Abstract

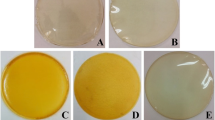

The current study represents the modification of the side-chain functionality of kafirin to prepare amide and ester derivatives. To explore the effect of the pendant group on kafirin protein, the derivatives were subjected to film formation by compression molding. Mechanical and thermal behaviors of these films were investigated. FTIR and NMR confirmed the formation of amide and ester derivatives. Amide-derived films showed a reduction in the water absorption capacity as compared to the ester-derived films. The mechanical properties of amide-derived films were higher than that of unmodified kafirin films due to the high proportion of grafted pendant groups. Kafirin treated with benzoyl chloride system has the highest tensile modulus as compared to the other modification. These findings suggest that the kafirin has the potential to be used as a packaging material in various sectors.

Graphic abstract

Similar content being viewed by others

References

Krochta JM (2002) Proteins as raw materials for films and coatings: definitions, current status and opportunities. In: Gennadios A (ed) Protein-based films and coatings. CRC Press, Boca Raton

Gao C, Taylor J, Wellner N, Yaruhanga Y, Parker M, Mills E, Belton P (2005) Effect of preparation conditions on protein secondary structure and biofilm formation of kafirin. J Agric Food Chem 53:306–312

Torres-Giner S, Gimenez E, Largaron J (2008) Characterization of the morphology and thermal properties of zein prolamin nanostructure obtained by electrospinning. Food Hydrocoll 22:601–614

Taylor J, Belton P, Minaar A (2009) Formation of kafirin microparticles by phase separation from an organic acid and their characterization. J Cereal Sci 50:99–105

Hiks K (2005) Encapsulation of essential oils in zein nano spherical particles. J Agric Food Chem 53:4788–4792

Gong S, Wang H, Sun Q, Xue S, Wang J (2006) Mechanical properties and in vitro biocompatibility of porous zein scaffolds. Biomaterials 27:3793–3799

Erickson D, Campanella O, Hamaker B (2012) Functionalizing maize zein in viscoelastic dough system through fibrous, β- Sheet rich protein network: an alternative, physicochemical approach to gluten-free breadmaking trends. Food Sci Technol 24:74–81

Perez C, Regaldo-gonz C, Rogriguez C, Barbosa J (2006) Incorporation of antimicrobial agents in food packaging films and coating. Adv Agric Food Biotechnol 37:193–216

Buchner S, Kinnear M, Crouch I, Taylor J, Minnaar A (2011) Extending the post-harvest sensory quality and shelflife of ‘Packham’s Triumph’ pears with a kafirin protein coating. J Sci Food Agric 91:2814–2820

Valerini D, Tammaro L, Di Benedetto F (2018) Aluminum-doped zinc coatings on polylactic acid films for antimicrobial food packaging. Thin Solid Films 645:187–192

Briassoulis D, Giannoulis A (2018) Evaluation of Biobased plastic mulching films. J Polym Test 67:99–109

Wu X, Zheng S, Daniel A, Aguilar B (2018) Transparent ice-phobic coatings using bio-based epoxy resin. Mater Design 140:516–523

Soltani S, Zerafat M, Sabbaghi S (2018) A comparative study of gelatin and starch-based nano-composite films modified by nano-cellulose and chitosan for food packaging applications. Carbohydr Polym 189:48–55

Cazóna P, Vázquezb M, Velazqueza G (2018) Cellulose-glycerol-polyvinyl alcohol composite films for food packaging: evaluation of water adsorption, mechanical properties, light-barrier properties and transparency. Carbohydr Polym 195:432–443

Xiao J, Yunqi L, Aljandro P, Qiuyang X, Qingrong H (2014) Structure, morphology and assembly behavior of kafirin. J Agric Food Chem 63:216–224

Belton P, Delgadillo I, Halford N, Shewry P (2006) Kafirin structure and functionality. J Cereal Sci 44(3):272–286

Taylor J, Anyango J (2013) Developments in the science of zein, kafirin and gluten protein bio-plastic materials. Cereal Chem 90:344–357

Raza H, Pasha I, Shoib M, Zaaboul F, Niazi S, Aboshora W (2017) Review on functional and rheological attributes of kafirin for utilization in the gluten-free baking industry. Am J Food Sci Nutr Res 4:150–157

De Mesa-Stonestreet N, Alavi S, Bean S (2010) Sorghum proteins: the concentration, isolation, modification, and food application of kafirins. J Food Sci 75(5):R90–R104

Xiao J, Chen Y, Huang Q (2017) Physicochemical properties of kafirin protein and its applications as building blocks of functional delivery systems. Food Funct. https://doi.org/10.1039/c6fo01217e

Fountoulakis M, Lahm H (1998) Hydrolysis and amino acid composition analysis of protein. J Chromatogr A 826(2):109–134

Zean Acetate (1941) Collins Veatch, La Grange III, assigner to corn product refining company, New York, NY. A corporation of New Jersey, Serial no. 2459822, US PATENT2236768

Biswas A, Sessa D, Lawton J, Gordon S, Willett J (2005) Microwave-assisted rapid modification of zein by octenyl succinic anhydride. Cereal Chem 82:1–3

Sessa D, Cheng H, Kim S, Selling G, Biswas A (2013) Zein based polymers formed by modifications with isocyanates. Ind Crops Prod 43:106–113

Yin H, Lu T, Liu L, Lu C (2014) Preparation, characterization and application of a novel biodegradable macromolecule: carboxymethyl. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2014.08.025

Qiangxian W, Tomoyuki Y, Hiroshi S, Hongkang Z, Seiichiro I (2003) Chemical modification of zein by bifunctional polycaprolactone. Polymer 44:3909–3919

Emmambux M, Stading M, Taylor J (2004) Sorghum kafirin film property modification with hydrolyzable and condensed tannins. J Cereal Sci 40:127–135

Byarhanga Y, Emmambux M, Wellner N, Ng KG, Taylor J (2006) Alteration of kafirin and kafirin film structure by heating with microwave energy and tannin complexation. J Agric Food Chem 54:4198–4207

Olivera N, Roufa T, Bonillaa J, Carriazob J, Dianda N, Kokinia J (2019) Effect of LAPONITE® addition on the mechanical, barrier and surface properties of novel biodegradable kafirin nanocomposite films. J Food Eng 245:24–32

Beckwith A, Wall J, Dimler R (1963) Amino groups as interaction sites in wheat gluten proteins: effect of amide-ester conversion. Arch Biochem Biophys 103:319–330

Biswas A, Sessa DJ, Gordon SH, Lawton JW, Willett JL (2005) Synthesis of zein derivatives and their mechanical properties. Polym biocatal biomater. https://doi.org/10.1021/bk-2005-0900.ch010

Padua G, Lai H, Geil P (1999) X-ray diffraction characterization of structure of zein-oleic acid films. J Appl Polym Sci 71:1267–1281

Park S, Baker J, Himmel M, Parilla P, Johnson D (2010) Cellulose crystallinity index: measurement technique and their impact on interpreting cellulose performance. Biotechnol Biofuel 3:10

Xiao J, Chen Y, Huang Q (2017) Physicochemical properties of kafirin protein and its applications as building blocks of functional delivery systems. Food Funct. https://doi.org/10.1039/c6fo01217e

Anyango J, Taylor J, Taylor J (2013) Role of γ-kafirin in the formation and organization of kafirin microstructures. J Agric Food Chem 61:10757–10765

Matveev Y, Grinberg V, Tolstoguzov V (2000) The plasticizing effect of water on proteins, polysaccharides and their mixtures: glassy state of biopolymer. Food Seed Food Hydrocoll 14:425–437

Reddy N, Tan Y, Li Y (2008) Effect of glutaraldehyde cross-linking condition on the strength and water stability of wheat gluten fibers. Macromol Mater Eng 293:614–620

Ringe D, Petsko G (2003) The glass transition on protein dynamics: what is it, why it occurs and how to exploit it. Biophys Chem 105:667–680

Brostow W, Chiu R, Kalogerqas IM, Vassilikou-Dova A (2008) Prediction of glass transition temperature, binary blends and copolymers. Mater Lett 62:3152–3155

Wang Y, Tilley M, Bean S, Sun X, Wang D (2009) Comparision of methods for extracting kafirin protein from sorghum distillers dried grains with solubles. J Agric Food Chem 57:8366–8372

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Mahajan, U.R., Mhaske, S.T. Kafirin-derived films for sustainable development by amidation and esterification. Polym. Bull. 77, 2719–2735 (2020). https://doi.org/10.1007/s00289-019-02876-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-019-02876-y