Abstract

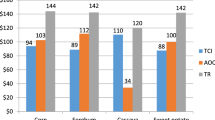

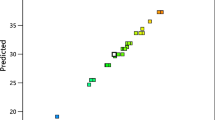

Cassava (Manihot esculenta) is a woody bush extensively cultivated as an annual crop in tropical and subtropical regions for its edible starchy tuberous root, a major source of carbohydrates. The main residue from its cultivation is the cassava stalk, which is normally used as soil fertilizer or in culture propagation. The main goal of this paper is to evaluate two routes (biochemical and thermochemical) for bioenergy production (ethanol and synthesis gas—electricity) using cassava stalk as raw material. A detailed techno-economic and energy assessment is carried out based on the simulation approach of both conversion routes to determine the production costs of main products and the overall energy efficiency of the processes. The electricity production costs vary from 0.008 to 0.037 USD/MJ, whereas the ethanol production costs range from 1.11 to 2.02 USD/L (including subsidies). The change in the production costs was observed due to the assumptions of the model, e.g., cassava stalk, transportation, and enzyme costs. The overall energy efficiency of the gasification and ethanol fermentation was 68.7 and 25.1%, respectively.

Similar content being viewed by others

References

Sivamani S, Chandrasekaran AP, Balajii M, Shanmugaprakash M, Hosseini-Bandegharaei A, Baskar R (2018) Evaluation of the potential of cassava-based residues for biofuels production. Rev Environ Sci Biotechnol 17:553–570. https://doi.org/10.1007/s11157-018-9475-0

Food and Agriculture Organization of the United States (FAO) (2017) Production of Cassava in the World

Ministerio de Agricultura y Desarrollo Rural (2017) Clúster de tubérculos en los departamentos de Bolívar, Córdoba y Sucre para las líneas productivas de Ñame, Yuca y Batata. Colombia

Red de Información y Comunicación del Sector Agropecuario de Colombia (AGRONET) (2018) Cassava crop production in Colombia

Tomei J, Helliwell R (2016) Food versus fuel? Going beyond biofuels. Land Use Policy 56:320–326. https://doi.org/10.1016/j.landusepol.2015.11.015

Veiga JPS, Valle TL, Feltran JC, Bizzo WA (2016) Characterization and productivity of cassava waste and its use as an energy source. Renew Energy 93:691–699. https://doi.org/10.1016/j.renene.2016.02.078

Klein C (2017) Handbook on cassava. Production, potential uses and recent advances. Nova Science Publisher Inc, New York

Okon A (2017) Prices of cassava stems drop to N400/bundle. In: Punch. https://punchng.com/prices-of-cassava-stems-drop-to-n400bundle/.

Zhu W, Lestander TA, Örberg H et al (2015) Cassava stems: a new resource to increase food and fuel production. GCB Bioenergy 7:72–83. https://doi.org/10.1111/gcbb.12112

Unidad de planeación Minero Energética (UPME) (2014) Law 1715 of 2014. Integration of non-conventional energy sources to the National Energetic System

Higueras D (2016) Law 1715. Friend of the stakeholders in renewable energies? Semana

CONPES (2008) Lineamientos de la política para promover la producción sostenible de biocombustibles en Colombia. Departamento Nacional de Planeación, Bogotá

de la República de Colombia C (2001) Ley 693 of 2001 - normas sobre el uso de alcoholes carburantes. Ministerio de Minas y Energía. Bogotá, Colombia

Asocaña (2019) General issues of sugarcane agroindustry: 2018–2019 annual report. Asocaña

García CA, Moncada J, Aristizábal Marulanda V, Cardona CA (2017) Techno-economic and energetic assessment of hydrogen production through gasification in the Colombian context: coffee cut-stems. Int J Hydrog Energy 42:5849–5864. https://doi.org/10.1016/j.ijheatmasstransfer.2017.09.038

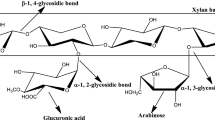

Martín C, Wei M, Xiong S, Jönsson LJ (2017) Enhancing saccharification of cassava stems by starch hydrolysis prior to pretreatment. Ind Crop Prod 97:21–31. https://doi.org/10.1016/j.indcrop.2016.11.067

Wooley RJ, Putsche V (1996) Development of an ASPEN PLUS physical property database for biofuels components. Victoria:1–38

Carolan J, Joshi S, Dale B (2007) Technical and financial feasibility analysis of distributed bioprocessing using regional biomass pre-processing centers. J Agric Food Ind Organ 5:1–29. https://doi.org/10.2202/1542-0485.1203

Hedman B, Boström D, Zhu W et al (2015) Enhancing fuel qualities of cassava crop residues by washing. Fuel Process Technol 139:127–134. https://doi.org/10.1016/j.fuproc.2015.06.052

Mayer FD, Gasparotto JM, Klauck E et al (2015) Conversion of cassava starch to ethanol and a byproduct under different hydrolysis conditions. Starch/Staerke 67:620–628. https://doi.org/10.1002/star.201500043

Ranatunga TD, Jervis J, Helm RF et al (1997) Toxicity of hardwood extractives toward Saccharomyces cerevisiae glucose fermentation. Biotechnol Lett 19:1125–1127. https://doi.org/10.1023/A:1018400912828

Han M, Kim Y, Kim Y et al (2011) Bioethanol production from optimized pretreatment of cassava stem. Korean J Chem Eng 28:119–125. https://doi.org/10.1007/s11814-010-0330-4

Esquivia Mercado MB, Castaño Peláez HI, Atehortua Garcés L et al (2014) Producción de etanol a partir de yuca en condiciones de alta concentración de sólidos (VHG). Rev Colomb Biotecnol 16:163. https://doi.org/10.15446/rev.colomb.biote.v16n1.44284

Pitt WW, Haag GL, Lee DD (1983) Recovery of ethanol from fermentation broths using selective sorption-desorption. Biotechnol Bioeng 25:123–131. https://doi.org/10.1002/bit.260250110

Risovic S, Dukic I, Vuckovic K (2008) Energy analysis of pellets made of wood residues. Croat J for Eng i:95–108

Baruah DCCD, Baruah DCCD (2014) Modeling of biomass gasification: a review. Renew Sust Energ Rev 39:806–815. https://doi.org/10.1016/j.rser.2014.07.129

Zhu X, Venderbosch R (2005) A correlation between stoichiometrical ratio of fuel and its higher heating value. Fuel 84:1007–1010. https://doi.org/10.1016/j.fuel.2004.12.002

García CA, Betancourt R, Cardona CA (2015) Stand-alone and biorefinery pathways to produce hydrogen through gasification and dark fermentation using Pinus Patula. J Environ Manag. https://doi.org/10.1016/j.jenvman.2016.04.001

García CA, Peña Á, Betancourt R, Cardona CA (2017) Energetic and environmental assessment of thermochemical and biochemical ways for producing energy from agricultural solid residues: coffee cut-stems case. J Environ Manag. https://doi.org/10.1016/j.jenvman.2017.04.029

Peters MS, Timmerhaus KD, West RE (2004) Plant design and economics for chemical engineers. McGraw-Hill, Fourth

Supply Corporation of Colombia (CORABASTOS) (2018) National market price of Cassava in Colombia. www.corabastos.com.co.

Jaller M (2006) Optimización de la cadena de valor del bio-etanol a partir de la caña de azúcar y la yuca. Universidad del Norte, Colombia

Ulrich GD, Vasudevan PT (2006) How to estimate utility costs. Chem Eng 113:66–69

Unidad de Planeación Minero - Energética (UPME) (2018) Energetic balance of Colombia. http://www1.upme.gov.co.

Linstrom PJ, Mallard WG (1998) NIST chemistry Webbook. Choice Rev Online 35:35–2709–35–2709. https://doi.org/10.5860/CHOICE.35-2709

Cardona CA, Quintero JA, Paz IC (2010) Production of bioethanol from sugarcane bagasse: status and perspectives. Bioresour Technol 101:4754–4766. https://doi.org/10.1016/j.biortech.2009.10.097

Moncada J, Cardona CA, Higuita JC et al (2016) Wood residue (Pinus patula bark) as an alternative feedstock for producing ethanol and furfural in Colombia: experimental, techno-economic and environmental assessments. Chem Eng Sci 140:309–318. https://doi.org/10.1016/j.ces.2015.10.027

García-Velásquez CA (2016) Hydrogen production through gasification and dark fermentation. National University of Colombia, Colombia

Johnson E (2016) Integrated enzyme production lowers the cost of cellulosic ethanol. Biofuels Bioprod Biorefin 10:164–174. https://doi.org/10.1002/bbb

Kalmanovitz S (2018) Gasoline price. El Espectador

Foust TD, Aden A, Dutta A, Phillips S (2009) An economic and environmental comparison of a biochemical and a thermochemical lignocellulosic ethanol conversion processes. Cellulose 16:547–565. https://doi.org/10.1007/s10570-009-9317-x

Gobierno de Colombia, INNpulsa (2018) Cluster initiatives in Colombia. Instruments for economical development and competitiveness., First. Colombian Government, Bogotá, Colombia

Gobierno de Colombia (2016) Summary of Colombia’s Peace Agreement, to End Conflict and Build Peace

Ministerio de Agricultura y Desarrollo Rural (2017) Lineamientos estratégicos de política pública para la Agricultura Campesina, Familiar y Comunitaria - Resolution 464 of 2017. Bogotá, Colombia

CONPES (2018) Estrategia para la implementación de los Objetivos de Desarrollo Sostenible (ODS) en Colombia - Documento Conpes 3918. Bogotá, Colombia

Aguilar E, Segreda A, Morales J et al (2017) Cassava crop manual (Manihot esculenta Crantz). San José, Costa Rica

Funding

The Universidad Nacional de Colombia Sede Manizales and the Dirección Nacional de Investigación (DIMA) financially supported this work through the project “entitled “Contrapartida Vicerrectoria de Investigación 2016 – 2018” Grant No. 201010013030.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

García-Velásquez, C.A., Daza, L. & Cardona, C.A. Economic and Energy Valorization of Cassava Stalks as Feedstock for Ethanol and Electricity Production. Bioenerg. Res. 13, 810–823 (2020). https://doi.org/10.1007/s12155-020-10098-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-020-10098-8