Abstract

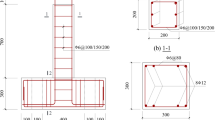

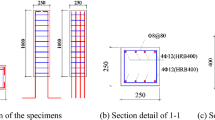

To investigate the influence of corroded steel bars on seismic performance of reinforced concrete (RC) columns, eight full-scale RC columns were designed and fabricated, which were composed of one uncorroded RC column, three RC columns with longitudinal reinforcement corrosion and four stirrup-corroded RC columns. The electrochemical test was conducted to accelerate the corrosion of steel bars in RC columns, and the low-cyclic repeated loading tests on RC columns with corrosion-damaged steel bars were carried out. The seismic behavior indicators, including the hysteretic curves, skeleton curves, displacement ductility coefficient, stiffness degradation curves and energy dissipation capacity of corroded RC columns and uncorroded columns, were compared and discussed. The experimental results show that with the increase in steel bars corrosion degree, the pinch phenomenon of the hysteretic curve gradually increases, and the energy dissipation capacity, stiffness and plastic deformation capacity of specimen reduce significantly. The ductility and energy dissipation coefficient decreased by 20% and 36%, respectively, when the stirrups corrosion ratio of specimen reaches 15.2%, and a shear failure surface was formed in the plastic hinge zone at the foot of the columns, which leads to the change of failure mode from ductile bending failure to shear failure with poor ductility under the ultimate load for corroded columns. The influence of stirrup corrosion on the failure mode of specimens is remarkable, but the effect of longitudinal reinforcement corrosion is negligible for specimens with the corrosion ratio within 14.7%. The adverse effects caused by over 15.2% stirrup corrosion should be considered in seismic design of structures in seismic zone.

Similar content being viewed by others

References

Cairns J, Plizzari GA, Du Y, et al. Mechanical properties of corrosion-damaged reinforcement. ACI Mater J. 2005;102(4):256–64.

Lowinska-Kluge A, Blaszczynski T. The influence of internal corrosion on the durability of concrete. Arch Civ Mech Eng. 2012;12:219–27.

Kong JS, Frangopol DM. Life-cycle reliability-based maintenance cost optimization of deteriorating structures with emphasis on bridges. J Struct Eng. 2003;129(6):818–28.

German M, Pamin J. FEM simulations of cracking in RC beams due to corrosion progress. Arch Civ Mech Eng. 2015;15:1160–72.

Yao L, Shi-ping Y, Wen-jie C. Seismic behavior of corrosion-damaged RC columns strengthened with TRC under a chloride environment. Constr Build Mater. 2019;201:736–45.

Yin S, Yang Y, Ye T, et al. Experimental research on seismic behavior of reinforced concrete columns strengthened with TRC under corrosion environment. J Struct Eng. 2016;143(5):04016231.

Cheng H, Li HN, Wang DS. Prediction for lateral deformation capacity of corroded reinforced concrete columns. Struct Des Tall Special Build. 2019;28(1):e1560.

Song HW, Shim HB, Petcherdchoo A, et al. Service life prediction of repaired concrete structures under chloride environment using finite difference method. Cem Concr Compos. 2009;31(2):120–7.

Yu Z, Chen Y, Liu P, et al. Accelerated simulation of chloride ingress into concrete under drying–wetting alternation condition chloride environment. Constr Build Mater. 2015;93:205–13.

Xu YL. Application of design principle of concrete structure and revised norms. Beijing: Tsinghua University Press; 2012.

Cabrera JG. Deterioration of concrete due to reinforcement steel corrosion. Cem Concr Compos. 1996;18(1):47–59.

Capozucca R. Damage to reinforced concrete due to reinforcement corrosion. Constr Build Mater. 1995;9(5):295–303.

Mehta PK. Durability of concrete–fifty years of progress. Spec Publ. 1991;126:1–32.

Apostolopoulos CA. Mechanical behavior of corroded reinforcing steel bars S500s tempcore under low cycle fatigue. Constr Build Mater. 2007;21(7):1447–56.

Kashani MM, Crewe AJ, Alexander NA. Nonlinear stress–strain behavior of corrosion-damaged reinforcing bars including inelastic buckling. Eng Struct. 2013;48:417–29.

Kashani MM, Crewe AJ, Alexander NA, et al. Nonlinear behavior of corroded RC columns under cyclic loading. In: 7th Int Conf Seismol Earthq Eng; 2015. p. 245–246.

Ou YC, Susanto YTT, Roh H. Tensile behavior of naturally and artificially corroded steel bars. Constr Build Mater. 2016;103:93–104.

Ma Y, Che Y, Gong J. Behavior of corrosion damaged circular reinforced concrete columns under cyclic loading. Constr Build Mater. 2012;29:548–56.

Aquino W, Hawkins NM. Seismic retrofitting of corroded reinforced concrete columns using carbon composites. ACI Struct J. 2007;104(3):348–56.

Revathy J, Suguna K, Raghunath PN. Effect of corrosion damage on the ductility performance of concrete columns. Am J Eng Appl Sci. 2009;2(2):324–7.

El Maaddawy TA, Soudki KA. Effectiveness of impressed current technique to simulate corrosion of steel reinforcement in concrete. J Mater Civ Eng. 2003;15(1):41–7.

Okada K, KobayashiI K, Miyagawa T. Influence of longitudinal cracking due to reinforcement corrosion on characteristics of reinforced concrete members. Struct J. 1988;85(2):134–40.

Yang SY, Song XB, Jia HX, et al. Experimental research on hysteretic behaviors of corroded reinforced concrete columns with different maximum amounts of corrosion of rebar. Constr Build Mater. 2016;121:319–27.

Meda A, Mostosi S, Rinaldi Z, et al. Experimental evaluation of the corrosion influence on the cyclic behavior of RC columns. Eng Struct. 2014;76:112–23.

Berto L, Vitaliani R, Saetta A, et al. Seismic assessment of existing RC structures affected by degradation phenomena. Struct Saf. 2009;31(4):284–97.

Li Q, Niu DT, Xiao QH, Guan X, et al. Experimental study on seismic behaviors of concrete columns confined by corroded stirrups and lateral strength prediction. Constr Build Mater. 2018;162:704–13.

Rajput AS, Sharma UK. Corroded reinforced concrete columns under simulated seismic loading. Eng Struct. 2018;171:453–63.

Di Carlo F, Meda A, Rinaldi Z. Numerical cyclic behavior of un-corroded and corroded RC columns reinforced with HPFRC jacket. Compos Struct. 2017;163:432–43.

Kashani MM, Lowes LN, Crewe AJ, Alexander NA. Nonlinear fiber element modelling of RC bridge piers considering inelastic buckling of reinforcement. Eng Struct. 2016;116:163–77.

Kashani MM, Maddocks J, Afsar Dizaj E. Residual capacity of corroded reinforced concrete bridge components: a state-of-the-art review. J Bridge Eng. 2019;24(7):03119001.

Afsar Dizaj E, Madandoust R, Kashani MM. Exploring the impact of chloride-induced corrosion on seismic damage limit states and residual capacity of reinforced concrete structures. Struct Infrastruct Eng. 2018;14(6):714–29.

Afsar Dizaj E, Madandoust R, Kashani MM. Probabilistic seismic vulnerability analysis of corroded reinforced concrete frames including spatial variability of pitting corrosion. Soil Dyn Earthq Eng. 2018;114:97–112.

Bournas DA, Triantafillou TC, Zygouris K, et al. Textile-reinforced mortar versus FRP jacketing in seismic retrofitting of RC columns with continuous or lap-spliced deformed bars. J Compos Constr. 2009;13(5):360–71.

Bournas DA, Triantafillou TC, Zygouris K, et al. Bar buckling in RC columns confined with composite materials. J Compos Constr. 2011;15(3):393–403.

Gadve S, Mukherjee A, Malhotra SN. Corrosion of steel reinforcements embedded in FRP wrapped concrete. Constr Build Mater. 2009;23(1):153–61.

Suh K, Mullins G, Sen R, et al. Effectiveness of fiber-reinforced polymer in reducing corrosion in marine environment. ACI Struct J. 2007;104(1):76–83.

Industry Standard of the People’s Republic of China. GB 50011-2010 code for seismic design of buildings. Beijing: China Architecture & Building Press; 2016.

Industry Standard of the People’s Republic of China. GB/T 228.1-2010 Metallic materials-Tensile testing—Part 1: Method of test at room temperature. Beijing: Standards Press of China; 2010.

Campione G, Cannella F. Engineering failure analysis of corroded RC beams in flexure and shear. Eng Fail Anal. 2018;86:100–14.

Pantazopoulou SJ, Bonacci JF, Sheikh S, et al. Repair of corrosion-damaged columns with FRP wraps. J Compos Constr. 2001;5(1):3–11.

Industry Standard of the People’s Republic of China. JGJ/T101-2015 Specification for seismic test of building. Beijing: China Architecture & Building Press; 2015.

Wu YF, Zhou YW, He XQ. Performance-based optimal design of compression-yielding FRP-reinforced concrete beams. Compos Struct. 2010;93(1):113–23.

Acknowledgements

The authors gratefully acknowledge the financial supports provided by the Natural Science Foundation of China (U1361204 and 11972379), the National key Research Program of China (Grant No. 2016YFC0701700), and Hunan Provincial Innovation Foundation for Postgraduate (CX20190127, 2019zzts071).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations

Rights and permissions

About this article

Cite this article

Luo, X., Cheng, J., Xiang, P. et al. Seismic behavior of corroded reinforced concrete column joints under low-cyclic repeated loading. Archiv.Civ.Mech.Eng 20, 40 (2020). https://doi.org/10.1007/s43452-020-00043-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-020-00043-z