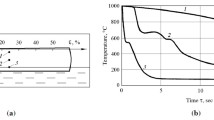

Possibilities of increasing the efficiency of technology for production of 8–16 (25) mm thick strip in strip mills having different consumer demand for hot-rolled sheet are demonstrated. Such production methods as redistribution of reductions in the roughing group stands, installation of induced cooling and heat protection screens on the intermediate roller table, rolling sheet of variable thickness (“wedgeshaped”) in the finishing group of stands, make it possible to control temperature effectively both over strip length and thickness without use of external heat sources, and without loss of continuous hot rolling high productivity.

Similar content being viewed by others

References

V. P. Polukhin and A. G. Vasil’chenko, “Mathematical modeling in a computer of steel broad strip hot rolling,” Coll. MISiS, Use of a Computer in Metallurgy [in Russian], Metallurgiya, Moscow (1975).

V. P. Polukhin, Mathematical Modeling and Calculation in a Computer of Sheet Rolling Mills [in Russian], Metallurgiya, Moscow (1972).

A. G. Vasil’chenko, “Study in a computer of hot rolling taking account of temperature distribution over a strip cross section and cooling before winding on a coil,” Diss. Cand. Techn. Sci., MISiS Moscow (1972).

V. G. Labeish, Liquid Cooling of High-Temperature Metal [in Russian], Izd. Leningr. Univ., Leningrad (1983).

M. Yu. Matrosov, L. I. Éfron, V. I. Il’inskii, Yu. I. Lipunov, and K. Yu. Éismondt, “Use of accelerated cooling for improving the mechanical and production properties of thick rolled sheet for preparing gas pipelines of considerable diameter,” Metallurg, No. 6, 49–54 (2005).

V. N. Khloponin and V. V. Cashchin, “Study of the temperature regime for the roughing group of contemporary broad strip mills,” Izv. Vuz., Chern. Met., No. 2, 82–86 (1976).

V. P. Polukhin and V. V. Chashchin, “Choice of rational reductions in a broad strip mill roughing group of stands,” Coll. MISiS No. 96, Theory and Technology of Metal Deformation [in Russian], Metallurgiya, Moscow (1975).

I. P. Shabalov, Yu. D. Morozov, and L. I. Éfron, Steel for Pipes and Building Structures with Improved Operating Properties [in Russian], ZAO Metallurgizdat, Moscow (2003).

M. Fantutstsin, E. Filippi, and A. Venanstini, “Use of active tunnel furnace in a hot rolling strip mill,” STEEL TIMES International in Russian language, No. 15, 22–24 (2005).

P. I. Polukhin, V. N. Khloponin, V. P. Polukhin, et al., “Thermal effect of screening a workpiece on a roll-out table of a broad strip hot rolling mill,” Coll. MISiS, No. 82, Use of a Computer in Metallurgy [in Russian], Metallurgiya, Moscow (1975).

B. N. Khloponin, “Saving energy in a CBSHRM production line of hot rolling broads strip mill,” in: Progressive OMD Technology, Guide, IRIAS. Moscow (1009).

V. N. Khloponin and V. V. Chashchin, “Use of wedged rolled product for stabilizing the temperature over strip length,” Coll. MISiS, Metal Deformation Technology and Theory [in Russian], Metallurgiya, Moscow (1977).

V. N. Khloponin, V. S. Savchenko, and V. V. Chashchin, “Stabilization of the temperature overs trip length during rolling wedgeshaped rolled product,” Coll. Theory and Technology of Metal Deformation [in Russian], Metallurgiya, Moscow (1979).

V. V. Сhashchin, “Controlled cooling of strip coils on the conveyer of a hotrolling mill,” Steel in Translation, 48, No. 6, 388–392 (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 63, No. 12, pp. 45–50, December, 2019.

Rights and permissions

About this article

Cite this article

Kuklev, A.V., Chashchin, V.V. Engineering and Production Solutions in Development of Manufacture of Increased Thickness Hot Strip Rolled Products. Metallurgist 63, 1287–1293 (2020). https://doi.org/10.1007/s11015-020-00950-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-020-00950-9