Abstract

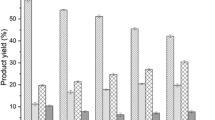

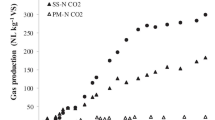

The potential of Scenedesmus obliquus biomass, after treating several wastewaters (WWs) (urban, dairy and brewery industries, cattle and poultry breeding), was evaluated for the production of bio-char, bio-oil and bio-gas, through a pyrolysis process. The experiments were carried out in a fixed bed reactor at a temperature of 748 K during 15 min. The thermochemical behaviour of each microalga was assessed by thermogravimetry analysis and infrared spectroscopy. The bio-oils obtained were also quantified and characterized. The results reveal that (i) all microalgae show a similar thermal degradation behaviour; (ii) microalga grown in urban WW shows a lower percentage of lipids; in dairy and cattle WWs, it shows a high percentage of both proteins and lipids, and in poultry and brewery WWs, it shows a higher carbohydrates content; (iii) the microalga grown in poultry WW shows the lowest protein content, whereas the urban grown microalga showed the highest protein content; (iv) the bio-oil obtained by pyrolysis process showed yields in the range 30–60% (w/w) and showed a high content of aromatic compounds.

Similar content being viewed by others

References

Pittman JK, Dean AP, Osundeko O (2011) The potential of sustainable algal biofuel production using wastewater resources. Bioresour Technol 102:17–25. https://doi.org/10.1016/j.biortech.2010.06.035

Lundquist T, Woertz I, Quinn N, Benemann J (2010) A realistic technology and engineering assessment of algae biofuel production. Energy Biosciences Institute, Univeristy of California p 1–178

Eurostat Eurostat 2013-2015. https://ec.europa.eu/eurostat/

Barth-Haas Group (2019) Beer production worldwide from 1998 to 2018 (in billion hectoliters). In: Statistics. Hops 2018/2019, p 9

Brewers Assiociation (2013) Wastewater Management Guidance Manual. 1–47

Simate GS, Cluett J, Iyuke SE et al (2011) The treatment of brewery wastewater for reuse: state of the art. Desalination 273:235–247. https://doi.org/10.1016/j.desal.2011.02.035

Maroneze MM, Barin JS, De Menezes CR et al (2014) Treatment of cattle-slaughterhouse wastewater and the reuse of sludge for biodiesel production by microalgal heterotrophic bioreactors. Sci Agric 4:521–524

Oswald WJ (2003) My sixty years in applied algology. J Appl Phycol 15:99–106. https://doi.org/10.1023/A:1023871903434

Craggs RJ, Adey WH, Jenson KR et al (1996) Phosphorus removal from wastewater using an algal turf scrubber. Water Sci Technol 33:191–198. https://doi.org/10.1016/0273-1223(96)00354-X

Green FB, Lundquist TJ, Oswald WJ (1995) Energetics of advanced integrated wastewater pond systems. Water Sci Technol 31:9–20. https://doi.org/10.1016/0273-1223(95)00488-9

Batista AP, Ambrosano L, Graça S, Sousa C, Marques PASS, Ribeiro B, Botrel EP, Castro Neto P, Gouveia L (2015) Combining urban wastewater treatment with biohydrogen production – an integrated microalgae-based approach. Bioresour Technol 184:230–235. https://doi.org/10.1016/j.biortech.2014.10.064

Gouveia L, Graça S, Sousa C et al (2016) Microalgae biomass production using wastewater: treatment and costs: scale-up considerations. Algal Res 16:167–176. https://doi.org/10.1016/j.algal.2016.03.010

Brennan L, Owende P (2010) Biofuels from microalgae—a review of technologies for production, processing, and extractions of biofuels and co-products. Renew Sust Energ Rev 14:557–577. https://doi.org/10.1016/j.rser.2009.10.009

Demirbaş A (2001) Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Convers Manag 42:1357–1378. https://doi.org/10.1016/S0196-8904(00)00137-0

Demirbas A (2008) Biofuels sources, biofuel policy, biofuel economy and global biofuel projections. Energy Convers Manag 49:2106–2116. https://doi.org/10.1016/j.enconman.2008.02.020

Marcilla A, Catalá L, García-Quesada JC et al (2013) A review of thermochemical conversion of microalgae. Renew Sust Energ Rev. https://doi.org/10.1016/j.rser.2013.06.032

Chen WH, Lin BJ, Huang MY, Chang JS (2014) Thermochemical conversion of microalgal biomass into biofuels: a review. Bioresour Technol. https://doi.org/10.1016/j.biortech.2014.11.050

Fermoso J, Hernando H, Jiménez-Sánchez S et al (2017) Bio-oil production by lignocellulose fast-pyrolysis: isolating and comparing the effects of indigenous versus external catalysts. Fuel Process Technol. https://doi.org/10.1016/j.fuproc.2017.08.009

Vereš J, Kolonicný J, Ochodek T (2014) Biochar status under international law and regulatory issues for the practical application. Chem Eng Trans. https://doi.org/10.3303/CET1437134

Özçimen D (2013) An approach to the characterization of biochar and bio-oil. In: Lohani SP (ed) Renewable energy for sustainable future, pp 41–58

Miao X, Wu Q, Yang C (2004) Fast pyrolysis of microalgae to produce renewable fuels. J Anal Appl Pyrolysis 71:855–863. https://doi.org/10.1016/j.jaap.2003.11.004

Yang C, Li R, Cui C et al (2016) Catalytic hydroprocessing of microalgae-derived biofuels: a review. Green Chem 18:3684–3699. https://doi.org/10.1039/c6gc01239f

Oliveira AC, Barata A, Batista AP, Gouveia L (2019) Scenedesmus obliquus in poultry wastewater bioremediation. Environ Technol 40:3735–3744. https://doi.org/10.1080/09593330.2018.1488003

Mendonça HV, Ometto JPHB, Otenio MH et al (2018) Microalgae-mediated bioremediation and valorization of cattle wastewater previously digested in a hybrid anaerobic reactor using a photobioreactor: comparison between batch and continuous operation. Sci Total Environ 633:1–11. https://doi.org/10.1016/J.SCITOTENV.2018.03.157

Ferreira A, Marques P, Ribeiro B, Assemany P, de Mendonça HV, Barata A, Oliveira AC, Reis A, Pinheiro HM, Gouveia L (2018) Combining biotechnology with circular bioeconomy: from poultry, swine, cattle, brewery, dairy and urban wastewaters to biohydrogen. Environ Res 164:32–38. https://doi.org/10.1016/J.ENVRES.2018.02.007

Batista AP, Moura P, Marques PASS et al (2014) Scenedesmus obliquus as feedstock for biohydrogen production by Enterobacter aerogenes and Clostridium butyricum. Fuel 117:537–543. https://doi.org/10.1016/j.fuel.2013.09.077

American Public Health Association (2005) Standard methods for the examination of water and wastewater, 23th ed. https://doi.org/10.2105/AJPH.51.6.940-a

Decree-Law No 236/98 (1998) Decree-Law 236/98 of the Portuguese Ministry of the Environment of 1 August establishing water quality standards. Diário da República: I Série-A 3676–3722

Molina Grima E, Belarbi E-H, Acién FF et al (2003) Recovery of microalgal biomass and metabolites: process options and economics. Biotechnol Adv 20:491–515. https://doi.org/10.1016/S0734-9750(02)00050-2

Hoebler C, Barry JL, David A, Delort-Laval J (1989) Rapid acid hydrolysis of plant cell wall polysaccharides and simplified quantitative determination of their neutral monosaccharides by gas-liquid chromatography. J Agric Food Chem 37:360–367. https://doi.org/10.1021/jf00086a020

DuBois M, Gilles KA, Hamilton JK et al (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356. https://doi.org/10.1021/ac60111a017

Jones DB (1941) Factors for converting percentages of nitrogen in foods and feeds into percentages of protein. US Department of Agriculture-circ. 183, Washington, DC

Ferreira AF, Soares Dias AP, Silva CM, Costa M (2015) Evaluation of thermochemical properties of raw and extracted microalgae. Energy 92:365–372. https://doi.org/10.1016/j.energy.2015.04.078

Rego F, Soares Dias AP, Casquilho M et al (2019) Fast determination of lignocellulosic composition of poplar biomass by thermogravimetry. Biomass Bioenergy 122:375–380. https://doi.org/10.1016/j.biombioe.2019.01.037

Ferreira AF, Dias APS, Silva CM, Costa M (2016) Effect of low frequency ultrasound on microalgae solvent extraction: analysis of products, energy consumption and emissions. Algal Res 14:9–16. https://doi.org/10.1016/j.algal.2015.12.015

Silva CM, Ferreira AF, Dias AP, Costa M (2016) A comparison between microalgae virtual biorefinery arrangements for bio-oil production based on lab-scale results. J Clean Prod 130:58–67. https://doi.org/10.1016/j.jclepro.2015.09.053

López-González D, Fernandez-Lopez M, Valverde JL, Sanchez-Silva L (2014) Kinetic analysis and thermal characterization of the microalgae combustion process by thermal analysis coupled to mass spectrometry. Appl Energy 114:227–237. https://doi.org/10.1016/j.apenergy.2013.09.055

Ranjith Kumar R, Ramesh D, Mutanda T et al (2015) Thermal behavior and pyrolytic characteristics of freshwater Scenedesmus sp. biomass. Energy Sour Part A 37:1383–1391. https://doi.org/10.1080/15567036.2011.605428

Vassilev SV, Vassileva CG (2016) Composition, properties and challenges of algae biomass for biofuel application: an overview. Fuel 181:1–33. https://doi.org/10.1016/j.fuel.2016.04.106

Kebelmann K, Hornung A, Karsten U, Griffiths G (2013) Intermediate pyrolysis and product identification by TGA and Py-GC/MS of green microalgae and their extracted protein and lipid components. Biomass Bioenergy 49:38–48. https://doi.org/10.1016/j.biombioe.2012.12.006

Yu J, Maliutina K, Tahmasebi A (2018) A review on the production of nitrogen-containing compounds from microalgal biomass via pyrolysis. Bioresour Technol 270:689–701. https://doi.org/10.1016/J.BIORTECH.2018.08.127

Álvarez-Díaz PD, Ruiz J, Arbib Z et al (2015) Wastewater treatment and biodiesel production by Scenedesmus obliquus in a two-stage cultivation process. Bioresour Technol 181:90–96. https://doi.org/10.1016/j.biortech.2015.01.018

Sun XM, Ren LJ, Zhao QY, Ji XJ, Huang H (2018) Microalgae for the production of lipid and carotenoids: a review with focus on stress regulation and adaptation. Biotechnol Biofuels 11:1–16. https://doi.org/10.1186/s13068-018-1275-9

Driver T, Bajhaiya AK, Allwood JW, Goodacre R, Pittman JK, Dean AP (2015) Metabolic responses of eukaryotic microalgae to environmental stress limit the ability of FT-IR spectroscopy for species identification. Algal Res 11:148–155. https://doi.org/10.1016/j.algal.2015.06.009

Thomas WH, Krauss RW (1955) Nitrogen metabolism in Scenedesmus as affected by environmental changes. Plant Physiol 30:113–122. https://doi.org/10.1104/pp.30.2.113

Voigt J, Stolarczyk A, Zych M, Malec P, Burczyk J (2014) The cell-wall glycoproteins of the green alga Scenedesmus obliquus. The predominant cell-wall polypeptide of Scenedesmus obliquus is related to the cell-wall glycoprotein gp3 of Chlamydomonas reinhardtii. Plant Sci 215–216:39–47. https://doi.org/10.1016/j.plantsci.2013.10.011

Jourabchi SA, Gan S, Ng HK (2014) Pyrolysis of Jatropha curcas pressed cake for bio-oil production in a fixed-bed system. Energy Convers Manag 78:518–526. https://doi.org/10.1016/j.enconman.2013.11.005

Klinghoffer NB, Castaldi MJ, Nzihou A (2015) Influence of char composition and inorganics on catalytic activity of char from biomass gasification. Fuel 157:37–47. https://doi.org/10.1016/j.fuel.2015.04.036

Yang C, Li R, Zhang B et al (2019) Pyrolysis of microalgae: a critical review. Fuel Process Technol 186:53–72. https://doi.org/10.1016/J.FUPROC.2018.12.012

Aboulkas A, Hammani H, El Achaby M et al (2017) Valorization of algal waste via pyrolysis in a fixed-bed reactor: production and characterization of bio-oil and bio-char. Bioresour Technol 243:400–408. https://doi.org/10.1016/j.biortech.2017.06.098

Peng X, Ma X, Lin Y (2016) Investigation on characteristics of liquefied products from solvolysis liquefaction of Chlorella pyrenoidosa in ethanol-water systems. Energy Fuels 30:6475–6485. https://doi.org/10.1021/acs.energyfuels.6b01103

Uzun BB, Apaydin-Varol E, Ateş F et al (2010) Synthetic fuel production from tea waste: characterisation of bio-oil and bio-char. Fuel 89:176–184. https://doi.org/10.1016/j.fuel.2009.08.040

Debiagi PEA, Trinchera M, Frassoldati A et al (2017) Algae characterization and multistep pyrolysis mechanism. J Anal Appl Pyrolysis 128:423–436. https://doi.org/10.1016/j.jaap.2017.08.007

Acknowledgements

The authors would like to thank Dr. Paula Assemany, Dr. Henrique Vieira de Mendonça MSc Ana Barata for microalga biomass production; Graça Gomes (LNEG) and Natércia Santos (LNEG) for microalgae culture maintenance and laboratory assistance.

Funding

The study was financially supported by the Project ALGAVALOR - MicroALGAs: produção integrada e VALORização da biomassa e das suas diversas aplicações, from the Portugal 2020 programme (grant agreement no. POCI-01-0247-FEDER-035234; LISBOA-01-0247-FEDER-035234; ALG-01-0247-FEDER-035234); GreenCoLab – Green Ocean Technologies and Products Collaborative Laboratory, no. ALG-05-3559-FSE-000010, Algarve 2020 Operational Regional Program, funded by European Social Fund and Portuguese Government budget; Biomass and Bioenergy Research Infrastructure (BBRI)-LISBOA-01-0145-FEDER-022059, supported by Operational Programme for Competitiveness and Internationalization (PORTUGAL2020), by Lisbon Portugal Regional Operational Programme (Lisboa 2020) and by North Portugal Regional Operational Programme (Norte 2020) under the Portugal 2020 Partnership Agreement, through the European Regional Development Fund (ERDF). Ana F. Ferreira and Ana Paula Dias would like to thank the financial support by the Fundação para a Ciência e a Tecnologia (FCT), through IDMEC, under LAETA, project UID/EMS/50022/2019. Alice Ferreira is pleased to acknowledge her PhD grant no. SFRH/BD/144122/2019 awarded by Fundação para a Ciência e Tecnologia.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ferreira, A.F., Ferreira, A., Dias, A.P.S. et al. Pyrolysis of Scenedesmus obliquus Biomass Following the Treatment of Different Wastewaters. Bioenerg. Res. 13, 896–906 (2020). https://doi.org/10.1007/s12155-020-10102-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-020-10102-1