Abstract

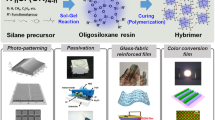

Photonic integrated circuits (PIC) can be mass-produced by 3D-printing technologies in combination with advanced hybrid inorganic–organic materials. In this work we present the development of hybrid inorganic–organic materials based on the fast sol–gel process (FSG) which can be used as a “tool kit” for the fabrication of advanced optical materials. We present routes to fabrication of FSG materials with a variety of properties: the materials may exhibit mechanical toughness or be elastic; they may be thermally and UV-curable, they can have a tailored refractive index value and tailored chemical environment, such as an aromatic matrix. Using these materials, we demonstrated strong optical bonding between optical components for solar energy and optical fiber coupler systems. We demonstrated fabrication of macroscale optical elements by 3D-printing methods, such as soft lithography, inkjet, and digital light processing (DLP) printing. We also demonstrated 3D-printing fabrication of nano/microscale optical elements by soft lithography, nanoimprint lithography (NIL), and direct laser writing (DLW). The obtained 3D-printed sol–gel optical elements were found to exhibit mechanical advantages: improved surface quality, resistance to solvents, improved adhesion to glass substrate and stability to temperature above 200 °C compared with 3D-printed organic polymer elements. In addition, the sol–gel elements present the following optical advantages: improved optical quality, improved optical transmission, and durability to laser radiation. We believe that this class of materials is a promising candidate for use in mass production of photonic integrated circuits (PIC) by 3D-printing technologies.

UV-curable fast sol–gel (FSG) bonding and 3D printing (a) Bonding of a BK7 glass prism to a silicon-based wafer by UV curing of FSG material, where the FSG is applied in the interface between them. (b) Macroscale “cubic” shaped optical element printed by 3D Digital light processing (DLP).

Highlights

-

Hybrid glassy materials with long shelf life were developed using the fast sol–gel process.

-

The process is a tool kit for fabrication of thermal/UV-curable resists with tailored properties.

-

Demonstration of optical bonding of components for solar energy and optical fiber coupler systems.

-

Demonstration of macroscale optical elements by 3D printing with inkjet and DLP printing.

-

Demonstration of microscale optical elements by 3D printing with NIL and DLW printing.

Similar content being viewed by others

References

Harris NC, Carolan J, Bundar D, Prabhu M, Hochberg M, Baehr-Jones T, Fanto ML, Smith AM, Tison CC, Alsing EnglundD (2018) Linear programmable nanophotonic processors. Optica 5:1623–1631

Alxoudi T, Terzenidis N, Pitris S, Moralis-Pegios M, Maniotis P, Vagionas C, Mitsolidou C, Mourgias-Alexandris G, Kanellos GT, Miliou A, Vyrsokinos K, Pleros N (2019) Optics in computing: from photonics network-on-chip to chip-to-chip interconnects and disintegrated architectures. JLT 37:363–379

Son G, Han S, Park J, Kwon k, Yu K (2018) High-efficiency broadband light coupling between optical fibers and photonic integrated circuts. Nanophotonics 7:1845–1864

Lipson H, Kurman (2013) Fabricated: the new world of 3D printing. John Wilely & Sons, Indianapolis USA

Cooperstein I, Sachyani-Keneth E, Shukrun-Farrell E, Rosental T, Wang X, Kamyshny A, Magdassi S (2018) Hybrid materials for functional 3D printing. Adv Mater Interfaces 5:1800996. https://doi.org/10.1002/admi.201800996

Brinker CJ, Scherer GW (1990) Sol-gel science: the physics and chemistry of sol-gel process. Academic press, Boston USA

Levy D, Zayat M (2015) The sol-gel handbook. Wiley-VCH, Weinheim Germany

Gvishi R (2009) Fast sol-gel technology—from fabrication to applications. J Sol-Gel Sci Technol 50:241–253

Gvishi R (2015) Monolithic sol-gel materials. In: Levy D, Zayat M, editors. The sol-gel handbook. Chapter 10. Wiley-VCH, Weinheim Germany

Camposeo A, Persano L, Farsari M, Pisignano D (2019) Additive manufacturing: applications and directions in photonics and optoelectronics. Adv Optical Mater 7:1800419. https://doi.org/10.1002/admi.201800419

Aghazzawi TF (2016) Advancements in CAD/CAM technology: options for practical implementation. J Prosthodont Res 69:72–84

Nguyen DT, Meyers C, Yee TD, Dudukovic NA, Destino JF, Zhu C, Duoss EB, Baumann TF, Suratwala T, Smay JE, Dylla-Spears R (2017) 3D-printed transparent glass. Adv Mater 29:1701181. https://doi.org/10.1002/admi.201701181

Yu CC, Chen HL (2015) Nanoimprint technology for patterning functional materials and its applications. Microelectron Eng 132:98–119

Selimis A, Mironov V, Farsari M (2015) Direct laser writing: principles and materials for scaffold 3D printing. Microelectron Eng 132:83–89

Dudukovic NA, Wong LL, Nguyen DT, Meyers C, Destino JF, Yee TD, Ryerson F, Suratwala T, Duoss EB, Dylla-Spears R (2018) Predicting nanoparticles suspension viscoelasticity for multimaterial 3D printing of silica-titania glass. AACS Appl Nano Mater 1:4038–4044

Destino JF, Dudukovic NA, Wong LL, Johnson MA, Nguyen DT, Yee TD, Egan GC, Sawvel AM, Steele WA, Baumann TF, Duoss EB, Suratwala T, Dylla-Spears R (2018) 3D printed optical quality silica and silica-titania glasses from sol-gel feedstocks. Adv Mater 3:1700323. https://doi.org/10.1002/admi.201700323

Gomez-Reino C, Perez MV, Bao C (2002) Gradient-index optics: fundamentals and applications. Springer-Verlag, Berlin Germany

Putz F, Scherer S, Ober M, Morak R, Paris O, Husing N (2018) 3D printing of hierachical porous silica and α-quartz. Adv Mater Technol 3:1800060. https://doi.org/10.1002/admi.201800060

Shukrun E, Cooperstein I, Magdassi S (2018) 3D-printed organic-ceramic complex hybrid structures with high silica content. Adv Mater Technol 5:1800061. https://doi.org/10.1002/admi.201800061

Cooperstein I, Shukrun E, Press O, Kamyshny A, Magdassi S (2018) Additive manufacturing of transparent silica glass from solutions. ACS Appl Mater Interfaces 10:18879–18885

Durisov J, Pudis D, Goraus M, Gaso P (2018) IP-DIP photoresist surfaces for photonic applications prepared by laser lithography and studied by AFM. Appl Surf Sci 461:108–112

Gailevicius D, Padolskyte V, Mikoliunaite L, Sakirzanovas S, Joudkazis S, Malinauskas M (2019) Additive-manufactoring of 3D glass-cermics down to nanoscale resolution. Nanoscale Horiz 4:647–651

Malinauskas M, Zukauskas A, Purlys V, Gaidukeviciute A, Balevicius Z, Piskarskas A, Fotakis C, Pissdakis S, Gray D, Gadonas R, Vamvakaki M, Farsari M (2012) 3D micro-optical elements formed in a photostructurable germanium silica by direct laser writing. Opt Laser Eng 50:1785–1788

Ovsianikov A, Gaidukeviciute A, Chichkov BN, Oubaha M, MacCraith BD, Sakellari I, Giakoumaki A, Gray D, Vamvakaki M, Farsari M, Fotakis C (2008) Two-photon polymerization of hybrid sol-gel materials for photonics applications. Laser Chem. https://doi.org/10.1155/2008/493059

Brusatin G, Giustina GD (2011) Hybrid organic-inorganic sol-gel materials for micro and nanofabrication. J Sol-Gel Sci Technol 60:299–314

Brigo L, Grenci G, Carpentiero A, Pistore A, Tormen M, Guglielmi M, Brusatin G (2011) Positive resist for UV and X-ray lithography synthesized through sol–gel chemistry. J Sol-Gel Sci Technol 60:400–407

Giustina GD, Brusatin G, Guglielmi M, Palazzesi C, Orsini E, Prosposito P (2010) Doubly patternable epoxy- based sol–gel structures by UV and soft lithography. Solid State Sci 12:1890–1893

Giustina GD, Garoli D, Romanato F, Brusatin G (2013) Zirconia based functional sol-gel resist for UV and high-resolution lithography. Microelectron Eng 110:436–440

Grenci G, Giustina GD, Pozzato A, Zanchetta E, Tormen M, Brusatin G (2012) Negative hybrid sol-gel resist as hard etching mask for pattern transfer with dry etching. Microelectron Eng 98:134–137

Brigo L, Auzelyte V, Lister KA, Brugger BrusatinG (2012) Phenyl-bridged polysilsquioxane positive and negative resist for electron beam lithography. Nanotechnology 23:325302

Gvishi R, Pokrass M, Strum G (2009) Optical bonding with fast sol-gel. J Eur Optical Soc, Rapid Publ 4:09026

Gvishi R, Pokrass M, Sturm G, Bar G (2011) Evaluation of sol-gel polymerization by multi-parameter Gel Permeation Chromatography (GPC). In: Poster Presentation In International Sol-gel Conference. Hangzhou, China

Pokrass M, Gouzman I, Bar G, Gvishi R (2011) Infrared and X-ray photoelectron spectroscopy studies of hybrid organic/inorganic fast sol–gel glasses. Optical Mater 34:341–346

Hanuhov T, Asolin E, Gvishi R (2017) Evaluation of opto-mechanical properties of UV-cured and thermally-cured sol-gel hybrids monoliths as a function of organic content and curing process. J Non-Crystalline Solids 471:301–311

Pokrass M, Burshtein Z, Gvishi R (2010) Thermo-optics coefficient in some hybrid organic/inorganic fast sol-gel glasses. Optical Mater 32:975–981

Galy T, Marszewski M, King S, Yan Y, Tolbert SH, Pilon L (2020) Comparing methods for measuring thickness, refractive index, and porosity of mesoporous thin films. Microporous Mesoporous Mater 291:109677. https://doi.org/10.1016/j.micromeso.2019.109677

Rogers JE, Slagle JE, Krein DM, Burke AR, Hall BC, Fratini A, McLean DG, Fleitz PA, Cooper TM, Drobizhev M, Makarov NS, Rebane A, Kim K-Y, Farley R, Schanze KS (2007) Platinum acetylide two-photon chromophores. Inorg Chem 46:6483–6494

Reban A, Drobizhev M, Makrov NS, Wicks G, Wunk P, Steaneko Y, Haley JE, Krein DM, Fore LJ, Burke AR, Slage JE, McLean DG, Cooper TM (2014) Symmetry breaking in platinum acetylide chromophores studied by femtosecond two-photon absorption spectroscopy. J Phys Chem A 118:3749–3759

Chateau D, Liotta A, Lunden H, Lerouge F, Chaput F, Krein DM, Cooper TM, Lopes C, El-Amay AAG, Lindgren M, Parola S (2016) Long distance enhancement of nonlinear optical properties using low concentration of plasmonic nanostrctures in dye doped monolithic Sol-Gel materials. Adv Func Mater. https://doi.org/10.1002/adfm.201601646

Cooper TM, Haley JE, Krein DM, Burke AR, Slagle JE, Mikhailov A, Reban A (2017) Two-photon spectroscopy of a series of platinum acetylide chromophores: conformation-induced ground-state symmetry breaking. J Phys Chem A 121:5442–5449

Gvishi R, Sintov Y, Sturm G, Glick Y, Englander A (2015) UV-curable adhesive material for bonding of optical components. In: Poster Presentation in International Sol-Gel Conference 2015, Kyoto, Japan

Sintov Y, Glick Y, Koplowitch T, Katz O, Nafcha Y, Shamir Y, Lavi R (2007) A novel side coupling technique for rugged all-fiber lasers and amplifiers. In: SPIE Proceedings Volume 6552, Laser Source Technology for Defense and Security III. https://doi.org/10.1117/12.721420

Shamir Y, Sintov Y, Shtaif M (2011) Large-mode-area fused-fiber combiners, with nearly lowest-mode brightness conservation. Opt Lett 36:2874–2876

Gvishi R, Strum G, Englander A (2012) UV-curable glassy material for the manufacture of bulk and nanostructured elements. J Eur Opt Soc Rap Public 7:12002

Li M, Wang J, Zhuang L, Chou SY (2000) Fabrication of circular optical structures with a 20 nm minimum feature size using nanoimprint lithography. Appl Phys Lett 76:673–675

Lightman S, Gvishi R, Hurvitz G, Arie A (2017) Comparative analysis of direct laser writing and nano-imprint lithography for fabrication of optical phase elements. Appl Opt 55:9724–9730

Brenner P, Bar-On O, Siegle T, Gvishi R, Eschenbaum C, Kalt H, Scheuer J, Lemmer U (2017) 3-D whispering gallery mode microlasers by direct laser writing and soft nanoimprint lithography. Appl Opt 56:3703–3708

Bar-On O, Brenner P, Siegle T, Gvishi R, Kalt H, Lemmer U, Scheuer J (2018) High quality 3D photonics using nano imprint lithography of fast sol-gel materials. Sci Rep 8:7833. https://doi.org/10.1038/s41598-018-26261-3

Armani DK, Kippenberg TJ, Spillane SM, Vahala KJ (2003) Ultrahigh-Q toroid microcavity on a chip. Nature 421:925–928

Muller P, Muller R, Hammer L, Barner-Kowollik C, Wegener M, Blasco E (2019) STED-Inspired laser lithography based on photoswitchable spirothiopyran moieties. Chem Mater 31:1966–1972

Lightman S, Gvishi R, Hurvitz G, Arie A (2015) Shaping of light beams by 3D direct laser writing on facets of nonlinear crystals. Opt Lett 40:4460–4463

Shapira A, Shiloh R, Juwiler I, Arie A (2012) Erratum: two-dimensional nonlinear beam shaping. Opt Lett 37:4795

Lightman S, Hurvitz G, Gvishi R, Arie A (2017) Tailoring lens functionality by 3D laser printing. Appl Opt 56:9038–9043

Lightman S, Gvishi R, Hurvitz G, Arie A (2017) Miniature wide-spectrum multiplexer for vortex beams produced by 3D laser printing. Optica 4:605–610

Acknowledgements

We would like acknowledge Dr Thomas Cooper, Air Force Research Laboratory (AFRL), Wright-Patterson Air Force Base OH, for supplying us the 2PA platinum complex (E1-BTAF-OH) chromophore. The work presented was partly funded by AFOSR/EOARD project grant number: FA955o-16-i-0201.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical statement

The manuscript is based on an invited contribution presented at the 2019 XX Sol–Gel Meeting St Petersburg and is submitted to the special issue dedicated to the 2019 XX Sol–Gel Meeting St Petersburg INVITED Contributions. Therefore, the manuscript summarizes our work on the fabrication of photonic devices by bonding or 3D-printing methods, based on UV-curable sol–gel hybrids we have developed, and includes some work that already was published. Proper acknowledgements are given by citation in the text both to other works, and to our previous publications. The data presented in the figures are original and to our knowledge do not include any material that is copyrighted.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gvishi, R., Sokolov, I. 3D sol–gel printing and sol–gel bonding for fabrication of macro- and micro/nano-structured photonic devices. J Sol-Gel Sci Technol 95, 635–648 (2020). https://doi.org/10.1007/s10971-020-05270-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-020-05270-7