, S. Szyniszewski, J.F. Hajjar, Steel foam for structures: a review of applications, manufacturing and material properties. J. Constr. Steel 71, 1–10 (2012)

L.D. Kenny, Mechanical properties of particles stabilized aluminium foam. Mater. Sci. Forum 217–222, 1883–1890 (1996)

O. Prakash, H. Sang, J.D. Embury, Structure and properties of AlSiC foam. Mater. Sci. Eng. A 199(2), 195–203 (1995)

P. Asholt, in Metal Foams and Porous Metal Structures, ed. by J. Banhart, M.F. Ashby, N.A. Fleck (MIT-Verlag, Bremen, 1999), p. 133

L. Ma, Z. Song, Cellular structure of aluminium foams during foaming process of aluminium melt. Scripta Mater. 39(11), 1523 (1998)

V. Shapovalov, in Porous and Cellular Materials for Structural Applications, vol. 521, ed. by D.S. Schwartz et al. (MRS, Warrendale, 1998), p. 281

F. Baumgartner, I. Duarte, J. Banhart, Industrialization of powder compact foaming process. Adv. Eng. Mater. 2, 168–174 (2000)

V. Gergely, B. Clyne, The FORMGRIP process: foaming of reinforced metals by gas release in precursors. Adv. Eng. Mater. 2, 175–178 (2000)

M. Fink, O. Anderson, T. Seidel, A. Schlott, Strongly orthotropic open cell porous metal structures for heat transfer applications. Metals 8, 554 (2018)

J. Banhart, Metal foams: production and stability. Adv. Eng. Mater. 8, 781–794 (2006)

Y.Y. Zhao, D.A. Sun, A novel sintering dissolution process for manufacturing Al foams. Script Materialia 44, 106–110 (2001)

M. Bram, C. Stiller, H.P. Buchkremer, D. Stover, H. Bauer, High-porosity titanium, stainless steel and superalloy parts. Adv. Eng. Mater. 2, 196 (2000)

A.J. Otaru, A.R. Kennedy, The permeability of virtual macroporous structures generated by sphere-packing models: comparison with analytical models. Scripta Mater. 124, 30–33 (2016)

J.E. Rehder, Manufacturing of Cast Iron with Pre-Reduced Iron Ore Pellets, United State Patent 44011469 (1983)

J. Banhart, J. Baumeister, Deformation characteristics of metal foams. Mater. Sci. 33, 1431–1440 (1998)

A.J. Otaru, H.P. Morvan, A.R. Kennedy, Measurement and simulation of pressure drop across replicated microcellular aluminium in the Darcy–Forchheimer regime. Acta Mater. 149, 265–275 (2018)

A.J. Otaru, H.P. Morvan, A.R. Kennedy, Airflow measurement across negatively infiltration processed porous aluminium structures. AIChE J. (2019). https://doi.org/10.1002/aic.16523

T.J. Lu, F. Chen, D. He, Sound absorption of cellular metals with semi-open cells. J. Acoust. Soc. Am. 108(4), 1697–1708 (2000)

Y. Li, L. Zhendong, F. Han, Airflow resistance and sound absorption behaviour of open-celled aluminium foams with spherical cells. Proc. Mater. Sci. 4, 187–190 (2014)

R. Goodall, A. Marmottant, L. Salvo, A. Mortensen, Spherical pore replicated microcellular aluminium: processing and influence on properties. Mater. Sci. Eng. A 465, 124–135 (2007)

B.N. Asmar, P.A. Langston, A.J. Matchett, A generalized mixing index in discrete element method simulation of vibrated particulate beds. Granul. Matter 4(3), 129–138 (2002)

P. Langston, A.R. Kennedy, Discrete element modelling of the packing of spheres and its application to the structure of porous metals made by infiltration of packed beds of NaCl beads. Powder Technol. 268, 210–218 (2014)

A.J. Otaru, Fluid Flow and Acoustic Absorption in Porous metallic Structures Using Numerical Simulation and Experimentation, Ph.D. thesis, The University of Nottingham, United Kingdom (2018)

Q.Z. Wang, D.M. Lu, C.X. Cui, L.M. Liang, Material science and engineering. J. Mater. Process. Technol. 211, 363 (2011)

E. Michael, The Dawn of Fluid Dynamics: A Discipline Between Science and Technology (Wiley, Hoboken, 2006), p. ix. ISBN 3-527-40513-5

M.A. Rao, Rheology of Fluid and Semisolid Foods: Principles and Applications, 2nd edn. (Springer, Berlin, 2007), p. 8. ISBN 978-0-387-70929-1

H.K. Versteeg, W. Malasekara, An Introduction to Computational Fluid Dynamics—The Finite Volume Method, 2nd edn. (Pearson Education Limited, London, 2007)

CMI, Clay Mathematic Institute, Millennium Prize Problem (2014). https://www.claymath.org/millennium-problems

D.A. Nield, A. Bejan, Convection in Porous Media, 2nd edn. (Springer, New York, 1992), pp. 8–91

S. Peng, Q. Hu, S. Dultz, M. Zhang, Using x-ray computed tomography pore structure characterization for Berea sandstone: resolution effect. J. Hydrol. 472–473, 254–261 (2012)

K.K. Bodla, J.Y. Murthy, S.V. Garimella, Microtomography-based simulation of transport through open-cell metal foams. Numer. Heat Transf. A Appl. 7, 527–544 (2010)

G.A. Narsilio, O. Buzzi, S. Fityus, T.S. Yun, D.W. Smith, Upscaling of Navier–Stokes equation in porous media: theoretical, numerical and experimental approach. Comput. Geotech. 36, 1200–1206 (2009)

T.P. De Carvalho, H.P. Morvan, D. Hargreaves, H. Oun, A. Kennedy, Pore-scale numerical investigation of pressure drop behaviour across open-cell metal foams. Transp. Porous Media 117(2), 311–336 (2017)

S. Whitaker, Flow in porous media I: a theoretical derivation of Darcy’s law. Transp. Porous Media 1, 3–25 (1986)

H. Darcy, Les Fotaines Publiques de la Ville de Dijon (Dalmont, Paris, 1856)

Comsol, Introduction to the Acoustic Module, US Patent, 7, 519, 518; 7, 596, 474 and 7, 623, 991 (2015)

M. Le Bars, M.G. Worster, Interfacial conditions between a pure and a porous medium: implications for binary alloy solidification. J. Fluid Mech. 550, 151–170 (2006)

H Mifflin, The American Heritage®, (Science Dictionary, 2014)

R.P. Hesketh, Flow Between Parallel Plates-Modified from the COMSOL ChE Library Module (Department of Chemical Engineering, Rowan University, Glassboro, 2008), pp. 3–4

A. Dybbs, R.V. Edwards, A new look at porous media fluid mechanics—Darcy to turbulent, in Fundamentals of Transport Phenomena in Porous Media. NATO ASI Series (Series E: Applied Sciences), vol. 82, ed. by J. Bear, M.Y. Corapcioglu (Springer, Dordrecht, 1984)

A. Bejan, Convection Heat Transfer (Wiley, Hoboken, 1984)

M. Piatek, A. Gancarczyk, M. Iwaniszyn, P.J. Jodlowski, J. Lojewska, A. Kolodziej, Gas-phase flow resistance of metal foams: experiments and modelling. AIChE J. 63(6), 1799–1803 (2017)

D. Edouard, M. Lacroix, C. Pham, M. Mbodji, C. Pham-Huu, Experimental measurements and multiphase flow models in solid SiC foam beds. AIChE J. 54(11), 2823–2832 (2008)

J.L. Lage, P.S. Krueger, A. Narasimham, Protocol for measuring permeability and form coefficient of porous media. Phys. Fluids 17, 088101 (2005)

L. Tadrist, M. Miscevis, O. Rahli, F. Topin, About the use of fibrous materials in compact heat exchangers. Exp. Thermal Fluid Sci. 28, 193–199 (2004)

N. Dukhan, Metal Foams: Fundamental and Applications (DESTECH Publication, Inc. Technology and Engineering, Lancaster, 2013), pp. 1–310

UAF, Universal Air Filter, (2014). www.uaf.com/frequently_asked_questions

N. Dukhan, C.A. Minjeur, A two-permeability approach for assessing flow properties in cellular metals. J. Porous Mater. 18(2), 417–424 (2010)

B. Antohe, J.L. Lage, D.C. Price, R.M. Weber, Experimental determination of the permeability and inertial coefficients of mechanically compressed aluminium metal layers. ASME J. Fluids Eng. 11, 404–412 (1997)

H. Oun, A.R. Kennedy, Experimental investigation of pressure drop characterization across multilayer porous metal structure. J. Porous Mater. 21, 1133–1141 (2014)

O. Reutter, E. Smirnova, J. Sauerhering, S. Angel, T. Fend, R. Pitz-Paal, Characterization of air flow through sintered metal foams. ASME J. Fluids Eng. 130(5), 051201 (2008)

N. Dukhan, R. Picón-Feliciano, A.R. Álvarez-Hernánde, Air flow through compressed and uncompressed aluminum foam: measurements and correlations. ASME J. Fluids Eng. 128(5), 1004–1012 (2006)

J.J. Lu, A. Hess, M.F. Ashby, Sound absorption of metallic foams. J. Appl. Phys. 99, 07511–07519 (1999)

J.F. Despois, A. Mortensen, Permeability of open-pore microcellular materials. Acta Mater. 53, 1381–1388 (2005)

A.J. Otaru, Enhancing the sound absorption performance of porous metals using tomography images. Appl. Acoust. 140, 183–189 (2019)

K. Seah, R. Thampuran, S. Teoh, Parametric studies of the mechanical behaviour of porous titanium. Met. Mater. 4(4), 672–675 (1998)

Y.B. Choi, T. Motoyama, K. Matsugi, G. Sasaki, Influence of the specific surface area of a porous nickel to the intermediate compound generated by reaction of a porous nickel and aluminium. Met. Mater. Int. 20(4), 741–745 (2014)

Y. Champoux, M.R. Stinson, On acoustical models for sound propagation in rigid frame porous materials and the influence of shape factors. J. Acoust. Soc. Am. 92(2), 1120–1131 (1992)

K. Boomsma, D. Poulikakos, The effect of comparison and pore size variations on the liquid flow characteristics in metal foams. ASME J. Fluids Eng. 124, 263–273 (2002)

J.P. Du Plessis, S. Wouldberg, Pore-scale derivation of Ergun equation to enhance its adaptability and generalization. Chem. Eng. Sci. 63, 2576–2586 (2008)

J.M. Coulson, The flow of fluids through granular beds: effects of particle shape and voids in streamline flow. Trans. Inst. Chem. Eng. 27, 237–257 (1949)

M. Muskat, H.G. Botset, Flow of gas through porous materials. Physics 1, 27–47 (1931)

S. Ergun, Fluid flow through packed column. Chem. Eng. 48, 89–94 (1952)

I. Kececioglu, Y. Jiang, Flow through porous media of packed spheres saturated with water. ASME J. Fluids Eng. 116, 164–170 (1994)

D. Edouard, M. Lacroix, C.P. Huu, F. Luck, Pressure drop modelling on solid foam: state-of-the-art correlation. Chem. Eng. J. 144, 299–311 (2008)

J.P. Bonnet, F. Topin, L. Tadrist, Flow laws in metal foams: compressibility and pore size effects. Trans. Porous Media 73, 149–163 (2008)

Acknowledgements

OAJ would like to thank the University of Nottingham Dean of Engineering Research Scholarship for International Excellence for providing me with the needed funds and facilities required for the successful completion of this work. Many thanks to Professor Andrew R. Kennedy (Lancaster University, UK) and Professor Herve P. Morvan (University of Nottingham, UK) for their overwhelming contributions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author of this work declares that He has no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Otaru, A.J. Review on Processing and Fluid Transport in Porous Metals with a Focus on Bottleneck Structures. Met. Mater. Int. 26, 510–525 (2020). https://doi.org/10.1007/s12540-019-00345-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00345-9