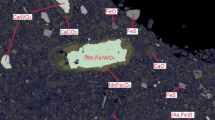

Hardmetals intended to perform in harsh operating conditions are developed with the use of metallic powders, in particular, tungsten powders. The growing consumption of tungsten in industry necessitates the improvement of techniques employed to produce it from industrial waste. The objective of this research effort was to reduce metallic tungsten (as a powder) from chloride and chloride–fluoride melts and determine the factors influencing its particle size. The starting material was tungsten oxide (WO3) produced electrochemically from processed raw material (VK-6 tungsten carbide pseudoalloy). The melts were KCl–NaCl–CsBr and NaCl–KCl–CsBr–Na3WO3F3 eutectic mixtures. When the melt with a high WO2F42− content was subjected to electrolysis, tungsten precipitated as a superfine powder. The precipitate morphology showed that the tungsten particle size was dependent on electrolysis conditions. A relatively inexpensive and effective method of producing tungsten powders was developed upon the research.

Similar content being viewed by others

References

S.S. Korovin, D.V. Drobot, and P.I. Fedorov, Rare and Trace Elements. Chemistry and Technology [in Russian], Mosk. Inst. Stali Splav., Moscow (1999), p. 461.

B.I. Bairachny and L.V. Liashok, Rare Trace and Noble Elements. Production and Application Technology: Course Book [in Russian], NTU Kharkiv Politekh. Inst., Kharkiv (2007), p. 288.

V.R. Ivashkiv, I.T. Yavorskii, and O.I. Kuntii, “Electrochemical behavior of WC–Co pseudoalloy in aqueous solutions of mineral acids and alkalis,” Fiz. Khim. Mekh. Mater., 476, 480 (2008).

M.I. Dvornik and A.D. Verkhoturov, “Spark erosion processing of hard tungsten-cobalt alloy in water and subsequent carbonization,” Powder Metall. Met. Ceram., 47, No. 7–8, 486–492 (2008).

V.V. Gostishchev, “Physicochemical aspects of metallothermic processing of scheelite concentrate in ionic melts,” Izv. Vuz. Tsvet. Metall., No. 3, 22–26 (2015).

Leo V.M. Antony and Ramana G. Reddy, “Processes for production of high-purity metal powders,” J. Miner. Met. Mater. Soc., 55, No. 3, 14 (2003).

C.W. Won, H.H. Nersisyan, H.I. Won, and J.H. Lee, “Refractory metal nanopowders: synthesis and characterization,” Curr. Opin. Solid State Mater. Sci., 14, No. 3–4, 53–68 (2010).

L.V. Liashok, V.P. Gomozov, M.P. Osmanova, and A.N. Zhuk, “Electrochemical synthesis of an oxidizing agent for dissolving the WC–Co alloy in hydrochloric acid,” Visn. Nats. Tekh. Univ. Kharkiv. Politekh. Inst. Ser. Khim. Khim. Tekhnol. Ekol., No. 35, 66–70 (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 58, Nos. 9–10 (529), pp. 3–8, 2019.

Rights and permissions

About this article

Cite this article

Tul’skij, G., Liashok, L., Osmanova, M. et al. Electrochemical Production of Tungsten Powders from Tungsten Hardmetal Waste. Powder Metall Met Ceram 58, 499–502 (2020). https://doi.org/10.1007/s11106-020-00102-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-020-00102-3