Abstract

Friction stir welding has the advantages of producing less material deformation and of simple joining of relatively thick materials, but the disadvantages of forming relatively large heat-affected zones around weld areas. In addition, in research on reductions in bulletproof performance in heat-affected zones, it is necessary to evaluate the ballistic limit velocity (V50), which measures bulletproof performance, and this requires specimens of a certain minimum size and has only limited application to local areas such as heat-affected zones. Instrumented indentation testing (IIT), a method of measuring material properties by utilizing load-depth curves measured by a small indenter leaving fine marks on the material, has no specimen size requirements; in addition, it has simple test procedures and is nondestructive. Here a theoretical model is proposed for evaluating V50 of aluminum alloys by ductile hole formation using IIT. Heat-affected zones generated after friction stir welding of for 7000-series aluminum alloys were simulated, and the model was validated through comparison with the conventional V50 test. In addition, there is currently no way to directly evaluate V50 for welded areas in 7000-series aluminum, but here IIT was used to assess V50 for each local part of the welded specimen. The conventional V50 test takes 15 min per shot and cannot be reused of specimens, but the test using IIT takes 1 min to complete one test and has benefits in terms of time, cost and safety.

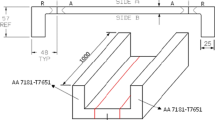

Graphic Abstract

Similar content being viewed by others

References

K.J. Colligan, J.J. Fisher, J.E. Gover, J.R. Pickens, Adv. Mater. Process. 160, 9 (2002)

K.J. Colligan, P.J. Konkol, J.J. Fisher, J.R. Pickens, Weld. J. 82, 3 (2003)

H.K. Kim, S.S. Hong, I.O. Shim, Compos. Res. 24, 2 (2011)

S.G. Im, S.S. Kim, C.G. Lee, S.J. Kim, Korean J. Met. Mater. 41, 11 (2003)

K. Sampath, Adv. Mater. Process. 163, 10 (2005)

B.W. Ahn, D.H. Choi, Y.M. Yeon, S.B. Jung, J. Weld. Joining. 31, 2 (2013)

R.S. Mishra, Z.Y. Ma, Mater. Sci. Eng. 50, 1–2 (2005)

A. Sullivan, C. Derry, J.D. Robson, I. Horsfall, P.B. Prangnell, Mater. Sci. Eng. A 528, 9 (2011)

M. Erdem, H. Cinici, U. Gokmen, H. Karakoc, M. Turker, Trans. Nonferrous Met. Soc. China 26, 1 (2016)

D.E. Carlucci, S.S. Jacobson, Ballistics: Theory and Design of Guns and Ammunition (CRCPrILlc, New York, 2007)

E. Meyer, Phy. Z. 9, 66 (1908)

R.A. George, S. Dinda, A.S. Kasper, Met. Prog. 109, 30 (1976)

W.C. Oliver, G.M. Pharr, J. Mater. Res. 7, 1564 (1992)

S.K. Kang, Y.C. Kim, K.H. Kim, J.Y. Kim, D.I. Kwon, Int. J. Plast. 49, 1 (2013)

W.S. Song, S.G. Kim, H.J. Ahn, K.H. Kim, D.I. Kwon, J. Korean Soc. Nondestruc. Test. 33, 2 (2013)

J.D. Robson, A. Sullivan, Mater. Sci. Technol. 22, 2 (2006)

Department of Defense Test Method Standard, MIL-STD-662F: V50 Ballistic Test for Armor (Virginia, US, 1997)

Y.H. Shin, J.H. Chung, J.H. Kim, Int. J. Nav. Archit. Ocean Eng. 10, 6 (2018)

T. Børvik, M.J. Forrestal, O.S. Hopperstad, T.L. Warren, M. Langseth, Int. J. Impact Eng. 36, 3 (2008)

R. Hill, The Mathematical Theory of Plasticity (Clarendon Press, Oxford, 1950)

A.J. Piekutowski, M.J. Forrestal, K.L. Poormon, T.L. Warren, Int. J. Impact Eng. 18, 7–8 (1996)

S. Ryan, L.H. Nguyen, D. Gallardy, S.J. Cimpoeru, Int. J. Impact Eng. 116, 34 (2018)

J.F. Chinella, B. Pothier, M.G. Wells, ARL-TR-1741: Mechanical Properties and Ballistic Impact Effects of Austempered Ductile Iron (Army Research Laboratory, Virginia, US, 1998)

Acknowledgements

This work was supported by a National Research Foundation of Korea (NRF) Grant funded by the Korean government (MSIT) (No. NRF-2015R1A5A1037627), and the Korea Institute of Energy Technology Evaluation and Planning (KETEP) and the Ministry of Trade, Industry & Energy (MOTIE) of the Republic of Korea (No. 20171520000360).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cho, C., Choi, S., Kwon, O.M. et al. Evaluation of Ballistic Limit Velocity Using Instrumented Indentation Test of 7xxx Aluminum Alloys After Friction Stir Welding. Met. Mater. Int. 27, 2264–2275 (2021). https://doi.org/10.1007/s12540-020-00680-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00680-2