Abstract

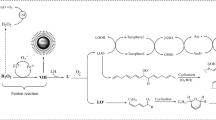

Ohmic heating is an alternative thermal treatment considered to be less destructive to bioactive compounds compared with conventional thermal processes. Bioactive compounds are well recognized as an important group of ingredients due to their nutritional value and their contribution to human health. The retention of these constituents during a thermal process, e.g., blanching, pasteurization, and sterilization, is a big challenge in the food industry and relevant industries. Furthermore, Ohmic heating as a moderate heating method also seems to be a promising technique for extraction of bioactive compounds. In the present study, the effects of Ohmic heating on degradation of different bioactive compounds such as phenolics, carotenoids, and vitamins, along with their degradation kinetics, have been reviewed.

Similar content being viewed by others

References

Jafari SM, McClements DJ (2017) Nanotechnology approaches for increasing nutrient bioavailability Adv Food Nutr Res 81:1-30 Elsevier

Martín Ortega AM, Segura Campos MR (2019) Chapter 13 - bioactive compounds as therapeutic alternatives. In: MRS C (ed) Bioactive compounds. Woodhead Publishing, pp 247–264

Xu C, Zhang R, Wen Z (2018) Bioactive compounds and biological functions of sea cucumbers as potential functional foods. J Funct Foods 49:73–84

Ahmad T, Butt MZ, Aadil RM, Inam-ur-Raheem M, Bekhit AED, Guimarães JT et al (2019) Impact of nonthermal processing on different milk enzymes. Int J Dairy Technol 72(4):481–495

Guimarães JT, Balthazar CF, Scudino H, Pimentel TC, Esmerino EA, Ashokkumar M et al (2019) High-intensity ultrasound: a novel technology for the development of probiotic and prebiotic dairy products. Ultrason Sonochem

Cullen PJ, Tiwari BK, Valdramidis VP (2012) Chapter 1 - status and trends of novel thermal and non-thermal technologies for fluid foods. In: Cullen PJ, Tiwari BK, Valdramidis VP (eds) Novel thermal and non-thermal technologies for fluid foods. Academic Press, San Diego, pp 1–6

Hiwilepo-van Hal P, Bosschaart C, van Twisk C, Verkerk R, Dekker M (2012) Kinetics of thermal degradation of vitamin C in marula fruit (Sclerocarya birrea subsp. caffra) as compared to other selected tropical fruits. LWT Food Sci Technol 49(2):188–191

Knirsch MC, Alves dos Santos C, Martins de Oliveira Soares Vicente AA, Vessoni Penna TC (2010) Ohmic heating – a review. Trends Food Sci Technol 21(9):436–441

Fellows PJ (2017) 19 - Dielectric, Ohmic and infrared heating. In: Fellows PJ (ed) Food processing technology, 4th edn. Woodhead Publishing, pp 813–844

Cappato LP, Ferreira MV, Guimaraes JT, Portela JB, Costa AL, Freitas MQ et al (2017) Ohmic heating in dairy processing: relevant aspects for safety and quality. Trends Food Sci Technol 62:104–112

Pereira R, Vicente A (2010) Environmental impact of novel thermal and non-thermal technologies in food processing. Food Res Int 43(7):1936–1943

Icier F (2012) Chapter 11 - Ohmic heating of fluid foods. In: Cullen PJ, Tiwari BK, Valdramidis VP (eds) Novel thermal and non-thermal technologies for fluid foods. Academic Press, San Diego, pp 305–367

Jaeger H, Roth A, Toepfl S, Holzhauser T, Engel K-H, Knorr D et al (2016) Opinion on the use of Ohmic heating for the treatment of foods. Trends Food Sci Technol 55:84–97

Gavahian M, Tiwari BK, Chu Y-H, Ting Y-W, Farahnaky A (2019) Food texture as affected by Ohmic heating: mechanisms involved, recent findings, benefits, and limitations. Trends Food Sci Technol 86:328–339

Sakr M, Liu S (2014) A comprehensive review on applications of Ohmic heating (OH). Renew Sust Energ Rev 39:262–269

Priyadarshini A, Rajauria G, O'Donnell CP, Tiwari BK (2019) Emerging food processing technologies and factors impacting their industrial adoption. Crit Rev Food Sci Nutr 59(19):3082–3101

Moreno-Vilet L, Hernández-Hernández H, Villanueva-Rodríguez S (2018) Current status of emerging food processing technologies in Latin America: novel thermal processing. Innovative Food Sci Emerg Technol 50:196–206

Hernández-Hernández H, Moreno-Vilet L, Villanueva-Rodríguez S (2019) Current status of emerging food processing technologies in Latin America: novel non-thermal processing. Innovative Food Sci Emerg Technol 102233

Ferreira MVS, Cappato LP, Silva R, Rocha RS, Neto RP, Tavares MIB et al (2019b) Processing raspberry-flavored whey drink using Ohmic heating: physical, thermal and microstructural considerations. Food Res Int 123:20–26

Makroo H, Rastogi N, Srivastava B (2020) Ohmic heating assisted inactivation of enzymes and microorganisms in foods: a review. Trends Food Sci Technol 97:451–465

Inmanee P, Kamonpatana P, Pirak T (2019) Ohmic heating effects on Listeria monocytogenes inactivation, and chemical, physical, and sensory characteristic alterations for vacuum packaged sausage during post pasteurization. LWT 108:183–189

Pires RP, Cappato LP, Guimarães JT, Rocha RS, Silva R, Balthazar CF et al (2020) Ohmic heating for infant formula processing: evaluating the effect of different voltage gradient. J Food Eng 280:109989

Rocha RS, Silva R, Guimarães JT, Balthazar CF, Pimentel TC, Neto RP et al (2020) Possibilities for using Ohmic heating in Minas Frescal cheese production. Food Res Int 131:109027

Kubo MT, Siguemoto ÉS, Funcia ES, Augusto PE, Curet S, Boillereaux L et al (2020) Non-thermal effects of microwave and Ohmic processing on microbial and enzyme inactivation: a critical review. Curr Opin Food Sci 35:36–48

Sastry S, Abdelrahim K, Ramaswamy HS, Marcotte M (2014) Ohmic heating in food processing. CRC press

Proctor A (2018) Alternatives to conventional food processing 2nd Edition (Vol. 53). Royal Society of Chemistry

Fadavi A, Salari S (2019) Ohmic heating of lemon and grapefruit juices under vacuum pressure—comparison of electrical conductivity and heating rate. J Food Sci 84(10):2868–2875

Icier F, Ilicali C (2005b) Temperature dependent electrical conductivities of fruit purees during Ohmic heating. Food Res Int 38(10):1135–1142

Cevik M, Icier F (2018) Effects of voltage gradient and fat content on changes of electrical conductivity of frozen minced beef meat during Ohmic thawing. J Food Process Eng 41(4):e12675

Llave Y, Udo T, Fukuoka M, Sakai N (2018) Ohmic heating of beef at 20 kHz and analysis of electrical conductivity at low and high frequencies. J Food Eng 228:91–101

Liu L, Llave Y, Jin Y, Zheng D-Y, Fukuoka M, Sakai N (2017) Electrical conductivity and Ohmic thawing of frozen tuna at high frequencies. J Food Eng 197:68–77

Icier F, Ilicali C (2005a) The effects of concentration on electrical conductivity of orange juice concentrates during Ohmic heating. Eur Food Res Technol 220(3–4):406–414

Zell M, Lyng JG, Cronin DA, Morgan DJ (2009) Ohmic heating of meats: electrical conductivities of whole meats and processed meat ingredients. Meat Sci 83(3):563–570

Fadavi A, Yousefi S, Darvishi H, Mirsaeedghazi H (2018) Comparative study of Ohmic vacuum, ohmic, and conventional-vacuum heating methods on the quality of tomato concentrate. Innovative Food Sci Emerg Technol 47:225–230

Icier F, Yildiz H, Sabanci S, Cevik M, Cokgezme OF (2017) Ohmic heating assisted vacuum evaporation of pomegranate juice: electrical conductivity changes. Innovative Food Sci Emerg Technol 39:241–246

Samaranayake CP, Sastry SK (2005) Electrode and pH effects on electrochemical reactions during Ohmic heating. J Electroanal Chem 577(1):125–135

Lima M, Heskitt BF, Burianek LL, Nokes SE, Sastry SK (1999) Ascorbic acid degradation kinetics during conventional and Ohmic hieating. J Food Process Preserv 23(5):421–443

Katouzian I, Jafari SM (2016) Nano-encapsulation as a promising approach for targeted delivery and controlled release of vitamins. Trends Food Sci Technol 53:34–48

Tomas M (2018) Jafari SM. Elsevier, Influence of food processing operations on vitamins Reference module in food science

Mercali GD, Jaeschke DP, Tessaro IC, Marczak LDF (2012) Study of vitamin C degradation in acerola pulp during Ohmic and conventional heat treatment. LWT Food Sci Technol 47(1):91–95

Assiry A, Sastry SK, Samaranayake C (2003) Degradation kinetics of ascorbic acid during Ohmic heating with stainless steel electrodes. J Appl Electrochem 33(2):187–196

Athmaselvi KA, Kumar C, Poojitha P (2017) Influence of temperature, voltage gradient and electrode on ascorbic acid degradation kinetics during Ohmic heating of tropical fruit pulp. J Food Meas Charact 11(1):144–155

Cappato LP, Ferreira MVS, Moraes J, Pires RP, Rocha RS, Silva R et al (2018a) Whey acerola-flavoured drink submitted Ohmic heating: bioactive compounds, antioxidant capacity, thermal behavior, water mobility, fatty acid profile and volatile compounds. Food Chem 263:81–88

Cappato LP, Ferreira MVS, Pires RPS, Cavalcanti RN, Bisaggio RC, Freitas MQ, Silva MC, Cruz AG (2018b) Whey acerola-flavoured drink submitted Ohmic heating processing: is there an optimal combination of the operational parameters? Food Chem 245:22–28

Jaeschke DP, Marczak LDF, Mercali GD (2016) Evaluation of non-thermal effects of electricity on ascorbic acid and carotenoid degradation in acerola pulp during Ohmic heating. Food Chem 199:128–134

Leizerson S, Shimoni E (2005) Effect of ultrahigh-temperature continuous Ohmic heating treatment on fresh orange juice. J Agric Food Chem 53(9):3519–3524

Saxena J, Makroo HA, Srivastava B (2016) Optimization of time-electric field combination for PPO inactivation in sugarcane juice by Ohmic heating and its shelf life assessment. LWT Food Sci Technol 71:329–338

Tumpanuvatr T, Jittanit W (2012) The temperature prediction of some botanical beverages, concentrated juices and purees of orange and pineapple during Ohmic heating. J Food Eng 113(2):226–233

Lee SY, Sagong HG, Ryu S, Kang DH (2012) Effect of continuous Ohmic heating to inactivate Escherichia coli O157: H7, Salmonella Typhimurium and Listeria monocytogenes in orange juice and tomato juice. J Appl Microbiol 112(4):723–731

Saberian H, Hamidi Esfahani Z, Abbasi S (2015) Effect of conventional and Ohmic pasteurization on some bioactive components of aloe vera gel juice. Iran J Chem Chem Eng (IJCCE) 34(3):99–108

Demirdöven A, Baysal T (2014) Optimization of Ohmic heating applications for pectin methylesterase inactivation in orange juice. J Food Sci Technol 51(9):1817–1826

Icier F (2010) Ohmic blanching effects on drying of vegetable byproduct. J Food Process Eng 33(4):661–683

Singh A, Santosh S, Kulshrestha M, Chand K, Lohani UC, Shahi NC (2013) Quality characteristics of Ohmic heated aonla (Emblica officinalis Gaertn.) pulp

Mercali GD, Schwartz S, Marczak LDF, Tessaro IC, Sastry S (2014a) Ascorbic acid degradation and color changes in acerola pulp during Ohmic heating: effect of electric field frequency. J Food Eng 123:1–7

Onwuka UN, Ejikeme C (2005) Influence of voltage and electrode type on the yield and quality of fruit juice extracted by Ohmic heating. Fruits 60(5):341–349

Assiry AM, Sastry SK, Samaranayake CP (2006) Influence of temperature, electrical conductivity, power and pH on ascorbic acid degradation kinetics during Ohmic heating using stainless steel electrodes. Bioelectrochemistry 68(1):7–13

Farahnaky A, Kamali E, Golmakani MT, Gavahian M, Mesbahi G, Majzoobi M (2018) Effect of Ohmic and microwave cooking on some bioactive compounds of kohlrabi, turnip, potato, and radish. J Food Meas Charact 12(4):2561–2569

Vikram VB, Ramesh MN, Prapulla SG (2005) Thermal degradation kinetics of nutrients in orange juice heated by electromagnetic and conventional methods. J Food Eng 69(1):31–40

Chakrabortya I, Athmaselvi KA (2014) Changes in physicochemical properties of guava juice during Ohmic heating. J Ready Eat Food 1(4):152–157

Gomathy K, Thangavel K, Balakrishnan M, Kasthuri R (2015) Effect of Ohmic heating on the electrical conductivity, biochemical and rheological properties of papaya pulp. J Food Process Eng 38(4):405–413

Makroo HA, Rastogi NK, Srivastava B (2017a) Enzyme inactivation of tomato juice by Ohmic heating and its effects on physico-chemical characteristics of concentrated tomato paste. J Food Process Eng 40(3):e12464

Pataro G, Donsì G, Ferrari G (2011) Aseptic processing of apricots in syrup by means of a continuous pilot scale Ohmic unit. LWT-Food Sci Technol 44(6):1546–1554

Rostamabadi H, Falsafi SR, Jafari SM (2019) Nanoencapsulation of carotenoids within lipid-based nanocarriers. J Control Release 298:38–67

Achir N, Dhuique-Mayer C, Hadjal T, Madani K, Pain J-P, Dornier M (2016) Pasteurization of citrus juices with Ohmic heating to preserve the carotenoid profile. Innovative Food Sci Emerg Technol 33:397–404

Mannozzi C, Fauster T, Haas K, Tylewicz U, Romani S, Dalla Rosa M, Jaeger H (2018) Role of thermal and electric field effects during the pre-treatment of fruit and vegetable mash by pulsed electric fields (PEF) and Ohmic heating (OH). Innovative Food Sci Emerg Technol 48:131–137

Makroo HA, Saxena J, Rastogi NK, Srivastava B (2017b) Ohmic heating assisted polyphenol oxidase inactivation of watermelon juice: effects of the treatment on pH, lycopene, total phenolic content, and color of the juice. J Food Process Preserv 41(6):e13271

Yildiz H, Icier F, Baysal T (2010) Changes in β-carotene, chlorophyll and color of spinach puree during Ohmic heating. J Food Process Eng 33(4):763–779

Assadpour E, Jafari SM, Esfanjani AF (2017) Protection of phenolic compounds within nanocarriers. CAB Reviews 12(057):1–8

Faridi Esfanjani A, Assadpour E, Jafari SM (2018) Improving the bioavailability of phenolic compounds by loading them within lipid-based nanocarriers. Trends Food Sci Technol 76:56–66

Brochier B, Mercali GD, Marczak LDF (2016) Influence of moderate electric field on inactivation kinetics of peroxidase and polyphenol oxidase and on phenolic compounds of sugarcane juice treated by Ohmic heating. LWT 74:396–403

Yildiz H, Bozkurt H, Icier F (2009) Ohmic and conventional heating of pomegranate juice: Effects on rheology, color, and total phenolics. Food Sci Technol Int 15(5):503–512

Guida V, Ferrari G, Pataro G, Chambery A, Di Maro A, Parente A (2013) The effects of Ohmic and conventional blanching on the nutritional, bioactive compounds and quality parameters of artichoke heads. LWT-Food Sci Technol 53(2):569–579

Ramírez-Jiménez AK, Rangel-Hernández J, Morales-Sánchez E, Loarca-Piña G, Gaytán-Martínez M (2019) Changes on the phytochemicals profile of instant corn flours obtained by traditional nixtamalization and Ohmic heating process. Food Chem 276:57–62

Moreno J, Gonzales M, Zúniga P, Petzold G, Mella K, Munoz O (2016) Ohmic heating and pulsed vacuum effect on dehydration processes and polyphenol component retention of osmodehydrated blueberries (cv. Tifblue). Innovative Food Sci Emerg Technol 36:112–119

Brochier B, Mercali GD, Marczak LDF (2018) Effect of Ohmic heating parameters on peroxidase inactivation, phenolic compounds degradation and color changes of sugarcane juice. Food Bioprod Process 111:62–71

Mercali GD, Jaeschke DP, Tessaro IC, Marczak LDF (2013) Degradation kinetics of anthocyanins in acerola pulp: comparison between Ohmic and conventional heat treatment. Food Chem 136(2):853–857

Sarkis JR, Jaeschke DP, Tessaro IC, Marczak LDF (2013) Effects of Ohmic and conventional heating on anthocyanin degradation during the processing of blueberry pulp. LWT-Food Sci Technol 51(1):79–85

Sarkis JR, Jaeschke DP, Mercali GD, Tessaro IC, Marczak LDF (2019) Degradation kinetics of anthocyanins in blackberry pulp during Ohmic and conventional heating. Int Food Res J 26(1):87–97

Mercali GD, Gurak PD, Schmitz F, Marczak LDF (2015) Evaluation of non-thermal effects of electricity on anthocyanin degradation during Ohmic heating of jaboticaba (Myrciaria cauliflora) juice. Food Chem 171:200–205

Sarabandi K, Jafari SM (2020) Effect of chitosan coating on the properties of nanoliposomes loaded with flaxseed-peptide fractions: stability during spray-drying. Food Chem 310:125951

Sarabandi K, Jafari SM, Mohammadi M, Akbarbaglu Z, Pezeshki A, Khakbaz Heshmati M (2019) Production of reconstitutable nanoliposomes loaded with flaxseed protein hydrolysates: stability and characterization. Food Hydrocoll 96:442–450

Herman LL, Bashir K (2019) Angiotensin converting enzyme inhibitors (ACEI). StatPearls [Internet]: StatPearls Publishing

Costa NR, Cappato LP, Ferreira MVS, Pires RP, Moraes J, Esmerino EA et al (2018) Ohmic heating: a potential technology for sweet whey processing. Food Res Int 106:771–779

Ferreira MVS, Cappato LP, Silva R, Rocha RS, Guimarães JT, Balthazar CF et al (2019a) Ohmic heating for processing of whey-raspberry flavored beverage. Food Chem 297:125018

Esfahani R, Jafari SM, Jafarpour A, Dehnad D (2019) Loading of fish oil into nanocarriers prepared through gelatin-gum Arabic complexation. Food Hydrocoll 90:291–298

Ghorbanzade T, Jafari SM, Akhavan S, Hadavi R (2017) Nano-encapsulation of fish oil in nano-liposomes and its application in fortification of yogurt. Food Chem 216:146–152

Pereira RN, Martins RC, Vicente AA (2008) Goat milk free fatty acid characterization during conventional and Ohmic heating pasteurization. J Dairy Sci 91(8):2925–2937

Mesías M, Wagner M, George S, Morales FJ (2016) Impact of conventional sterilization and Ohmic heating on the amino acid profile in vegetable baby foods. Innovative Food Sci Emerg Technol 34:24–28

Mercali GD, Schwartz S, Marczak LDF, Tessaro IC, Sastry S (2014b) Effect of the electric field frequency on ascorbic acid degradation during thermal treatment by Ohmic heating. J Agric Food Chem 62(25):5865–5870

Castro I, Teixeira JA, Salengke S, Sastry SK, Vicente AA (2004) Ohmic heating of strawberry products: electrical conductivity measurements and ascorbic acid degradation kinetics. Innovative Food Sci Emerg Technol 5(1):27–36

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Salari, S., Jafari, S.M. The Influence of Ohmic Heating on Degradation of Food Bioactive Ingredients. Food Eng Rev 12, 191–208 (2020). https://doi.org/10.1007/s12393-020-09217-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-020-09217-0