Abstract

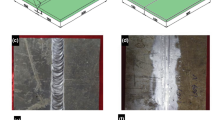

Friction stir welding (FSW) and gas tungsten arc welding (GTAW) were employed to manufacture the spiral pipes by a double-sided synchronization approach. The fatigue crack growth properties for base metal (BM) and welded metal (WM) in FSW and GTAW were studied using standard compact tension specimens manufactured from the welded pipes of the AA 5754 aluminum alloys. The highest crack growth rate occurred in WM of GTAW specimen, while WM of FSW specimen showed the lowest crack growth rate. Moreover, the crack growth rate of BM specimen fell in between them. This was because of the combination of the coarse grains and a high residual stress in WM of GTAW in comparison with WM of FSW and BM. The increase in fatigue crack rate matched well with the variation in the plastic region at the crack tip.

Similar content being viewed by others

References

C.-Q. Huang, J. Deng, S.-X. Wang, and L.-L. Liu, An Investigation on the Softening Mechanism of 5754 Aluminum Alloy During Multistage Hot Deformation, Metals, 2017, 7(4), p 107–112

M.A. Haseeb and M.J. Thomas, Disconnector Switching Induced Transient Voltage and Radiated Fields in a 1100 kV Gas Insulated Substation, Electr. Pow. Syst. Res., 2018, 161, p 86–94

I.A. Metwally, Status Review on Partial Discharge Measurement Techniques in Gas-Insulated Switchgear/Lines, Electr. Pow. Syst. Res., 2004, 69(1), p 25–36

G. Casalino, S. Campanelli, and A.D. Ludovico, Hybrid welding of AA5754-H111 alloy using a fiber laser, Adv. Mater. Res., 2013, 628(628), p 193–198

D.T. Cai, S.G. Han, S.D. Zheng, D.J. Yan, J.Q. Luo, X.L. Liu, and Z.Y. Luo, Plasma-MIG Hybrid Welding Process of 5083 Marine Aluminum Alloy, Mater. Sci. Forum, 2016, 850, p 519–525

D. Texier, F. Atmani, P. Bocher, F. Nadeau, J. Chen, Y. Zedan, N. Vanderesse, and V. Demers, Fatigue Performances of FSW and GMAW Aluminum Alloys Welded Joints: Competition Between Microstructural And Structural-Contact-Fretting Crack Initiation, Int. J. Fatigue, 2018, 116, p 220–233

J.S. Jesus, J.M. Costa, A. Loureiro, and J.M. Ferreira, Fatigue Strength Improvement of GMAW T-welds in AA 5083 by Friction-Stir Processing, Int. J. Fatigue, 2017, 97, p 124–134

A. Liu, X. Tang, and F. Lu, Study on Welding Process and Prosperities of AA5754 Al-alloy Welded by Double Pulsed Gas Metal Arc Welding, Mater. Des., 2013, 50(17), p 149–155

Y. Chen, H. Ding, J. Li, Z. Cai, J. Zhao, and W. Yang, Influence of Multi-Pass Friction Stir Processing on the Microstructure and Mechanical Properties of Al-5083 Alloy, Mater. Sci. Eng. A, 2016, 650, p 281–289

A.K. Bodukuri, K. Eswaraiah, and K. Rajendar, Comparison of Aluminum Alloy 5083 Properties on TIGW and FSW Processes, Mater. Today Proc., 2017, 4(9), p 10197–10201

K. Vasu, H. Chelladurai, A. Ramaswamy, S. Malarvizhi, and V. Balasubramanian, Effect of Fusion Welding Processes on Tensile Properties of Armor Grade, High Thickness, Non-Heat Treatable Aluminium Alloy Joints, Def. Technol., 2019, 15(3), p 353–362

Z.L. Hu, X.S. Wang, Q. Pang, F. Huang, X.P. Qin, and L. Hua, The Effect of Postprocessing on Tensile Property and Microstructure Evolution of Friction Stir Welding Aluminum Alloy Joint, Mater. Charact., 2015, 99, p 180–187

M.M. Attallah, C.L. Davis, and M. Strangwood, Influence of Base Metal Microstructure on Microstructural Development in Aluminium Based Alloy Friction Stir Welds, Sci. Technol. Weld. Join., 2007, 12(4), p 361–369

N. Contuzzi, S.L. Campanelli, G. Casalino, and A.D. Ludovico, On the Role of the Thermal Contact Conductance During the Friction Stir Welding of an AA5754-H111 Butt Joint, Appl. Therm. Eng., 2016, 104, p 263–273

T. Nakamura, T. Obikawa, I. Nishizaki, M. Enomoto, and Z. Fang, Friction Stir Welding of Non-Heat-Treatable High-Strength Alloy 5083-O, Metals, 2018, 8(4), p 208

C. Zhou, X. Yang, and G. Luan, Fatigue Properties of Friction Stir Welds in Al 5083 Alloy, Scripta Mater., 2005, 53(10), p 1187–1191

K.V. Jata, K.K. Sankaran, and J.J. Ruschau, Friction-Stir Welding Effects on Microstructure and Fatigue of Aluminum Alloy 7050-T7451, Metall. Mater. Trans. A, 2000, 31(9), p 2181–2192

V.X. Tran, J. Pan, and T. Pan, Fatigue Behavior of Aluminum 5754-O and 6111-T4 Spot Friction Welds in Lap-Shear Specimens, Int. J. Fatigue, 2008, 30(12), p 2175–2190

Z.J. Yan, X.S. Liu, and H.Y. Fang, Fatigue Behavior of Dissimilar Al-Mg-Si/Al-Zn-Mg Aluminum Alloys Friction Stir Welding Joints, Acta Metall. Sin., 2016, 29(12), p 1–8

M. Ma, J. Zhang, D. Yi, and B. Wang, Investigation of High-Cycle Fatigue and Fatigue Crack Propagation Characteristic in 5083-O Aluminum Alloy, Int. J. Fatigue, 2019, 126, p 357–368

Z. Barlas and U. Ozsarac, Effects of FSW Parameters on Joint Properties of AlMg3 Alloy, Weld. J., 2012, 91(1), p 16s–22s

M. Garware, G.T. Kridli, and P.K. Mallick, Tensile and Fatigue Behavior of Friction-Stir Welded Tailor-Welded Blank of Aluminum Alloy 5754, J. Mater. Eng. Perform., 2010, 19(8), p 1161–1171

L.A.C. De Filippis, L.M. Serio, D. Palumbo, R. De Finis, and U. Galietti, Optimization and Characterization of the Friction Stir Welded Sheets of AA 5754-H111: Monitoring of the Quality of Joints with Thermographic Techniques, Materials, 2017, 10(10), p 1165

J. Zhang and Q. Zhang, Fatigue Crack Growth Behavior of a New Type of 10% Cr Martensitic Steel Welded Joints with Ni-Based Weld Metal, J. Mater. Eng. Perform., 2017, 26(8), p 1–8

O. Hatamleh, S. Forth, and A.P. Reynolds, Fatigue Crack Growth of Peened Friction Stir-Welded 7075 Aluminum Alloy under Different Load Ratios, J. Mater. Eng. Perform., 2010, 19(1), p 99–106

J.X. Huang, The Double-sided Synchronous TIG Procedure and Matching Analysis of Corresponding Joint of X7Ni9 Steel, Procedia Eng., 2015, 130, p 517–523

W. Qiang and K. Wang, Shielding Gas Effects on Double-Sided Synchronous Autogenous GTA Weldability of High Nitrogen Austenitic Stainless Steel, J. Mater. Process. Technol., 2017, 250, p 169–181

O. Hatamleh, J. Lyons, and R. Forman, Laser and Shot Peening Effects on Fatigue Crack Growth in Friction Stir Welded 7075-T7351 Aluminum Alloy Joints, Int. J. Fatigue, 2007, 29(3), p 421–434

N. Alatorre, R.R. Ambriz, A. Amrouche, C. García, and D. Jaramillo, Fatigue Crack Growth in Al-Zn-Mg (7075-T651) Welds Obtained by Modified Indirect and Gas Metal Arc Welding Techniques, J. Mater. Process. Technol., 2017, 248, p 207–217

A.A. Korda, Y. Miyashita, and Y. Mutoh, The role of cyclic plastic zone size on fatigue crack growth behavior in high strength steels. in International Conference on Mathematics & Natural Sciences, 2015

J.C. Newman, Jr., E.L. Anagnostou, and D. Rusk, Fatigue and Crack-Growth Analyses on 7075-T651 Aluminum Alloy Coupons Under Constant- and Variable-Amplitude Loading, Int. J. Fatigue, 2014, 62(2), p 133–143

S.J. Kim, Y.H. Jeong, H.J. Sohn, G.D. Haryadi, Statistical aspects of fatigue crack growth life of base metal, weld metal and heat affected zone in FSWed 7075–T651 aluminum alloy. in International Conference on Quality, 2013.

Acknowledgment

This research work was financially supported by Science and Technology Foundation of State Grid Corporation of China (Contract No.SGZJ0000KXJS1800302).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qiao, Y., Zhang, H., Zhao, L. et al. Fatigue Crack Growth Properties of AA 5754 Aluminum Alloy Gas Tungsten Arc Welding and Friction Stir Welding Joints. J. of Materi Eng and Perform 29, 2113–2124 (2020). https://doi.org/10.1007/s11665-020-04739-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04739-4