Abstract

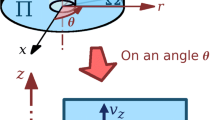

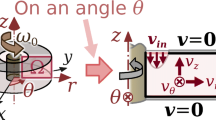

The performance of fluid devices, such as channels, valves, nozzles, and pumps, may be improved by designing them through the topology optimization method. There are various fluid flow problems that can be elaborated in order to design fluid devices and among them there is a specific type which comprises axisymmetric flow with a rotation (swirl flow) around an axis. This specific type of problem allows the simplification of the computationally more expensive 3D fluid flow model to a computationally less expensive 2D swirl flow model. The topology optimization method applied to a Newtonian fluid in 2D swirl flow has already been analyzed before, however not all fluids feature Newtonian (linear) properties, and can exhibit non-Newtonian (nonlinear) effects, such as shear-thinning, which means that the fluid should feature a higher viscosity when under lower shear stresses. Some fluids that exhibit such behavior are, for example, blood, activated sludge, and ketchup. In this work, the effect of a non-Newtonian fluid flow is considered for the design of 2D swirl flow devices by using the topology optimization method. The non-Newtonian fluid is modeled by the Carreau-Yasuda model, which is known to be able to accurately predict velocity distributions for blood flow. The design comprises the minimization of the relative energy dissipation considering the viscous, porous, and inertial effects, and is solved by using the finite element method. The traditional pseudo-density material model for topology optimization is adopted with a nodal design variable. A penalization scheme is introduced for 2D swirl flow in order to enforce the low shear stress behavior of the non-Newtonian viscosity inside the modeled solid material. The optimization is performed with IPOPT (Interior Point Optimization algorithm). Numerical examples are presented for some 2D swirl flow problems, comparing the non-Newtonian with the Newtonian fluid designs.

Similar content being viewed by others

References

Abraham F, Behr M, Heinkenschloss M (2005) Shape optimization in steady blood flow: a numerical study of non-newtonian effects. Comput Methods Biomech Biomed Eng 8(2):127–137

Alonso DH, de Sá LFN, Saenz JSR, Silva ECN (2018) Topology optimization applied to the design of 2d swirl flow devices. Struct Multidiscip Optim 58(6):2341–2364. https://doi.org/10.1007/s00158-018-2078-0

Alonso DH, de Sá LFN, Saenz JSR, Silva ECN (2019) Topology optimization based on a two-dimensional swirl flow model of tesla-type pump devices. Comput Math Appl 77(9):2499–2533. https://doi.org/10.1016/j.camwa.2018.12.035, http://www.sciencedirect.com/science/article/pii/S0898122118307338

Amestoy PR, Duff IS, Koster J, L’Excellent JY (2001) A fully asynchronous multifrontal solver using distributed dynamic scheduling. SIAM J Matrix Anal Appl 23(1):15–41

Anand M, Rajagopal KR (2017) A short review of advances in the modelling of blood rheology and clot formation. Fluids 2(3)

Andreasen CS, Gersborg AR, Sigmund O (2009) Topology optimization of microfluidic mixers. Int J Numer Methods Fluids 61:498–513. https://doi.org/10.1002/fld.1964

Arora D, Behr M, Pasquali M (2004) A tensor-based measure for estimating blood damage. Artif Organs 28(11):1002–1015

Barnes HA (1997) Thixotropy—a review. J Non-Newt Fluid Mech 70(1):1–33. https://doi.org/10.1016/S0377-0257(97)00004-9, http://www.sciencedirect.com/science/article/pii/S0377025797000049

Barth L, Carey GF (2007) On a boundary condition for pressure-driven laminar flow of incompressible fluids. Int J Numer Methods Fluids 54(11):1313–1325. https://doi.org/10.1002/fld.1427

Bayod E, Willers EP, Tornberg E (2008) Rheological and structural characterization of tomato paste and its influence on the quality of ketchup. LWT-Food Sci Technol 41(7):1289–1300

Behbahani M, Behr M, Hormes M, Steinseifer U, Arora D, Coronado O, Pasquali M (2009) A review of computational fluid dynamics analysis of blood pumps. Eur J Appl Math 20(4):363–397

Bird RB, Armstrong RC, Hassager O (1987) Dynamics of polymeric liquids, Volume 1: Fluid mechanics, 1st edn. Wiley, New York

Borrvall T, Petersson J (2003) Topology optimization of fluids in stokes flow. Int J Numer Methods Fluids 41(1):77–107. https://doi.org/10.1002/fld.426

Brandenburg C, Lindemann F, Ulbrich M, Ulbrich S (2009) A continuous adjoint approach to shape optimization for navier stokes flow. In: Kunisch K, Sprekels J, Leugering G, Tröltzsch F (eds) Optimal control of coupled systems of partial differential equations. Basel, Birkhäuser Basel, pp 35–56

Brezzi F, Fortin M (1991) Mixed and hybrid finite element methods. Springer, Berlin

Cho YI, Kenssey KR (1991) Effects of the non-newtonian viscosity of blood on flows in a diseased arterial vessel. Part 1: Steady flows. Biorheology 28:241–262

Deng Y, Liu Z, Wu Y (2013) Topology optimization of steady and unsteady incompressible navier—stokes flows driven by body forces. Struct Multidiscip Optim 47(4):555–570. https://doi.org/10.1007/s00158-012-0847-8

Deng Y, Wu Y, Liu Z (2018) Topology optimization theory for laminar flow. Springer, Singapore

Dilgen CB, Dilgen SB, Fuhrman DR, Sigmund O, Lazarov BS (2018) Topology optimization of turbulent flows. Comput Methods Appl Mech Eng 331:363–393. https://doi.org/10.1016/j.cma.2017.11.029

Duan X, Li F, Qin X (2016) Topology optimization of incompressible navier–stokes problem by level set based adaptive mesh method. Comput Math Appl 72(4):1131–1141. https://doi.org/10.1016/j.camwa.2016.06.034, http://www.sciencedirect.com/science/article/pii/S0898122116303662

Duan XB, Li FF, Qin XQ (2015) Adaptive mesh method for topology optimization of fluid flow. Appl Math Lett 44:40–44

Evgrafov A (2004) Topology optimization of navier-stokes equations. In: Nordic MPS 2004. The ninth meeting of the nordic section of the mathematical programming society. Linköping University Electronic Press, vol 014, pp 37–55

Evgrafov A (2006) Topology optimization of slightly compressible fluids. ZAMM-J Appl Math Mech/Z Angew Math Mech 86(1):46–62

Evgrafov A (2015) On chebyshev’s method for topology optimization of stokes flows. Struct Multidiscip Optim 51(4):801–811

Farrell PE, Ham DA, Funke SW, Rognes ME (2013) Automated derivation of the adjoint of high-level transient finite element programs. SIAM J Sci Comput 35(4):C369–C393

Ferraris CF, deLarrard F (1998) Testing and modeling of fresh concrete rheology. Technical report, NIST

Galvin KJ (2013) Advancements in finite element methods for newtonian and non-newtonian flows. PhD thesis, Clemson University

Garakani AHK, Mostoufi N, Sadeghi F, Hosseinzadeh M, Fatourechi H, Sarrafzadeh MH, Mehrnia MR (2011) Comparison between different models for rheological characterization of activated sludge. Iran J Environ Health Sci Eng 8(3):255

Gijsen FJH, van de Vosse FN, Janssen JD (1999) The influence of the non-newtonian properties of blood on the flow in large arteries: steady flow in a carotid bifurcation model. J Biomech 32(6): 601–608. https://doi.org/10.1016/S0021-9290(99)00015-9, http://www.sciencedirect.com/science/article/pii/S0021929099000159

Girault V, Raviart p (2012) Finite element methods for Navier-Stokes equations: theory and algorithms. Springer Series in Computational Mathematics. Springer, Berlin

Guest JK, Prévost JH (2006) Topology optimization of creeping fluid flows using a darcy–stokes finite element. Int J Numer Methods Eng 66(3):461–484. https://doi.org/10.1002/nme.1560

Gupta DK, van Keulen F, Langelaar M (2020) Design and analysis adaptivity in multiresolution topology optimization. Int J Numer Methods Eng 121(3):450–476

Gurtin ME (1981) An introduction to continuum mechanics, 1st edn. Academic Press, New York

Guzmán J, Salgado AJ, Sayas FJ (2013) A note on the ladyženskaja-babuška-brezzi condition. J Sci Comput 56(2):219–229. https://doi.org/10.1007/s10915-012-9670-z

Hinghofer-Szalkay H, Greenleaf J (1987) Continuous monitoring of blood volume changes in humans. J Appl Physiol 63(3):1003–1007

Hyun J, Wang S, Yang S (2014) Topology optimization of the shear thinning non-newtonian fluidic systems for minimizing wall shear stress. Comput Math Appl 67(5):1154–1170. https://doi.org/10.1016/j.camwa.2013.12.013, http://www.sciencedirect.com/science/article/pii/S0898122113007074

Jensen KE (2013) Structural optimization of non-newtonian microfluidics. PhD thesis, Technical University of Denmark, phD thesis

Jensen KE, Szabo P, Okkels F (2012) Topology optimization of viscoelastic rectifiers. Appl Phys Lett 100(23):234102

Jiang L, Chen S, Sadasivan C, Jiao X (2017) Structural topology optimization for generative design of personalized aneurysm implants: design, additive manufacturing, and experimental validation. In: 2017 IEEE Healthcare innovations and point of care technologies (HI-POCT). IEEE, pp 9–13

Kian JdM (2017) Topology optimization method applied to design channels considering non-newtonian fluid flow. Master’s thesis, Universidade de São Paulo, http://www.teses.usp.br/teses/disponiveis/3/3152/tde-16032017-103709/en.php

Lai W M, Rubin D, Krempl E (2009) Introduction to continuum mechanics. Butterworth-Heinemann, Oxford

Langtangen HP, Logg A (2016) Solving PDEs in minutes – the FEniCS Tutorial Volume I. https://fenicsproject.org/book/

Leondes C (2000) Biomechanical systems: techniques and applications, Volume II: Cardiovascular Techniques, 1st edn. Biomechanical Systems, Techniques and Applications. CRC Press

Logg A, Mardal KA, Wells G (2012) Automated solution of differential equations by the finite element method: The FEniCS book, vol 84. Springer Science & Business Media, https://fenicsproject.org/book/

McArdle CR, Pritchard D, Wilson SK (2012) The stokes boundary layer for a thixotropic or antithixotropic fluid. J Non-Newt Fluid Mech 185-186:18–38. https://doi.org/10.1016/j.jnnfm.2012.08.001, http://www.sciencedirect.com/science/article/pii/S0377025712001358

Munson BR, Young DF, Okiishi TH (2009) Fundamentals of fluid mechanics, 6th edn. Wiley, New York

Nørgaard S, Sigmund O, Lazarov B (2016) Topology optimization of unsteady flow problems using the lattice boltzmann method. J Comput Phys 307(C):291–307. https://doi.org/10.1016/j.jcp.2015.12.023

Olesen LH, Okkels F, Bruus H (2006) A high-level programming-language implementation of topology optimization applied to steady-state navier–stokes flow. Int J Numer Methods Eng 65(7):975–1001

Pingen G, Maute K (2010) Optimal design for non-newtonian flows using a topology optimization approach. Comput Math Appl 59(7):2340–2350

Pratumwal Y, Limtrakarn W, Muengtaweepongsa S, Phakdeesan P, Duangburong S, Eiamaram P, Intharakham K (2017) Whole blood viscosity modeling using power law, casson, and carreau yasuda models integrated with image scanning u-tube viscometer technique. Songklanakarin J Sci Technol 39(5)

Quarteroni A, Tuveri M, Veneziani A (2000) Computational vascular fluid dynamics: problems, models and methods. Comput Vis Sci 2(4):163–197

Ramalingom D, Cocquet PH, Bastide A (2018) A new interpolation technique to deal with fluid-porous media interfaces for topology optimization of heat transfer. Comput Fluids 168 :144–158. https://doi.org/10.1016/j.compfluid.2018.04.005, http://www.sciencedirect.com/science/article/pii/S0045793018301932

Reddy JN, Gartling DK (2010) The finite element method in heat transfer and fluid dynamics, 3rd edn. CRC Press, Boca Raton

Romero J, Silva E (2014) A topology optimization approach applied to laminar flow machine rotor design. Comput Methods Appl Mech Eng 279(Supplement C):268–300. https://doi.org/10.1016/j.cma.2014.06.029, http://www.sciencedirect.com/science/article/pii/S0045782514002151

Romero JS, Silva ECN (2017) Non-newtonian laminar flow machine rotor design by using topology optimization. Struct Multidiscip Optim 55(5):1711–1732

Sá LFN, Amigo RCR, Novotny AA, Silva ECN (2016) Topological derivatives applied to fluid flow channel design optimization problems. Struct Multidiscip Optim 54(2):249–264. https://doi.org/10.1007/s00158-016-1399-0

Sato Y, Yaji K, Izui K, Yamada T, Nishiwaki S (2018) An optimum design method for a thermal-fluid device incorporating multiobjective topology optimization with an adaptive weighting scheme. J Mech Des 140(3):031402

Slaughter MS, Pagani FD, Rogers JG, Miller LW, Sun B, Russell SD, Starling RC, Chen L, Boyle AJ, Chillcott S, Adamson RM, Blood MS, Camacho MT, Idrissi KA, Petty M, Sobieski M, Wright S, Myers TJ, Farrar DJ (2010) Clinical management of continuous-flow left ventricular assist devices in advanced heart failure. J Heart Lung Transplant 29(4, Supplement):S1 – S39. https://doi.org/10.1016/j.healun.2010.01.011, http://www.sciencedirect.com/science/article/pii/S1053249810000434, clinical Management of Continuous-flow Left Ventricular Assist Devices in Advanced Heart Failure

Sokolowski J, Zochowski A (1999) On the topological derivative in shape optimization. SIAM J Control Optim 37(4):1251– 1272

Song XG, Wang L, Baek SH, Park YC (2009) Multidisciplinary optimization of a butterfly valve. ISA Trans 48(3):370–377

Tesch K (2013) On invariants of fluid mechanics tensors. Task Quart 17(3-4):228–230

Vafai K (2005) Handbook of porous media, 2nd edn. CRC Press, Boca raton

Varchanis S, Syrakos A, Dimakopoulos Y, Tsamopoulos J (2019) A new finite element formulation for viscoelastic flows: circumventing simultaneously the lbb condition and the high-weissenberg number problem. J Non-Newt Fluid Mech 267:78–97

Vlachopoulos C, O’Rourke M, Nichols WW (2011) Mcdonald’s blood flow in arteries: theoretical experimental and clinical principles, 6th edn. Hodder Arnold, London

Wächter A, Biegler LT (2006) On the implementation of an interior-point filter line-search algorithm for large-scale nonlinear programming. Math Programm 106(1):25–57

White FM (2011) Fluid mechanics, 7th edn., McGraw-Hill, New York

Wiker N, Klarbring A, Borrvall T (2007) Topology optimization of regions of darcy and stokes flow. Int J Numer Methods Eng 69(7):1374–1404

Yoon GH (2016) Topology optimization for turbulent flow with spalart–allmaras model. Comput Methods Appl Mech Eng 303:288–311. https://doi.org/10.1016/j.cma.2016.01.014, http://www.sciencedirect.com/science/article/pii/S004578251630007X

Zhang B, Liu X (2015) Topology optimization study of arterial bypass configurations using the level set method. Struct Multidiscip Optim 51(3):773–798. https://doi.org/10.1007/s00158-014-1175-y

Zhang B, Liu X, Sun J (2016) Topology optimization design of non-newtonian roller-type viscous micropumps. Struct Multidiscip Optim 53(3):409–424

Zhou S, Li Q (2008) A variationals level set method for the topology optimization of steady-state navier–stokes flow. J Comput Phys 227(24):10178–10195

Funding

This research was partly supported by CNPq (Brazilian Research Council), FAPERJ (Research Foundation of the State of Rio de Janeiro), and FAPESP (São Paulo Research Foundation). The authors thank the supporting institutions. The first author thanks the financial support of FAPESP under grant 2017/27049-0. The third author thanks the financial support of CNPq (National Council for Research and Development) under grant 302658/2018-1 and of FAPESP under grant 2013/24434-0. The authors also acknowledge the support of the RCGI (Research Centre for Gas Innovation), hosted by the University of São Paulo (USP) and sponsored by FAPESP (2014/50279-4) and Shell Brazil.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Replication of results

The implementation in the FEniCS platform is direct from the description provided of the equations and numerical implementation in the article, because FEniCS uses a high-level description for the variational formulation (UFL) and automates the generation of the matrix equations. In the case of 2D swirl flow, the coordinates are cylindrical, which means that the differential operators (“grad”, “curl”, “div”) must be programmed by hand by using the “Dx(var,component_num)” or “var.dx(component_num)” functions, because the operators provided by FEniCS assume Cartesian coordinates. The pseudocode of the implementation is represented in Algorithm 1, where the main FEniCS/dolfin-adjoint functions being used are given between parentheses. When using dolfin-adjoint, the dolfin-adjoint library provides an interface to IPOPT. In the case of using a continuous adjoint model (such as the one presented in Appendix 1), the interface to IPOPT needs to be manually programmed.

Additional information

Responsible Editor: Vassili Toropov

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1. Continuous adjoint model for the non-Newtonian 2D swirl flow

The continuous adjoint model for the 2D swirl flow problem is derived as follows. The adjoint (dual) equations for Navier-Stokes flow have already been deduced in Brandenburg et al. (2009). However, in this Appendix, they are particularized for the 2D swirl flow model in a rotating reference frame, and an approach for dealing with the non-Newtonian viscosity is suggested. In the following development, 2D coordinates are considered in the equations, the domain is given in cylindrical coordinates (in which the differential volume and area are given by, respectively, 2πrdΩ and 2πrdΓ), axisymmetry is considered (\(\frac {\partial (\ )}{\partial \theta } = 0\)), and the differential operators correspond to their cylindrical coordinate system versions (Lai et al. 2009).

The adjoint equation is first presented in Section 4.5 and is based on the Lagrangian function of the optimization problem, which is given by

where (v, p) are the state (primal) variables (velocity and pressure), α is the design variable, (λv, λp) are the adjoint (dual) variables (adjoint velocity and adjoint pressure) (that is, the adjoint variable presented in Section 4.5 separated in its components: λJ = (λv, λp)), J((v, p), α) = Φrel((v, p), α) is the objective function (relative energy dissipation), and F((v, p), α, (λv, λp)) is given in (12) (i.e., (10) and (11) without the division by 2π, and with the test functions wv and wp replaced by the adjoint variables λv and λp, respectively).

Then, in order to obtain the weak form of the adjoint equation (Fλ = 0), the equations that compose (21) need to be derived in function of the state variables (v, p), as shown in Section 4.5. This is given by the directional derivative of the Lagrangian function (21), with respect to the state variables (v and p) and in the directions given by \(\textit {\textbf {w}}_{\lambda ,v} =\left [\begin {array}{ll}{\textit {w}}_{\lambda ,v,r}\\{\textit {w}}_{\lambda ,v,\theta }\\ {\textit {w}}_{\lambda ,v,z} \end {array}\right ]\) and wλ, p (test functions for the adjoint equations), respectively for each state variable:

where \(L(\textit {\textbf {v}}; \underline {{\textit {\textbf {w}}}_{\lambda ,v}})\) is the directional derivative of L with respect to v in the direction of wλ, v, and \(L(p; \underline {\textit {w}_{\lambda ,p}})\) is the directional derivative of L with respect to p in the direction of wλ, p.

The dependency of the non-Newtonian viscosity (μ) with respect to the state variables (v, p) can be separated by applying the chain rule. In this case,

where \(\mu ((\textit {\textbf {v}}, p); \underline {(\textit {\textbf {w}}_{\lambda ,v}, {\textit {w}}_{\lambda ,p})})\) is the directional derivative of μ with respect to (v, p) in the direction of (wλ, v, wλ, p). In the case of the non-Newtonian viscosity given by (7), which does not depend on p, \(\mu ((\textit {\textbf {v}}, p); \underline {(\textit {\textbf {w}}_{\lambda ,v}, \textit {w}_{\lambda ,p})}) = \mu (\textit {\textbf {v}}; \underline {\textit {\textbf {w}}_{\lambda ,v}})\). Note that, if \(\mu = \mu _{\infty }\) (Newtonian viscosity), \(\mu ((\textit {\textbf {v}}, p); \underline {(\textit {\textbf {w}}_{\lambda ,v}, \textit {w}_{\lambda ,p})}) = 0\).

The first term of the weak form of the adjoint equation (23) (\(L((\textit {\textbf {v}}, p); \underline {(\textit {\textbf {w}}_{\lambda ,v}, {\textit {w}}_{\lambda ,p}}))\)) becomes, after dividing the forward equations by 2π:

where T(wλ, v, wλ, p) is the stress tensor (3) calculated by substituting v and p by wλ, v and wλ, p, respectively; and the symbols “(+)” and “(–)” serve to indicate the signal that is already considered in the equation and that is multiplying each adjoint form.

The second term of the weak form of the adjoint equation (23) (\(\frac {\partial L(\mu )}{\partial \mu } \mu (\textit {\textbf {v}}; \underline {\textit {\textbf {w}}_{\lambda ,v}})\)) can be calculated from (11) as, after dividing the forward equations by 2π:

where \(\frac {\partial \textit {\textbf {T}}(\textit {\textbf {v}}, p)}{\partial \mu } = \nabla \textit {\textbf {v}} + \nabla \textit {\textbf {v}}^{T}\). Since it may be difficult and laborious to calculate \(\mu (\textit {\textbf {v}}; \underline {\textit {\textbf {w}}_{\lambda ,v}})\) (sensitivity of the non-Newtonian viscosity) from (7) or (14 (or any other non-Newtonian fluid with a more complex constitutive equation), this term may be calculated by automatic differentiation, such as the algorithm used in the FEniCS platform.

From (23), it would be possible to derive the strong form of the adjoint equation (by applying Gauss’s Theorem of Divergence). However, it would require the sensitivity of the non-Newtonian viscosity to be analytically evaluated. Since the finite element method only requires the weak form of the adjoint equation, this step does not need to be performed.

The Dirichlet boundary conditions from (9) assume constant velocity values, which means that their corresponding adjoint boundary conditions are homogeneous (i.e., equal to zero). By also including the Neumann boundary condition, the adjoint boundary conditions become, from (9):

where λv, r is the radial component of the adjoint velocity (λv = (λv, r, λv, 𝜃, λv, z)). It can also be mentioned that, in (25), the term which relies on \(\left (\frac {\partial \textit {\textbf {T}}(\textit {\textbf {v}}, p)}{\partial \mu }{\bullet }\boldsymbol {\lambda }_{v}\right ){\bullet }\textit {\textbf {n}}\) is zero on Γout, because T(v, p)∙n = 0 on Γout (9) (\(\left (\frac {\partial \textit {\textbf {T}}(\textit {\textbf {v}}, p)}{\partial \mu }{\bullet }\boldsymbol {\lambda }_{v}\right ){\bullet }\textit {\textbf {n}}\)\(= \left (\frac {\partial \textit {\textbf {T}}(\textit {\textbf {v}}, p)}{\partial \mu }{\bullet }\textit {\textbf {n}}\right ){\bullet }\boldsymbol {\lambda }_{v} = \left (\frac {\partial [\textit {\textbf {T}}(\textit {\textbf {v}}, p){\bullet }\textit {\textbf {n}}]}{\partial \mu }\right ){\bullet }\boldsymbol {\lambda }_{v} = \textbf {{0}}\), since T is symmetric and n does not depend on μ).

Appendix 2. Simulation of the effect of the non-Newtonian penalization

In order to check the effect of the non-Newtonian penalization, a test example of a channel with an obstacle in the middle is simulated (see Fig. 31). The obstacle is modeled by using a rotating material model (ωmat = ω0) located in the middle of the channel, the flow rate is 0.5 L/min, the rotation is 20 rpm, and the dimensions are given by: H = 15.0 mm, R = 10.0 mm, ro = 2.5 mm, and ho = 2.5 mm. The mesh is the same as the one shown in Fig. 25. The outlet boundary condition is a weak imposition of zero pressure on the outlet, imposing the radial and axial components of the velocity (vr, vz) to be perpendicular to the outlet section (i.e., with zero tangential component) (Dirichlet boundary condition), and imposing zero normal stress on the interface (n∙Tn = 0) (Neumann boundary condition). The demonstration of this boundary condition is shown in Alonso et al. (2018) for 2D swirl flow, and in Barth and Carey (2007) for 2D flow.

When the material model is blocking the fluid flow (i.e., with a sufficiently high value in \(\kappa _{\max \limits }\), chosen in this case as \(\kappa _{\max \limits } = 2.5 \times 10^{8} \mu _{\infty }\)), there is little difference between using only the inverse permeability (“κ(α)”), or using both inverse permeability and non-Newtonian penalization (“κ(α), μ(α)”). This is shown in Fig. 32a. Figure 32b shows the difference fractions for the modeled obstacles, which correspond to the absolute difference of the variable in the cut and modeled obstacles divided by the range of the variable: \(f_{x} = \frac {|x_{\text {material}} - x_{\text {cut}}|}{\max \limits (x_{\text {cut}}) - \min \limits (x_{\text {cut}})}\), where x is the variable being considered: relative tangential velocity (v𝜃), pressure (p) or non-Newtonian viscosity (μ). For the magnitude of the radial-axial velocity (\(v_{rz,\text {mag}} = \|\textit {\textbf {v}}_{rz}\| = \|(v_{r}, v_{z})\| = \sqrt {{v_{r}^{2}} + {v_{z}^{2}}}\)), the definition is changed to \(f_{{v}_{rz,\text {mag}}} = \frac {\|\textit {\textbf {v}}_{rz,\text {material}} - \textit {\textbf {v}}_{rz,\text {cut}}\|}{\max \limits (\|\textit {\textbf {v}}_{rz,\text {cut}}\|) - \min \limits (\|\textit {\textbf {v}}_{rz,\text {cut}}\|)}\). From Fig. 32b: \(f_{{v}_{rz,\text {mag}}}\) is mostly small, but features a 0.33 peak near the edge for “κ(α), μ(α)”; \(f_{{v}_{\theta }}\) is even smaller, with a maximum value of 0.091; fp is higher near the edge of the obstacle, reaching a relatively high peak of 0.5 in “κ(α), μ(α)”; and fμ is higher around the obstacle for “κ(α), μ(α)”. As can be noticed, the highest values of the difference fractions are concentrated near the obstacle / edge of the obstacle. These differences, and, more specifically, the higher values of fμ on the obstacle, are mainly due to the nodal interpolation used for the design variable (α), which does not exactly match the effect of the “cut obstacle,” such that it “slightly softens” the effect of the edge because of the linear interpolation, and “forces,” when considering the non-Newtonian penalization (“κ(α), μ(α)”), the nodal values of the non-Newtonian viscosity (μ) to the maximum dynamic viscosity value (μ0).

The difference between simulation results is more apparent for lower values of \(\kappa _{\max \limits }\), which may occur during topology optimization due to the interpolation of the material model (“gray values”). Therefore, \(\kappa _{\max \limits }\) is reduced to \(\kappa _{\max \limits } = 2.5 \times 10^{6} \mu _{\infty }\) in Fig. 33. From Fig. 33, when including the non-Newtonian penalization (“κ(α), μ(α)”), the radial-axial velocity ((vr, vz)) is more reduced inside the modeled obstacle than in the case without the non-Newtonian penalization (“κ(α)”). This is due to the higher and uniform non-Newtonian viscosity inside the modeled obstacle. The relative tangential velocity (v𝜃) does not show significant differences between both modeled obstacles.

Therefore, by imposing a uniform non-Newtonian viscosity inside the solid material of the obstacle, the non-Newtonian penalization seems to show a more noticeable effect in the radial-axial velocity ((vr, vz)) during topology optimization rather than in its end.

Rights and permissions

About this article

Cite this article

Alonso, D.H., Saenz, J.S.R. & Silva, E.C.N. Non-newtonian laminar 2D swirl flow design by the topology optimization method. Struct Multidisc Optim 62, 299–321 (2020). https://doi.org/10.1007/s00158-020-02499-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-020-02499-2