Abstract

A report on the manipulation of structural, optical, and electrical properties of nanocrystalline CdS (ncCdS) thin films in the framework of varying Ar ambient pressure in pulsed laser deposition (PLD) is presented here. Increase in Ar ambient pressure results in reduction of crystallite size which in turns increases the structural imperfections and structural phase transformation of ncCdS thin films. The most significant observation here is the bleaching of multiphonon Raman modes (MRMs) particularly LO + 2E2, 2LO + 2E2, etc. in ncCdS thin films. An acute investigation on the reason of bleaching of LO + 2E2, 2LO + 2E2, etc. modes is carried out here and concluded that it is due to the fading of E2 mode with increasing Ar pressure as confirmed by low-frequency micro-Raman measurements. UV–visible absorption and photoluminescence spectroscopies are used to examine the optical properties like bandgap and possible electronic transitions in ncCdS thin films. Further, transport properties of ncCdS thin films are investigated using Hall measurement and I–V characteristics.

Similar content being viewed by others

1 Introduction

Nanocrystalline CdS (ncCdS) is persistently a field of intense research due to its promising applications and fundamental interests. Though, high-quality CdS nanostructured thin films have been synthesized so far by variety of deposition methods with various remarkable optical, electrical, and magnetic properties, suitable for a wide range of applications [1,2,3,4,5]. However, the desirable properties for application of interest are strongly depend on the choice of synthesis method and deposition parameters. Therefore, continuous efforts have been carried out by the researchers in this direction. Among various deposition methods for growth of high-quality thin films, pulsed laser deposition (PLD) is extensively used because of its characteristics like easy operation and relatively economic. Despite various researchers have been used PLD to grow high-quality films of variety of materials [1, 5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22], Ullrich and co-workers have carried out numerous works using this technique and studied effects of various parameters including ablation wavelength and laser fluence [9, 14, 15], substrate temperature [17], substrate type [18], lasers with different pulse widths [22], etc. on the diverse properties of CdS thin films grown in vacuum.

However, a critical parameter like inert ambient gas pressure for controlling the properties of ncCdS thin films remains untouched. Since diverse properties of materials are interlinked with the deposition parameters, the investigation of it is a solemn demand for better understanding and perfections. Specifically, the alteration in vibrational and electronic properties upon conversion of the bulk semiconductor crystal into the nanocrystals form is not completely understood [23]. Various properties of nanomaterials, such as the energy relaxation rate of excited carriers, phonon replicas of excitons in the luminescence spectra, and nonlinear optical processes, have been essentially influenced by electron–phonon (e–p) interaction, and therefore, it is of immense significance for device applications [24, 25]. For future progress of existing devices, insight investigation of the phonon structure and e–p coupling in low-dimensional materials is of considerable interest. The examination of one phonon Raman scattering only is not sufficient for this purpose. Hence, the concern on multiphonon Raman modes (MRMs), particularly their dependence on crystallite size, is of enormous attention.

MRMs are readily noticeable in bulk semiconductors when excited with near exciton resonances, but were expected to be weakened in nanostructures. However, the MRMs related to fundamental longitudinal optical (LO) and transverse optical (TO) phonon Raman modes appear as 2LO, 2TO, 3LO, 3TO, etc. in many case of ncCdS, but the combination of fundamental modes rarely appears. An optically active new Raman mode was first observed by Jerominek et al. [26] at 394 cm−1 in CdS microcrystallite-doped glass thin film, but it remained unidentified at that time. Previously, our group investigated two new Raman modes at 390 cm−1 and 690 cm−1 in ncCdS thin films deposited in vacuum by PLD using a target made of CdS quantum dots, QDs [10]. The peak observed at 390 cm−1 was very close to the peak observed by Jerominek and co-workers. In support to [26] and to identify the peaks observed in our experiment [10], we had performed low-frequency Raman (LFR) measurement of ncCdS thin film. The LFR spectrum showed the presence of E2 branch at ~ 43.3 cm−1 which was reported at 44 cm−1 for bulk CdS in the literature [27]. The peak at ~ 43.3 cm−1 enabled us to identify the peak at 390 cm−1 and 690 cm−1 as corresponding to LO + 2E2 and 2LO + 2E2, respectively. These peaks are also observed later by Li et al. [28] and recently by Rondiya et al. [29]. To the best of our knowledge, the bleaching of these or similar modes due to change in any deposition parameter is seldom reported anywhere. Moreover, the effect of ambient pressure of inert gas in PLD grown ncCdS is rarely found in literature.

In this work, we investigate the interplay between the Ar ambient pressure and various morphological, structural, optical, and electrical properties of ncCdS thin films. The bleaching of MRMs induced by Ar ambient pressure in ncCdS thin films has been observed and its mechanism has been discussed. Further, its implications on the luminescence and electrical behavior of ncCdS thin films are studied.

2 Experimental section

2.1 Synthesis of ncCdS thin films

The procedure for growth of ncCdS thin films by PLD is similar to that used before [30]. Briefly, all the samples investigated here were synthesized using PLD by guiding the third harmonic of a continuum Nd:YAG laser, i.e., wavelength of 355 nm onto a target of chemically synthesized CdS QDs on glass and Si \(\langle 100\rangle\) n-type wafer substrates. The method of preparation of CdS QDs is discussed in detail elsewhere [31]. The laser beam of energy 200 mJ pulse−1 is focused onto a rotating target mounted at an oblique angle of 30° with respect to the incident laser beam. The target and substrates were kept at a distance of 4 cm. The deposition is carried out inside a clean stainless steel (SS304) vacuum chamber keeping at a base pressure better than 5 × 10−6 Torr and maintaining the substrates at 200 °C temperature. Ar pressure was varied from 0 to 100 mTorr in the chamber. Before starting the deposition, Ar gas was flown in the chamber for half an hour to exactly maintain Ar ambient pressure. The thickness of the films deposited on Si substrate at 0.0 mT and 100 mT was measured and found to be ~ 200 nm and ~ 90 nm, respectively.

2.2 Characterizations

The surface morphology and grain size studies were carried out using atomic force microscopy (AFM) with Nanoscope IIIa SPM Atomic Force Microscope in tapping mode. To investigate the structural changes as an influence of Ar ambient pressure, glancing angle X-ray diffraction (GAXRD) studies were carried out at a glancing angle of 1° using Bruker D8 advance diffractometer (Cu Kα radiation, λ = 1.54 Å) and micro-Raman spectroscopy using Renishaw Invia Raman microscope with excitation wavelength of 514.5 nm from an Ar-ion laser. The low-frequency micro-Raman scattering measurements were performed in the back-scattering geometry using a Jobin Yvon T64000 triple monochromator with a Coherent INNOVA 99 Ar+ laser (514.5 nm) equipped with a charge-coupled device detector. The films deposited on glass substrates were analyzed using UV–Vis absorption spectroscopy (Hitachi 3300 UV/visible spectrophotometer) to study the optical properties. Photoluminescence (PL) spectroscopy studies are carried out at room temperature with excitation wavelength at 405 nm from continuous-wave diode laser. The PL spectra were collected with an Ocean Optics QEPro-FL spectrometer through a 425-nm high-performance OD 4 long-pass filter (Edmund Optics) and optical cable. In this study, Hall measurements were carried out to study the carrier concentration, conductivity, mobility, and nature of the majority charge carriers using an ECOPIA-HMS-3000 Hall measurement setup operating at a magnetic field of 0.57 T. The I–V characteristics were measured in the voltage range of − 5 V to + 5 V under dark conditions in ambient air at room temperature using Keithley 2450 series source meter. For the same purpose, a metal–semiconductor–metal (M–S–M) structure was employed with symmetric geometry for all films using high-quality Ag paste.

3 Results and discussion

3.1 Morphology analysis

To investigate the influence of varying Ar ambient pressure on surface morphology and average crystallite size (ACS) in thin films, AFM studies were performed. It is evident by the section analysis of two-dimensional AFM images (Fig. 1 in 0.5 μm × 0.5 μm scale) of films that the porosity, surface roughness, and crystallite size vary as a function of Ar ambient pressure. The films are of uniform texture containing well-distinguished particles. Insets of each micrograph show corresponding crystallite size histograms. The estimated ACS is ~ 38.5 nm, 28.6 nm, 23.4 nm, 16.2 nm, and 11.5 nm for the films grown at Ar pressure of 0.0 mT, 0.1 mT, 1 mT, 10 mT, and 100 mT, respectively. The root-mean-square (RMS) roughness of the films increases with increasing Ar ambient pressure. The change in roughness is indication of translation of the growth mode from layer-by-layer growth to island (Stranski–Krastanov) growth with varying Ar pressure. The presence of a background gas results in relatively slow growth of films in PLD, because of the fact that before transportation of the ablated materials to the substrate, it undergoes more collisions [32]; as a result, films are produced with significantly less thickness. This slow film growth rate permits additional time for the growth of nanostructures and thermalization of the ablated material, which results in growth of relatively rough nanostructured films. On the contrary, the relatively high nucleation density on the substrate and high surface mobility of the deposited species due to high kinetic energy is likely to produce smoother films in the absence of background gas. The observations of present study are consistent with previous reports of ZnS grown by PLD in the presence of N2 background gas [33].

3.2 Structural analysis

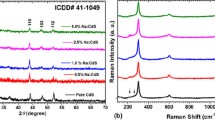

Figure 2a shows GAXRD scans of ncCdS thin films grown at different Ar ambient pressure. It is clear from diffraction patterns that all ncCdS films except the film deposited at 100 mT Ar pressure exhibit diffraction peaks at ~ 24.9°, 26.8°, 28.3°, 36.9°, 44.1°, and 48.6° corresponding to the planes (100), (002), (101), (102), (110), and (103), respectively, of stable hexagonal (wurtzite) phase of CdS (PCPDF WIN-020549) with lattice constants a = 4.142 Ǻ and c = 6.724 Ǻ. It is obvious from Fig. 2a that the rise in Ar ambient pressure reduces intensities of diffraction peaks with increase in full-width at half-maximum (FWHM), indicating reduction in crystallinity/crystallite size. One can see that translation from stable hexagonal to metastable cubic (zinc blend) structure of CdS starts to evolve at highest Ar pressure (100 mT) as clear by the merging of ~ 24.9°, 26.8°, and 28.3° three peaks into a broader peak with small humps corresponding to the planes (100), (002), and (101) and fading of peak corresponding to plane (102) of hexagonal phase. It can be inferred from above discussion that an increase in Ar ambient pressure in deposition chamber provokes structural phase transition from stable wurtzite to metastable zinc blende structure of CdS. The structural alteration induced by Ar ambient pressure in this study is well supported with the results observed by Kurnia et al. [33] for ZnS thin films grown by PLD in vacuum and at 100 mT base pressure of N2. They also observed a phase transition from stable zinc blende to metastable wurtzite structure of ZnS. However, the present results of XRD differ from their study in respect of complete structural phase transition observed by them at 100 mT N2 pressure, which is not the case here. We have observed only the signature of phase transformation at same pressure of Ar here. Further, rise in Ar ambient pressure may lead to complete phase transition in CdS. The difference in ambient inert gas pressure responsible for complete phase transition in these two aforementioned studies may be due to a variety of reasons: (i) disparity in bandgap of two materials, (ii) diversity in inert gas species, and (iii) discrepancy in other deposition parameters such as laser energy, substrate temperature, laser frequency, and so on . However, this is out of scope of discussion here; indeed it opens new area of research for the better understanding of deposition mechanism of high-quality films.

FWHM of the XRD peaks is taken as a measure of crystallinity/crystallite size. Therefore, the ACSs are estimated by well-known Debye–Scherrer’s formula \(D=k\lambda /{\beta }_{hkl}\mathrm{c}\mathrm{o}\mathrm{s}\theta\), where k is the shape factor (k = 0.9), λ is the wave length of the X-rays (λ = 0.154056 nm for Cu Kα radiation), and θ is Bragg diffraction angle, \({\beta }_{hkl}\) is broadening of the hkl diffraction peak and measured as FWHM in radian. The estimated ACSs are ~ 11 nm, 6.1 nm, 4.8 nm, 3.98 nm, and 2.32 nm for the films grown at Ar pressure 0.0 mT, 0.1 mT, 1 mT, 10 mT, and 100 mT, respectively.

Indeed, X-ray peak broadening is related to both the quantum confinement effect due to crystallite size and lattice strain due to large volume of grain boundaries. Usually, strain-induced peak broadenings are given by ε ≈ βs/tanθ, which shows dependency on the diffraction angle θ and results from crystal imperfections and distortion. In order to distinguish between above two causes of broadening, insightful analysis of XRD patterns is needed. Fortunately, Williamson–Hall (W–H) method allows discrimination between the two aforementioned, if both quantum confinement and micro-strain are responsible for broadening, it follows tanθ dependency instead of 1/cosθ dependency that follows in Scherrer’s method. Therefore, W–H analysis is carried out to study the actual change in crystallite size and strain as a function of Ar ambient pressure. The W–H equation is expressed as [34, 35] follows:

Here, Eq. (1) stands for uniform deformation model, which considers uniform strain in all crystallographic directions, D is the crystallite size (nm), and k, λ, θ, and βhkl have usual meanings as mentioned earlier. Here, βhkl is given as follows:

where βD is instrument-corrected broadening and expressed as follows:

To examine the diffraction patterns of ncCdS thin films grown at varying Ar pressure, the term βcosθ is plotted as a variation of 4sinθ for all the peaks and is shown in Fig. 2b–e. Strains and particle sizes are calculated from the slopes and intercepts on the y-axis of the fitted lines, respectively. The plots show a negative strain for the ncCdS thin films. This strain may be due to the lattice shrinkage. The ACSs estimated by intercept on y-axis in W–H plot are ~ 9.9 nm, 5.54 nm, 4.47 nm, and 3.85 nm for the films grown at Ar ambient pressure 0.0 mT, 0.1 mT, 1 mT, and 10 mT, respectively. W–H analysis was not performed for the film grown at Ar pressure 100 mT because of the presence of only one peak with small humps.

3.3 Optical analysis

To inspect the effect of Ar ambient pressure on the optical bandgap of grown films and thereby the crystallite size, UV–visible absorption studies are carried out. The direct optical bandgap values are estimated using Tauc plots (Fig. 3) as ~ 2.43 eV, 2.47 eV, 2.50 eV, 2.54 eV, and 2.73 eV for the films grown at Ar pressure of 0.0 mT, 0.1 mT, 1 mT, 10 mT, and 100 mT, respectively. It is obvious that the bandgap of films is blue shifted than the bandgap of bulk CdS (~ 2.42 eV) due to quantum confinement. The ACSs are calculated using mass approximation formula for energy shift as used in [24];

where \(\Delta E\) is estimated by absorption studies, \({m}_{\mathrm{e}}^{*}\)=0.19mo and \({m}_{\mathrm{h}}^{*}\)=0.80mo are effective masses of electron and hole for CdS, respectively, ε = 5.7 is dielectric constant of CdS and \({E}_{\mathrm{R}\mathrm{Y}}^{*}\) is effective Rydberg energy. The ACSs for the films grown at various Ar pressures viz. 0.0–100 mT are found to be 12.8 nm, 6.7 nm, 5.4 nm, 4.5 nm, and 2.75 nm, respectively, which are consistent with AFM and GAXRD studies as summarized in Table 1.

To examine the effect of Ar ambient pressure on vibrational states of ncCdS thin films, micro-Raman spectra are recorded. In this study, five optically active Raman modes are observed at ~ 301 cm−1, 390 cm−1, 602 cm−1, 690 cm−1, and 903 cm−1 for ncCdS thin film grown at 0.0 mT Ar ambient pressure, i.e., in vacuum with continuously decreasing intensity on raising Ar ambient pressure as shown in Fig. 4a. The intense and broad peaks at 301 cm−1, 602 cm−1, and 903 cm−1 are the usual features of CdS and assigned as fundamental longitudinal optical (LO) mode, its first (2LO), and second (3LO) overtones, respectively [36, 37]. The noticeable asymmetry and peak shift towards lower frequency side with respect to the observed peaks for bulk CdS is due to the reduction in particle size, i.e., quantum confinement effect, which had been theoretically calculated and experimentally observed [10].

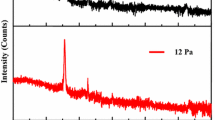

The weak Raman peaks at 390 and 690 cm−1 result from multiphonon scattering [10]. In order to support it, low-frequency Raman (LFR) measurements of ncCdS thin films grown at 0.0 mT, 10 mT, and 100 mT pressures are carried out, as shown in Fig. 4d. The presence of peak at ~ 43.3 cm−1 in LFR of ncCdS film grown at 0.0 mT Ar pressure, i.e., in vacuum, which is red shifted to the E2 branch of bulk CdS (44 cm−1), confirms our identification regarding Raman peaks at 390 and 690 cm−1 as MRMs. It is evident that the intensity of all vibration modes reduces with increase in Ar pressure and bleaching of MRMs (Fig. 4c) occurs at higher Ar pressure owing to bleaching of E2 mode (Fig. 4d). The origin of bleaching of E2 mode and thereby the bleaching of MRMs will be discussed later.

It can be seen that the asymmetry and broadening of LO mode increase on increasing Ar pressure with negligible blue shift (Fig. 4b). To study the effect of Ar pressure on e–p coupling strength, the ratio of first overtone to fundamental mode (I2LO/ILO) is calculated and plotted along with particle size as a function of Ar pressure as shown in Fig. 5. It is observed that I2LO/ILO reduces exponentially as a function of Ar pressure, suggesting reduction in e–p coupling strength. The mechanism of e–p coupling is explained on the basis of deformation potential and the Fröhlich potential [25, 38].

Generally, the short-range interaction between the lattice displacement and the electrons is responsible for the deformation potential, which determines the TO Raman scattering cross-section. In contrast, the displacement of partial ion nuclei creates the long-range interaction that leads to Fröhlich potential. The consequence of both the deformation potential and the Fröhlich potential is LO Raman scattering cross-section. The absence of TO modes in this study rules out the role of deformation potential in the ncCdS samples and suggests that the e–p coupling in the samples is mainly associated with the Fröhlich interaction. This is consistent with the findings of Zhang et al. [39] for ZnTe nanorods. Weakening of e–p coupling strength is a direct signature of poor crystallinity as well as reduction in particle size [38, 40, 41]. Since, as the size decreases, the degree of the excitonic wave function is limited to a small region with a smaller electron–hole separation, and these excitons couple weakly with the polarization field of LO phonons at the surface region, leading to a small Huang–Rhys factor S, which is proportional to the ratio I2LO/ILO [38, 39]. In other words, weakening in e–p coupling strength may be due to reduction in Fröhlich potential which can be attributed to the increase in defects/vacancies on the surface of the ncCdS with decreasing size [38, 40, 41]. The estimation of particle size using AFM, XRD, and UV–visible absorption spectroscopy indicates reduction in particle size as a function of increasing Ar pressure (Fig. 5) and supported the above explanation regarding fading of e–p coupling strength. Moreover, the fading of all the modes is also a signature of the poor crystallinity resulted by the reduction in particle size, with increase in Ar pressure as it has been well established that lower the number of vibrational mode, the poorer the crystallinity [38, 42]. Here, one can see the disappearance of MRMs along with second over tone of LO, i.e., 3LO at 100 mT Ar pressure again indicating poor crystallinity of film at this pressure. Therefore, it may be concluded here that the bleaching of E2 mode and hence MRMs in this study may be occurred due to combined effect of reduction in particle size and weakening in e–p coupling strength.

The optical and electrical properties of the materials are significantly influenced by e–p coupling as it plays a vital role in the relaxation rate of excited carries and the transport properties [39]. PL spectra for the ncCdS thin films with varying Ar pressure along with the glass substrate are shown in Fig. 6. It is evident from Fig. 6 that all the films show intense and broad peak at ~ 629 nm corresponding to red emission (RE). The transition of bound electrons from surface states to the valence band (VB) is accountable for RE in ncCdS. The defects responsible for such transitions are sulfur vacancies (\({V}_{\mathrm{S}}^{2+}\)) or cadmium vacancies (\({V}_{\mathrm{C}\mathrm{d}}^{2-}\)) [24, 31, 34]. One can also see a very weak kink at ~ 509 nm corresponding to green emission (GE) for all the films except for the film grown at 100 mT Ar ambient pressure. The GE in ncCdS is credited to the transition of S-vacancy donors (\({V}_{\mathrm{S}}^{+}\)) to the valence band and conduction band to S-interstitial (\({I}_{\mathrm{S}}^{-}\)) [10, 24, 34, 37]. It is observed that the intensity variation of RE and GE follows opposite trend with variation in Ar ambient pressure. The intensity of GE is in proportion to gas pressure. On the contrary, RE intensity is inversely proportional to gas pressure. Therefore, it can be said that amplification in GE intensity with rise in Ar pressure is at the cost of drop in RE intensity. The reduction in crystallinity and thickness of the films is jointly responsible for such intensity variation behavior. As thickness of the film reduces, the volumetric excitation centers reduce thereafter emission intensity demeans. On the other hand, reduction in crystallinity may provoke the scattering phenomenon from grain boundaries and thereby promotes non-radiative electronic transition that turns into diminishing the intensity. As discussed in preceding section, that presence of gas environment in chamber increases the number of collision that results in slow growth of films and offers extra time for the growth of nanostructures and thermalization of the ablated material. Particularly, thermalization may alter the radiative/non-radiative centers’ density. Here, we believe thermalization is the cause of such variation in emission intensities. The absence of GE kink in PL spectrum of film grown at Ar ambient pressure 100 mT with sudden increase in intensity of RE may be due to the shared effect of initiation of structural phase transition and alteration in radiative center densities due to thermalization. Moreover, the change in emission behavior at 100 mT is different from others and believed that it may be interlinked with bleaching of MRMs as it occurs at the same pressure.

3.4 Electrical analysis

To explore the effect of Ar ambient pressure on the electrical transport parameters, Hall and I–V measurements are carried out. The different parameters obtained from Hall measurement are summarized in Table 2. Hall studies suggested that all films are n-type as Hall coefficient of all the films is negative which means that the concentration of electrons is higher than the holes. It is obvious that the electrical resistivity increases and the carrier (electron) mobility reduces, which in turn reduces the electrical conductivity as a function of Ar ambient pressure.

I–V characteristics of all the samples under dark conditions are shown in Fig. 7. It is clear that the current reduces with increase in Ar ambient pressure. It is evident that the I–V characteristics show nearly Ohmic behavior for all the films other than the film grown at 100 mT Ar ambient pressure, which shows nearly Schottky behavior. It can be seen that dark current decreases by a factor of about 103 as Ar ambient pressure increases from 0.0 to 100 mT (inset Fig. 7). The fall in current is resulted from the collective effect of trimming down of thickness [43], enlarged grain boundaries, and roughness [44] of the films induced by Ar pressure inside deposition chamber. The increase in roughness and grain boundaries together increases the scattering centers which hinder the free motion of charge carriers under applied field and turns into diminution in mobility that results decrease/increase in conductivity/resistivity. Alternatively, the drop in conductivity with thickness is mainly due to a reduction in the mobility following the increase in the intergrain barrier height [43]. The effective barrier mobility in polycrystalline films is given by \(\mu ={\mu }_{0}{\mathrm{e}}^{-\varphi /kT}\), where \(\varphi\) is the barrier height and \({\mu }_{0}\) is a constant. This reflects in conductivity according to \({\sigma }_{\mathrm{d}}=ne\mu\), where n, e, and \(\mu\) are having usual meanings [43]. The drastic reduction in conductivity and hence current for the film grown at 100 mT Ar pressure is due to huge fall in both carrier concentration and carrier mobility. It may be the result of pooled effect of very small crystallite size, highest roughness, and large number of grain boundaries as well as initiation of structural phase transition. Further, bleaching of MRMs is also supposed to be the main cause of drastic reduction in carrier density and mobility and thus the electrical conductivity.

4 Conclusions

A systematic effect of Ar ambient pressure on various properties viz.; morphological, structural, optical, and electrical properties of ncCdS thin films grown by PLD is studied. The highlighting feature of this study is bleaching of MRMs like LO + 2E2, 2LO + 2E2, and 3LO at highest Ar pressure (100 mT). The bleaching of MRMs is believed to be due to reduction in crystallinity and crystallite size with increase in pressure. Further, the impact of MRMs bleaching on optical and electric properties of the films is studied. It is found that at same pressure (100 mT), there is a drastic change in radiative centers, charge carrier density, and carrier mobility which reflects as change in emission peak intensities and conductivity of the films. This study emphasizes the importance of vibrational states for tunable electronic properties and transport phenomenon.

References

P. Kumar, N. Saxena, S. Dewan, F. Singh, V. Gupta, Giant UV-sensitivity of ion beam irradiated nanocrystalline CdS thin films. RSC Adv. 6, 3642–3649 (2016)

J.R. Esparza, A.M. Mena, I.G. Sancha, P.R. Fragoso, G.G. de la Cruz, R. Mondragón, L.R. Fragoso, Synthesis, characterization and biocompatibility of cadmium sulfide nanoparticles capped with dextrin for in vivo and in vitro imaging application. J. Nanobiotechnol. 13, 83 (2015)

B. Qiu, Q. Zhu, M. Du, L. Fan, M. Xing, J. Zhang, Efficient solar light harvesting CdS/Co9S8 hollow cubes for Z-scheme photocatalytic water splitting. Angew. Chem. 129, 2728–2732 (2017)

T. Chtouki, Y. El Kouari, B. Kulyk, A. Louardi, A. Rmili, H. Erguig, B. Elidrissi, L. Soumahoro, B. Sahraoui, Spin-coated nickel doped cadmium sulfide thin films for third harmonic generation applications. J. Alloys Compd 696, 1292–1297 (2017)

N. Saxena, P. Kumar, V. Gupta, CdS:SiO2 nanocomposite as a luminescence based wide range temperature sensor. RSC Adv. 5, 73545–73551 (2015)

A. Bylica, P. Sagan, I. Virt, G. Wisz, M. Bester, I. Stefaniuk, M. Kuzma, Layers of CdTe and CdS obtained by PLD on ITO substrates. Thin Solid Films 511–512, 439–442 (2006)

W.P. Shen, H.S. Kwok, Crystalline phases of II–VI compound semiconductors grown by pulsed laser deposition. Appl. Phys. Lett. 65(17), 2162–2164 (1994)

J.C. Orlianges, C. Champeaux, P. Dutheil, A. Catherinot, T. Merle Mejean, Structural, electrical and optical properties of carbon-doped CdS thin films prepared by pulsed-laser deposition. Thin Solid Films 519, 7611–7614 (2011)

B. Ullrich, H. Sakai, N.M. Dushkina, H. Ezumi, S. Keitoku, T. Kobayashi, The influence of the laser fluence on the transmission features of thin CdS films formed by laser ablation. Microelectron. Eng. 43–44, 695–700 (1998)

P. Kumar, N. Saxena, R. Chandra, V. Gupta, A. Agarwal, D. Kanjilal, Nanotwinning and structural phase transition in CdS quantum dots. Nanoscale Res. Lett. 7, 584 (2012)

H. Wang, Y. Zhu, P.P. Ong, Effect of substrate temperature on the formation of CdO composite in CdS doped SiO2 films as deposited by PLD. J. Cryst. Growth 241, 183–188 (2002)

H. Wang, Y. Zhu, P.P. Ong, Structural properties of CdS-doped glass nanocrystallites grown by pulsed laser deposition in high vacuum. J. Vac. Sci. Technol. A 19(1), 306–310 (2000)

M. Herrera, R. Castro-Rodriguez, O. Gomez, V. Rejon, P. Bartolo-Perez, S. Barkun, A. Martel, J.L. Pena, Multitarget system for growth of thin films by pulsed laser deposition. Rev. Mex. De Fis. 48(1), 61–66 (2002)

B. Ullrich, Thin-film CdS formed with pulsed-laser deposition towards optical and hybrid device applications. J. Mater. Sci. Mater. Electron. 18, 1105–1108 (2007)

B. Ullrich, H. Sakai, Y. Segawa, Optoelectronic properties of thin film CdS formed by ultraviolet and infrared pulsed-laser deposition. Thin Solid Films 385, 220–224 (2001)

X.L. Tong, Q.G. Zheng, S.L. Hu, Y.X. Qin, Z.H. Ding, Structural characterization and optoelectronic properties of GaN thin films on Si(111) substrates using pulsed laser deposition assisted by gas discharge. Appl. Phys. A 79, 1959–1963 (2004)

H. Sakai, T. Tamaru, T. Sumomogi, H. Ezumi, U. Ullrich, Crystal direction of CdS thin film produced by laser ablation. Jpn. J. Appl. Phys. 37, 4149–4153 (1998)

K.P. Acharya, H. Khatri, S. Marsillac, B. Ullrich, P. Anzenbacher, M. Zamkov, Pulsed laser deposition of graphite counter electrodes for dye-sensitized solar cells. Appl. Phys. Lett. 97, 201108 (2010)

S.M. Mahdavi, A. Iraji zad, R.M. Tilaki, The effect of target annealing temperature on optical and structural properties and composition of CdS thin films prepared by pulsed laser. Opt. Mater. 27, 1583–1586 (2005)

G. Perna, V. Capozzi, M. Ambrico, V. Augelli, T. Ligonzo, A. Minafra, L. Schiavulli, M. Pallara, Structural and optical characterization of undoped and indium-doped CdS films grown by pulsed laser deposition. Thin Solid Films 453–454, 187–194 (2004)

H.S. Kwok, J.P. Zheng, S. Witanachchi, P. Mattocks, L. Shi, Q.Y. Ying, X.W. Wang, D.T. Shaw, Growth of highly oriented CdS thin films by laser-evaporation deposition. Appl. Phys. Lett. 52(13), 1095–1097 (1988)

S. Yano, B. Ullrich, Identity of green single- and two-photon excited interband emission in thin film CdS on glass. Thin Solid Films 444, 295–298 (2003)

F. Singh, R.G. Singh, V. Kumar, S.A. Khan, J.C. Pivin, Softening of phonons by lattice defects and structural strain in heavy ion irradiated nanocrystalline zinc oxide films. J. Appl. Phys. 110, 083520 (2011)

P. Kumar, N. Saxena, V. Gupta, F. Singh, A. Agarwal, Correlation between surface phonon mode and luminescence in nanocrystalline CdS thin films: an effect of ion beam irradiation. J. Appl. Phys. 116, 043517 (2014)

D. Fan, R. Zhang, Y. Zhu, H. Peng, Size dependence of surface optical mode and electron–phonon coupling in ZnO nanocombs. Phys. B 407, 3510–3514 (2012)

H. Jerominek, M. Pigeon, S. Patela, Z. Jakubczyk, C. Delisle, CdS microcrystallites doped thin film glass waveguides. J. Appl. Phys. 63, 957–959 (1988)

B. Tell, T.C. Damen, S.P.S. Porto, Raman effect in cadmium sulfide. Phys. Rev. B 144, 771–774 (1966)

Y. Li, S.Q. Yuan, X.J. Li, White light emission from CdS/Si nanoheterostructure array. Mater. Lett. 136, 67–70 (2014)

S. Rondiya, A. Rokade, B.A. Funde;, Synthesis of CdS thin films at room temperature by RF-magnetron sputtering and study of its structural, electrical, optical and morphology properties. Thin Solid Films 631, 41–49 (2017)

P. Kumar, N. Saxena, V. Gupta, K. Gao, F. Singh, A. Agarwal, Effect of swift heavy ions on pulsed laser deposited Ag doped CdS nanocrystalline thin films. Adv. Sci. Lett. 20, 977–983 (2014)

P. Kumar, N. Saxena, F. Singh, A. Agarwal, Nanotwinning in CdS quantum dots. Phys. B 407, 3347–3351 (2012)

K.A. Bogle, V. Anbusathaiah, M. Arredondo, J.-Y. Lin, Y.-H. Chu, C. Oneill, J.M. Gregg, M.R. Castell, V. Nagarajan, Synthesis of epitaxial metal oxide nanocrystals via a phase separation approach. ACS Nano 4, 5139–5146 (2010)

F. Kurnia, Y.H. Ng, Y. Tang, R. Amal, N. Valanoor, J.N. Hart, ZnS thin films for visible-light active photoelectrodes: effect of film morphology and crystal structure. Cryst. Growth Des. 16, 2461–2465 (2016)

N. Saxena, T. Kalsi, P. Uttam, P. Kumar, Morphological evolution in nanocrystalline CdS thin films from flowers to salt rock like structures. Opt. Mater. 84, 625–630 (2018)

M. Sathya, K. Pushpanathan, Synthesis and optical properties of Pb doped ZnO nanoparticles. Appl. Surf. Sci. 449, 346–357 (2018)

P. Kumar, N. Saxena, F. Singh, V. Gupta, Swift heavy ion induced structural phase generation and enhanced luminescence from CdS based nanocomposites. Surf. Coat. Technol. 306, 305–308 (2016)

P. Kumar, N. Saxena, R. Chandra, K. Gao, S. Zhou, A. Agarwal, F. Singh, V. Gupta, D. Kanjilal, SHI induced enhancement in green emission from nanocrystalline CdS thin films for photonic applications. J. Lumin. 147, 184–189 (2014)

C. Hu, X. Zeng, J. Cui, H. Chen, J. Lu, Size effects of Raman and photoluminescence spectra of CdS nanobelts. J. Phys. Chem. C 117, 20998–21005 (2013)

Q. Zhang, J. Zhang, M.I.B. Utama, B. Peng, M. de la Mata, J. Arbiol, Q. Xiong, Exciton–phonon coupling in individual ZnTe nanorods studied by resonant Raman spectroscopy. Phys. Rev. B 85, 085418 (2012)

J.J. Shiang, S.H. Risbud, A.P. Alivisatos, Resonance Raman studies of the ground and lowest electronic excited state in CdS nanocrystals. J. Chem. Phys. 98, 8432 (1993)

K.Y. Lee, J.R. Lim, H. Rho, Y.J. Choi, K.J. Choi, J.G. Park, Evolution of optical phonons in CdS nanowires, nanobelts, and nanosheets. Appl. Phys. Lett. 91, 201901 (2007)

S. Dhara, S. Chandra, G. Mangamma, S. Kalavathi, P. Shankar, K.G.M. Nair, A.K. Tyagi, C.W. Hsu, C.C. Kuo, L.C. Chen, K.H. Chen, K.K. Sriram, Multiphonon Raman scattering in GaN nanowires. Appl. Phys. Lett. 90, 213104 (2007)

F. El Akkad, H. Ashour, Photoinduced current transient spectroscopy technique applied to the study of point defects in polycrystalline CdS thin films. J. Appl. Phys. 105, 093113 (2009)

K. Hartman, J.L. Johnson, M.I. Bertoni, D. Recht, M.J. Aziz, M.A. Scarpulla, T. Buonassisi, SnS thin films by RF sputtering at room temperature. Thin Solid Films 519, 7421–7424 (2011)

Acknowledgements

The author (PK) is pleased to acknowledge Science and Engineering Research Board, New Delhi, India, for providing financial assistance under the Project ECR/2016/001468. One of the authors (NS) is thankful to Council of Scientific and Industrial Research (CSIR), New Delhi, India, for providing Senior Research Associateship under the Scientists’ Pool scheme (Pool No. 8920-A).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding authors state that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, P., Saxena, N. & Gupta, V. Vital role of Ar ambient pressure in controlled properties of nanocrystalline CdS thin films. J Mater Sci: Mater Electron 31, 6755–6763 (2020). https://doi.org/10.1007/s10854-020-03233-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03233-w