Abstract

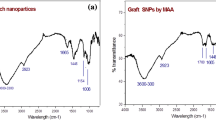

In this study our previously prepared and fully characterized starch nanoparticles (SNPs) were graft copolymerize with acrylonitrile (AN) by microwave irradiation method without toxic chemical initiator. This was done to see the impact of microwave irradiation method as green and efficient tool with respect to reduction in organic solvents, toxic chemical initiator and exposer time on maximizing the graft yield % in comparison with other classical tools. The grafting parameters were expressed in terms of graft yield %. The latter was estimated gravimetrically (based on dry weight method) and titrimetrically (based on nitrogen %) to evaluate the best accurate standard metrological method for estimating the graft yield. The foremost factors affecting the grafting reaction were studied in terms of microwave power, acrylonitrile and starch nanoparticles concentration as well as contact time. The optimum reaction conditions were obtained when; starch nanoparticles, 1 g; acrylonitrile, 1.5 ml; microwave irradiation power, 500 W, reaction time 90 S were used. Starch nanoparticles and poly (AN)-starch nanoparticles graft copolymers were characterized by various analytical techniques. It was found from the obtained results that, Fourier transform infrared spectroscopy (FT-IR) analysis ascertains nitrile group attachment to starch nanoparticles chains. X-ray diffraction and scanning electron microscopy demonstrate an increased amorphous region of starch nanoparticles and grafted copolymers, while the thermo gravimetric analysis (TGA) emphasized the increase in thermal stability of the copolymers in comparison with starch nanoparticles counterparts. Tentative mechanisms, which demonstrate all occasions that happen during the whole course of the polymerization reaction, have been proffered.

Similar content being viewed by others

References

Bel Haaj S, Thielemans W, Magnin A, Boufi S (2016) Starch nanocrystals and starch nanoparticles from waxy maize as Nano reinforcement: a comparative study. Carbohydr Polym 143:310–317

Mohammad AA, Razavi SMA (2016) A fast and efficient approach to prepare starch nanocrystals from normal corn starch. Food Hydrocoll 57:132–138

Mostafa KM, Ameen HA, Morsy MS, El-ebiasy A, Youssef AMA, Salah AM (2019) Harnessing of starch nanoparticles as non-fibrous textile for production of high performance easy-care cotton fabrics. Pigm Resin Technol 48(2):156–168

Mostafa KM, Ameen HA, Morsy MS, El-ebiasy A, Youssef A, Adel M, Salah AM (2019) Production of high performance textiles via pioneering strengthening approach using starch nanoparticles. J Ind Text. https://doi.org/10.1177/1528083719827365

Mostafa KM, Morsy MS (2004) Utilization of newly tailored modified starch products in easy- care finishing. Carbohydr Polym 55(3):323–331

Ailing F, Guanglei W, Yiqun W, Chen P (2017) Synthesis, preparation and mechanical property of wood fiber-reinforced poly(vinyl chloride) composites. J Nano Science Nanotechnol 17(6):3859–3863

Ailing F, Guanglei W, Yiqun W (2017) The behavior of acid treating carbon fiber and the mechanical properties and thermal conductivity of phenolic resin matrix composites. J Nano Science Nanotechnol 17(6):3786–3791

Ailing F, Mingliang M, Zirui J, Meng Z, Guanglei W (2019) Fabrication of NiFe2O4@carbon fiber coated with phytic acid-doped polyaniline composite and its application as an electromagnetic wave absorber. RSC Adv 9:25932–25941

Mostafa KM, El-Meged HA, Morsy MS, El -ebasiy A, Elsanabary AA (2019) Structural modification of starch nanoparticles via graft copolymerization using KMnO4, HCIO4 and HNO3 redox pair. J Polym Environ 27:996–1006

Lin N, Huang J, Chang PR, Anderson DP, Yu J (2011) Preparation, modification, and application of starch nanocrystals in nanomaterials. J Nanomater 2011:573687

Khalil MI, Mostafa KM, Hebeish A (1990) Synthesis of poly (methacrylic acid)-starch graft copolymers using Mn-IV-acidsystem. Starch/Starke 42:107–111

Khalil MI, Mostafa KM, Hebeish A (1993) Graft polymerization of acryl amide onto maize starch using potassium persulfate asinitiator. Die Angewandte Macromolecular Chemie 213:14

Mostafa KM (1995) Graft polymerization of acrylic acid onto starch using potassium permanganate acid (redox system). J Appl Polym Sci 56:263–269

Mostafa KM (1995) Graft polymerization of methacrylic acid onto starch and hydrolyzed starch. Polym Degrad Stab 50:189–194

Mostafa KM (1997) Synthesis of poly (acrylamide)—starch and hydrolyzed starches graft copolymers as a size base materials for cotton textiles. Polym Degrad Stab 55:125–130

Mostafa KM, El-Sanabary AA (1997) Carboxyl containing starch and hydrolyzed starch derivatives as a size base materials for cotton textiles. Polym Degrad Stab 55:181–184

Mostafa KM (2003) Evaluation of nitrogen containing starch and hydrolyzed starch derivatives as a size base material for cotton yarns. Carbohydr Polym 51:63–68

Mostafa KM, El-Sanabary AA (2003) Graft polymerization of different monomers onto carbamated starches derived from native and hydrolyzed starches. J Appl Polym Sci 88:959–965

Mostafa KM, Morsy MS (2004) Modification of carbohydrate polymers via grafting of meth acrylonitrile onto pregelled starch using potassium monopersulphate /Fe2+ redox pair. Polym Int 53(7):885–890

Mostafa KM, Samarkandy AR, El-Sanabary AA (2011) Grafting onto carbohydrate polymer using novel potassium persulphate/ tetramethylethylene diamine redox system for initiating grafting. Advances in Polymer Technolgy 30(2):138–149

Mostafa KhM, El-Sanabary AA (2013) Synthesis and characterization of novel smart flocculant based on poly (MAam)—pregelled starch graft copolymers and their degraded products. Adv Polym Technol 32(2) (art. no. 21339)

Mostafa KM, Osman E, Mahmoud RI, El-Sanabary AA (2018) Towards synthesis and characterization of smart materials based on chitosan using Mn-IV itaconic acid as a novel redox pair. J Polym Environ 26:3250–3261

Ashok K, Swati S, Rajesh K (2020) The graft copolymerization of N-vinyl-2-pyrrolidone onto carboxymethyl cellulose and its application for controlled release of water-soluble levofloxacin. J Polym Res 27:46

Clough RL (2001) High-energy radiation and polymers: a review of commercial processes and emerging applications. Nucl Instrum Methods Phys Res, Sect B 185(1–4):8–33

Huq T, Khan A, Dussault D, Salmieri S, Khan RA, Lacroix M (2012) Effect of gamma radiation on the physico-chemical properties of alginate-based films and beads. Radiat Phys Chem 81(8):945–948

Kiatkamjornwong S, Chomsaksakul W, Sonsuk M (2000) Radiation modification of water absorption of cassava starch by acrylic acid/acrylamide. Radiat Phys Chem 59(4):413–427

Mubarak AK, Bhattachariaa SK, Kaderb MA, Baharic K (2006) Preparation and characterization of ultra violet (UV) radiation cured bio-degradable films of sago starch/PVA blend. Carbohydr Polym 63(4):500–506

Zhang X, Liu Z (2012) Recent advances in microwave initiated synthesis of nanocarbon materials. Nanoscale 4(3):707–714

Vandana S, Tripathi DN, Tiwari A, Sanghi R (2006) Microwave synthesized chitosan-graft-poly(methylmethacrylate): an efficient Zn2+ ion binder. Carbohydr Polym 65(1):35–41

Gupta VK, Pathania D, Priya B, Singh AS, Sharma G (2014) Microwave induced synthesis of graft copolymer of binary vinyl monomer mixtures onto delignified Grewiaoptiva fiber :application in dyeremoval. Front Chem 2 ,Article 59:1–9

Singh V, Tiwari A, Tripathi DN, Sanghi R (2004) Grafting of polyacrylonitrile onto guar gum under microwave irradiation. J Appl Polym Sci 92:1569–1575

Mishra S, Mukul A, Sen G, Jha U (2011) Microwave assisted synthesis of polyacrylamide grafted starch (St-g-PAM) and its applicability as flocculant for water treatment. Int J Biol Macromol 48(1):106–111

Singh V, Tiwari A, Pandey S, Singh SK (2006) Microwave-accelerated synthesis and characterization of potato starch-g-poly(acryiamide). Starch/Staerke 58(10):536–543

Rani P, Sen G, Mishra S, Jha U (2012) Microwave assisted synthesis of polyacrylamide grafted gum ghatti and its application as flocculant. Carbohydr Polym 89(1):275–281

Singh AV, Nath LK, Guha M (2011) Microwave assisted synthesis and characterization of Phaseolus aconitifolius starch-g-acrylamide. Carbohydr Polym 86(2):872–876

Kaity S, Isaac J, Kumar PM, Bose A, Wong TW, Ghosh A (2013) Microwave assisted synthesis of acrylamide grafted locust bean gum and its application in drug delivery. Carbohydr Polym 98(1):1083–1094

Wang JP, Chen YZ, Zhang SJ, Yu HQ (2008) A chitosan - based flocculant prepared with gamma-irradiation-induced grafting. Bioresour Technol 99:3397–3402

Vahdat A, Bahrami H, Ansari N, Ziai F (2007) Radiation grafting of styrene onto polypropylene fibres by a 10 MeV electron beam. Phys Chem 76:787–793

Singh V, Kumar P, Sanghi R (2012) Use of microwave irradiation in the grafting modification of the polysaccharides – A review. Prog Polym Sci 37, 2:340–364

Loupy A (ed) Microwaves in Organic SynthesisSecond edn. Copyright © (2006) WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim ISBN: 3–527–31452-0

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mostafa, K.M., EL-Sanabary, A.A. Green and efficient tool for grafting acrylonitrile onto starch nanoparticles using microwave irradiation. J Polym Res 27, 92 (2020). https://doi.org/10.1007/s10965-020-02069-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-020-02069-6