Abstract

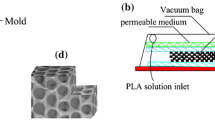

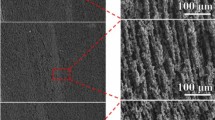

In this paper, we investigate several types of “natural or bio sourced templates” (sugar, salt, bone, coral, PLA 3D-printed scaffolds) for a the simple elaboration of macro porous thermoplastic or thermosetting polymers, especially based on resins commonly used in composites manufacturing. Open-cell, macro porous polymer foams are obtained from resin impregnation of the template. The process consists of 3 simple steps: (a) impregnation (infiltration/infusion) of the template, (b) polymerization of the resin, (c) removal of template, mainly by water. We compared several resins and showed that a low viscosity and a sufficient wettability enable fast impregnation of templates, where impregnation times are < 4 min for samples on 10 to 30 mm thicknesses. The resulting polymeric porous structure is the overall replication of the template, exhibiting mainly open pores in the range of 100 to 500 μm, and densities from 0.25 to 0.4 g cm−3. Such open foams behave as sponges and can (re) absorb liquids either polar (water), alcohols or non polar liquids such as silicon oil, which are filling the entire void volume. We proved the feasibility of an easy and fast impregnation by composite resins to provide either rigid or soft porous polymers (or ‘foams’) that can be further chemically modified. On the other side, before polymerization, the introduction of a functional additive to the reactive infusion formulation, provides homogeneously functionalized foams. Here an impact modifier is tested.

Similar content being viewed by others

References

D. Wu, F. Xu, B. Sun, R. Fu, H. He, K. Matyjaszewski, Design and preparation of porous polymers. Chem. Rev. 112, 3959–4015 (2012)

X.-Y. Yang, L.-H. Chen, Y. Li, J.-C. Rooke, C. Sanchez, B.-L. Su, Hierarchically porous materials: synthesis strategies and structure design. Chem Soc Rev 46, 481 (2017)

M. Stucki, M. Loepfe, W.-J. Stark, Porous polymer membranes by hard templating: a review. Adv. Eng. Mater. 20(1), 1700611 (2018)

C. Gaillard, J.-F. Despois, A. Mortensen, Processing of NaCl powders of controlled size and shape for the microstructural tailoring of aluminum foams. Mater. Sci. Eng. A 374(1–2), 250–262 (2004)

Y. Conde, J.-F. Despois, R. Goodall, A. Marmottant, L. Salvo, C. SanMarchi, A. Mortensen, Replication processing of highly porous materials. Adv. Eng. Mater. 8(9), 795–803 (2006)

R. Goodall, A. Mortensen, Porous metals. Phys. Metall. 32, 2399–2595 (2014)

E.-M. ElizondoLuna, F. Barari, R. Wooley, R. Goodall, Casting protocols for the production of open cell amuminum foams by replication technique and the effect of porosity. J. Vis. Exp. 94, 52268 (2014)

J.-F. Despois, Y. Conde, C. SanMarchi, A. Mortensen, Tensile behavior of replicated aluminium foams. Adv. Eng. Mater. 6(6), 444–447 (2004)

R. Goodall, J.-F. Despois, A. Mortensen, Sintering of NaCl powder: mechanisms and first stage kinetics. J. Eur. Ceram. Soc. 26, 3487–3497 (2006)

D.M. Yunos, O. Bretcanu, A.R. Boccaccini, Polymer-bioceramic composites for tissue engineering scaffolds. J. Mater. Sci. 43, 4433–4442 (2008)

S. Jiang, S. Agarwal, A. Greiner, Low-density open cellular sponges as functional materials. Angew. Chem. Int. Ed. 56, 15520–15538 (2017)

G. Franchin, P. Colombo, Porous geopolymer components through inverse replica of 3D printed sacrificial templates. J. Ceram. Sci. Tech. 06(02), 105–112 (2015)

K. Shahidi, D. Rodrigue, Production of composite membranes by coupling coating and melt extrusion/salt leaching. Ind. Eng. Chem. Res. 56, 1306–1315 (2017)

X. Wang, W. Zeng, L. Hong, W. Xu, H. Yang, F. Wang, H. Duan, M. Tang, H. Jiang, Stress-driven lithium dendrite growth mechanism and dendrite mitigation by electroplating on soft substrates. Nat. Energy 3, 227–235 (2018)

Q. Hou, D.-W. Grijpma, J. Feijen, Preparation of interconnected highly porous polymeric structures by a replication and freeze-drying process. J. Biomed. Mater. Res. Part B 67B, 732–740 (2003)

G. Wei, P.-X. Ma, Macroporous and nanofibrous polymer scaffolds and polymer/bone-like apatite composite scaffolds generated by sugar spheres. J. Biomed. Mater. Res Part A 306–315, 78 (2006)

J.S. Capes, H.Y. Ando, R.E. Cameron, Fabrication of polymeric scaffolds with a controlled distribution of pores. J. Mater. Sci. 16, 1069–1075 (2005)

S.J. Choi, T.H. Kwon, H. Im, D.I. Moon, D.J. Baek, M.L. Seol, J.-P. Duarte, Y.K. Choi, A polydimethylsiloxane (PDMS) sponge for the selective absorption of oil from water. ACS Appl. Mater. Interfaces 3(12), 4552–4556 (2011)

C. Yu, C. Lu, L. Cui, Z. Song, X. Zhao, Y. Ma, L. Jiang, Facile preparation of the porous PDMS oil-absorbent for oil/water separation. Adv. Mater. Interfaces 4, 1600862 (2017)

R. Hickmana, E. Walkerb, S. Chowdhury, TiO2-PDMS composite sponge for adsorption and solar mediated photodegradation of dye pollutants. J. Water Process Eng. 24, 74–82 (2018)

I. Miletto, C. Ivaldi, G. Paul, S. Chapman, L. Marchese, R. Raja, E. Gianotti, Hierarchical SAPO-34 architectures with tailored acid sites using sustainable sugar templates. ChemistryOpen 7, 297–301 (2018)

R.V. Festarini, M.-H. Pham, X. Liu, D.P.J. Barz, A sugar-template manufacturing method for microsystem ion-exchange membranes. J. Micromech. Microeng. 27(7), 075011 (2017). https://doi.org/10.1088/1361-6439/aa736b

Y. Lee, S. Lee, C.M. Jin, J.A. Kwon, T. Kang, I. Choi, Facile fabrication of large-scale porous and flexible three-dimensional plasmonic networks. ACS Appl. Mater. Interfaces 10(33), 28242–28249 (2018). https://doi.org/10.1021/acsami.8b11055

J.F. Patrick, B.P. Krull, M. Garg, C.L. Mangun, J.S. Moore, N.R. Sottos, S.R. White, Robust sacrificial polymer templates for 3D interconnected, microvasculature in fiber-reinforced composites. Composites 100, 361–370 (2017)

X.-B. Wang, X.-F. Jiang, Y. Bando, Blowing route towards advanced inorganic foams. Bull. Chem. Soc. Jpn. 92, 245–263 (2019)

C.R. Kellenberger, N.A. Luechinger, A. Lamprou, M. Rossier, R.N. Grass, W.J. Stark, Soluble nanoparticles as removable pore templates for the preparation of polymer ultrafiltration membranes. J. Membr. Sci. 387–388, 76–82 (2012)

B. Doshi, M. Sillanpää, S. Kalliola, A review of bio-based materials for oil spill treatment. Water Res. 135, 262–277 (2018)

M. Naffakh, M. Dumon, J.-F. Gerard, Modeling the chemorheological behavior of epoxy/liquid aromatic diamine for resin transfer molding applications. J. Appl. Polym. Sci. 102, 4228–4237 (2006)

M. Naffakh, M. Dumon, J.F. Gerard, Study of a reactive epoxy–amine resin enabling in situ dissolution of thermoplastic films during resin transfer moulding for toughening composites. Compos. Sci. Technol. 66, 1376–1384 (2006)

P. Gerard, N. PassadeBoupat, T. Fine, L. Gervat, J.-P. Pascault, Toughness properties of lightly crosslinked epoxies using block copolymers. Macromol. Symp. 256, 55–64 (2007)

W. BinHon, L. Li, M. Cao, X.-M. Chen, Plastic deformation and effects of water in room-temperature cold sintering of NaCl microwave dielectric ceramics. J. Am. Ceram. Soc. 101, 4038–4043 (2018)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Siddiqui, S., Coupy, A., Tallon, JM. et al. Facile fabrication of porous open-cell polymer structures from sacrificial “natural templates” and composite resins. J Porous Mater 27, 1013–1025 (2020). https://doi.org/10.1007/s10934-020-00878-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-020-00878-0